The device and adjustment of the carburetor K-45

Motoblock Neva of the MB-1 and MB-2 models is equipped with a DM-1K engine with a K-45 carburetor. There are also modifications of the model, such as K-45R, K-45U, K-45M.

For the correct setup, we will briefly consider its device.

A carburetor is an engine unit that pours fuel, mixing it with air, and regulates its flow into the cylinders.

Consider the K-45 scheme. Here, the throttle lever 11 is located at the bottom of the damper, which regulates the amount of the mixture of gasoline and air. The regulator rod is attached to it. At the top of the throttle valve there is a stop screw 5. The main throttle lever 14 controls its position. In the closed position, it is held by a spring, and when the internal combustion engine is started, it opens to a certain angle. The degree of the angle is calculated so that there is no excessive enrichment in the fuel mixture of the cold engine of the walk-behind tractor.

Adjustment of the K-45 allows the entire power system and the engine itself to work without interruption:

- prepare the carburetor for tuning and warm up the motor-block motor;

- reduce the engine rotation speed with screw 5;

- using screw 8 it is necessary to set the maximum idle speed of the engine;

- and finally change the rotation speed by turning the screw in the opposite direction 0.25 turns.

Repair of K-45: basic recommendations, video

In order to repair the carburetor with your own hands, we suggest that you familiarize yourself with the video of repairing the Neva MB-2 walk-behind tractor.

Consider the main malfunctions of the K-45:

- If an excessive amount of air enters the internal combustion engine chamber. Try replacing the gasket between the head and the carburetor and tightening the fastening nuts on the joint tighter. If this does not help, the cause may be wear on the shaft on the damper or the hole where it is connected. Such a shaft must be replaced, and in the case of broken holes, the entire device is replaced.

- When too much fuel enters the float chamber. In this case, check and replace worn parts: float, jets, needle.

- If the carburetor is low on gas, check the filter and sump, fuel hoses, and gas tank. Contaminated elements must be rinsed or replaced, and if the inside of the tank is corroded, it will have to be cleaned with caustic soda.

- If there is an increase in fuel consumption, adjust the carburetor by referring to the operating instructions.

Replacing with another carburetor

In order for the carburetor of the walk-behind tractor to work properly and without interruptions, it is necessary to constantly monitor the condition of the filters, adjust for the correct supply of fuel and air, and also use gasoline with an octane rating of at least 92. In case the breakdown of the K-45 could not be avoided :

- purchase an original node;

- dismantle the faulty mechanism, starting from the engine head;

- drain the remaining fuel from the faulty carburetor;

- clean the connection and replace the assembly.

Or contact the service for a replacement. If you want to put a different brand of carburetor on the unit, buy the necessary adapter.

Ural with a Chinese engine

Many owners of Ural engine blocks lack the capacity of a conventional power unit. Instead, Chinese engines or other imported engines are often used. The Chinese engine is installed on a standard frame through additional cross members. The crosses are attached to the frame by welding or bolts. Imported power supplies have an increased engine speed, so you need to use homemade pulleys in the clutch.

The increased power of the power unit expands the possibilities of modification with your own hands. The equipment is capable of operating in winter with an installed rotary snow blower.

Description

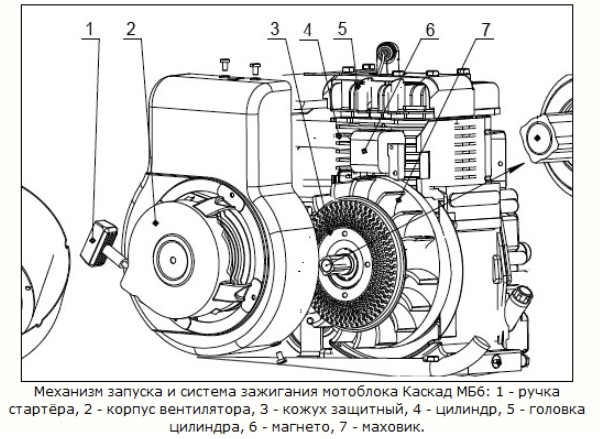

Motoblocks "Cascade" have established themselves as reliable assistants to the farmer. They are productive, durable machines capable of working with a full range of attachments, performing the functions of a cultivator, plowing machine, mower, snow sweeper and many others.

