Hammer design

Any device for certain jobs must be designed in such a way as to ensure high accuracy and efficiency in performing the assigned tasks. That is why there are about 15 types of hammers, each of which increases labor productivity and reduces the amount of physical effort expended. However, any device consists of several parts, which may differ externally, but perform the same task. A tool such as a hammer is no exception, and has two functional parts. Each of them must meet requirements and standards, which helps to complete tasks with minimal effort.

The most important is the firing pin. Durability depends on its shape and quality.

In addition, this part of the hammer performs the main mechanical work, that is, it is exposed to the maximum impact and wears out faster. The end opposite to the striker is called the spout. As a rule, it has functional differences in different versions of hammers, which allows you to perform specific types of tasks - pulling out nails, crushing stone, giving relief to hard surfaces. There are models in which the spout is a firing pin of the same shape or a smaller diameter. Such hammers allow you to perform operations with greater precision and force, since the impact area is reduced, but the mass of the head remains the same.

Also, the hammer head contains a part called the cheek - the surface between the spout and the striker. Its thickness must be sufficient in order to withstand the required load during operation and not break. And the iron part of the hammer must have a hole for the handle. An exception is the all-metal tool, which is poured in shape. However, it is used in quite rare cases for specific work.

The role of the handle should be noted separately, because safety depends on the quality of its fastening. Most often, in hammers with a wooden handle, a conical shape is chosen. It allows you to tightly fix the head, and an additional wedge driven into the center improves the reliability of this connection. In more modern models, the hammer device does not require this, since the parts are made according to accurate measurements and using special materials and fasteners.

The dimensions of the device and its structure are also important. Accuracy and transmitted impact force depend on the cross-sectional shape of the striker and the length of the handle. Additional functionality is provided by the shape of the back of the striker. The impact force and its effectiveness depend on what mass the head has. For example, the weight of a nail hammer typically ranges from 250 grams to a kilogram. But the weight of a sledgehammer for forging or driving piles can even reach 12 kg.

The weight of a hammer depends a lot on what tasks it is designed to perform. Many models have certain technical characteristics - a state standard that must be taken into account and implemented. For example, for a locksmith hammer, there are requirements that describe its shape with an accurate representation of the head and handle diagrams, as well as a description of the smallest parts and the weight of each part.

Therefore, if at the time of purchase on the product there is an inscription “metalwork hammer GOST 2310 77”, you can vouch for its quality.

What to look for when buying?

Of course,

in order to choose a roof hammer, you need to know everything about it

as detailed as possible. First of all, this concerns the material from which

hammer head and handle are made. The striker of a good hammer is made of

high strength chrome vanadium steel that is heat treated, and

high temperature hardening. This allows a high degree of hardness to be achieved.

material - about 50-55 units, according to the Rockwell scale. In addition, so that

prevent corrosion and oxidation processes, the surface of roof hammers

covered with a protective varnish layer.

Hammer handle

can also be made of various materials. It can be wooden

handle, or an all-metal hammer - which has a handle and a working part

form a single whole. Also, the handle can be made of fiberglass.

This is a completely new material that is 70% fiberglass. Also,

this material contains polyester resins, resulting in the handle

it turns out to be super strong, not amenable to decay or fading, does not become

fragile and so on. The main advantages of fiberglass are considered to be

high strength, which, by the way, is 9 times higher than the strength of PVC, and

2-3 times higher than the strength of aluminum. In addition, this material is not

lends itself to deformation due to thermal expansion and contraction of the glass.

Also, for

When choosing a roof hammer, you should pay attention to the weight of the tool. it

applies to absolutely all types of hammers, no matter what you

choose - carpentry or locksmith, roofing, or hammer-nail

In any

case, and the requirements for the choice are very simple - you need to proceed from the fact that

what work will you carry out with your hammer. If required

carrying out work where you need to make great efforts - it is worth paying

attention to weighty hammer models weighing from 600-900 g. If roofing

the work is insignificant, it is enough to choose a small and light hammer, weighing from

200-500 g.

• Types of hammer you should know about

In the design of the hammer, invented in the prehistoric era, little has changed over the past centuries. Instead of a piece of stone tied to a stick, now forged steel heads and ergonomic handles are used, but the essence remains the same: hit, and you will achieve your goal.

