MB-1D2M16

Milling walk-behind tractor "Oka", improved by the imported Lifan 177F OHV PRO engine with a pulling force of 9 hp. It copes with the task of plowing the soil on medium-sized land plots (up to 50 acres). Complete with cutters, opener, 2 axle extensions and a pair of pneumatic wheels (50 cm in diameter). Together with additional devices it turns into a hiller, potato digger, communal machine.

Performance properties:

- undemanding to the quality of fuel, the consumption of which does not exceed 2.1 l / h;

- spacious fuel tank - 4.6 liters;

- 6-position gearbox;

- soil cultivation 30 cm deep and up to 72 cm wide;

- weight - 98 kg.

Description of the MB-1 walk-behind tractor

Motoblocks MB-1 are very popular in our country. They began to be produced in the 80s and are constantly being improved. Their traction class is 0.1, with additional and trailed equipment. This figure indicates the pulling power of the vehicle.

Attached equipment allows the cultivator to plow the soil, huddle it, loosen it, dig up roots and rake the grass. Various loads are transported using a trailer. The optimal cultivated area is 6-40 ares.

After purchasing the MB-1 unit, you need to carefully study all the recommendations presented, which are contained in the operation manual.

For the MB-1 cultivator, the characteristics are as follows:

- The main part on which all units are mounted is the cylinder block.

- An internal combustion engine is a gas distribution mechanism that controls gas flows. This mechanism consists of a camshaft and associated components (exhaust and intake valves).

- The camshaft diameter is 30 mm, the length is 280 mm.

- KShM - crank mechanism - provides rotary movement of the piston.

- Fuel system - feeds and filters fuel from the tank and supplies it to the cylinders.

- There is an ignition system for the appearance of an electric spark.

- A launcher that assists in starting the engine.

- Cooling system to prevent overheating of the motor.

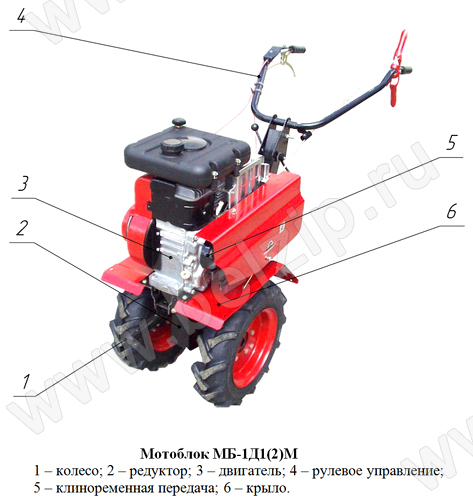

One of the manufacturers of the MB-1 Oka walk-behind tractor is the Kaluga Engine plant, located in the city of Kaluga. He produces three versions of motoblocks: A, B and C:

- Option A. Motoblock MB-1D1M 10.

- Option B. Motoblock MB-1D2M.

- Option B. Motoblock MB-1D3M.

Each of them is equipped with different engines:

- MB-1D1 (2, 3) M - engine DM 1M, power 8.0 / 5.9 (hp / kW);

- MB-1D1 (2, 3) M 1 - engine DM 1M, power 8.0 / 5.9 (hp / kW);

- MB-1D1 (2, 3) M 1 - Mitsubishi GT600 engine, power 6.0 / 4.4;

- MB-1DK (2, 3) M 7 - engine I / C 6.0 HP, power 6.0 / 4.4;

- MB-1D1 (2, 3) M 9 - engine NONDA GX - 200, power 6.5 / 4.8;

- MB-1D1 (2, 3) M 10 - engine Lifan 168 F-2A, power 6.5 / 4.8;

- MB-1D1 (2, 3) M 10 - engine Lifan 168 F-2A, power 6.5 / 4.8;

- MB-1D1 (2, 3) M 11 - Vanguard 6.5 HP engine, 6.5 / 4.8 power;

- MB-1D1 (2, 3) M 12 - Lianlong 168F 1A engine, power 6.5 / 4.8;

- MB-1DK (2, 3) M 13 - Robin Subaru EX 17 engine, power 6.0 / 4.4;

- MB-1DK (2, 3) M 14 - Robin Subaru EX 21 engine, power 7.0 / 5.2;

- MB-1D1 (2, 3) M 15 - engine KADVI 168F - 2A, power 6.5 / 4.8.