Motoblock Cascade series MB 6-06

Motoblock Cascade series MB 6-06

Timely maintenance of the walk-behind tractor is also important. For "Cascade", the maintenance schedule is the same as for any other household walk-behind tractor:

- scheduled maintenance: once a season, at the end of seasonal work and before their start (at the beginning and at the end of spring, at the beginning and at the end of summer, etc.);

- regular mini-technical inspection - every day upon completion of work and turning off the walk-behind tractor, as well as an external examination in order to identify damage, paint chips, etc.;

- winter storage - it is allocated in a separate category of maintenance, since it provides for the discharge of all fuels and lubricants and storage of the walk-behind tractor in a room with a positive temperature, upon completion of the winter "conservation", the unit is refueled with fuel and lubricants;

- annual engine prophylaxis (identification of malfunctions, their elimination, maximum extension of the service life of the engine and other key components of the unit).

Next, we will consider the basic rules and requirements for fuels and lubricants, the process of starting and running in the "Cascade" walk-behind tractor, as well as the most common malfunctions of these devices.

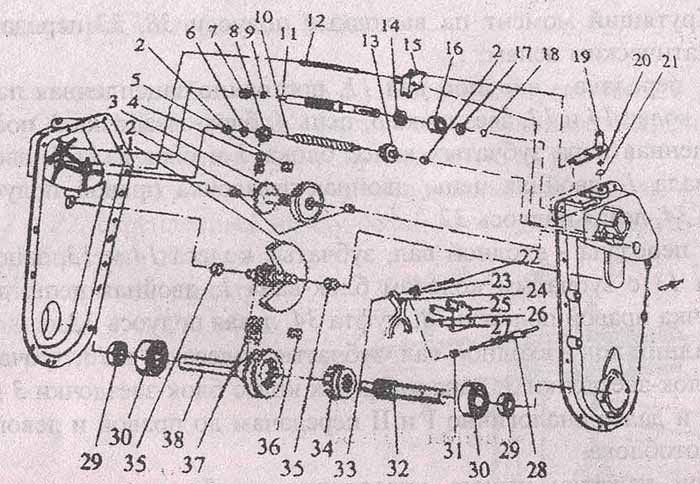

Reducer

Owners of Oka walk-behind tractors, like any other equipment, sometimes encounter malfunctions. Including in the operation of the gearbox.

Next, we will consider the most common difficulties, their probable causes and solutions to the problem:

- oil flows on the output shaft: it is possible that the axle shaft seal is worn out (replacing the cuff will help);

- the gearbox is jammed (one of the reasons is an open circuit; it needs to be changed);

- it is not possible to switch gears (you should disassemble the gearbox and replace the broken parts);

- the mechanism for separating the semi-axles has been disrupted (adjustment of the tension of the control cable for the semi-axles will help).