However, the variety of types of this simple tool, indispensable in everyday life, construction and in many other areas, is simply amazing. Which hammer you should use in a given situation depends on the material you are hitting and the goal you need to achieve. To clarify this point, we'll cover the different types of hammers and under what circumstances each should be used.

Clipper

The most common type of hammer, weighing between 450 and 680 grams. The claw usually has a notch that is used to pull nails out of wood.

Weighing about 400 grams, the hammer is designed to remove dents on car dashboards.

Good for driving large bolts. Weighs approximately 1.2 kilograms.

Designed specifically to shape metal jewelry. Weighs about 200 grams.

Titanium hammer

Titanium hammer with rubber grip for the most stubborn nails. Weight is approximately 1 kilogram.

Full metal hammer

Its one-piece forged steel construction can handle heavy loads. Designed for locksmith and carpentry work. Weighs from 400 to 900 grams.

Welding hammer

At first glance, the rather odd looking hammer handle fits well in the hand and dissipates heat. Weight is about 0.5 kilograms.

Round Payne

It is also sometimes called an engineering hammer. Used for shaping metal, closing rivets, rounding edges from metal fonts. The weight of the ball-payne varies from 55 to 165 grams.

Tinsmith's hammer

Designed to handle sheet metal parts for roofing and sheet metal work. Weighs approximately 0.9 kilograms.

Geologist's Hammer

On the one hand, it is an ax for breaking pieces of rock. The flat head is designed for breaking up small rocks. Bricklayers use this hammer to free the joints in the brickwork. Its weight is 1 kilogram.

The long neck hammer helps electricians drive nails into hard-to-reach places. Weighs about 0.9 kilograms.

Drywall hammer

Has a small hatchet on one end of the head and a hammer on the other. The hammer is designed to work with a dry wall, the ax is used to cut drywall and make holes in the gypsum board. Weighs about 400 grams.

Tool hammer

It has a hole in the head that holds a magnifying glass. Used for delicate work in machine shops. Weighs 200 grams.

Soft hammer

Rubber soft hammers are designed to not damage the surface to be treated, be it metal, wood or plastic. Weight is about 0.5 kilograms.

Hammer for driving buttons

Weighs 200 grams. Its bifurcated head is, in fact, a magnet designed to secure wide-headed nails or buttons.

Breaker hammer

An iron fist in a velvet glove. A sledgehammer with a rubber knob at the end. Has an internal cavity filled with shot. Beats with terrible force. Weighs 700 grams.

Hammer for driving railway crutches

Railroad spikes or nails are used to fasten the rail to the wooden sleepers. And this hammer is for driving them. Its weight is about 6 kilograms.

Serves for crushing stones. Weighs a little over 4 kilograms.

Blacksmith hammer

Ideally designed for shaping red-hot steel workpieces. It is successfully used for the destruction of masonry, concrete and stone structures. Weighs from 3 to 11 kg.

Sledgehammer

The best tool for knocking down wedges. Indispensable when carrying out construction work. Weighs from 5 kg and has a very long handle.

Bushing hammer

It looks like it is intended for beating huge chunks of meat, but is actually used for stone work. Weighs approximately 1.7 kilograms.

Half hammer, half ax - it's simple. Weighs almost 1 kilogram.

Bricklayer's hammer

Used to peel old mortar from brick or tile. Perfect for breaking bricks into equal halves. Weighs a little over a kilogram.

Like? Click:

Subtleties of use

Unfortunately, the "Soviet" labor lessons are deeply past and in a rare school boys are taught to handle construction tools. It is not surprising that many people start work incorrectly, which often leads to injuries. First, remember the following rules:

- when carrying out any work, use only a specialized hammer, for example, it is not worth buying a tool weighing 900 g for upholstering furniture, models weighing 200 g are unsuitable for making tables and chairs;

- it is strictly forbidden to use the tool if the striker is wobbling - when swinging, it can fly off and greatly harm others;

- do not use a hammer if it is cracked, deformed or chipped.

Now let's take a look at the basic rules of work.

- You need to pull the hammer correctly. When hammering in nails, increased accuracy is needed, so it is best to keep the tool as close to the firing pin as possible. If a strong blow is fundamental to you, then, on the contrary, grab it by the very end of the handle.

