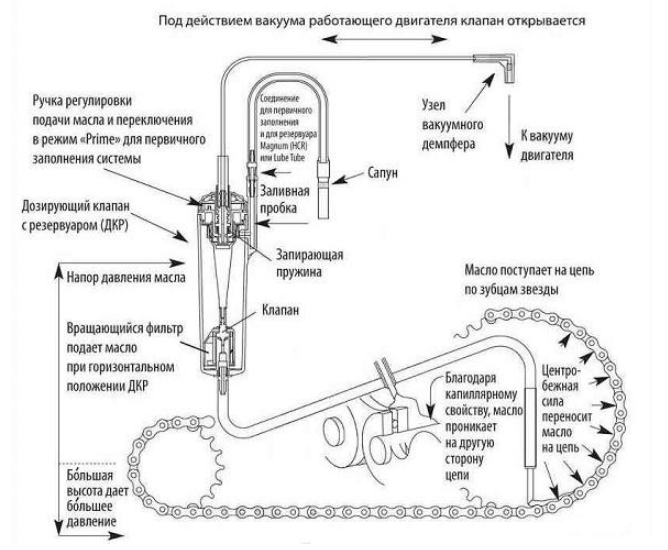

Lubrication system device

Depending on the brand of the chainsaw, the details of the lubrication system may differ slightly in design, but their total number and connection diagram remain unchanged.

The main components of the lubrication system are:

- the oil tank is usually located in the engine crankcase.

- The filter element is installed in the tank.

- The oil line is a small diameter oil-resistant rubber hose.

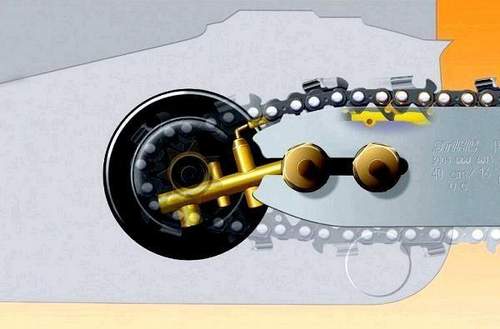

- The heart of the system is the oil pump.

- The worm gear is the transmitting force from the engine to the pump.

- The tire of a chainsaw, it can also be considered an element of the lubrication system, since it has special holes for supplying oil, by the way, the chain itself is involved in the transportation of oil and, accordingly, also has some elements designed specifically to provide lubrication.

Popular brands

As mentioned above, there are many brands of modern saw oils. Among them there are both little-known and very popular ones. If you decide to purchase high-quality and reliable saw oil, then you should familiarize yourself with the list of the most popular models.

Forest plus

This oil is in great demand and has excellent adhesion properties. Forest plus is characterized by the fact that it can be operated if the temperature outside the window is not lower than -15 degrees.

Bio Plus

The company's products called Bio Plus are plant-based. Oils of this company, when penetrating into the soil, very soon begin to decompose. Not every oil can boast of such a distinction. It is permissible to use this product at temperatures up to -15 degrees, like the previous version.

Sunth plus

This equally popular oil is made on the basis of synthetic components. It can easily endure a fairly serious load on the equipment.

Because of this, the oil will not stop acting and flow to the desired nodes.

Champion

Champion adhesive oil is usually used for work with a fairly wide temperature range. This grease is sold in containers of 3 and 10 liters. The product is inexpensive and easy to use.

Husqvarna

The name of this world famous brand inspires trust. Husqvarna Saw Oil is the most cost effective and economical solution for lubricating your electric saw mechanism. These products are characterized by moderate consumption and high efficiency.

No oil is supplied to the chain, repair of the electric saw, replacement of the oil pump

Even the most reliable tool has its own degree of wear, it is periodically required to correct small or.

Chainsaw fuel system: 1 - fuel filter, 2 - carburetor, 3 - manual pre-priming pump.

If the carburetor is adjusted correctly, the fuel will be consumed in the allowable volume. Otherwise, it will end too quickly.

It is normal to slowly deplete fuel during saw operation. If it is absent, the chain is lubricated incorrectly, so the work with the chainsaw must be harmonious. It is necessary not only to be able to eliminate breakdowns, but also to identify them yourself.

You can manually change the fuel intake. The correct operation of the lubrication system is determined by applying the tire. If oil splashes appear, then everything is fine.

Read the same

Cutting is desirable with a significant amount of lubricant. If work is to be done with softwood, a small amount of fuel is supplied.

