Service features

Different maintenance measures are applied to each specific model.

In this case, the quality of the fuel and oil used, as well as the degree of intensity of operation of the device, play a role, it is equally important which spare parts for gas generators are used. If you average the period that you should wait before carrying out the next service, it turns out that approximately every 50 hours of operation of the device, it is necessary to perform maintenance.

The main measures that are being taken:

- External inspection of the structure, while checking whether it is necessary to replace the oil for the gas generator or to increase the amount of fuel;

- Cleaning the main units from dust and coarse dirt, especially if the device is used outdoors;

- Checking bolt fasteners for strength;

- Monitoring the reliability of the connection of contacts.

If for full-fledged operation it is important to timely change the engine oil for an autonomous gas generator, then such a unit as an alternator practically does not require maintenance, it is enough just to remove dust from the cooling fins. Before the first start-up of new equipment, the following actions are performed:

- The instruction manual is being studied.

- Oil is filled for an autonomous gasoline generator.

- The fuel tank is filled with enough gasoline to operate for a specified period of time.

- If it is planned to operate the device indoors, and the design does not provide for some spare parts for autonomous gas generators (in particular, a discharge hose for exhaust), then they should be installed.

- Grounding is in progress.

We watch the video, we make the first launch:

The device is launched on a flat surface, which will ensure high efficiency of such equipment and somewhat reduce vibrations during operation. Disconnect all consumers from the power supply immediately before starting.

Oil type depending on engine type

Gasoline power plants can be equipped with two-stroke or four-stroke engines. A feature of the two-stroke engine is that its design does not provide for a separate crankcase into which oil must be poured. An engine of this type consumes a mixture of gasoline and oil that has been prepared in certain proportions. This type of generator requires an oil that will quickly and completely dissolve in gasoline. It should also completely burn out, leaving no residue on the motor valves. A series of oils of T2 standard is produced especially for two-stroke engines.

But in this case, you need to be careful. This series of oils for two-stroke engines also includes the TC-W3 fuel and lubricants type. But they cannot be used in generator motors. This is a series of oils for engines of motor boats and jet skis that are in constant contact with water.

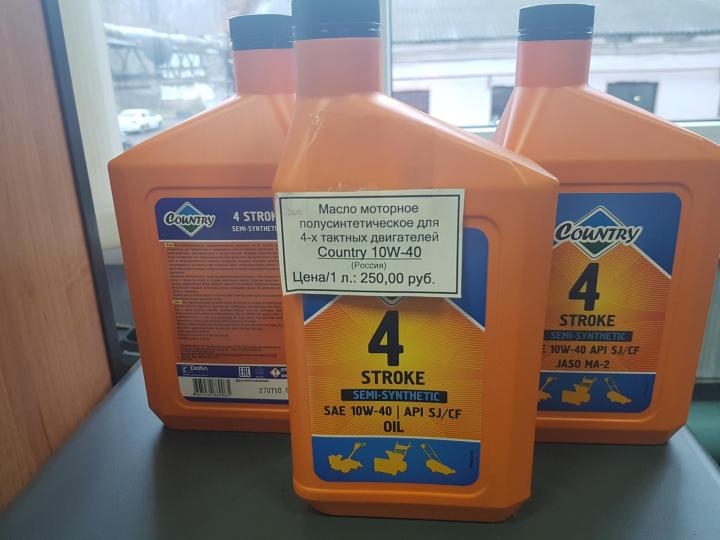

Gasoline power plants equipped with four-stroke engines have a wide range of engine oils. This somewhat complicates the choice of fuels and lubricants if the technical documentation for the generator is lost. Four-stroke engine oil is evaluated according to two main criteria:

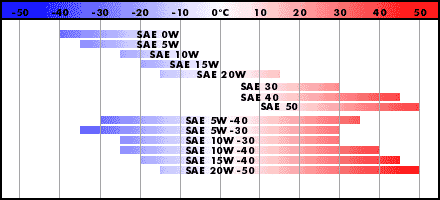

- Viscosity (SAE);

- Operational properties (API).