When working with the MB-1 motor cultivator, the operating instructions will help the farmer understand the main aspects of the unit's operation.

There is another walk-behind tractor from a Chinese manufacturer, which is approved by our GOST. This is a MB-2 m walk-behind tractor. The motor power of the walk-behind tractor is 6.5 hp. It copes well with the soil and at the same time spends little gasoline. In user reviews regarding the Chinese model, there are complaints about parts that are not made of metal, but of plastic. With intensive work, there is a minus in one: cutters often break and the starter cord is torn.

Forza walk-behind tractors from the UralBenzoTech manufacturer, which produces improved equipment, as well as spare parts and attachments, are also popular.The basic model is the FZ-01-6.5F cultivator. They have a modern design, they are quite reliable and durable.

All about belts for walk-behind tractors Cascade

Features of belts for motor-blocks Cascade

There are not so many models of Cascade walk-behind tractors on the agricultural market, but it is necessary to accurately select all the missing components for the existing models. Any discrepancy, even the smallest, can lead to very rapid belt wear. That is why the manufacturer strongly recommends purchasing only belts of its own production.

Each manufacturer of agricultural machinery uses belt drives, but they are far from always interchangeable - a belt for a walk-behind tractor from one manufacturer may not fit a walk-behind tractor of another. Even models of motoblocks from the same manufacturer may have differences in belts. That is why it is imperative to look at the marking and catalog number in the operating manual.

Production of belts for the walk-behind tractor Cascade

Modern belts for the Cascade walk-behind tractor (their sizes can be of any size) are made of the following materials:

- polyurethane;

- rubber.

The functionality of this agroelement is due to the cord (this is the name of the main belt part). Cord is made from polyester, steel and Kevlar materials, specialized fabrics, fabric cords.

The size of the belts for the walk-behind tractor Cascade

From practice: the reverse belt on the walk-behind tractor Cascade is used much less often than the front one. Consequently, the front elements wear out faster, although as a rule, belts can last even a year for the groomers. But it happens that the "life span" of a belt component is calculated in days. Some farmers have found a solution to this problem in the fact that they purchase agricultural accessories from foreign motoblocks (with internal teeth), which fit the Cascade in size. The size of the belt marking on the Cascade walk-behind tractor is A-1180 or A-1213 GOST 1284 (for forward gear), A-1400 (for reverse gear). Profile "A" is thirteen millimeters. The marking number will help to make the correct order of the fixture from the catalog.

Replacing the drive belt on the cascade walk-behind tractor

Tensioning belts on walk-behind tractors is a simple and quick job. To make the correct belt replacement on the Cascade walk-behind tractor, use our instructions:

In neutral, turn off the tiller.

Stop the engine.

Remove the protective cover.

Remove old, worn out belts. If they are not torn, but simply worn out, cut them open.

Connect new agricultural accessories. First, remove the pulley from the motor drive. Pull the belt over the geared pulley (the latter remains in place), then install the motor pulley

It is important to double-check that the belts are not twisted and are located in the strictly designated areas.

Reinstall the protective cover.

Operating manual for the Neva MB-23B-8.0 walk-behind tractor

The small-sized device is equipped with trailed and mounted implements for plowing, loosening, cultivating the soil. The instruction manual introduces the user to the general provisions, which contain information regarding the operation of the walk-behind tractor, maintenance and storage of the unit.

The operating manual contains information on possible malfunctions and tips for their elimination. The instructions indicate the features of the engine for any modification of the walk-behind tractor.

The manual of the Neva Compact walk-behind tractor indicates the purpose of the main parts of the unit:

- reducer;

- cutter clutch mechanism;

- coupling shackle;

- cultivation depth limiter.

The user, having familiarized himself with the control mechanism of the walk-behind tractor, determines how to increase the speed when plowing heavy soil. The instructions indicate a lever that allows you to shift gears with the engine running and the clutch disengaged to the nearest neutral gear.

Accelerated operation of the motor with distorted vibration is a reason for inspecting the walk-behind tractor and repairing damage. The usual set of cutters is completely replaced if the edges of the knives are damaged.