- If you intend to hammer in a nail, hold it between your left thumb and forefinger. The nail is grabbed closer to the cap, at the very top. If you take it by the lower part, it will begin to dangle from one side to the other and the hammer will most likely jump off - in such a situation, limb injuries are not excluded.

- If you are working with very small nails, you can hit your fingers.To prevent this from happening, use a little trick - just take a small piece of very thick cardboard and stick it on a nail - this way, you will not be holding it with your fingers, but with the help of paper. After the nail is at the base, it will not be difficult to remove the paper.

- Some hardwoods are too dense, so it makes sense to drill a narrow pilot hole beforehand. In this case, wood splitting is prevented, and the work itself goes much faster.

- In order to safely store the hammer, it is better to make a small hole at the bottom and hang the tool on a special nail, always with the striking part down. This will not only save time searching for tools, but also protect the surrounding objects from damage if the hammer falls from the shelf.

For an overview of the Brigadier locksmith hammer, see the video below.

Hammers - what are they?

The main purpose of the hammer is to hammer in nails. Did you know that with a hammer you can remove dried mortar, and it is also used for tiling. Hammers differ in weight, shape, metal.

Hammers are metalwork - these are the most common among this tool. It is considered universal - it can be used when working with metal, it can be used to hammer in nails. His firing pin is straight. In cross section, it has a round or square shape. The butt plate is similar to the Latin letter V.

The hammer, which is also called a carpentry hammer, has a bifurcation in the butt plate, it is very convenient for them to pull out nails. To do this, it must be positioned at the correct angle.

The specimen used by the bricklayer has a slightly elongated firing pin. The butt plate narrows towards the end. A bricklayer with the help of such a tool helps to make bricks of the required sizes and shapes.

The plastering hammer is equipped with 2 butt pads (flat). It is used to get rid of old plaster or to apply incisions, which will improve the adhesion of the plaster layer.

A roofer hammer looks more like a locksmith's hammer. The butt plate is shaped like a small hatchet. They usually chop the roofing material, make the necessary holes.

The most massive hammer is considered to be a sledgehammer. He has a very large head. On both sides it has the same strikers, which can be either round or square. This tool is used for dismantling work.

There are a variety of hammers with rubber and wooden heads. Rubber hammers are used for construction and renovation work. This design allows for more gentle blows to the material.

Hammer kits can include several models that can be useful to you in your home arsenal.

Hammer selection rules

The classic model has only three component parts: the handle, the head and the connecting piece. In the simplest instances, the knot is replaced with a wedge.

The most important part of the tool is the head. It is made of steel, which must be of sufficient quality so as not to deform under impact. All working parts must be pre-hardened: the firing pin - in an aqueous medium, the nail puller - in oil.

The hammer head, made of cast steel, will have a rough surface and a light gray color. If you come across such a copy, it is better to refuse this purchase. It will be covered with rust very quickly, and it will not serve for long.

Forged steel has a dark color, smooth surface. Such a tool will serve for a long time and faithfully.

The handle made of steel or fiberglass is strong enough to be water resistant. Unfortunately, it does not dampen vibrations. To reduce vibration even slightly, such handles are equipped with a rubber grip. The rubber grip hammer is quite popular due to the reduced vibration from operation. Steel models are hollow inside.

Hammer rating

Evaluation of the tool includes several parameters: durability, reliability of the connection between the head and handle, the amount of recoil, ease of grip.

But, since the purpose of hammers is different, they have to be evaluated taking into account the category.

The best carpentry option is the Matrix 10340 weighing 600 g.

Forged head, firmly attached.

Fiberglass handle, rubber coated.

The tool is comfortable, does not slip out of hands, transfers effort well.

Topex 02A305 is considered the most popular carpentry mallet.

Product weight 450 g, steel handle, rubber coated.

The striking part is made of rubber.

Among the mason's hammers, consumers single out the Bison Master 2015-05_z01.

The weight of the product is 500 g, the head is made of 55 grade steel, the handle is made of ash.

The head is hardened and has a high impact resistance.

Stanley FatMax AVX AntiVibe Rip Claw 1-51-212 - carpentry hammer-nailer.

The head and handle are a single forged design, perfectly balanced and comfortable.

