Motoblock Centaur 2016B

Gasoline walk-behind tractor Centaur 2016B is one of the most powerful units produced by the Centaur brand. The assembly of a heavy agrotechnical device is carried out in the Republic of Belarus, which significantly reduces the cost of the unit, thereby making it available to a larger number of consumers.

Motoblock Centaur 2016B

Motoblock Centaur 2016B

The cost depends on the configuration, which can be standard or optional. The average market price for this walk-behind tractor varies from 41 to 47 thousand rubles. The standard equipment includes a cutter and large pneumatic wheels with industrial tread.

Additional equipment includes:

Features of the walk-behind tractor Centaur 2016B:

- Motoblock Centaur 2016B has a relatively low weight - 145 kg.

- At the same time, a professional Japanese-made Kama power plant was installed on it, providing a power of 16 liters. with.

- The engine is equipped with an air overheating protection.

- Inertial starting system (from a manual starter).

- A power take-off shaft is available, which allows you to attach attachments of both passive and active types to the walk-behind tractor.

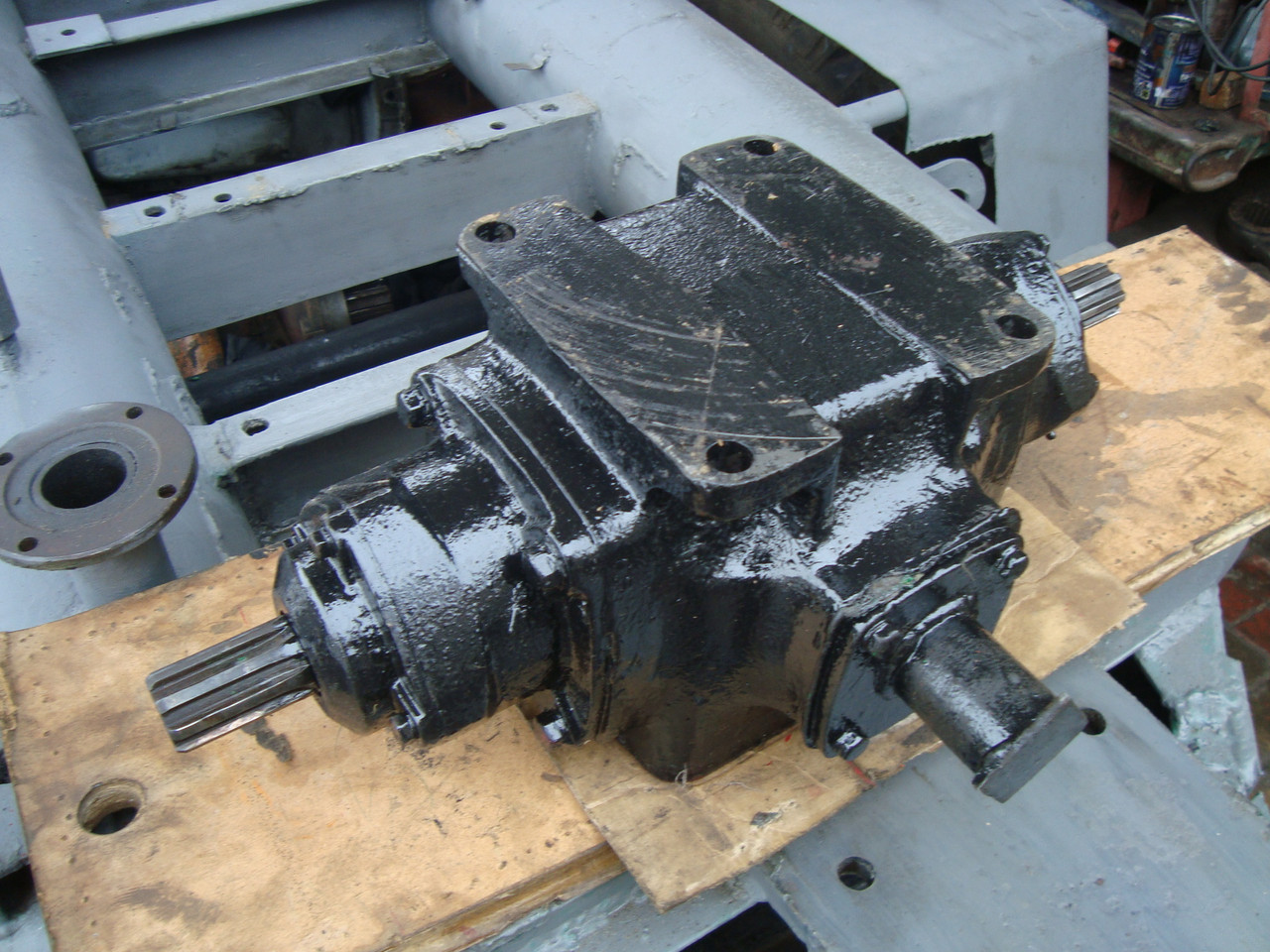

- The gearbox is mechanical, two-stage, gives two speeds forward and reverse.

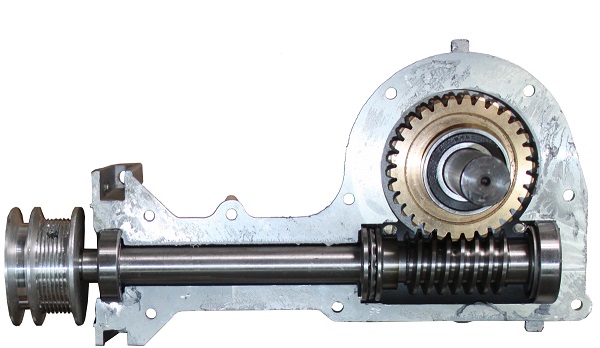

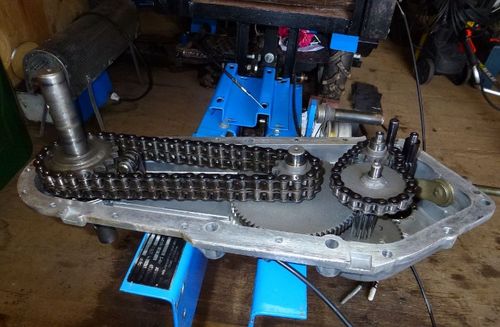

