How to choose a concrete mixer?

When choosing a concrete mixer, you need to be guided by several principles that will help you choose a high-quality concrete mixer for your household needs.

The capacity of a concrete mixer drum depends on the amount of concrete mixture with which this technique will have to work. However, the size of the drum cannot directly correspond to this number. As a rule, the design assumes that the volume should be 10-15% more than the volume of the mixture. For small construction work, a concrete mixer with a volume of 100-150 liters is enough.

Power is almost impossible to determine without access to technical information. Therefore, buyers are guided by devices with maximum power. However, this is the wrong choice, since you will have to pay for power with a large energy consumption, besides, extremely powerful concrete mixers are much more expensive than more rational models. Thus, a 700 W engine is enough to work with equipment with a capacity of 130 liters.

All concrete mixers are divided into two groups:

- periodic operation;

- continuous action.

Concrete mixers of the first group are used for the construction of small objects, and, as a rule, need to be switched off periodically. If it works all the time, then it will quickly become unusable. Thus, mixers are perfect for country and cottage construction. Continuous machines are difficult to operate and more expensive, but they can operate continuously for a long time. These units are used on large construction sites.

There are two types of mixing technology:

- models with forced mixing;

- gravity concrete mixers.

Models of the first type work on the basis of continuously rotating blades, which makes it possible to obtain concrete of a liquid consistency; gravity concrete mixers are used in cases where it is necessary to achieve a mixture with a solid content. If you need to buy a concrete mixer for work in the country, then a concrete mixer with forced mixing is better suited here.

The manufacturing company is also of great importance. The best plants are produced in Germany, France and Italy, but their price is extremely high. Therefore, they choose mixers from lesser-known companies - Limex, Altrad, Guy Nuel.

How to choose the right concrete mixer

Recommendations for the right choice:

Seasonality. Many unit models are designed to function during warmer months.

Dimensions. If you need mobile units, you need to buy compact models that can be disassembled and quickly packaged for transportation.

Concrete mixer class. When choosing, they are guided by tasks and needs. For mixing concrete mortar up to 8-9 m³ per day, you need to buy home modifications. Professional grade concrete mixers are used for regular and continuous mixing of large quantities of concrete. Gravity models are capable of handling simple tasks.

Motor power level. This indicator affects the duration of the concrete mixer. For large volumes of construction work, where continuous mixing of the concrete mixture is required, it is necessary to choose units with an engine power of 1000 W or more. Concrete mixers with a 700 W motor cope with household tasks

When choosing a unit, it is important to consider the motor mount. It should be made of durable metal to minimize rapid wear.

Voltage indicator

For the construction and repair of private houses, 220 V motors are excellent.Professional models operate on 380 V.

Drum capacity. For household construction, it is enough to buy models of 100-300 liters. When choosing parameters, the intensity of work must be taken into account.

An additional function is a bowl overload sensor. If the temperature in the winding rises to a critical value, the motor turns off automatically. This sensor allows you to preserve the performance of the internal mechanisms, to extend the life of the concrete mixer.

Simplification of working with concrete. The masters will not have any difficulties with management and work.

The concrete mixers are available in different colors. The SNIP stipulates the requirements that units of this type should be painted in bright shades, from which the eyes do not get tired. Another factor is budget. The price of the best gravity-type concrete mixers with a bowl capacity of 150 liters is 8-15 thousand rubles.

High-performance units cost from 17 thousand rubles. Increasingly, homeowners are buying forced-type structures. Their price starts from 52 thousand rubles. Many buyers are interested in the question of manufacturers.

Models from German, Polish, Czech manufacturers differ in high quality. They are functional and comfortable to use.

Varieties of concrete mixers.

Chinese units have an affordable price. Domestic models are of higher quality, but in the event of a breakdown, it is difficult to find spare parts and components. They are not inferior to European counterparts. It is profitable to buy a concrete mixer in specialized stores, where a guarantee is provided. They work directly with trusted and trusted manufacturers. The buyer will be entitled to service and repair in the event of a breakdown.

RedVerg RD

One of the advantages of this design is the large opening for filling the solution. This concrete mixer has a low weight (only 95 kg), and provides the possibility of free transportation of the product.

The volume of the equipment is 260 liters, however, full functioning without overloading means filling up to 150 liters of the mixture being produced.

The engine is powerful enough - 1.3 kW. The remarkable design has a significant drawback: the drum crown is not protected in all places, but only in the place of engagement with the main gear. This means that the mechanism can be damaged by a pebble that accidentally fell into the “weak zone”.