The chain must always be well lubricated.This will avoid smoke and further failure of the entire chainsaw. If oil leaks or does not flow at all, it is necessary to identify the cause of the breakdown. It is not recommended to use the tool before repair.

When choosing a fuel, you need to do it right. The desire to save money leads to the fact that the chain quickly breaks down. In order to avoid unpleasant consequences, it is undesirable to choose oil, the manufacturer of which is China. Preference should be given to original firms. In terms of their price category, they are much higher, but their quality is also better.

Groups of oils suitable for chainsaws

The operation of the chainsaw is quite simple. The higher the speed, the more the pump rotates and allows the lubricant to flow to the saw head. The oil is poured into a special tank, from which it goes to the saw. This container will have to be filled with grease every time. In other words, with proper use, the saw will work great for a long time.

In addition to understanding how this simple equipment functions, you can begin to select a special lubricant composition. Determining which substance is better is not easy. Usually, people are guided by reviews from other buyers and recommendations from manufacturers. Modern lubricants are divided into several groups. I will make a table:

| Group of greases | Specifications |

| Original | This option may prove to be the most convenient, since equipment manufacturers are trying to optimize the lubricant for a specific model. Such compositions are often based on rapeseed bases, which almost does not harm the environment and human well-being. Among the disadvantages, it is worth noting the high cost of such lubricants. |

| Narrow profile | They are used for third-party tools, and are also relatively cheap. In terms of performance, they practically do not differ from the compositions of the previous group. |

| Industrial | The most common formulations that have worked well when pouring into a chainsaw. They are significantly inferior to the original in terms of working capabilities, but the cost is also significantly lower. Low viscosity. |

| New engine or transmission | Economically not a very reasonable decision, since they are sold in large volumes, and for a saw operated at home, they are simply not needed. They have good viscosity and are suitable for equipment operation in winter. |

| Testing | It is absolutely not worth pouring already used oils into the tank. This can significantly damage the instrument, as well as harm human health. The lubricating characteristics of the substance are extremely small, and therefore it is not worth using such a product at all. |

Usually, manufacturers of original formulations inflate the cost of lubricant, therefore, you just need to know what characteristics are different for certain products, and then, use them for a specific model of chainsaw. A video on the topic will add to what has been said:

Lubrication system malfunctions and how they are eliminated

The main malfunctions of the oil supply system on a chainsaw can be divided into two main types, these are general malfunctions inherent in all chainsaws and individual ones, which may differ depending on the type of pump and worm gear installed on a particular model. Let's start sorting out the faults in order.

Signs of a malfunction of the lubrication system, checking its performance

- Chainsaw chain is dry and has a pale shade without shine.

- The chain stretches relatively quickly.

- The tire is very hot and may even partially melt the paint.

- The oil from the tank is practically not reduced.

- Decreased cutting efficiency on a sharp chain

All of these signs indicate that the lubrication process is malfunctioning. In order to check the oil supply by the lubrication system, it is necessary to remove the side tire of the chainsaw and start it.Further, you need to slightly increase the speed while observing the place where the oil line ends. If oil is flowing in, it is likely that there is not enough oil for proper lubrication and the filter needs to be cleaned or replaced and, if possible, adjusted the flow. In the case when it is not received, the problem is more serious and requires further diagnostics.

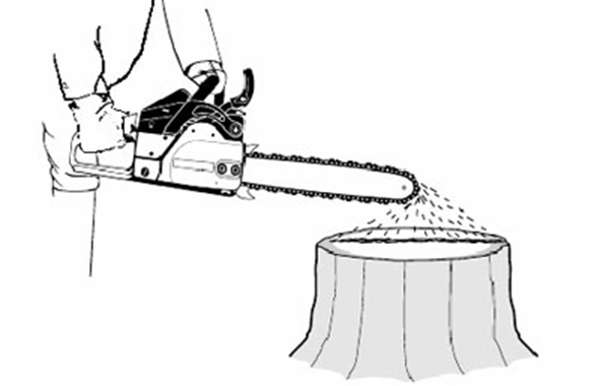

There is a way to check the oil supply without removing the tires. To do this, it is necessary to direct the end of the tire towards, for example, a freshly sawn block from the cutting side and increase the speed as much as possible, while trying to keep the end of the tire at a distance of no more than 10 cm from the block. If oil spots start to appear on its surface, then oil is being supplied.

Troubleshooting

After it has been determined that oil is not being supplied, further diagnostics is possible only if the oil system is completely removed. Of course, changing the filter helps in some situations, but this is very rare.