A magnet is installed in the striker, so you can hammer the fasteners with one hand.

The product is very durable but expensive.

A hammer is a popular tool in everyday life or at a construction site.

There are dozens of types of percussion tools, so that the master can choose a model for carpentry, carpentry, and finishing.

Bench hammer: scope and parameters

It is used for:

- felling;

- drilling holes;

- edits;

- riveting.

What is it made of? From butt, wood or plastic handle.

MS properties According to GOST (h3)

GOST applies to everything that a person encounters and a locksmith's hammer is no exception. This type is made thanks to GOST 2310-77 and applies to hammers weighing from 0.05 to 1000 g.

| The weight | name, scope of use |

|---|---|

|

From 300 to 500 gr |

For home use |

|

2 Kg |

The most difficult, for locksmith work |

|

50, 100, 150 gr, 200 and 300 gr |

In order to carry out instrumental work |

|

400 gr, 500 and 600 gr |

For locksmith work |

|

800 g |

For locksmith work, where a large impact force is needed |

|

1 kg |

For repair work |

Locksmith hammer for those. must not have cracks, burrs and work hardening. The steel firing pin should be slightly convex and as smooth as possible. In the manufacture of a handle, which must not be in length

Moreover, the fibers of the tree must have an appointment along the length of the handle, otherwise it will simply break. The vibration damping properties of the handle on impact are provided by a special system. Butts are mainly made of carbon steel grades U7 and U8.

| Model | Description |

|---|---|

|

400gr kwb 4509-14 |

Weight, kg: 0.52. Dimensions, mm: 310 x 110 x 25. |

|

STAYER PROFI 20050-04 |

Weight, kg: 0.50. Dimensions, mm: 450 x 120 x 50. |

|

Stanley FatMax AVX AntiVibe |

It can be of various sizes. Made of solid carbon steel with nailer functions. |

The main thing! OKOF (All-Russian Classifier of Fixed Assets OK 013-94) is a regulatory document in which a locksmith under the OKPD2 code is provided.

Bench hammer, definition

A hammer is an impact tool that is designed to hammer in or, conversely, break some objects (in the first case, these are, as a rule, nails, in the second, for example, dirty, tightly separable joints). It is also used for the production of some percussion work (when manipulating a chisel or a screwdriver with a thrust bearing). Its weight, dimensions and design features are determined by GOST 2310-77 "Steel bench hammers". He also clarifies the concept of "locksmith" - created for the needs of the national economy and export.

Design

A steel bench hammer has a weight of 50 grams to 1 kilogram. The design of the tool: a head (for striking a work surface), a wedge that holds the first element, preventing it from flying "in flight" at the next blow, and a handle that serves to increase the swing, and at the same time makes the whole object more convenient for the worker ...

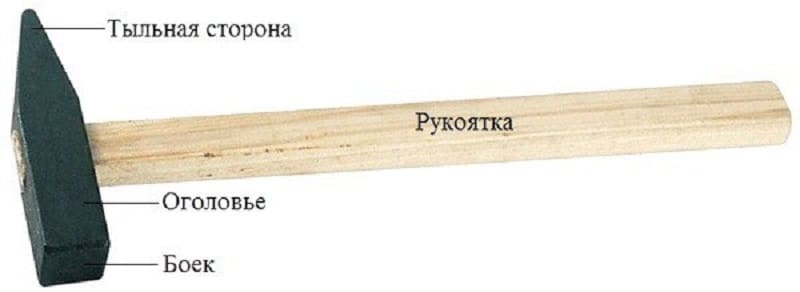

The working part of the locksmith's hammer - the head, also has features. Its two ends: the toe and the firing pin, differ in shape, which allows them to be manipulated in different ways.

The striker can be round or square. The toe is usually thinner, may be triangular or cylindrical, or rounded at the end.

In the photo: 1 - head, 1а - firing pin, 1b - toe, 2 - handle.

In the photo: 1 - head, 1а - firing pin, 1b - toe, 2 - handle.

According to GOST, a bench hammer must have a head made of steel grades 50 or U7.Other brands that are not inferior in properties to the named ones are also allowed. A prerequisite is the presence of a coating, protective or protective and decorative. Being steel, the tool head is usually galvanized. The coating can be oxide, phosphate, followed by oiling or painting in enamel or varnish.