- The gear-chain reducer transmits the maximum torque, while it is characterized by high wear resistance and reliability.

- The gearbox housing is collapsible, which makes it easy and cost-effective to carry out repair work.

- To improve stability, the developers have lowered the center of gravity of the walk-behind tractor.

- The comfortable, adjustable handle is equipped with an emergency stop button for the engine.

- Unlocking the wheel differential allows the machine to maneuver from a standstill in any direction.

Specifications

| Shaft Diameter: | 18 mm |

| The weight: | 172 kg |

| Dimensions: | 1700x870x1380 mm |

| Engine make: | KAMA |

| Engine's type: | Petrol |

| Power: | 16 h.p. |

| Engine displacement: | 418 cc m. |

| Fuel consumption: | 1.3 l / engine hour |

| Launch system: | Inertial |

| Cooling system: | Air |

| Number of gears: | 2 forward 1 reverse |

| Maximum speed: | 18 km / h |

| Wheel size: | 6,00-12 |

| Track width: | 750 mm |

| Coverage of the rotary tiller: | 450 - 1350 mm |

| Processing depth: | 20 cm |

Maintenance of motoblocks "Centaur"

Diagnosed every shift:

- tanks for technical liquids for leaks,

- bolt ties of the frame and drive wheel;

- oil level;

- belt tension.

After running out of the first 100 operating hours:

- replace the engine oil with a new one;

- clean the filter of the oil distributor box;

- check and re-establish the clearance between the release bearing and the expanding action bracket.