Most common malfunctions

- Broken oil hose. It can sometimes be detected by visual inspection. The problem is solved by replacing the defective part.

- The absence of threads on the shaft of the oil pump will help to replace it.

- A defective thread on the pump drive gear is similarly solved by installing a new part.

- Absence of a corkscrew of the main shaft (relevant for some models of tools, for example, Homelite). You can fix it by installing instead of the native corkscrew, suitable for the diameter of the studs, cutting it to the required length.

- Blockage in the line. Can be removed by blowing with compressed air or mechanically using a wire of suitable diameter.

- Clogged filter element.

- The tool Calm MS 180, the pump of which is not separable, often clogs. You can try to rinse in clean gasoline if replacement does not help.

- In Chinese chainsaws (Gypsy), it very often cuts off the grooves on the main gear, through which the force from the sprocket is transmitted to it.

Individual malfunction of the Stihl MS 180 lubrication system

In view of the fact that the Stihl MS 180 is one of the most common models of chainsaws, I would like to dwell on one inherent only malfunction and describe a way to eliminate it without replacing parts.

Quite often, on the Stihl MS 180 chainsaw, there is a depressurization of the oil line in the place where the oil line from the tank is installed in the saw body. The malfunction can be determined by the characteristic grease leaks on the bottom of the tool.

To eliminate the malfunction, it is necessary to remove the chainsaw handle, remove the hose from the bore, clean and degrease. After all these manipulations, apply sealant to the hose seat and install it in the chainsaw body.

You can find out more about troubleshooting and full diagnostics of the lubrication system of the chainsaw calm by watching the video, which shows step by step the process of disassembling and repairing the lubrication system.

What oil to use to lubricate the chain

This part requires constant lubrication, for which you can fill in a special oil for a chainsaw, and it must be of high quality. It is recommended that you select chain saw oil from the manufacturer of the saw itself. Its consumption is low, so you should not save on the purchase. But it is not necessary to pour liquid onto the chain itself. There are entire systems for lubrication to help it flow to the tire without interruption.

There are other criteria for choosing a saw lubricant:

- resistance to freezing, because the saw sometimes has to be used in winter, including lubricating with oil, which means that at negative temperatures it should not freeze;

- optimum chain oil viscosity;

- the oil that is used should not leave a deposit on candles and other spare parts;

- no impurities.

It is necessary to replace the chain oil if the part heats up and various breakdowns appear.

Chain lubrication diagram

The chainsaw chain lubrication system consists of the following elements:

- oil tank, which is located in the engine crankcase;

- filter in the tank;

- oil line, that is, a small diameter hose;

- oil pump.

Chainsaws are equipped with an automatic lubrication system. This means that oil is supplied to the chain only if it comes into contact with the wood. The scheme of the system is as follows. The gear, which is located on the main shaft, drives the oil pump shaft. This creates pressure in the oil line, which forces the oil to move towards the tire.

The oil channel ends at the point where the tire of the device touches the crankcase of the chainsaw. Chainsaw chain tension for oil supply does not matter. She still lubricates herself.

Oil does not flow to the chain

The fact that oil does not go to the chain can be recognized by the following signs:

- dryness of the part and lack of shine;

- its rapid stretching;

- heat;

- no reduction of oil from the tank;

- decrease in cutting efficiency.

If oil stains appear on the surface of the wood, then there is no problem with the oil supply. It may be necessary to adjust the feed.

The reasons for the lack of oil supply can be:

- Missing threads on the oil pump shaft. In this case, it will need to be replaced.

- Broken oil hose.

- Defective threads on the pump drive gear.

- No corkscrew of the main shaft. You can solve the problem by installing a stud of a suitable diameter and required length.

- Blockage. The line can be cleaned by blowing it out with compressed air or using a thin wire. If the blockage is in the filter or in the pump itself, then these parts are best replaced.

Manufacturers of adhesive oils

Almost all manufacturers of chainsaws are engaged in the production of consumables for them, explaining that these products are most suitable for use in conjunction with their saws. There is no information about how true this is, but based on the experience of operating and repairing chainsaws, it can be noted that there are no significant differences in the service life of parts or at least visible wear.

But the fact is the fact, the manufacturers recommend and cannot be hidden. So, back to the manufacturers, and let's start with the popular Shtil brand.