According to GOST, a steel metalwork hammer can have one of three types of handles. The most common of them is an oval, rectangular handle. Others - its modifications, oval with a narrowing or double narrowing for more convenience. GOST also allows other ergonomic forms. The width of the handles, depending on the size of the heads to be fitted, ranges from 18 to 41 mm. Length - from 200 to 400 mm. Locksmith hammers for household use are often handle length from 250 to 350 mm and corresponding head weighing from 100 to 400 grams.

Hammer handles should be smooth, free from burrs, and resilient and heavy enough to reduce stress on the hand when working. Hardwood has suitable properties. The most commonly used are birch, oak, maple, rowan, ash, hornbeam and dogwood. Modern materials - high-strength plastic and rubber spraying. Another GOST requirement is the absence of any cracks on the tool handle outside of its articulation with the head (in the place of wedging).

Locksmith hammer, marking

Everything a potential owner needs to know about the hammer must be printed on the tool head. This is the recommendation of the state standard. The list of data should include the manufacturer's trademark and the nominal weight of the product.

Previously, a mandatory indication of the price was required, but now this data is optional, as is the ability to apply the manufacturer's emblem to the hammer elements.

Why an ordinary hammer is not suitable for beating slag

A conventional hammer is not suitable for removing the slag crust, since it is not effective enough to perform the procedure. An ordinary instrument weighs more than a special one, thereby greatly overloading the performer's hand.

A conventional hammer is not suitable for removing the slag crust, since it is not effective enough to perform the procedure. An ordinary instrument weighs more than a special one, thereby greatly overloading the performer's hand.

The unique design of the welder's chisel allows you not to feel the kickback, such an advantage a conventional hammer does not have

And perhaps most importantly, a conventional tool does not have pointed ends and therefore may not “reach” some of the joints. Therefore, for the convenience of the welder and to improve the quality of the slag breaking process, a special hammer should be used.

A bit of theory

When hammering in a nail, we do not think about the most complex physical transformations in the hammer / nail / solid system. The coefficient of efficiency (the ratio of the useful work and the energy expended to drive the hammer) is 70 - 97%. For most modern machines and mechanisms, this is an unattainable limit.

The main part of the energy loss goes to the kickback of the hammer, due to the emergence of elastic forces. The amount of recoil depends on the material of the hammer head and the properties of the material. For a steel tool, energy losses are about 30%, for titanium - in the range of 3 - 5%. But these indicators also depend on other parameters:

- the type and shape of the striking part;

- material and length of the handle;

- tool mass;

- contact angle;

- matching the type of hammer to the operation being performed.

The last item on the list is very important - in mechanical engineering, stone processing, construction, various types of hammers of different levels of versatility are used. Among them, you can choose a tool for all occasions, for domestic and semi-professional use, and highly specialized, "sharpened" for performing one or two operations, but with the highest efficiency.

The two main parts that make up the hammer - the handle and the head - are firmly connected to each other.When moving on a massive head, sufficiently large forces act - when sliding off the handle during an impact, the kinetic energy of the head allows it to fly several tens of meters. If at the junction there is the slightest wobble or cracks appear on the handle, the hammer must never be used. It becomes dangerous for the worker and those around him.

The head consists of several parts:

1. Sock; 2. Hole for the handle (vzad);

3. Wedge; 4. Nail puller;

5. Striker; 6. Cheek; 7. Lever.

The striker, the head striking part, is usually flat, has sufficient area and strength to withstand a significant amount of shock contacts with solid objects without deformation. The impact surface is flat or slightly convex. In cross-section, it is a square, rectangle or circle.

The back of the hammer is generally wedge-shaped. This allows you to develop a significantly greater impact force, by reducing the contact area. Wedge strikes are used when it is necessary to split the material or emboss. The back part can be spherical, depending on the scope of the hammer and its main purpose.

The seat is made in the form of an oval or round through hole, the walls of which slightly expand from the center to the upper part, to prevent possible slipping from the handle. On some types of hammers, a forging is provided around the bore hole in the form of a metal collar, which goes over the top of the handle by a few centimeters. This part of the tool protects the handle from kinking when hitting too hard or inaccurately.