Every 500 hours of operation:

- clean the cylinder cover, exhaust outlet, filter;

- change engine oil;

- grease lubricate the clutch bearings - front and release;

- for diesel motoblocks, it is imperative to remove scale from the hydraulic tank.

Inspection after 1.5-2 thousand hours includes checking:

- bearings and quickly wearing parts, which, if necessary, are replaced with new spare parts;

- control springs.

Selection Tips

A wide range of various motoblocks is produced under the Centaur brand. Prices for the model range vary from 12 to 65 thousand rubles - it directly depends on the power of the device.

Diesel and gasoline units are sold under the Centaur brand, with each option having its own advantages and disadvantages.

"Centaurs" of gasoline type are produced with power characteristics from 6 (model "MB 2016 B") to 16 liters. with. ("Model MB 3060B"). The positive aspects of a gasoline engine include a relatively low price, lightness and ease of use. The disadvantages are high thrust at reduced speeds, as well as the fact that you need to constantly keep the revs at a fairly high level.

Diesel units are represented by models with a capacity from 4 (model MB 3040D) to 13 liters. with. (product MB 1013D). Among the shortcomings, the high price for such products is distinguished. However, there are many more advantages - these models are characterized by high traction, increased service life and relatively low fuel cost.

The models differ in the type of cooling: they separate air and water. Air, as a rule, is installed on any type of motoblocks with low power and low weight. For larger installations, an air system is provided (these are models such as "MB 1070D", as well as "MB 1010D"). Parts with an air-cooled system have a longer service life.

When buying motoblocks, you should also proceed from the parameters of the site. If you have a small plot of land on which it is planned to carry out work on heaving, cultivation and weeding, then you should give preference to gasoline blocks with a capacity of 6 liters. with. or diesel with the corresponding parameter of 4 liters. with.

For plots less than 1.5 hectares, models with a capacity of 7-9 liters are suitable. with. and weighing 125 kg or more. Models "MB 2080B" and "MB 2091 D" correspond to these requirements.

Separately, it is worth mentioning heavy diesel models with a water cooling system, such as "MB 1012 D" and "MB 1081 D" - they are suitable for intensive processing of large land plots.

If you need to use the walk-behind tractor in cold weather, then it is worth stopping at such models as "MB 2061D" or "MB 2091 B".

These models are made of composite compounds and equipped with type-setting cutters to protect the seedlings. The design of such motoblocks has been improved in comparison with outdated modifications. These include "MB 2081 D" and "2050 DM-2".

Attachment overview

Cutters

Cutters for "Favorite" are supplied complete with the main device. They are always packed in disassembled form, so the owner must carry out the assembly himself. The assembly process must be carried out in thick fabric gloves, observing safety rules and following the instructions from the instructions for the walk-behind tractor.

It is allowed to use both ordinary saber-shaped knives and "crow's feet". There are no special recommendations on the types of cutters for "Favorite", you can use ordinary knives with a standard method of fastening (bolts).

The following video clearly shows the process of the walk-behind tractor with cutters

Adapter, trailer

The adapter is one of the most useful types of attachments for the walk-behind tractor. It differs from the cart by the presence of a seat. Trailers can be with or without a seat. Given the sufficient power of the Favorit motoblocks (6 hp and more), it is allowed to use adapters, tipper trailers, and conventional trolleys with devices.

Adapter for walk-behind tractor

Recommended types of adapters or trailers: universal for motoblocks Neva, Kaskad, Oka, Favorit, Salyut, Centaur, for example, TM Yarilo, But, Motor Sich, Veima, Zirka-61 and others.

Mowers

A novelty of ZID production is a rotary mower "Favorit" (release of 2013). Other models of mowers suitable for all motoblocks of the model range: Zarya, Centaur, Ship, KR-1, KR-02, VM-02 Forte, Zubr, Grunfeld. Volcano. It is allowed to use other types of mowers, for example, segment mowers.