Troubleshooting

The manufacturer guarantees uninterrupted operation of the equipment for up to 5 years, provided that all recommendations for care and maintenance are carefully followed. The warranty period for use is 24 months. During this time, there should be no attempts to independently repair the equipment with the opening of the seals.

Units may have the following faults:

- The walk-behind tractor Cascade does not start, the engine does not start.

- The ignition system does not work. The ignition adjustment of the walk-behind tractor is based on the inspection of the spark plugs, as described above.

- Unstable motor operation or stopping after starting.

- Difficult starting of the engine, black exhaust fumes come out.

- The walk-behind tractor does not move forward or backward.

- Lamination of the V-belt transmission.

- The engine does not develop power.

These are typical failures and malfunctions in the operation of the walk-behind tractor.

Causes

If the engine does not start, then the reasons may be as follows:

- lack of fuel in the tank;

- the gas tap is closed;

- clogging of the fuel system;

- clogged hole in the tank plug;

- fuel leaks out of the carburetor;

- the ignition system does not work;

- sucking air into the carburetor through the flanges.

With unstable engine operation, the reason is low fuel consumption, with difficult starting and the presence of exhaust gases - on the contrary, high fuel consumption, clogged air filter, excess oil in the crankcase.

If the engine is not operating at the rated power, then the problem is a weakening of the spring or carbon deposits in the combustion chamber.

Repair of a walk-behind tractor

Repair work is carried out in accordance with the repair instructions for the Cascade walk-behind tractor.

Service is recommended to be carried out at a repair company. Specialists will adjust the carburetor, if there is no forward or reverse gear, they will check the gearbox, repair the gearbox, and replace worn parts.

The Cascade walk-behind tractor repair manual was compiled taking into account the most common malfunctions. It contains information on the types of equipment malfunction, possible causes and methods of their elimination.

For example, the engine may not start due to malfunctions in the fuel or ignition system. If the engine is unstable (shutdown immediately after starting, black exhaust gases, etc.), the reason may be a malfunction of the carburetor or a clogged air filter. Carburetor breakdowns are best corrected by a specialist.

In case of minor malfunctions of the walk-behind tractor, the owner can eliminate the cause on his own.

In case of problems with the fuel system, the following actions must be taken:

- Add fuel.

- Check for clogging of the hole in the plug. To do this, you need to remove the plug in the tank, clean the hole.

- Drain the fuel from the tank, rinse it with gasoline, blow out the carburetor jets with a pump.

Malfunctions in the ignition system are solved by the following methods:

- Replace spark plug.

- Check and replace spark plug tip.

- Adjust the clearance between the stator and the flywheel magnetic shoe when changing the allowable clearance.

If the air filter is clogged, clean the filter element.

If the causes of failures in the V-belt transmission, check the tension of the belts, adjust them or replace them.

After repairing the walk-behind tractor, the Cascade unit should work efficiently and for a long time.

Advantages of Favorit walk-behind tractors

The product created by a domestic manufacturer can operate in any weather, in conditions of extremely low and high temperatures, under the scorching sun and rain. Low fuel consumption allows you to process large areas without taking off for refueling.

The advantages of Favorit brand walk-behind tractors are as follows:

- Adaptation to almost all attachments and overhead equipment produced by domestic and foreign manufacturers. This allows you to quickly find and buy the part you need at the lowest price.

- Durability and reliability. The frame and engine are shock- and heavy-duty resistant. The manufacturer gives a 36 month warranty for its products and 5 years of service, provided it is used correctly.

- Ergonomics. All machine controls are close at hand. The operator does not need to be distracted from work and make unnecessary efforts to switch the walk-behind tractor to the desired operating mode. The steering wheel is vertically and horizontally adjustable for operator convenience.

- Compact dimensions and low weight. The equipment can be transported in a passenger car by loading it into the trunk. To store the walk-behind tractor does not require a lot of space.

- Security. The operator is protected by wide wings from stones, dust and earth flying from under the wheels. If control is lost, the unit will automatically stop moving.

- Easy to maintain. Repair of the Favorite walk-behind tractor can be carried out independently with the usual set of tools in a home workshop.

The purchase of this unit is a profitable and promising investment of funds. Lightweight and reliable equipment will save agricultural workers from hard manual labor for many years.

Are you the owner of Favorit walk-behind tractor? What attachments do you use?