Rating of the best concrete mixers according to user reviews

Next, we present to your attention the rating of concrete mixers in terms of reliability, based on user reviews.

| Zitrek B1510 FK 024-1002 | Lebedyan SBR-132A.5 95446 | Limex 165 LS 024-1008 | Zitrek B 1308 FK 024-1000 | Lebedyan SBR-132N / 220 | |

| type of drive | Crown | Crown | Crown | Crown | Reducer |

| Crown material | Cast iron | Cast iron | Cast iron | Cast iron | — |

| Power, W | 1000 | 700 | 700 | 800 | 550 |

| Drum volume, l | 155 | 132 | 165 | 130 | 132 |

| The volume of the finished solution, l | 110 | 64 | 110 | 80 | 64 |

| Weight, kg | 56 | 55 | 65 | 52 | 47 |

| Dimensions, mm | 1240x790x1350 | 1140x740x1290 | 1220 x 790 x 1355 | 1240x790x1250 | 1090х700х1410 |

Concrete mixer Zitrek B1510 FK 024-1002

+ Pros of Zitrek B1510 FK 024-1002

- Fast, even mixing;

- Powerful model;

- Really designed for making a heavy mix;

- Easy transportation after purchase.

- Cons Zitrek B1510 FK 024-1002

- When assembling, problems arise with the size of the bolt holes, many buyers expand them on their own;

- Noises during work;

- Requires mandatory cleaning after use.

Concrete mixer Lebedyan SBR-132A.5 95446

+ Pros of Lebedyan SBR-132А.5 95446

- Durable body and drum;

- Reliable blades;

- Withstands overload (customers loaded the drum instead of the recommended weight of 64 liters to 100 liters).

- Cons Lebedyan SBR-132A.5 95446

- Unprotected drive shaft bearing (during operation it is contaminated with a solution, requires mandatory cleaning);

- During operation, the engine casing heats up, the fans do not have time to cool it;

- During operation, the starter breaks down (the part is easily repaired, you can buy it for replacement).

Concrete mixer Limex 165 LS 024-1008

+ Pluses LIMEX 165 LS 024-1008

- Large drum volume;

- It is convenient to remove the resulting solution in the required amount thanks to the clamps;

- It is convenient to move around the site due to the wheels and a special handle.

- Cons LIMEX 165 LS 024-1008

- Does not withstand overload, if instead of the specified rate the device is overloaded, then the bearing breaks;

- The engine casing is heated;

- For some buyers, the starter button is out of order.

Concrete mixer Zitrek B 1308 FK 024-1000

+ Pros of ZITREK B 1308 FK 024-1000

- The construction is really solid;

- Easy to transport and assemble;

- Doesn't make much noise.

- Cons ZITREK B 1308 FK 024-1000

- Those who assembled the model on their own for the first time had difficulties in assembly.

Concrete mixer Lebedyan SBR-132N / 220

+ Pros Lebedyan SBR-132N / 220

- Virtually silent model;

- Mixes a good quality solution quickly;

- No exposed parts such as gear, crown or belt drive;

- The drum turns around itself, due to which it is possible to unload the mixture, unfold and load components without moving the concrete mixer (this feature is appreciated by those who are forced to work in tight spaces);

- Easy assembly

- Cons Lebedyan SBR-132N / 220

- There is no lock for different degrees of drum inclination;

- The engine cover heats up.

The principle of operation and the device of a concrete mixer

The concrete mixer is designed for the preparation of cement mortar in the conditions of a construction site. It would seem at first glance that it is easier to buy ready-made concrete, but there are also some "buts" here. Firstly, having calculated the difference in the cost of the finished concrete solution and its constituent components, you will understand that with a large amount of work, the new concrete mixer will pay off very soon. Secondly, preparing the solution on your own allows you to adjust its amount in accordance with changes in current plans.

It should be borne in mind that the concrete solution must be mixed all the time, otherwise it will quickly set. If you did not manage to correctly estimate the amount of work that your team of workers will be able to perform in the very near future, or for some reason your plans were violated, it turns out that the money spent on the purchase of concrete will be wasted (moreover, you you still have to pay for its disposal).