The head is made of hard metal by forging, casting or milling. It is protected from corrosive effects by special types of paint or galvanic coating. Before applying the protective layer, the head is hardened, in most cases selectively. The impact part (firing pin) reaches the highest hardness (up to 52 units on the Rockwell scale). Hardening is carried out by the electric induction method, which makes it possible to accurately control the depth of surface hardening. On the striker, the hardening depth reaches 3 - 5 mm.

The back part (wedge or nose) is hardened up to 36 - 42, and the area of the bore hole - up to 24 - 30 units on the same scale. The shape, weight, dimensions and other characteristics of industrial hammers are determined by GOST 11042-90 and 2310-77, which describe almost all types of hammers and their purpose.

Many manufacturers produce percussion tools according to their own specifications, which take into account most of the requirements given in national standards. The changes concern the use of new alloys, the length and shape of the handles with improved ergonomics, computer-modeled, more accurate surface treatment.

Sledgehammer: types and technical specifics

The sledgehammer is used in construction, in blacksmithing, tire fitting, foundry. Consists of a striker head (made of steel) and a sledgehammer handle.

For example, a Russian sledgehammer stands out from the hammer by the mass of the striker and the length of the handle. This tool, its types and requirements are regulated by GOST 11402-75.

| Model | Description |

|---|---|

|

Blunt-nosed |

2 to 16 kg |

|

Pointed transverse |

3 to eight kilograms |

|

Pointed longitudinal |

3 to eight kilograms |

The sledgehammer (construction and locksmith) has different weights and different uses

|

20 Kg |

Tactical infantry anti-tank sledgehammer |

|

16 Kg |

Heavy blacksmith work, where a large impact force is needed |

|

15 Kg |

Difficult work, where not a small impact force is needed |

|

12 Kg |

As a percussion tool that deforms the workpiece on the anvil during hand forging and other works that involve striking, different in strength and purpose |

|

10 Kg |

For blacksmith work, when installing and dismantling various structures, where strong and powerful blows are needed |

|

8 Kg |

For repair, dismantling work |

|

5 Kg |

When demolishing walls, straightening metal sheets (deformation or straightening), driving large stakes into the ground and other work |

|

4 Kg |

For knocking out fasteners stuck due to various reasons, breaking bricks |

|

3 Kg |

In blacksmithing |

|

2 Kg |

V blacksmithing, dismantling and installation of various structures |

|

1 kg |

In blacksmithing, dismantling and assembly of various structures |

More details on the site - do-it-yourself repair and construction site.

The weight of a blunt sledgehammer is from 2 to 16 kg. There are:

- with wood handle;

- forged;

- copper;

- copper-plated;

- rubber.

An overview of sledgehammers and hammers:

Sledgehammer handle

Since a sledgehammer is a traumatic tool, its quality is treated with very high attention, especially since it concerns the handle for the sledgehammer and fastening. A good sledgehammer handle should be

durable hardwood

Very often, you can find birch sledgehammer handles on sale. The handle for the sledgehammer must be strong, first of all, to bear heavy shock loads, to reduce the recoil when working with the tool.

Sledgehammer handles - various lengths. With a long handle, more impact force. Sledgehammers with a fiberglass handle are very popular and are used onshore in engineering seismic operations as a source of elastic vibrations, since they are better than substitutes made of wood.

| Brand | Manufacturer country | Specifics, scope of use |

|---|---|---|

| Bison | Russian Federation | For work with high impact force; forged head made of tool steel and induction hardened |

| Matrix | Germany | For work with high impact force; with good grip and fiberglass handle; long service life |

| Wilton | United States, China, Poland | For work with high impact force; flat striker, anti-vibration nozzle; a protection plate that prevents the handle from moving; development of Unbreakable (it is usually impossible to break it) |

| Stayer | Germany | To carry out work with a large by the force of the blow; durable forged steel head with hardened surface; not proven to deform when hitting hard surfaces; the handle to the cue ball is widened, which removes the risk of the working part flying out |

| Truper | Mexico | To carry out work with a large by the force of the blow; excellent absorption of recoil; steel head with special finishing; many models are equipped with fiberglass handles |

What does it consist of?