Rotary mower KR-3 for the Favorit walk-behind tractor

Lugs

The lugs are usually used for a better plowing process in combination with a plow. They represent an iron wheel, are attached to the place of wheels on a walk-behind tractor.Lugs are also included in the set of soil cultivation kits (except for lugs, the kit usually includes a hiller, plow, fasteners, opener).

Lugs

Such kits are convenient in that they are attached in a universal way, they are suitable for the bulk of heavy and medium motoblocks, and they allow you to save money in comparison with buying all the components separately. Dimensions (models) lugs for motoblocks Favorite: Intertool TL600-1, Neva 560x130, Intertool TL700-1, 600x200.

Plow

You can choose any plow for the Favorit walk-behind tractor, even the most common and inexpensive one. The universal model of the plow is the PNM 1-20 plow, the Krot plow, 1-20 TM. Plows from motoblocks Neva, Centaur, Salyut, Oka, Ugra, Zubr, Kaskad are perfect for "Favorite". In the video later in the article, you can study in detail the process of installing the plow and lugs on the walk-behind tractor.

Snow blower, blade-shovel

The following models of snow blowers are suitable for Favorit walk-behind tractors: Weima, WM1050, Grunfeld ST360, Volodar, Zirka-61. To connect a snow blower, the walk-behind tractor must have a PTO and a power of 6 horsepower or more. A shovel-blade for a walk-behind tractor can have different sizes, mainly the difference lies in the length of the equipment.

Snow plow ZiD SM-1

The plows can be 1 m, 90 cm, 80 and even 60 cm long. A shovel with a rubber pad on the lower edge is better for public works, and a classic version without a rubber pad for snow removal.

Potato digger and potato planter

Even for powerful motoblocks, to which the Favorit belongs, it is quite acceptable to use a fixed-type potato digger, for example, Mole, Mastertul, Premium, KV-2. This equipment is attached in a simple way - with bolts. In order to increase the amount of dug out potatoes, more complex designs can be used, such as a vibrating potato digger.

Potato planters for the Favorit walk-behind tractor: Bomet, KSN-1, KSN-1m, APK-3, KSM-2, KSC-1 and others.

Other useful attachments include such types of equipment as weighting agents, hillers, rakes, tedders, various types of couplings (universal or for a specific type of equipment). The weighting agent is used on difficult soils, virgin soil, usually this type of attachments is not used for working on soft soils. The most common weighting materials weighing 8, 10, 15 kg.

Specifications

The device of the walk-behind tractor is distinguished by a rational design and has the following advantages:

- gasoline engine Kama (Japan) of high build quality, durable and reliable in operation;

- the presence of a power take-off shaft allows you to aggregate a walk-behind tractor with various implements and perform a full cycle of agricultural work;

- advanced oil bath disc clutch for smooth ride;

- easy starting thanks to the inertial starter;

- economical gasoline consumption - 0.9 kg / h;

- reduced noise and vibration during operation;

- increased permeability, the possibility of hilling tall plants without damage due to high agro-illumination.

Centaur 2080 B

When creating the Centaur 2080 B walk-behind tractor, the manufacturer took into account the ergonomics of work as much as possible - the steering wheel is adjusted vertically and horizontally in order to adjust the control with a minimum load on the operator's hands when performing various types of work. To increase the maneuverability of the Centaur 2080 B and for more agile handling in confined spaces, swivel hubs can be installed.

Thanks to the adjustment of the working width (30cm - 110cm), with the help of the milling cutter, you can efficiently process various areas - from narrow row spacings to impressive areas. A functional cutter in the form of 24 saber knives confidently processes virgin soil, will help to successfully cope with wheatgrass.