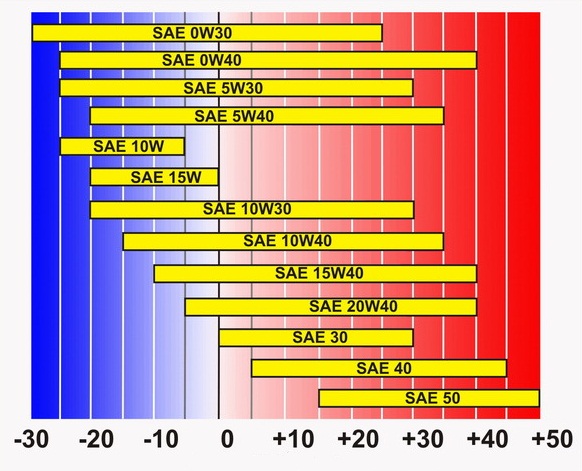

Viscosity tells us the temperature of the air at which the use of this type of oil will be most effective and beneficial for the engine. Lubricants are available for winter and summer operation. By choosing the appropriate type of oil, you ensure the best lubrication of every part of the engine, which means that you extend its service life.Depending on the air temperature "overboard", it is necessary to use oil of the following viscosity grades:

- At temperatures from +4 ° C and above: 10W30, 10W40, 15W30, 15W40, 20W30, 20W40, SAE 30.

- At temperatures from -20 ° C to +4 ° C: 0W40, 0W50, 5W30, 5W40, 5W50, 10W30, 10W40.

In summer, 10W30 oil may be the best choice, in the off-season it is better to give preference to samples 0W40, 0W50 (but preferably those that are labeled according to API SJ or SL). This marking indicates that these fuels and lubricants belong to the category of high-tech, in terms of their properties and characteristics, they perfectly meet the requirements of gasoline four-stroke engines.

The generator will work for a long time and flawlessly if you adhere to the following simple rules during its operation:

- Maintain the "running-in" mode of the new motor. This is usually the first 20 hours of operation. After that, it is advisable to change the oil.

- Observe the manufacturer's recommended service intervals. Change after 50-100 operating hours, depending on the type of oil used (mineral or synthetic).

- Before draining the old oil and filling in new oil, it is advisable to warm up the generator motor and carry out this procedure at its operating temperature.

- Before each engine start, check the oil level with a special dipstick. If necessary, top up to the minimum value.

- Immediately after starting the generator, let it idle for a couple of minutes, and only after the engine warms up, connect the load.

- If the unit is to be operated continuously for several hours, check the oil level periodically.

- Regardless of whether you start the station or not, the oil must be changed in autumn and spring (according to the operating season).

- Remember that a gasoline generator cannot run continuously, it needs to be switched off periodically to cool the engine.

And most importantly, you should not save on the quality of fuels and lubricants and the frequency of oil changes. Depending on what kind of oil you pour into the crankcase, the generator will work reliably and for a long time, or it can constantly break down and "be capricious"

It is important not only to change the oil on time, but also to fill it in accordance with the operating season. One of the most common reasons a generator can fail is a lack of lubrication in the crankcase of its engine.

To make the right choice and to be sure which oil is best suited for your generator engine, contact our consultants for help. Use the feedback form to ask your question, and in the very near future you will be provided with a qualified recommendation.

Preparing the device for winter

So that you do not have to change spare parts for gasoline generators in the spring, you should take care of the tightness of the structure on the eve of the onset of cold weather, then moisture will not penetrate into the mechanism

It is important that the fuel tank is empty and the main components are lubricated. Most often it is recommended to do the following manipulations:

- Empty the tank completely. This can be done by removing the plug or running out of leftover gasoline.

- After removing the spark plug, pour in engine oil. Then, without turning on the generator, pull on the hand rod. This will allow the engine to crank.

- The oil must be drained and a new portion refilled. This time, the hand pull should be pulled slowly and until a certain point, until resistance is felt.

The need to drain gasoline is due to its quality. If the user is sure that the fuel is good, you can, on the contrary, fill the gas tank full.

Engine oil selection

When deciding which oil to pour into an autonomous gas generator, you should be guided by the following parameters:

- SAE viscosity;

- API performance properties.

The viscosity and fluidity of an oil determine its ability to interact with a metal surface. There are different brands, each of which corresponds to a specific temperature range.For example, motor oil for a gas generator 10W30 is a universal substance that can be used in any season and, accordingly, at any temperature up to -30 degrees.

Generator greases and oils

Generator greases and oils

The most famous and popular brands among users are Castrol and Shell helix. The cost depends on the quantity and characteristics of the oil. You can pay from 900 to 4,000 rubles. To know exactly what oil to fill into an autonomous gas generator, you need to decide on the operating conditions of the equipment, as well as know its characteristics.

