Description of famous models

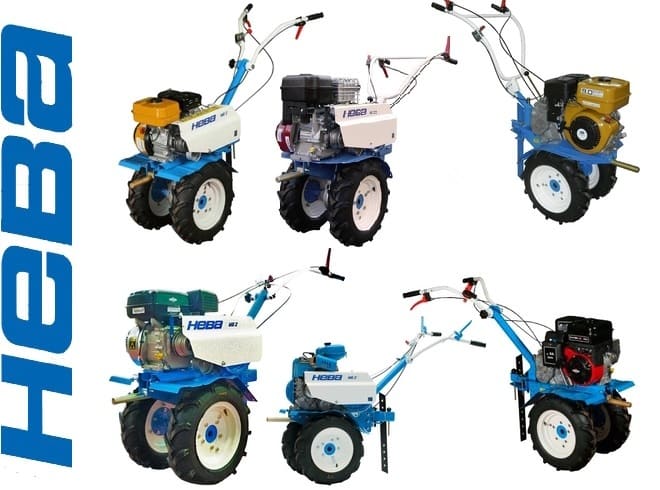

Among all models of Neva MB motoblocks, several models are in significant demand. They are united by the ability to process up to 25 acres, as well as the performance of any agrotechnical operation. Popular models include:

- MB-2K;

- MB-2B;

- MB-23;

- MB-2H;

- MB-2S.

The main difference between these modifications is the engine that is installed on them.

MB-2K

It is considered the base model that runs on 92 gasoline. The letter K in the name indicates that the device is equipped with a domestic motor "DM-1K". If this is a semi-professional model, then its power is 6.5 hp. If professional - 7.5 hp. Due to the special ball bearings that are in the crankshaft, the walk-behind tractor functions stably under any load fluctuations. The structure weighs 100 kg, and processes the soil at a speed of 12 km / h. Works in 6 gears - 4 forward and 2 reverse.

You can separately purchase attachments, due to which the device will plow, mill the ground, plant, weed, huddle or dig out the crop. And if you attach a shovel or brush, then the unit is used for public works.

On a note! The MB-2K model has an electronic start. At his expense, the walk-behind tractor is started and operated throughout the year.

MB-2B

The letter B indicates that they are using foreign motors "Brigg & Stratton". These are American manufacturers with 6 and 7.5 hp. The dimensions of the unit coincide with the parameters of the previous model, and weighs up to 102 kg. Thanks to the ability to use additional equipment, motor vehicles perform the entire range of earthworks. It is possible to additionally attach a trolley, which transports up to 450 kg of cargo.

In winter, the device is used to remove snow. The model differs in low fuel consumption, versatility during operation in any weather and season.

MB-23

Another model that performs many functions. It runs on American and Japanese engines with a power rating of 8 to 10 hp. The unit is more suitable for long-term strenuous work. At the same time, the processing depth reaches 35 cm. The device is produced in several modifications. The weight of the structure is 103 kg, the capture width is 80-170 cm. It works in 4 forward gears and 2 reverse gears.

The model has high maneuverability, which is achieved due to a special mechanism for decoupling the installed wheels. This model is used in large areas.

MB-2N

The letter H means that the model uses a Honda engine with 5.5 and 6.5 hp. Despite the fact that the power is not significant, the motor has a high efficiency with torque, which makes the model reliable. The walk-behind tractor of this model is lightweight (89 kg). The device behaves well under significant loads. The unit operates at two forward and one reverse speeds.

MB-2S

The motoblock is equipped with a Japanese Subaru engine with a power of 6 and 7 hp. The model attracts by its small size (89 kg), with a grip of 170 cm, and a plowing depth of 25 cm. The box is multistage, as in the MB-23 model. There is a function to turn off one wheel, thereby increasing maneuverability and making it easier to turn. It operates on AI-92 and AI-95 fuel.