The guarantee of stable operation of the Centaur 2080 B walk-behind tractor lies in the timely maintenance of the mini-equipment.Recommendations for the first start-up, oil change, the frequency of maintenance work are indicated in the operating instructions for the walk-behind tractor, and maintenance is not difficult even for novice farmers.

Features and purpose

Motoblocks "Centaur" are produced in China, but this does not mean that their reliability is "lame". Quite the opposite - the products are distinguished by exceptional ergonomics, durability and practicality. The acquisition of such equipment allows plowing the land, planting plants, collecting and transporting crops without much effort.

Separately, it is worth dwelling on diesel motoblocks of the "Centaur" brand - such units are distinguished by increased power. In addition, everyone knows that diesel fuel is much cheaper than gasoline, so these machines are optimal for virgin lands, as well as large land plots.

Many owners have even adapted to modernize such units, making them mini-tractors with their own hands. By the way, diesel mechanisms are best suited for these machines.

To date, quite a lot of models are produced under the Centaur brand, so each user will be able to choose the best option for himself based on the size of the site, the type of soil and the assigned functionality.

Regardless of which model you need to purchase, you should take into account the main advantages of these products

The advantages of such models include the following positions:

- durability of the engine, the quality of which meets all European standards;

- due to the cast-iron crankcase, the walk-behind tractor is resistant to overheating, can withstand frequent use, and also increases the resource of the electric motor;

- multi-plate clutch, due to which the speed of torque increases many times and the smoothness of the movement of equipment is determined;

- multi-stage gearbox - due to this, the operator has the opportunity to choose the most suitable mode for effective work with various settings;

- the gear reducer has an increased margin of safety, therefore it can endure the most prolonged loads;

- the tool has the option to unlock the differential, making the installation maneuverable;

- the steering wheel is adjustable both vertically and horizontally, which makes the maintenance of the walk-behind tractor more comfortable, reduces physical activity and keeps the user's spine in the correct position.

There are drawbacks, but there are few of them, and they are isolated - buyers note that with the onset of winter, the walk-behind tractor begins to rust. The second drawback concerns additional parts, which, according to users, quickly fail. However, spare parts can be bought at any store at a low price and replaced in just an hour.

Care features

Any equipment sooner or later fails, and it is impossible to avoid this, but any user is quite capable of delaying the breakdown of mechanisms. To do this, maintain the manufacturer's specified mode of use without creating any peak loads.

Gasoline engines, like diesel engines, must not be used at idle speed. In this case, the risk of failure of the mechanism increases sharply.

If the engine does not start, then:

- make sure there is enough fuel;

- adjust the throttle;

- clean the air filter from dirt.

If the motor overheats:

- check the amount of oil;

- make sure that no foreign object has fallen into the muffler;

- clean the ventilation.

If there is no spark, then you need to clean the spark plug cap from carbon deposits.

If the walk-behind tractor vibrates too much, then it is necessary to check the position of the cutters, and also make sure they are intact.

Obviously, plowing the land and cultivating plants using the Centaur walk-behind tractor is a great relief for the owner of the site and a high degree of comfort. However, like any other technique, this unit requires the most careful handling.It is necessary to use only clean and high-quality fuel, as well as timely repair and replace defective parts.

For an overview of the Centaur 2013 B walk-behind tractor model, see the next video.

Let’s block ads! (Why?)

Operating rules

The use of "Centaur" walk-behind tractors does not require special skills - you just need to follow all the manufacturer's recommendations. One of them is the requirement of compulsory running-in of the machine - it is carried out to ensure the grinding of the basic elements. It is produced according to the following scheme: the first 3 hours - at 1/2 power, another 3 hours - by 2⁄3.

It is very important to follow the safety rules:

before starting the engine, make sure that the gearshift knob is in neutral;

care must be taken when working with knives;

you need to use only clean fuel and the highest quality lubricant;

The clutch should be engaged before shifting gears.

Description

Centaur mini tractors are made in China. They are successfully used on farm plots up to 6 hectares. In addition, they are used by public utilities to clean streets and maintain park areas.