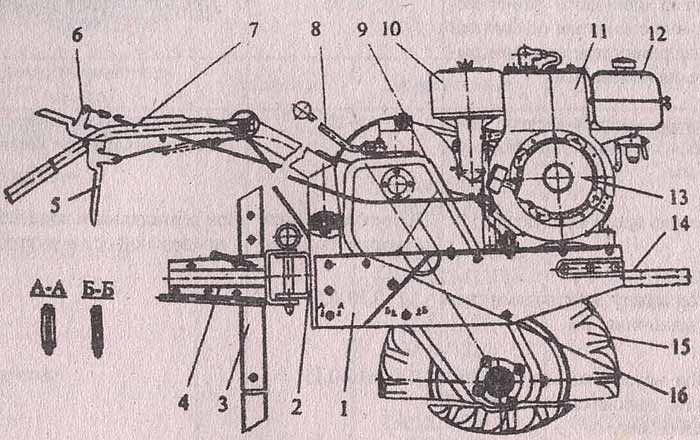

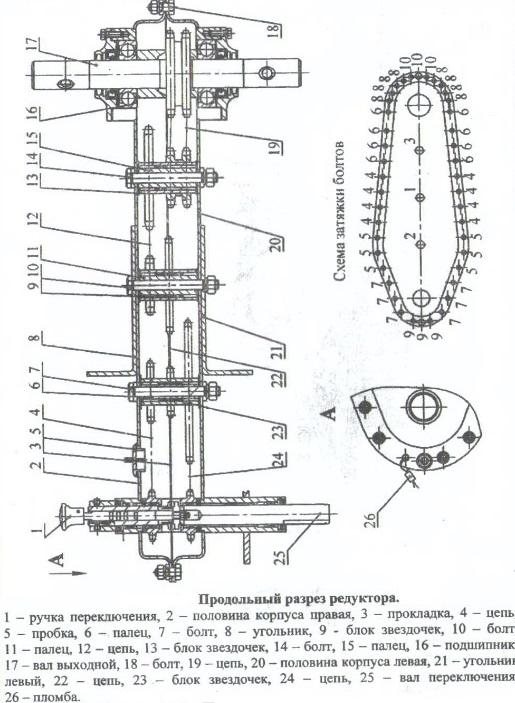

The figure below shows a cutaway diagram of a walk-behind tractor gearbox

Sectional view of the walk-behind tractor gearbox

In the event of a malfunction of the oil seals, namely when oil leaks, the oil seals should be removed, inspected for cracks, wear. Replace if necessary.

Repair manual for walk-behind tractor Luch MB 1

The Luch MB 1 motoblock, although it is extremely reliable and unpretentious, however, like any other installation, requires timely maintenance and repair. Consider the main recommendations from the walk-behind tractor manual, which allow you to extend the service life of the equipment, as well as maintain it in a constant working rhythm:

- instructions for working with a cultivator contain tips for the mandatory running-in of special equipment;

- immediately after purchase, you need to check the level of consumables, as well as lubricants;

- as with any other soil treatment device, consumables are changed by the hour, not mileage;

- it is necessary to carry out both scheduled maintenance and comprehensive maintenance of the walk-behind tractor;

- it is required to change parts only for the original or a high-quality analogue, which significantly increases the resource of work;

- do not overload this device with work at the final stage before carrying out maintenance;

- you should always monitor the lubricant level in all power elements (transmission, gearbox, as well as the engine).

It should be understood that special equipment is specific and has nothing in common with conventional vehicles. That is why it is better to entrust complex repair work to specialists.During the operation of the Luch MB 1 model, you should use 92 gasoline, and also occasionally clean the engine by adding fuel with a high octane number (95 gasoline).

Alterations

Motoblock Ray is a rather old technique, so all its alterations are quite expedient. In addition, now it is quite difficult to find a new unit, therefore all the walk-behind tractors presented in the open sale have already been in use for a certain time.

As for some improvements, there are several examples of useful, in our opinion, alterations:

- The first thing to try to replace is the front drive belt tensioner. The fact is that the standard roller makes a lot of noise during operation, especially after prolonged operation.

- The reason for this is the dry lubrication of the bearing, and there is no way to replace it with a new one, because it has flared sides.

- As a replacement, you can use a roller from the timing belt of a VAZ 2112 car (or similar). On both sides of the roller there are two springs - one main, leading to the control lever, and the second pulls the roller back.

- You can also weld a new muffler. From the old we have a cast-iron knee, on which it is quite problematic to weld anything. This problem is solved by simply turning to turners, who will carve a thread, where you can already weld a steel corner.