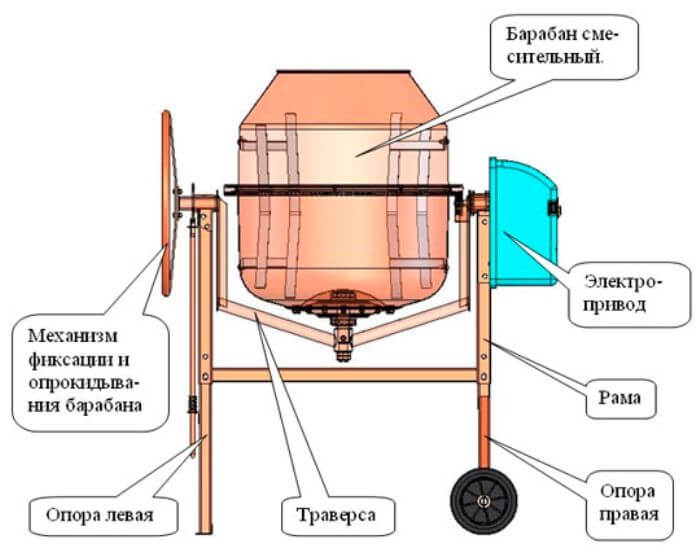

There are many types of concrete mixers, but they all have three main structural elements:

A working container called a "drum" or "pear". In it itself, during rotation, the components that make up the concrete solution mix. To improve the quality of concrete mixing, there are blades inside the tank, which, depending on the type of concrete mixer, can either be fixed rigidly on the walls of the rotating drum, or, having their own drive, rotate inside the stationary tank. The volume of the "pear" can vary from several tens to several hundred liters.

The power unit, consisting of an engine and a transmission, converts energy into a rotary motion necessary to stir the contents of the working container.

Frame - a structure made of metal pipes and / or profiles that holds the working vessel and power unit. If this frame is equipped with wheels, then the concrete mixer becomes mobile.

1. The top of the pear. 2. Blades. 3. The lower part of the pear. 4. Toothed rim. 5. Corkscrew ring 6. Bearing snap ring 7. Bearing.

8. Bearing corkscrew. 9. Bearing. 10. Cradle. 11. Anther. 12. Frame. 13. Check disk. 14. Spring.

15. Circle. 16. Footrest. 17. Wheel stand. 18. Wheels. 19. Wheel plug 20. Engine 21. Corkscrew. 22. Gear.

Criterias of choice

Although the construction of concrete mixers is quite simple, if it breaks down at the most crucial moment, then the whole construction will stop. It will also be unpleasant if it does not function effectively enough.For high-quality work, in order to understand which concrete mixer is better, even when choosing it, you need to evaluate some additional parameters.

Forced or combined gravity

It all depends on the price that the buyer is willing to pay, and the solution with which you have to work. Forced concrete mixers mix faster, but they consume more electricity and do not cope well with large fractions of impurities (at least household appliances).

The design of gravitational ones is simpler, so they are highly reliable and unpretentious. The unloading of the solution from the forced concrete mixers is most often done through the hatch in the bottom of the mixer, and the gravity bucket simply tilts and the finished mixture is poured out.

As a result, the best choice of a good concrete mixer for the home is a combined gravity mixer.

Mortar drum capacity

This indicator determines how much of a solution a concrete mixer can prepare in one cycle. It should be borne in mind that it is not recommended to fill the tub by more than 30-40% - otherwise the solution may spill out or mix poorly. For home use, in most cases, a device with a capacity of 100-150 liters is sufficient. The maximum for household mixers is 350 liters, and 50-60 is enough for periodic work.

Electric motor power

How to choose a concrete mixer if a larger mixer volume requires less engine power? This is one of the controversial indicators and it depends more on the personal preferences of the owner of the concrete mixer

Things to Consider:

Electricity consumption. On the one hand, the more powerful the engine, the greater the consumption of electricity.

In practice, few people during construction pay attention to the overrun of a dozen or two, even hundreds or two kilowatts.

Starting the concrete mixer after an unscheduled shutdown, for example, if the power goes out or the cable is pulled out of the socket. Yes, a weaker engine may not pull a full drum, but usually it is enough to simply turn it a little by hand to get the engine up and running.

Reviews of the owners of concrete mixers say that an engine of 0.7-1 kilowatts is quite enough for the confident operation of a device with a drum up to 130 liters. It's another matter if a forced-type concrete mixer - with it such "help" is a very traumatic occupation.

Overheating of the engine. All manufacturers of household appliances recommend not to overload the concrete mixer and periodically give it a “rest”. In practice, this recommendation is rarely heeded - often the concrete mixer simply does not turn off (at least the gravity mixer), and components are loaded and unloaded on the fly.

As a result, the main criterion is possible overheating, therefore it is better not to take into account engines of too small powers.