The popularity of the Centaur mini tractors is due to a number of reasons:

Quality hydraulic system

In all Centaur minitractors, the hydraulic cylinder is located on top, which prevents dirt and dust from entering it. It also has 3 positions, so you can choose a comfortable mode for a specific task.

Increased service life of drive belts

The idler rollers are specially shaped to prevent twisting or chafing of the drive belts.

Universal hitch

Thanks to this, Centaur mini tractors can operate attachments not only from a Chinese manufacturer, but also from third-party ones.

Kama engine

All mini tractors of the Centaur model range are equipped with Kama diesel engines. They are distinguished by their reliability and increased service life of engine hours. He is able to work for 10 hours without stopping. Fuel consumption depends on the power of the mini tractor. On average, it is about 1.5 liters per hour.

During soil cultivation with a milling cutter, a heavy load is placed on the drive belt, so they often break and become unusable. In Centaur mini tractors, the cutter is driven by a double chain.

Track size

During processing of already emerged crops, an important factor is not to damage them. Minitractors Centaur allow their owners to set an inter-wheel distance from 1 to 1.2 m.

Materials (edit)

The Chinese manufacturer has tried to extend the service life of the mini tractor as much as possible by using only high-quality consumables. For example, the gearbox is made of an alloy of steel and cast iron, which increases its strength and resistance to load drops.

The greatest load during operation of the Centaur minitractor goes to the frame and bridge, they were additionally reinforced to prevent damage during operation.

Device

Diesel engine R 175 AN

The tiller is equipped with a professional economical liquid-cooled R 175 AN diesel engine.

The presence of a differential with forced locking and a solid weight of the machine (210 kg) provide high cross-country ability in hard-to-reach places, on difficult ground. The large size of the transport wheels contributes to good maneuverability.

The presence of 2 power take-off shafts: a front belt - for connecting active implements, and a rear gear - for a soil milling machine, turns the walk-behind tractor into a multifunctional technique.

Stable work is possible with a hiller, a mowing machine, a potato digger and a potato planter, a plow, pumps, trailers.

Video review of the work of the Centaur MB 1070D with various attachments:

Thanks to the continuous contact single plate clutch, the Centaur runs smoothly and brakes.The machine is equipped with durable ring brakes with internal expanding pads.

A wide range of speeds - 6 front and 2 reversible, make it possible to select the optimal rhythm of work, depending on the attached implements. The cultivation parameters with an active soil cutter are: depth 80-140 mm, width - 700 mm.

Review of popular models

Below is a description of the most popular varieties of "Centaur" walk-behind tractors.

"MB 1080D". This is a diesel walk-behind tractor. This model is optimal for plowing the land, planting plants and harvesting. In addition, it is effective in the maintenance of the garden and vegetable garden.

The model has the following performance characteristics:

- power - 8 liters. with.;

- box - 6 speed modes forward and 2 - in the opposite direction;

- steering type of control;

- lock option;

- rubberized wheels;

- halogen headlight;

- plowing parameters: width (length) - 100 cm, depth - 19 cm;

- mechanical type starter;

- cutter and plow - included;

- unit weight - 220 kg.

This walk-behind tractor is distinguished by a relatively inexpensive cost, while it works efficiently and efficiently. Thanks to the expanded range of various attachments, using a walk-behind tractor, you can not only cultivate the soil, but also sow seeds, and also harvest root crops and other vegetable crops.

A distinctive feature of this walk-behind tractor is low fuel consumption. This mechanism runs on a diesel engine and consumes no more than 1.8 liters of fuel in one hour of operation without interruption. The tank is designed for 5 liters of fuel, while, as shown by the test results, the use of such a model turns out to be much more efficient than the use of equipment with a volume of 7-9 liters.