Lubricant selection

Before buying oil for a backup gas generator, you should understand the difference between lubricant for an engine with rotating elements and for plain and rolling bearings. In the second case, grease oils are used. Bearings require regular maintenance, but as these elements are replaced, the grease is changed.

The main parameters that you should pay attention to when choosing:

-

High level of grease plasticity;

- Oxidation stability;

- Unchanged lubricant properties under the influence of extreme temperature values.

The most common types of lubricants are Tsiatim-221 and Litol-24. Both are heat resistant. The average price for one packaged unit (grease is supplied in cans) is about 1,200 rubles.

Major breakdowns

The cause of malfunctions usually lies in two main components: the engine and the alternator. Lack of oil and fuel, as well as dirty air filter fins, lead to problems almost immediately. Each of these reasons can lead to serious problems, for the solution of which it will be necessary to install new spare parts for backup gas generators.

For example, the lack of oil causes friction between the elements of the main components of the mechanism, and this leads to rapid wear. A clogged air filter causes overheating. But in the operation of a generator (alternator) it is not so easy to determine the cause, since a breakdown can be caused by a number of factors: a malfunction of the excitation regulator, burnout of capacitors, lack of contact, etc.

Repair recommendations

If the user has sufficient knowledge in this area, then it is quite realistic to repair the generator on his own, in other cases it is better to entrust this task to a specialist. The question of which parts to install: new or used parts is often decided

It is important here to clearly separate the nodes of the mechanism. Those parts that are subject to friction wear out with use, respectively, they should be replaced only with completely new analogues.

Thus, timely maintenance of the generator will allow avoiding a number of problems in the future, as well as significantly extending the service life of this device. Correctly selected oil, its timely replacement, control of the fuel level in the tank, the presence of grease in the rolling bearings, control of oil and gasoline leaks, and much more are the factors due to which this kind of equipment will function as much as declared by the manufacturer and even more.

When and how to change the oil?

A new generator is first poured with lubricant for running-in, and after 5 hours it is drained. An oil change is recommended every 20-50 hours of operation (depending on the specific model). It is advisable to follow the interval indicated in the technical data sheet of the equipment.

It is not difficult to fill oil into the engine of a gasoline generator. By the same principle, the lubricant in a car engine is changed. Regardless of the intensity of generator operation, replacement should be performed every season, the main thing is to use a quality product from a reliable manufacturer. Use a lubricant with the correct specification.

When the generator is started for the first time, the oil will take on all dirt and metal particles, so it will need to be changed to a new one immediately.

A container is placed under the drain hole, then the bolt in the oil sump or tank is unscrewed or loosened. After draining the old oil, tighten the bolt and fill the system with a new one through the filling plug. After making sure that the oil level is optimal, screw the filler cap tightly.

A high-quality lubricant will ensure long-term operation of the generator and prevent its premature failure. Regular and correct replacement of the protective oil ensures long equipment operation.

Selection Tips oil for a gasoline generator, see the following video.

Model overview

The Russian market of gasoline power plants can boast of a huge variety of modifications available on it. The most demanded at the moment are the following units: Huter DY3000L, Huter DY5000L, Huter DY8000LX and Huter DY6500LX.

The Huter DY6500LX gasoline generator belongs to the category of small electrical installations intended for domestic use. It is equipped motor with a power of 5 kW, the fuel consumption of which is equal to 1.8 l / h. The gas tank capacity of 22 liters makes it possible to ensure non-stop operation of the unit for 9 hours. A manual or automatic starting method can be used to start the generator. The structure of the gas generator contains such important components as a voltage regulation unit and a short circuit protection complex.

Huter DY5000L is a mobile outdoor gasoline generator. It is equipped with a 4-stroke engine and has a power of 4 kW. Its fuel consumption is 1.5 l / h. A 22-liter gas tank is enough for several hours of non-stop work. The unit is equipped with a forced air cooling system. External noise parameters are in the range of 70-72 dB. The gasoline generator is equipped with an overload protection system and an hour meter that will promptly prompt when to perform maintenance. The weight of the equipment is 77 kilograms.