Brand and manufacturer

The manufacturer of Oka motoblocks of the MB-1 series is the Kaluga enterprise OJSC Kaluga Engine, located in the Russian city of Kaluga at st. Moskovskaya, 247. According to the manufacturer, there is also a service center where maintenance and repair of motoblocks is carried out.

location of JSC "Kaluga Engine"

The network of service centers is very wide, the full list of addresses can be clarified by contacting the contact number of the factory service center.

JSC "Kaluga Engine"

The history of the appearance of "Kadvi" dates back to 1966 - at that time the Kaluga Experimental Motorcycle Plant was created. At present, the Kadvi plant produces technical equipment, not only motor vehicles, but also spare parts for large equipment, parts and components of heavy industrial equipment. Motoblocks made in Kaluga are known not only in Russia, but also in neighboring countries, for example, in Ukraine, Moldova, Kazakhstan, Uzbekistan, Belarus.

Distinctive characteristics of all motoblocks, united by the Kadvi brand, are reliability, high quality, stability of operation, durability and the possibility of widespread use in agriculture and farming. Attachments for "Oka" are also suitable for motoblocks "Ugra", some products can be attached to machines of other manufacturers - Ukrainian, Belarusian, etc.

This is interesting: How to properly run a new walk-behind tractor - we explain in detail

Motoblock Pecheneg PMB-900

The Pecheneg PMB-900 walk-behind tractor has a cultivator that is used in various types of land work in different areas.

The standard package includes wheels and cutters, operating instructions and a passport for working equipment. Additionally, you can purchase an opener, potato digger, snowplow, lawn mower, trailer and other tools.

The enlarged fenders allow the use of 10 "wheels, lugs.

It is also possible to operate hinged structures from other manufacturers, such as "Neva" and "Oka". For this, a special extension adapter is attached.

Specifications:

- Engine power - 7 l / s.

- Volume - 207 cm³.

- The plowing depth is 35 cm.

- Plowing width - 75-100 cm.

- Fuel capacity - 4 liters.

- Transmission - three-speed (2 forward and 1 reverse).

- Gearbox type - cast iron.

- Country of origin - Belarus.

- Fuel type - AI-92 gasoline and diesel.

- The mass of the walk-behind tractor is 90 kg.

The price for different regions varies between 24-35 thousand rubles.

The reviews of the owners are mostly positive, because for such an acceptable amount they purchased a miracle of technology that made their farm life easier.

Some reviews, like the previous model, say that the cutters consist of fragile steel, very thin and fragile, which breaks down on hard rocks (clay, soil).

Motoblocks Pecheneg 900 and 950, equipped with a cast-iron gearbox, unlike an aluminum one, are more firmly adhered to the surface, not burrowing into the ground during plowing, without entering drifts, because these machines are heavier and easier to drive.

The packaging of motoblocks consists of plywood. The kit must include a product passport and operating instructions.

The improved steering wheel will allow owners to work on different planes of the ground, the unit moves smoothly when cornering, without leaving large furrows behind it. Also, the steering wheel is adjusted with a special lever: up and down, left and right.

Farmers can cultivate 17 acres of land or more per day, which is a significant indicator. With small volumes of fuel tanks, the engine has a fairly large power. The cost of gasoline and diesel is small, there are no negative reviews on this matter.

The new models, in contrast to the outdated ones, have low noise and vibration levels due to rubber wheels and low engine torque. Moreover, a gasoline engine sounds several times quieter than a diesel one.

The Pecheneg motor-cultivator is intended for individual use, small lands, estates and large fields. By purchasing this unit, the owner makes it several times easier to care for the garden, because the walk-behind tractors have the functions of plowing, hilling, potato digging (and planting), a snowplow, and a lawn mower.

Some summer residents use the cultivator in winter, plowing the frozen land in the spring. Customer reviews indicate that the Pecheneg motor cultivator is a useful purchase at a fairly low price.

Model range of motor cultivators Neva MK-200

Various modifications of the cultivator of this series differ in the engine brand and assembly features. Depending on which engine is installed - Briggs & Stratton 750 Series, Honda or Robin Subaru, the marking of the cultivators is respectively indicated.