"Centaur 1070D". This is another model of motoblocks with a water cooling system. The model is equipped with a gear reducer and a water-based radiator, making the mechanism significantly different from all similar machines in this class. To connect a variety of equipment, there is a built-in generator, the purpose of which is to feed the headlight. The unit is designed to work on a land plot of less than 2 hectares.

The main technical and operational characteristics of the device:

- a mechanical transmission of a mixed type;

- 6 speed modes forward and 2 - backward;

- power - 7 liters. with.;

- weight - 200 kg;

- rotary control principle, blocking option, there is a clamp;

- the ring braking system is equipped with internal pads.

Motoblock "Centaur 2090D". This model is optimal if you need to process small areas. The device is quite hardy, powerful and practical.

The unit is equipped with a high-class diesel engine, its capacity is 9 liters. with. The scheme includes a gearbox and a multi-plate clutch. The gearbox is mechanical, the wheels are pneumatic. Installation weight - 30 kg.

Popular models also include the following modifications: "1081D", "2016B", "2016B", "2013B", "2016B", "KEN_009", "2091D" and "2060D".

Motoblock "Centaur" 1080D

Heavy diesel motoblock equipped with a single-cylinder 4-stroke R180N engine from the Zirka brand. It has a reinforced body, the high maneuverability of which is achieved by a differential lock: this gives, if necessary, the rotation of the walk-behind tractor by 180 or 360 0. Oversized tires with a coarse tread will be the optimal solution for swampy soils, chernozems, as well as when hilling crops of tall crops. The significant weight of the walk-behind tractor allows you to save on lugs and weighting materials.

Advantages:

- high-speed diesel engine, resistant to overheating due to liquid cooling;

- capacious gas tank, full filling of which is enough for 3 hours of continuous operation;

- handles adjustable for the operator's height with comfortable rubber pads and ergonomic arrangement of control levers;

- 12 inch tires with anti-slip effect and deep tread for plowing on any substrate;

- 8-speed transmission with 6 forward speeds;

- built-in halogen lamp;

- competitive lifting capacity - about 0.6 tons.

Working properties:

- Traction - 6.5 hp;

- Gas tank - 5 l;

- Max. plowing (width / depth) - 1 / 0.19 m;

- Dimensions - 2.18 x 0.89 x 1.25 m;

- Weight - 220 kg.

User manual

Before you start working with the Centaur 2016B walk-behind tractor, you should study the instructions for use in detail, which is always included in the package. This procedure should be approached responsibly. The document discloses the following information:

- Safety requirements when working with a walk-behind tractor.

- Unit device.

- Model characteristics.

- Step by step assembly with descriptions and pictures.

- The procedure for the first start of the walk-behind tractor.

- Running-in (running-in).

- What does maintenance include.

- Malfunctions, reasons, which caused them and their elimination.

The section "Safety precautions" describes in detail the unsafe areas of the motorized device and safe ways to work with them.

It is important to remember that the greatest danger is posed by:

- gas tank with combustible fuel;

- starting system with high voltage wire;

- pulleys with belts;

- tillers rotating at high revolutions, etc.

First start-up and running-in

Before the first start, make sure that the crankcase is filled with the required amount of oil and the gas tank is full of fuel. We once again check the reliability of the fasteners. Now we carry out all the actions that are described in the guide for starting the walk-behind tractor.

Running in takes place in several stages:

- warming up the engine;

- operation of the motor at 1/3 power - 3 hours;

- complete oil change;

- operation of the power plant at ¾ power - 4-5 hours.

After such preparation, the Centaur 2016B walk-behind tractor is completely ready to work on a land plot with appropriate loads.

Maintenance

Maintenance includes several stages:

- daily care;

- inspection once a month;

- oil change according to the table;

- inspection at the service center once a year;

- preservation of the walk-behind tractor for a long storage period.

Let's describe the daily actions that will extend the service life for many years. The work is carried out in two stages.