The golden mean is 0.75-1 kilowatts and it is advisable to pay attention to the ventilation of the motor

"Seasonality" of use

The first question is relevant only if the work is planned at subzero temperatures. By default, any concrete mixer will operate flawlessly in the temperature range from +5 to +40 ° C. If you plan to operate it at subzero temperatures, then you need to look closely at the winter options for the device.

If you need to start a "summer" concrete mixer in winter, you must remember about the possibility of condensation in the engine, which will lead to a short circuit. It is advisable to carefully warm it up before starting it with a blowtorch or heat gun, start it and then do not turn it off.

Number of motor phases

The number of phases has one dependence - a single-phase device can be powered from a three-phase network, but the opposite will not work. Three-phase motors are installed on industrial equipment - they are rarely found in household devices.

It is also worth considering whether a concrete mixer will work in one place, or it will be transported from object to object - if there are three phases “here and now”, it’s not a fact that they will be “there and then”.

Clearly about the selection of the design in the video:

What to look for when choosing?

We examined all sorts of characteristics and types of concrete mixers, as well as what you need to pay attention to when buying a product.

When buying a unit, you need to find out from the seller of the goods what guarantees for the concrete mixer the company gives, ask him what to do in the event of a breakdown.

You also need to decide on the choice of the country of the manufacturer of the concrete mixer.

The choice, as they say, is up to the buyer. If you need a concrete mixer for some specific time, then it is best to rent it, this can save you significant money, given the not cheap cost of mixers today.

Requirements for concrete mixers

When choosing a concrete mixer for preparing a concrete mixture with your own hands, first of all, a list of requirements for the technique is drawn up.

The units offered by different manufacturers differ:

- Characteristics;

- Technical parameters;

- Design features.

Factors to consider when choosing

There are several factors to consider when choosing a concrete mixer.

These include:

The principle of operation of the unit:

- Gravitational. Such a device is used for mixing heavy compounds, due to the force of gravity of its components. It is ideal for mixing mixtures with coarse gravel. The equipment has a fairly large capacity.

- Forced. In this case, a high-power engine drives the blades fixed on the axis, with a stationary capacity. This type of equipment is not recommended for use in private construction.

Device type:

- Coronary. These are concrete mixers of relatively small dimensions, in which a gear wheel encircles a drum.

- Gearbox. They are also suitable for household work, but the price of the units is much higher than the previous ones, however, their service life is longer, and the products break less often.

- Basic technical characteristics. The equipment differs in the volume of the concrete mixing tank and the engine power;

- Rating of concrete mixers. Manufacturers that produce better and more convenient units have more positive feedback from consumers, which increases their rating.

These indicators determine the characteristics of a concrete mixer, help to choose the right structure for work in the country or in a private house.

Mechanism selection criteria

What is the best concrete mixer? The rating of a model depends on its technical characteristics.

To choose the right device you need:

Decide on the size of the drum to do a specific job. If small buildings are being built, it is worth choosing small household concrete mixers with a volume of approximately 45 - 150 liters;

Clarify the operating mode of the unit

This can be constant or periodic mixing of the solution;

Pay attention to the material used for the manufacture of model elements. The rating of a concrete mixer with a steel drum is much higher, due to the high strength of the material;

In this case, the wall of the container must be at least 2 mm thick, so that during operation the solution does not damage its integrity;

Plan the right time of year for construction. Majority models are designed to work summer

But in any case, the engine of the unit must be protected from the effects of precipitation;

Many manufacturers make special concrete mixers for use in winter as well. But still, it is not recommended to pour the mortar at sub-zero temperatures - this will worsen the quality of concrete.

As with any device, a concrete mixer can break down after prolonged use.

In the absence of an opportunity to purchase an expensive model, you need to adhere to the following recommendations:

Pay attention to the maintainability of the equipment;

Choose a model with the placement of bearing assemblies outside the tank;

Check for parts that might break in markets or nearby outlets.

When choosing any brand, it should be borne in mind that a concrete mixer, whose rating is not too high, may not be reliable and durable enough.

Concrete mixer volume

The volume of the drum for mixing the components is the main factor when choosing a model. In this case, it is not necessary to measure the unit with a tape measure, determining its dimensions. All units are accompanied by the manufacturer's instructions, which indicate the dimensions and other characteristics of the equipment, including the volume of the tank, for mixing the solution.

So, if the passport indicates that the capacity reaches up to 100 liters, in practice, in one run with this unit, you can get about 65 liters of the finished solution. Tip: Do not fill the drum with a larger mass of raw materials. This will significantly reduce the quality of the solution, and the machine itself will fail in a short time.