- The muffler can was taken from the PD 10 engine, which is located at the very end of its exhaust pipe. From above, the same corner is welded to the can that was used at the base of the homemade muffler.

- The engine breather also requires certain changes. The fact is that the standard breather goes in one straight line, connecting to the air cleaner with a fairly short hose.

- During operation, it was revealed that the oil mixture enters this hose, which leads to further movement of the oil into the air cleaner, and then into the carburetor. To get rid of these consequences, you can use a longer hose, placing it in a loop.

- Even if a certain amount of the oil mixture gets into this hose, it will not be able to go further, but will return back to the engine.

We did not mention replacing the engine with another, or how the ignition works, because this is a topic for a separate consideration.

In this article, we pay attention only to some small improvements that make it possible to work with the Luch walk-behind tractor more comfortable and efficient.

Description

Motoblocks "Luch" have come a long way from creation to the present day. Initially, the manufacturer of these motoblocks was the company Perm Motors OJSC, which in the 90s became part of the Perm Engine-Building Complex.

The units enjoy a well-deserved popularity among domestic farmers, they have a reputation for powerful, productive, fault-resistant devices with various capacities. Each owner can choose a model of a walk-behind tractor, based on the site, amount of work, purpose.

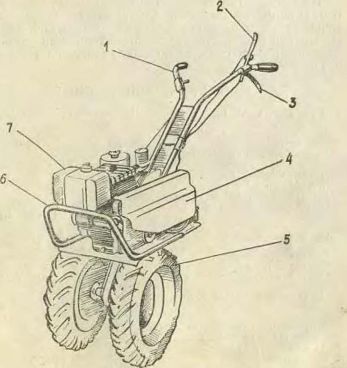

Photo of the "Luch" MB-1 walk-behind tractor

Features of "Luch" walk-behind tractors are as follows:

- affordable price and high build quality;

- attachments suitable for many other domestic and Chinese models;

- endurance, the ability to operate in any season;

- the ability to run on any type of fuel (AI-92, AI-76, AI-82 gasoline and other types of gasoline);

- almost complete absence of bad reviews about walk-behind tractors (among the positive reviews there are many references to endurance, good assembly, reliability and power of the device).

It is interesting: Review of the characteristics of the Lifan walk-behind tractor: we explain in detail

Device

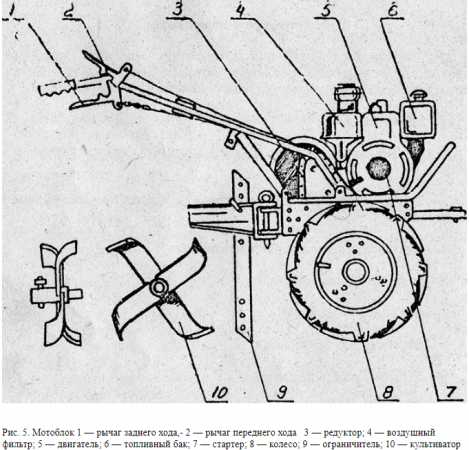

Motoblock MB 1 was very popular at one time, namely, in the eighties - nineties of the last century.

Then the market of special equipment, if it can be called such, was filled with the products of Soviet factories, among whose products the equipment of "Lucha" was considered one of the best of its kind.Motoblock "Luch" MB 1 confidently competed with a similar walk-behind tractor "Niva".

He regularly performed his main function - processing a field or vegetable garden, transporting goods: crops, firewood, building materials. It was then that the spread of home-made trailers began, and the tendency to turn these motoblocks into mini tractors was established.

MB1

Although the technical characteristics of the "Luch" MB 1 are in many ways inferior to modern walk-behind tractors, during the peak of its distribution they were at a height - the mass of the assembled device is equal to one hundred kilograms, the speed is from 3.6 to 9 kilometers per hour, on a flat track, loaded , it steadily produces 8-99 kilometers per hour.