Stihl adhesive oils

The company's website contains the following adhesive oils designed for various operating temperatures and having a good lubricating performance:

- ForestPlus adhesive oil - recommended for use at temperatures up to - 15 ° C, shelf life under storage conditions is 3 years. Supplied in 1 liter or 5 liter containers;

- BioPlus - its peculiarity is a vegetable base, which allows it to decompose quickly when it gets into the soil. It is used up to minus 15, it is supplied in three, five and one liter containers;

- The latest SynthPlus oil is characterized by its ability to maintain performance at minus 25 ° C.

HUSQVARNA oils

The company offers its customers Husqvarna Bio Advanced oil for use in normal and extreme conditions. The oil is produced from plant components and is environmentally friendly, supplied in one liter and five liter containers.

As an economical solution, the company has Vegoil oil, according to the manufacturer, its consumption is reduced by 40% compared to others. Supplied in a liter container.

The company also produces bearing grease, which it recommends for lubricating the bearings of the drive sprocket and the sprocket on the saw bar.

Less common, but popular with chainsaw owners, are:

- Polar Lube mineral - Oleo-Mac;

- Adhesive CHAMPION, sold in containers up to 10 liters, which is convenient for use in forestry;

- Makita Biotop;

- Anchor.

You can get acquainted with some oils for chains by watching the video below, in which a seller of a large network of tools comments on the use of adhesive oils from various manufacturers.

Can 95 gasoline be poured into a chainsaw?

Sometimes, in the instructions for some imported chainsaws, their manufacturers indicate AI-95 gasoline as the recommended fuel.Is it possible to prepare a gasoline mixture based on such fuel and use it to refuel garden tools? First of all, it should be remembered that imported and domestic gasoline of the 95th grade are 2 different things.

Abroad, such fuel is distinguished by its purity and high quality at the same time as the domestic 95th gasoline is not much different from the 92nd. The fact is that the octane number of domestic gasoline is artificially achieved through the use of various impurities, which, in fact, do not improve its quality in any way. Therefore, it is not worth pouring such fuel into the chainsaw tank. Otherwise, the owner of the saw will face expensive repairs, and at his own expense, since none of the warranty service centers will agree to repair the tool under warranty.

How to shorten the chain yourself

You can repair the chainsaw chain with your own hands, provided that you have a special tool (most often it comes with a saw). Most often it is necessary to shorten it, especially if it is stretched. This is difficult, but possible. To repair it by shortening, you need to prepare the following tools:

- vice;

- file;

- hammer;

- pliers;

- beard.

Some work can be performed with a welding machine, if you have doubts about your own abilities.

To shorten the chain on a chainsaw, you need to rivet it. Since it is made of durable steel, the process can be tricky. It is connected on the inside of the rivet. The reduction is performed in the following sequence:

- Fix the part in a vice.

- File off the protruding part with a file or file.

- Knock out the rivets with a beard.

- Do the same work in one more place. This will allow her to be riveted.

- Remove links.

- Connect to old rivets, while pressing them on the sides. The rivet can be welded to the lateral parts of the link, after which all excess can be grinded off with a file.

Useful Tips

It is important to keep in mind that under conditions of increasing engine speed, the pumping speed of the lubricating composition also increases significantly. That is why it is required to pour the oil mixture into the electric saw only if the engine is turned off.

You should buy lubricants for the electric saw chain exclusively at specialized retail outlets. Only such products are of high quality and effective. You should not buy goods in markets or street shops. Most likely, they will sell you a fake there, which will not only turn out to be useless, but will also lead to a breakdown of the instrument.

There are a lot of oils on sale. But the best option is an oil that has good adhesion properties. These products contain special additives. Thanks to the latter, the composition does not shake off and does not flow off the saw chain as it actively rotates. Only such a remedy will be effective and will have a beneficial effect on the condition of the instrument.

You will learn how to choose oil for your electric saw from the video below.

How the saw chain is lubricated

Important! Make sure the saw is de-energized before lubricating it. The chain and guide bar must be lubricated with biodegradable oil with an additive that improves oil adhesion

This will prevent it from flying apart during operation. Mineral oils are not recommended for use due to their negative impact on the environment.

The chain lubrication of budget saw models is done manually using the following tools:

- special flask;

- syringe;

- brushes or paddles, depending on the viscosity of the oil.

Using a brush or a spatula, try to evenly apply a layer of lubricant to the chain. It is necessary to work with gloves, avoid contact with the skin and mucous membranes of the eyes and nose. If, nevertheless, the lubricant gets on the skin, rinse the area with running water and consult a doctor.

In the more expensive models with an integrated chain lubrication mechanism, the process should be carried out as follows. Before starting the operation, it is necessary to remove dirt from the oil tank cap in order to prevent them from entering the tank. Then you need to open the lid, pour oil to the lower edge of the neck. Screw the lid back on, wipe the drips with a cloth.