Oil and Fuel Level Limit

Oil and Fuel Level Limit

Before starting field work:

- oil level control;

- fuel level control;

- checking the reliability of bolted connections.

At the end of the field work:

- thoroughly clean and wash the walk-behind tractor;

- dry in the shade;

- lubricate all parts and assemblies with the necessary lubricants.

Basic problems and how to fix them

The manual contains a table of malfunctions, which lists the entire list of breakdowns with an indication of the reasons for their occurrence and methods of elimination. Let's list a few of them.

Engine stalls, won't start:

- check for the presence of gasoline in the fuel tank;

- low-quality fuel;

- the high voltage wire is disconnected from the spark plug;

- the filter is clogged;

- spark plug problems;

- malfunctioning magneto;

- fuel hoses are worn out or clogged;

- problems in the carburetor.

Tillers stopped rotating:

- the fastening bolts have loosened;

- stones or clods of earth are stuck in the tillers;

- the clutch cable is loose;

- belts are broken or stretched.

Rumble in gearbox:

- broken teeth;

- the mounting bolts have loosened;

- running out of lubrication;

- bearing incorrectly installed or broken.

Description of the walk-behind tractor

Motoblock Hoper 1000 is a newer and more advanced version of the Hoper 900 model. There are three modifications in the Hoper 1000 line:

- Hopper 1000U;

- Hopper 1000U 7B;

- Hopper 1000U 5D.

Gasoline motoblock Khoper 1000 U

The main advantages of this model are:

- high power for work in areas up to 70 acres;

- quick and easy start;

- good build quality;

- reasonable prices for new walk-behind tractors.

Motoblock Khoper 1000U 7B

Engine

Let's take a closer look at what engine each of the modifications of the Hopper 1000 series is equipped with:

- Khoper 1000U - Lifan engine, gasoline, engine brand Lifan 168 F-2, power 6.5 hp, volume 196 cm3;

- Khoper 1000U 7B - Lifan gasoline engine, Lifan 168 F-2 brand, power 7 hp,

- Khoper 1000U 5D - diesel engine MQ171D, manual start, power 5 h.p.

Motoblock Khoper 1000U 5D

Used units, in some cases, can be bought with any attachments. The price for used walk-behind tractors is lower than for new ones and depends on the degree of wear of the unit.

- all types of gardening and summer cottage work, for example, planting potatoes, digging up potatoes, cultivation, plowing, hilling;

- transportation of any cargo weighing up to 300 kg;

- utilities (street cleaning, snow removal);

- other functions (fertilizing, spraying herbicides, etc.);

- mowing grass;

- when connecting the adapter - transportation of one person (walk-behind tractor operator).

Motoblocks "Centaur": preparation for work, running in and maintenance

Before commissioning any Centaur walk-behind tractor, they read the user's manual and prepare it for work.

Setting up "Centaur" walk-behind tractors includes:

- Tensioning the drive belts - unscrew the 4 screws under the motor, move it and tighten the nuts. A correctly adjusted belt sags by 3 cm when pressed with 4 fingers;

- Correct installation of the clutch bracket (as indicated in the diagram);

- Checking the health of the brakes - using the clutch release lever (it is engaged only when the brake is compressed);

- Steering column and track width adjustment;

- Setting the neutral working speed;

- Release of the release lever;

- Transferring the throttle valve to the starting point.

After that, they proceed to starting the motor. The process of the correct first launch of the Centaur walk-behind tractors is described in detail in the video instructions.

The running-in of "Centaur" walk-behind tractors lasts about 10 hours and consists of the following sequential actions:

- Refueling with gasoline (diesel, engine oil and coolant (only for diesel). The manufacturer insists on refueling with AI-92 gasoline and 10W30 or 15W40 grease;

- Tire pressure checks;

- Operation at partial load, for which the following schemes are followed:

At the same stage, the serviceability of the steering wheel and brakes is checked.

After running in, they begin to replace the motor lubricant and maintain the device.