Overclocking to a hundred, in principle, is possible, but only in very specific conditions, which hardly anyone has recreated. The fuel consumption is 1.5-2 liters per hour, the volume of the fuel tank is 3.6 liters, so experienced drivers always have a fuel canister in reserve.

Its big plus is that the engine does not require constant oil filling - timely maintenance is sufficient, if necessary. The walk-behind tractor is quite easy to operate - this process does not require much physical effort.

The minimum space required for turning has a radius of only 1100 millimeters. The movement of the walk-behind tractor is smooth, thanks to a chain reducer with a V-belt transmission, gear changes are smooth, without jerks.

For more details about the Luch MB1 walk-behind tractor, see the video:

The transmission of the walk-behind tractor is quite reliable, has two forward and two reverse gears, and the engine is powerful enough for such a product - 5 horsepower, provides good traction and stable speed. High rates of cross-country ability and traction with the soil are achieved due to pneumatic tires with a large tread.

Also, MB 1 is easy to transport thanks to the quick-release steering wheel and wheels. As for possible malfunctions, the occurrence of which is inevitable during the operation of any equipment, especially those made during the Soviet era, the repair of the "Luch" walk-behind tractor will not become a serious problem.

For all the years that it has been used by farmers, summer residents and farm owners, a large amount of information has accumulated regarding quick, inexpensive and reliable repairs. Thanks to the experience of its owners, who have found all the causes of malfunctions, you can repair your Luch walk-behind tractor at no extra cost.

Malfunctions, no matter how serious they seem, can be eliminated in a home workshop, using the most ordinary tool, without resorting to the help of specialists. The only thing that is required of you is to diagnose the breakdown as accurately as possible, and then it's up to the little things.

Advantages of the Neva MB-1 walk-behind tractor

According to the operating instructions, this machine is designed to perform various tasks in the backyard and in the garden. With the help of a walk-behind tractor, you can mow, remove snow, huddle and plant root crops. The equipment is intended for use in swampy areas or wooded areas.

The advantages of the walk-behind tractor include such parameters as:

- Small size.

- Easy to operate.

- High performance, made possible by the installed 4-stroke engine.

- Large selection of attachments. In the basic configuration, the walk-behind tractor is equipped only with a cultivator, which is suitable for loosening the soil, turning it over. If it becomes necessary to install additional equipment, then it can be bought in a specialized store.

Easily find parts to repair yourself. In the event that the walk-behind tractor does not start or it is necessary to adjust the carburetor, you should contact a specialized service.

You can use the recommendations that are set out in the operating manual, but not every owner of the Neva walk-behind tractor is able to repair the equipment himself or adjust the internal systems.In this case, it is worth contacting professionals to set up a walk-behind tractor, since an ordinary user can take several weeks to repair it.

Motoblock Neva MB-1 has several modifications that differ from each other in the type of installed engine. There are the following models of equipment:

- Neva MB-1C-7.0 - has a Subaru engine, type EX21. It is a single-cylinder, four-stroke engine with an air-cooled system and a recoil starter.

- Neva MB-1B-6.5 - an I / C 6.5 engine from Briggs and Stratton is installed, which has the characteristics described above.

- Model MB-1C-6,5 Pro - EX17 motor installed.

- MB-1B-6.0 - I / C 6.0 engine from Briggs and Stratton.

- MB-1B-6.0-FS - differs from other engines in that the developers of the firm Briggs and Stratton installed an electric starter and a generator on it.

- MB-1B-6.0 K is another product of Briggs and Stratton.

- MB-1S-7.0 Premium - produced by Subaru, type EX21.

- MB-1C-6.0 Pro Premium - motor type EX17.

- MB-1S-6.0-FS Premium - I / C 6.0 engine from Briggs and Stratton, on which a generator and an electric starter are installed.

Thus, in the Neva MB-1 model range, single-cylinder engines with a manual starter are installed. And only 2 models have an electric starter and 1 generator each.