The Huter DY3000L gasoline generator is a typical representative of electrical appliances intended for domestic use. Its power is 2.5 kW with a fuel consumption of 1.3 l / h. This sample has a gas tank capacity of 12 liters. This is enough for 10 hours of stable operation of the main consumers of electricity in the house. In comparison with other modifications of the Huter, this gas generator has a fairly low noise level, it equals 67 dB. The generator is easy and simple to transport, and this is favored by its low weight - 43 kilograms.

Gasoline generator Huter DY8000LX is a representative of the middle segment of power plants operating on liquid fuel. This unit has a power of 6.5 kW. Its fuel consumption is 2 l / h. The fuel tank holds 25 liters. The gas generator can operate for about 8 hours on one tank. During operation, the unit emits a fairly strong noise, the level of which can be higher than 80 dB. The gasoline generator has a mass of 96 kilograms, therefore it is equipped with wheels and handles for moving.

Description

To know exactly which oil is best used for a gasoline generator, you need to understand what it is. In its original form, it is crude oil. It has good lubricating properties and is tough enough to hold onto lubricated parts. These properties were discovered at the end of the nineteenth century and patented in the United States. The first brand in the world was called "Valvoline". But the product from ordinary oil, although it performs its function, is not clean enough for modern technology - sulfur and paraffin create pollution and fumes, which negatively affects engine performance.Therefore, an alternative has become a synthetic oil used for a gas generator, which is extracted by distilling oil and disassembling it to the main components from which the base substance is made.

Various additives are added to it, thanks to which its performance characteristics are increased.

Another opinion on the choice of oil

Rating of the best oils for 2T generators

What kind of oil to pour into a generator with a 2T engine, a list of popular lubricants:

- Ravenol Vollsynthetisches Zweitakoel VSZ. Fully synthetic oil based on esters and polyisobutane. Suitable for 2T engines with air and water cooling, mixed or separate lubrication system, air and water cooling. API class TD, ISO L-EGD. Ensures cleanliness of working parts and low emission of gases into the atmosphere.

- LUKOIL MOTO 2T. Mineral engine oil, suitable for use in generators and other equipment. Meets the requirements of API ТС, JASO FB, ISO E-GB. Low ash, reduces the amount of carbon deposits and smoke.

- ROLF Garden 2T. It can be used in engines with a separate and mixed lubrication system, injection and carburetor, with an air or water cooling system. Complies with JASO FD / ISO-L-EGD, API TC. The oil is semi-synthetic and low-ash, environmentally friendly, can be used in harsh conditions.

- Esso 2T Special. Oil for air-cooled engines, with and without separate lubrication. API class TC, JACO FC. Provides good lubrication and cleanliness of internal parts.

- MGD-14M. Surprisingly good oil from a domestic manufacturer. Suitable for vehicles with a working volume of up to 200 cm3. Shows low opacity, economy and good lubrication.

How to replace it correctly?

There is nothing complicated about changing the engine oil of the generator.

The process is identical in everything to changing the lubricant in a car engine, but taking into account that no matter how often the generator is used, it must be replaced every season. Depending on the temperature at which it will work, it is necessary to use gasoline generator oil with the appropriate characteristics, but you can also fill in machine oil, because there is no fundamental difference between them. You should be especially careful during the first start-up and the initial twenty hours of generator operation - during this time, all debris and metal particles will collect in the lubricant, and it will go a full circle. It should be replaced immediately with a new one. Before draining the old oil, the engine should be warmed up, so the product will flow out without residue. The new one needs to be poured, controlling its level with a dipstick - it must be in its place.

Peculiarities

Any Huter gasoline electric generator contains an internal combustion engine, an alternator and a control unit. Such an installation makes it possible to produce electric current by converting mechanical energy into electrical energy. Gas generators from 1 kW to 6.5 kW equipped with an air cooling system, a synchronous generator and with auto start are especially in demand among Russian consumers.

The advantages of power plants manufactured by a company from Germany include the following factors:

- a wide range of products;

- good productivity;

- economical fuel consumption;

- good quality of the produced current;

- wide range of operating temperatures;

- long period of non-stop work;

- high level of environmental friendliness;

- small size;

- solid guarantee.

But there are also small drawbacks - a high noise level and incorrect operation of the sensor, which is responsible for measuring the volume of fuel. If we talk about noise, then, in fact, any Huter gasoline generator makes a lot of noise, and its level sometimes reaches 90 dB. To eliminate this problem, auxiliary sound insulation is used.