Electric saw oil - for chain and gasoline, video, features

The electric saw has a rather complex device, like any other tool.

On sale you can find many models that do not require special care - they have a self-sharpening chain and oil is supplied automatically.

If you want your equipment to last as long as possible, you should not only buy high-quality consumables, but also know some of the nuances of the device.

In this article, we will talk about the oil for chain saws. You will learn why it is necessary, why you need to choose only high-quality lubricant, and what can happen if the oil in the electric saw runs out during operation.

Saw chain oil

If we compare an electric saw with a chainsaw, then the first does not require special care. The chainsaw has an engine, the device of which must be constantly lubricated, because if the lubricant runs out, there can be very sad consequences.

In an electric saw, oil is used to lubricate the chain. Without lubrication, she will have to put in more effort to get the job done. Without it, the chain will become very hot during sawing, the links will become dull. Everything can end up with the chain part together with the tire simply completely failing. Therefore, always check the lubricant level.

Modern models of electric saws have a built-in oil pump. But you can still find models that do not have this device. To do this, periodically you need to stop work and lower the chain into a bucket of lubricant. If you do not do this, then it will be extremely difficult to work.

Electric chain saw oil is poured into a special container that has a screw cap. Experts recommend filling it to 75% of the total capacity. Many electric saws have a special transparent window through which you can check the lubricant level.

Check for traces of lubricant on the chain. If no oil is supplied to the saw chain, you need to idle the tool for about 20 seconds. Then check again.

Which oil to choose?

Every owner of expensive equipment knows that you need to take care of it and not save on materials and spare parts. Then the devices will work for a long time and without failures. The same is the case with the choice of oil.

What kind of oil should I put in a chain saw? You need to carefully study the instructions, which will indicate which oil is right for your saw model. There are several options:

- Engine and transmission oil. If the instructions indicate that such a lubricant is suitable for your electric saw, you can safely buy it. But remember that mineral oil is absolutely not suitable for these purposes. Also, various systems can be cleaned with engine oil - oil residues form a jelly-like coating that must be removed;

- Special lubricant for electric saws. There are a huge number of such liquids on the market. Often, companies that manufacture electric saws also produce materials for them, such as oils, tires, chains, and more. It has the main difference - the presence of adhesive additives. The oil is not shaken off the chain during operation. This is the best option, since the material is specially designed for saws, but at the same time it is branded, therefore, its price will be quite high;

- Plain vegetable oil can also work in some cases:

- suitable exclusively for lubricating the chain - if it goes into the cylinders, then it is strictly forbidden to use it;

- it must be refined;

- it must be completely developed, and after that the system is thoroughly washed;

- Used engine oil. This material is very dirty and will clog the entire system as well as the chain itself. Many owners say that everything works for them, but experts do not recommend risking their equipment.

All about saw oil Link to main publication

What kind of oil should I put in a chain saw?

Oil is one of the main consumables of an electric saw. Special requirements are always made to it, because the serviceability of the lubrication system and the service life of the saw set of garden tools largely depend on its quality.

First of all, it is not recommended to use waste fluids for lubricating the cutting attachment of an electric saw, which novice gardeners drain from gearboxes or engines of mopeds and motorcycles to pour them into the oil reservoir of the tool. Such compositions contain a large amount of dust and rust particles, which, getting into the oil pump of the electric saw, lead to clogging. As a result, the pump is blocked, overheats and completely fails.

To prevent this, it is necessary to select only specialized lubricants.

It should be remembered, however, that the oil for an electric chain saw must meet the following criteria:

- a suitable base - the lubricant should be made on the basis of synthetics, which does not harm the operation of the oil pump;

- tightness - the oil for the electric saw chain should not be too thick to cover the parts of the lubrication system and the saw organs of the garden tool with a strong oily film;

- increased adhesion - the property of oil to stick and stay on the surface of the guide and chain allows it to spread evenly along the entire length of the cutting organs;

- the ability to completely decompose - the qualitative composition does not leave behind carbon deposits and other decay products. This protects the oil pump and other parts of the lubrication system from clogging;

- anti-corrosion properties - the oil must protect the parts of the lubrication system from rust, the centers of which appear as a result of moisture entering the system.

An important role in the choice of oil for an electric saw is played by its manufacturer. Gardening tool manufacturers advise using their own lubricants - they are developed taking into account the design features and capabilities of electric saws. In addition to branded liquids, experienced gardeners use oils from the brands Ravenol, Motul, Divinol and Liqui Moly.