The construction of this production tool is quite simple. The main components are a handle and an impact attachment (head), which is made of steel. As a rule, from different sides it is not the same in shape. One side along the edges is flat, called a striker, the other has a sharpness (wedge) or the so-called "dovetail" used to pull out nails. The hammer usually hammers, and the wedge-shaped side splits, the "tail" is used as a nailer.

Some add an attachment point to the design. It is a small element that provides a secure and solid connection between the handle and the head. In the most ordinary version, it is a special metal wedge (of various shapes), which is hammered in such a way that the handle expands as much as possible. The wedge-shaped part of the striker transmits the force to a minimum area, which provides more effective breaking or is used in some variants in the embossing process. The hardened steel striker must be very “tough” and withstand a lot of intense impacts. In cross-sectional shape, it is round, square and rectangular.

The head is protected from corrosion with a special paint, if it is made of copper, titanium or wood, the coating is not applied. The handle is made of hard wood, plastic or metal, with a special rubber coating that prevents slipping in the hand and is resistant to moisture. The length of the handle depends on the weight of the product.On average, it does not exceed 32 centimeters, for heavy hammers - 45 cm. The shape of the end in the form of a cone is designed to prevent the separation of parts at the junction.

Wood for the manufacture of the handle is used in the classic case. In this option, wooden parts made of hard or flexible species are recommended, without knots, pine, spruce or alder are definitely not suitable here. The surface must be dry and free from external defects. The use of a wooden handle automatically implies the need for a wedge, which will prevent the bit from jumping off. The fibers of the part on which the striker is mounted should run along, and not across, as this significantly reduces the risk of injury in the event of a breakdown. In addition to wood, metals coated with rubber materials or various plastics are also used here.

Forms

The main working elements of the slag bumper are the handle and the double-sided head (another name is the firing pin). The head can have different shapes. Manufacturers offer several combinations of these configurations. Consider the most popular combinations, as well as what kind of work the welder can perform with each type.

The main working elements of the slag bumper are the handle and the double-sided head (another name is the firing pin). The head can have different shapes. Manufacturers offer several combinations of these configurations. Consider the most popular combinations, as well as what kind of work the welder can perform with each type.

Pike and chisel

Hammers with a chisel on one side of the head and a lance on the other are quite in demand among welders. The chisel conveniently and effectively removes slag and discards metal spatter; can be used for forging connections. A pike (sting) helps to get rid of points with poorly welded places, and will also be an excellent option for beating thin seams. Manufacturers offer models where the chisel is located along (parallel) to the handle and across (perpendicular) to it.

Bars SV000006758

Bars SV000006758

- The Bars hammer is used to control the quality of the joint during welding with coated electrodes; designed for slag and metal spatter beating.

- On the one hand, the hammer head has the shape of a chisel, located parallel to the handle, on the other, a sharp sting.

- Spring-loaded design cushions recoil during impacts.

- The weight of the Bars hammer is 440 g.

Stanley

- Country of origin - USA.

- The tool is designed for descaling.

- The head is made of hardened tool steel, black lacquered; On the one hand, it has the shape of a chisel located across the handle, on the other - a wedge.

- Curved wooden handle.

- Weight - 300 gr.

- Length - 240 mm.

Chisel and Chisel

Welders are provided with hammer models where the head is shaped like a standard chisel on both sides. On the one hand, the chisel is located parallel to the handle, on the other - perpendicularly. This type of tool effectively removes slag and splashes. The performer can choose the location of the chisel that will be convenient for him.

NORGAU

NORGAU

- The forged firing pin is made of special steel.

- The ergonomic handle is made of hickory wood with a high level of break resistance.

- Weight - 454 gr.

- Length - 328 mm.

Z-shaped lance - why

Some manufacturers offer hammers in which the pointed part of the head is bent into a shape that resembles the letter Z. With this bent tip, the welder can clean the surface of the weld seam away from him. This technique allows you to increase the level of safety of the work carried out.

ESAB SH2

- The hammer is made of high quality steel.

- Comfortable handle.

Chisel and flat head

A convenient option for a hammer is a tool with a chisel and a flat head. The chisel removes dirt, and with the flat head you can crush, bend and flatten metal where necessary. There are no such models on sale. Therefore, we recommend that you familiarize yourself with the video below and make such a hammer yourself.