With Subaru engine

Motorcycle Neva, which is based on the "Subaru" engine from the Japanese manufacturer. The device is reliable, efficient and durable. Due to the high performance of the engine and high-quality suspension with a gearbox, the walk-behind tractor is considered the best in its range. In addition, the equipment is easy to operate, easy to maintain and a high opportunity to buy various parts. During operation, the equipment does not consume much fuel.You can work in any weather conditions.

Application

According to the operating instructions, before turning on the walk-behind tractor, it is necessary to carry out preparatory work:

- check all units and fasteners for tightness and reliability;

- familiarize yourself with the safety measures described in the manual;

- check the engine oil level;

- fill the fuel tank with pure AI-95 or AI-92 gasoline;

- to re-preserve the walk-behind tractor;

- check the presence of oil in the gearbox;

- inspect tires.

Running in

Running-in is an important stage in the operation of any equipment. If the process is carried out incorrectly and the walk-behind tractor is poorly maintained, its service life is reduced, the mechanisms fail.

The depth of soil cultivation reaches no more than 10 cm. Experts recommend carrying out this process without loads.

After running-in, you need to do the following:

- make the first oil change;

- check the strength of the fasteners;

- adjust the belt for the walk-behind tractor;

- check the operation of the disengagement of the left wheel;

- remove additional restrictive gaskets between the carburetor outlet flange and the pipe flange.

See »The most popular Weim walk-behind tractors

Cultivation

When operating a walk-behind tractor with a cultivator, it is necessary to adhere to the following algorithm:

- Place the equipment in a horizontal position, check the steering.

- Adjust the tillage limiter to the desired depth.

- Cultivate with the carburetor throttle half closed.

- When working in low temperatures, if the walk-behind tractor does not start, use the following method:

- soak the equipment for about 10 hours in a warm room, then turn it on quickly;

- fill the engine with oil with a temperature of + 50 ... 60 ° С;

- warm up the carburetor pipe and the system itself by applying a rag soaked in hot water on them.

Motoblock "Farmer" 902 PRO-S

Professional series petrol 4-stroke walk-behind tractor. Designed for the processing of medium-sized land, the size of which does not exceed 5 hectares. Thanks to the improved cross-country ability of the tires, the unit does not need to be lugged on light and sandy soils. The excellent weight distribution of the structure makes it suitable for working on slight slopes and bumpy terrain.

Advantages:

- reverse function;

- 3 working speeds, providing processing of 6-12 m of the field per minute;

- 6 liter fuel tank for 3 hours of continuous use;

- equipping with a power take-off shaft, which simplifies the complete set of the walk-behind tractor with active attachments;

- completeness with main and auxiliary cutters for plowing soil of any density and composition without loading the motor part;

- Extensive protective shields to prevent dirt particles from entering the operator.

Specifications:

- Traction - 9 HP;

- Milling length - 0.85 .. 1 m;

- Cultivation depth - 300 mm;

- Oil tank - 1.1 l;

- Dimensions - 135 x 97 x 130 cm;

- Weight - 120 kg.

2 Attachments and the use of the Favorit walk-behind tractor

All attachments are connected to the machine through a special power take-off coupler. To expand the list of attachments used from other models, a special universal coupling is used. It does not come with a walk-behind tractor, but is purchased in specialized stores.

Trailer mechanism of the walk-behind tractor Favorite

The following attachments are attached to the Favorit walk-behind tractor:

- adapter for the operator;

- metal wheel lugs;

- milling cutter for walk-behind tractor;

- large plow;

- potato digger and potato planter;

- trailer for transportation of various goods.

2.1 Adapter

This model does not provide an official adapter. But, since the machine is universal, an adapter from any other domestic model is suitable for it.This attachment is an additional frame on which the operator's seat is installed, control levers for additional attachments, one more link and a second wheel axle. The adapter is used for more comfortable transportation of the machine over long distances.