An important role in the choice of oil for an electric saw is played by its manufacturer. Gardening tool manufacturers advise using their own lubricants - they are developed taking into account the design features and capabilities of electric saws. In addition to branded liquids, experienced gardeners use oils from the brands Ravenol, Motul, Divinol and Liqui Moly.

Choosing the Right Saw Lubricant

If there are no special instructions and recommendations in the technical documentation, then you should use the products of reliable companies. Such materials are of high quality and meet the requirements. Manufacturers usually recommend lubricant grades that correspond to the brands of the tool itself, they are the most suitable. However, their cost is also high, this will also have to be taken into account. The correct choice of lubricant for the electric saw is the key to obtaining the desired result of work and preserving the device.

An example of an inexpensive and quality product is the Champion brand. It is suitable for working in various temperature conditions. On sale you can find packages of 3 and 10 liters. It is easy and convenient to use. Another well-known brand is the Husqvarna brand. This oil is very effective. At the same time, its cost is also moderate.

Forest plus and Bio Plus also manufacture chain saw lubricants. The latter also differs in that it decomposes quickly when it enters the soil. Under suitable conditions, these materials have a shelf life of 3 years. However, they can be used at an air temperature of at least -15 ° C.

Sunth Plus oil is suitable for use in fairly severe frosts, down to -25 ° C. It is made on a synthetic base. It tolerates even high loads during the operation of the equipment. This brand is one of the best.

Do not trust handicraft products, the price of which is very low. Not only are they ineffective, they can even cause serious damage to the instrument. This also applies to the waste product. It contaminates the saw chain and mechanism.

Classification of oils that are suitable for use

You need to use oils for work only those that include useful antioxidant, anti-corrosion and stabilizing components that prevent premature failure of the chainsaw parts. The operating conditions of the saw headset are quite difficult, so it is advisable to choose only high-quality oils for your tool. The leading manufacturers in this area are Stihl, Bosch, Husqvarna, Daewoo and others. Chinese manufacturers are not much inferior to the leaders in this field, since recently they began to monitor the quality of the product. When choosing an oil, it is advisable to focus on the climatic conditions in which the saw will work.

You need to purchase oil for two-stroke engines, which is sold in specialized stores. There are 2 types:

- Mineral;

- Synthetic.

CHAMPION oil for chain lubrication

CHAMPION oil for chain lubrication

Synthetic oil is more expensive and it is it that experts advise to use it. Synthetic oil prevents sludge build-up and helps to extend tool life.

When choosing, pay attention to the viscosity index, which may differ for the operation of the unit at different times of the year. For the summer period, it is best to use oils with a viscosity of 15-40, and for the winter period - 10-30

Brand M8 or M10. It is advisable to use the same brand all the time, as this allows you to better study the features of the saw.

How to make the mixture correctly

Many experts use self-prepared mixtures.

In this case, it is important to follow the instructions and respect the proportions. Usually the oil is diluted with gasoline in a ratio of 1:50 or 1:40.

Gasoline is used only for A-92 and A-95. Better to use fresh gasoline to prevent breakage. Use oil only for API-TB and API-TC two-stroke engines. The finished mixture cannot be stored for a long time. The ideal option is to prepare a certain amount and use it within a month.

Saw chain oil

If we compare an electric saw with a chainsaw, then the first does not require special care. The chainsaw has an engine, the device of which must be constantly lubricated, because if the lubricant runs out, there can be very sad consequences.

If we compare an electric saw with a chainsaw, then the first does not require special care. The chainsaw has an engine, the device of which must be constantly lubricated, because if the lubricant runs out, there can be very sad consequences.

In an electric saw, oil is used to lubricate the chain. Without lubrication, she will have to put in more effort to get the job done. Without it, the chain will become very hot during sawing, the links will become dull. Everything can end up with the chain part together with the tire simply completely failing. Therefore, always check the lubricant level.

Modern models of electric saws have a built-in oil pump. But you can still find models that do not have this device. To do this, periodically you need to stop work and lower the chain into a bucket of lubricant. If you do not do this, then it will be extremely difficult to work.

Electric chain saw oil is poured into a special container that has a screw cap. Experts recommend filling it to 75% of the total capacity. Many electric saws have a special transparent window through which you can check the lubricant level.

Check for traces of lubricant on the chain.If no oil is supplied to the saw chain, you need to idle the tool for about 20 seconds. Then check again.