Homemade large volume concrete mixer

Homemade large volume concrete mixer

What to choose: imported or domestic?

Units from different manufacturers

Units from different manufacturers

It should be noted that the modern market offers a wide range of concrete mixers from various manufacturers. As experts advise, it is better to give your preference to imported ones, for example, made in Italy, Poland, Germany, France. Despite the fact that foreign models will cost more, their service life will be much longer in comparison with domestic ones. Moreover, imported concrete mixers are supplied in a complete set, which includes wheels, which is a big plus. So, let's consider the most famous imported brands of concrete mixers.

Concrete mixer drive

Which concrete mixer to choose also implies the selection of the type of its drive. As a rule, this is an electric motor, but there are other options.

Handmade homemade product

Handmade homemade product

Let's describe them:

- Manual drive. There are no industrially manufactured samples, but hand-made ones are not such a rare case. One can argue about the effectiveness, but it still seems to me more convenient than shoveling the solution, and the mixture turns out to be more homogeneous.

- The second option is the drive from the power take-off shaft of the machine. An excellent solution to the problem is a concrete mixer for the house, which one to choose if you have a tractor or walk-behind tractor. The problem with the routing of the power cables and their protection from accidental damage disappears.

PTO driven design: how to choose a concrete mixing plant

PTO driven design: how to choose a concrete mixing plant

Drive from its own internal combustion engine. There are also such models. They are several times more expensive and have decent dimensions and weight.

The photo below shows just such a model. They are mainly used not by private owners, but by construction organizations.

The choice of a concrete mixer for a summer residence should not be stopped on this option, since if there really are problems with the power supply, then it is easier to purchase a separate generator with an internal combustion engine, from which you can also power another power tool, a welding transformer, and also use it as a backup power source for the house ...

Diesel concrete mixer

Diesel concrete mixer

For domestic use, concrete mixers are usually chosen with a single-phase motor or (more often) with a three-phase connected to a single-phase network. This is not entirely correct, the efficiency of the unit is significantly reduced and, consequently, the cost of electricity.

Thinking how to choose the right concrete mixer, if possible, and this is not difficult, conduct a full-fledged power network to your site and choose three-phase models. By the way, this also applies to any other equipment of a home master.

By design, the drives are divided into gear and girth gear.Consider the question of how to choose a concrete mixer, given these structural differences.

Gear drive

Even the slowest electric motor does not provide a low speed, which is necessary for high-quality mixing of concrete. Therefore, the drum shaft is not connected to the engine directly, but through a reduction gear, less often through a belt drive.

This method of transmitting torque is considered by many to be the best, since the gears are hidden from contamination by the housing and are reliably lubricated. Advising how to choose a concrete mixing plant, we note that the gear drive also has disadvantages, which many are silent about. The axis around which the drum tilts is already above the center of gravity.

In addition, in the case of unloading the mixture from a concrete mixer with a gear drive, the lever has to lift the mass of ready concrete, and the weight of the motor with a gearbox, located at a great distance from the axis, is also added to it. For concrete mixers of a small volume, this is not a problem yet, but if the volume is larger than a cube, then you need to provide either a large-diameter steering wheel, or an additional gearbox, or an autonomous drive in general.

In addition, this design increases the height of the throat, therefore, complicates the loading of the mixture components.

Another disadvantage of the gearbox is that if it breaks down, then its repair is relatively difficult and expensive, and it is difficult to find spare parts for some manufacturers' units. When deciding how to choose a concrete mixer for your home, consider this feature as well.

Gear drive

Gear drive

Girth drive

In this case, the gear on the shaft moves through an intermediate belt drive, or the gearbox interacts with the crown on the outer surface of the drum, which is located in the same plane as the axis of its turn for loading and unloading.

Girth drive

Girth drive

This design is simpler. It does not increase the mass of the drum, since the drive attached to the frame stirrers. The mixer height may be slightly higher than the drum height.

The disadvantages in all the tips - "how to choose a concrete mixer?" include the fact that the gear and the crown are not protected from contamination. They can quickly fail from interaction with abrasive particles of aggregates, cement and hardened concrete. This happens especially often if these parts are made not of steel, cast iron or, in extreme cases, of fluoroplastic, but of cheap polymers.

But if there are no problems with spare parts, then the repair is not difficult. With careful work, the problem of contamination is not so acute. The disadvantages of the girth drive include increased noise, if the crown and gear are metal. This is a disadvantage if the work is carried out in a residential apartment building.