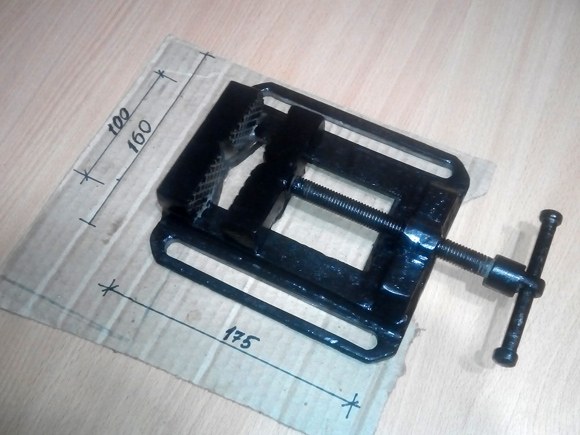

Locksmith vice dimensions

The working parameters of the vise are determined by the width and the maximum extension distance. Another indicator is the clamping force, which directly depends on the weight and dimensions of the model and is indicated in the product passport in units of kilogram-force (kgf).

The three-dimensional dimensions of the vice (width, height, length) determine the required working space for the use of the tool. Weight range - from 4 to 60 kg. There are also lighter compact models for household use.

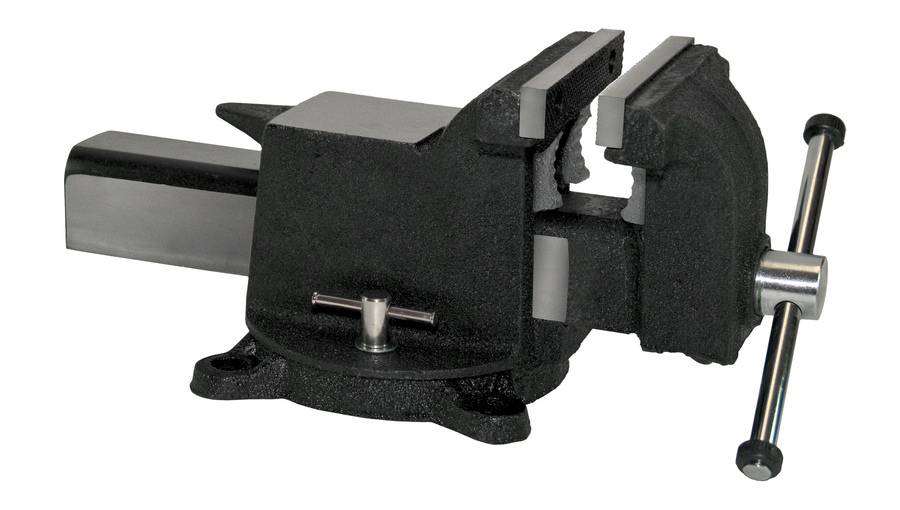

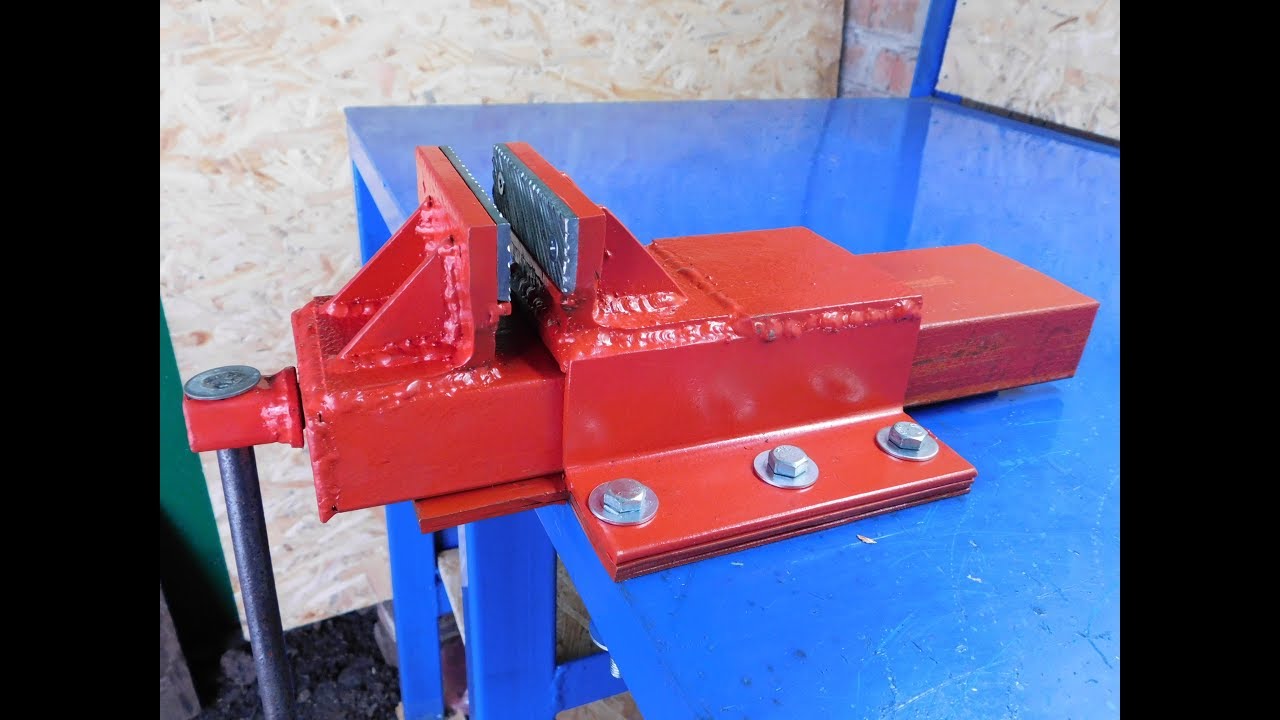

The presence of an additional surface on the vise body - an anvil, such as in the photo, will optimize the workflow.