Motor-cultivator Neva MK 200-S6.0

The cultivator is powered by a 6 hp Robin Subaru Japanese engine. The model is designed to perform agricultural and economic work on small and medium-sized land plots.

Motor-cultivator Neva MK 200-S6.0

- Thanks to the upgraded Subaru EX 17 engine, the cultivator can be easily started even at subzero temperatures.

- The 2F / 1R transmission allows for optimal pace of work.

- The adjustable handlebars are adjusted to suit the operator's height and steering angle.

- Thanks to the "Park position" option, changing the cutters is quick and easy.

- For the Neva motor-cultivator, it is possible to connect any mounted implements for performing agrotechnical work.

- The unit is characterized by high maneuverability, simple control and simple maintenance.

- The front support wheel provides the necessary stability during cultivation and transport.

Technical characteristics of the MK-200 model

| Engine brand | Subaru (Japan) |

| Engine | EX 17 |

| Power, h.p. (kw) | 5.7 (4.2) |

| Fuel tank, l | 3.6 |

| Weight, kg | 65 |

| Number of gears | 2+1 |

| Working volume, cm3 | 169 |

| Fuel type | Pure gasoline AI - 92, AI - 95 |

| Transmission | Oil-filled, chain-gear reducer in aluminum housing |

| Cultivation width, cm | 65-100 |

| Shaft speed | 28-40 (1 gear) 90-130 (2nd gear) |

| Depth of processing, cm | 16 |

Neva MK-200 V5.0RS

The cultivator is equipped with an American Briggs & Stratton 5 hp engine, which allows to effectively operate the machine throughout the year on soils of varying complexity.

Motor-cultivator Neva MK-200 V5.0RS

- The cultivator is characterized by high maneuverability and simple operation.

- The shift lever for 2 speeds forward and 1 reverse is ergonomically located on the steering wheel.

- There is an option "Parking position"

- The capabilities of the Neva motor cultivator have been significantly expanded due to the available aggregation with various additional implements.

- The replacement of attachments, thanks to the rational design of the coupling mechanism, is simple and quick.

- Thanks to the double front transport wheel, the cultivator can be conveniently moved on any surface to the place of work. When cultivating the soil, the wheel acts as a support wheel.

Specifications

| Engine brand | Briggs & Stratton (USA) |

| Engine | RS750 |

| Power, h.p. (kw) | 5.0 (3.7) |

| Weight, kg | 65 |

| Number of gears | 2+1 |

| Working volume, cm3 | 163 |

| Fuel type | Pure gasoline AI - 92, AI - 95 |

| Transmission | Oil-filled, chain-gear reducer in aluminum housing |

| Cultivation width, cm | 65-100 |

| Shaft speed | 28-40 (1 gear) 90-130 (2nd gear) |

| Depth of processing, cm | 16 |

Neva MK-200 N5.0

The MK-200 H5.0 model is equipped with the Japanese Honda GP 160 engine, with which the cultivator can be operated for a long time in intensive mode with reduced fuel consumption. The unit is designed for the processing of heavy clay soils, virgin lands.

Motor-cultivator Neva MK-200 N5.0

- The cultivator is equipped with a transmission with 2 forward and 1 reverse gears. Oil-filled gear-chain reducer, aluminum housing.

- The ergonomic steering wheel adjusts to suit the operator's height and direction of travel.

- Thanks to the double support wheel, the unit has good maneuverability, is conveniently transported, and excessive sinking into the ground is excluded.

- The model is equipped with a coupling device, similar to the device on the walk-behind tractor, which provides the connection of additional devices that are installed on the walk-behind tractor.

- The soil mills provide a working width of 65-100 cm to a depth of 16 cm.

Technical characteristics of the MK-200 H5.0 model

| Engine brand | Honda (Japan) |

| Engine | GP 160 |

| Power, h.p. (kw) | 4.9 (3.6) |

| Fuel tank, l | 3.1 |

| Weight, kg | 65 |

| Number of gears | 2+1 |

| Working volume, cm3 | 163 |

| Fuel type | Pure gasoline AI - 92, AI - 95 |

| Transmission | Oil-filled, chain-gear reducer in aluminum housing |

| Cultivation width, cm | 65-100 |

| Shaft speed | 28-40 (1 gear) 90-130 (2nd gear) |

| Depth of processing, cm | 16 |