2.2 Metal wheel lugs

This equipment represents metal wheels with an increased diameter and pronounced tread. Lugs are used on plowed soil, off-road, icy surfaces and flooded areas where standard pneumatic tires cannot handle.

wheels and lugs

They are mounted directly on the wheel axle, instead of conventional wheels.

2.3 Mills on a walk-behind tractor

Cutters are disc-type or have a cruciform shape. They are attached to a special rod, which, in turn, is attached to the vehicle's wheel axle. This equipment allows you to easily cut off the top ball of soil and mix it, loosening the area for planting. In fact, the same cutters turn the walk-behind tractor into a full-fledged cultivator. But, in terms of power, the latter is significantly inferior to the Favorite models.

2.4 Plow

The plow for such a machine is a universal passive tool. With its help, you can carry out both ordinary plowing of the land area, and make furrows for planting tuberous and other crops. The passivity of this device lies in the fact that there is no movable working body on it, and all work performed by tractive effort of the front axle. Thanks to the ability to adjust the working body, you can customize the nature of the land cultivation.

2.6 Potato digger and potato planter

There are a lot of varieties of this technique. With the walk-behind tractor, both standard simple designs of potato diggers in the form of a rake with long teeth and automatic vibration models are used. The second type is equipped with a special grate that vibrates to get rid of excess earth.

Potato planters are also divided into different types. The main mechanism of such a device is as follows: a hopper is attached to the frame for placing tubers for planting. Below, slightly in front of the hopper, on the lower surface of the device, a plow is installed, which makes a furrow. A tuber falls out of the bunker, which is buried with hilling discs installed at the back.

Automatic models operate on engine torque, which is transmitted through a power take-off system.

2.7 Trailer

Such a mechanism is used to transport garbage, humus to a land plot, boards, stone, sand and other materials. By type, there are dump trailers and stable ones. At the same time, they can be equipped with additional brakes and a driver's seat.

Cross-country ability and transportation of goods

The capabilities of Favorit motoblocks are not limited to soil cultivation and the creation of torque on the power take-off shaft. Thanks to its robust hull structure, deep tread wheels and axle extensions, the unit can be used as a tug for transporting trailers, sleds and carts. A hitch is used to connect the machine to these attachments. At the same time, it remains possible to connect suspended equipment (plow, potato digger, hiller).

A problem with all small agricultural machinery is poor traction. This is due to the low weight of the hand-held equipment. There are several ways to resolve this issue.

The following devices are installed on walk-behind tractors:

- Wheel weights. These parts are discs or containers with sand, fixed on axle shafts or wheels. Discs are made from rod pancakes or cast from iron or lead filled concrete.

- Weights for the body. Initially, a steel frame made of an iron corner is attached to the unit frame.Already metal blanks are screwed to the frame, containers with water or sandbags are placed.

- Ground hooks. These products are attached instead of wheels. Their rim is an iron strip with welded strips. The lugs for the walk-behind tractor have a diameter of 30-70 cm and a weight of 25-40 kg.

In some cases, it is possible to improve the adhesion of the equipment to the ground and increase its cross-country ability by installing an additional semi-axle with pneumatic wheels and a wide track.

The functionality of Favorit walk-behind tractors is expanded due to rigid adhesion with such mobile devices:

- Cargo trailers. Body dimensions reach 3 m in length and 1.5 m in width with a side height of up to 80 cm. The tiller is capable of transporting a loaded trailer weighing up to 500 kg at a speed of 10 km / h on a flat road.

- Universal carts. They consist of a wheelbase, frame, body, driver and passenger seats. Modern carts are equipped with headlights and side lights, which makes it possible to use them on public roads. On the farm, universal carts are used for planting and collecting potatoes and other garden crops.

- Snow sled. They are made of polymer plastic, which makes the products very light. In winter time, a wide variety of property is transported on a sled when there is no possibility of using a wheelbarrow and a car.

The scope of application of Favorit walk-behind tractors is so wide that they are purchased by utilities to perform a variety of planned and emergency work.