Testing before buying

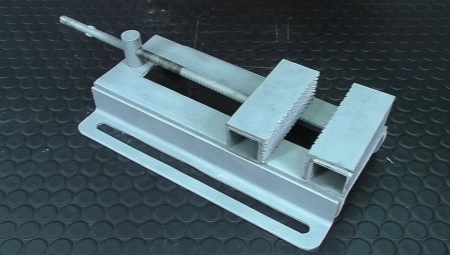

This mandatory procedure involves a visual check of the parallel arrangement of the jaws and uniform adhesion over their entire area. The stability of the bed is another important factor.

To exclude defects, you need to install the tool at eye level, and check for unwanted gaps. It is also worth checking the comfort of the grip and the smoothness of movement in action.

Proper thickness and a smooth, undamaged lead screw surface are essential for the operation of the mechanism. A lock nut must be attached to the end of the screw, which prevents the movable part from falling out when the vice is fully open.

What is a locksmith vise for?

As already mentioned, a vise, first of all, is a device for securing workpieces, which allows you to work with them alone and not ask anyone to hold the part. They are suitable for operations with metals, wood or plastic products. At the same time, with softer material, it is worth using protective pads on the steel plates of the vice, so as not to damage the workpiece. This tool will find its place in the home workshop, and in the garage, and in industrial workshops, because it greatly facilitates:

- surface polishing;

- removing excess paint or rust;

- drilling holes;

- elimination of irregularities and defects;

- welding of spare parts;

- milling and other types of work.

Model overview

There are many different models on the market today. Such an assortment and a variety of tools are due to the demand for it. A small bench vise is an indispensable item in every home. We want to offer you some of the highest quality, reliable and durable models of the device for your review.

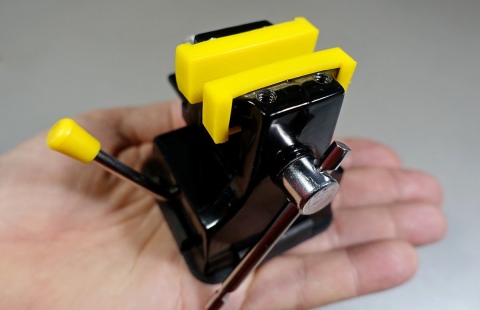

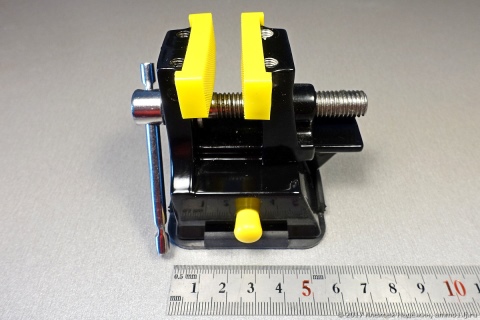

Intertool HT 0056 is a mini locksmith mechanism. The tool can be used for delicate machining of small parts. This vise can be called miniature. Cast iron is used for the production of the case. The width of the sponges is 5 centimeters, the weight of the product is 500 g.

Locksmith vice rating

In the sea of a huge selection of vices on store shelves, there are unconditional favorites among buyers:

- WILTON WI 21400... This model is equipped with a swivel structure that allows easy turning around its own axis. Strong anvil, replaceable lips, stylish design and reliability have rightly received the highest ratings from users. Wilton locksmith vices are also famous for their durability.

- TSCH-180... Having an unsightly design, this model will give a head start in reliability and stability to its prettier brothers. A solid instrument of Russian-Belarusian production with an excellent rotary mechanism also attracts with an affordable price.

- STAYER 3247-70_Z01... The instrument is unique in its miniature size. Weighing less than a kilogram, this baby will firmly fix the product with strong lips 50 mm wide with an opening of 40 mm.Unsuitable for powerful forging, these vices will still take pride of place in any home workshop.

- SPARTA 186255... High-strength large swivel model with 180 mm wide jaws, easily fixing the product up to 80 mm. Reliability is the main and indisputable advantage of this tool.

How to choose?

The final result of the work, the quality of performance, also depends on the correct choice of this mechanical device. The following characteristics of the device must be taken into account.

- Dimensions - be sure to consider what parts and blanks you will be working with.

- What material the tool is made of - this parameter affects the strength and reliability of the product. Ideal if the movement is made of high quality steel. In this case, the nominal tensile strength of the device is 5273, 02 kgf / cm². Malleable iron, cast steel and gray cast iron are also used for the manufacture of equipment. The nominal strength of the latter is insignificant, the smallest. Experts recommend buying this kind of equipment from well-known manufacturers who use only high-quality materials and raw materials in the production process, do not save money.

- Thread pitch of the rotary mechanism - focusing on this parameter of the tool, you need to take into account the type of work.

- What is the size and structure of the surface - it depends on whether there will be any traces on the product, which is fixed in a vice. Therefore, it is best to choose models with a flat lip structure. But the size of the latter is not very significant - the wider they are, the more expensive the product.

- Additional functionality - for example, can the device be used as an anvil. This function will be useful if you are doing plumbing work.

Also, be sure to carefully study the information indicated by the manufacturer in the technical passport. It is in this document that a complete description of the mechanical device can be found.

The following video provides an overview of the Intertool HT 0056 vice.

How to choose?

Before you buy a vise for your home, you should decide on the cost. It is not recommended to save on vice. In extreme cases, you should not pay attention to models that cost no more than 3 thousand rubles. Inexpensive models are often of poor quality, so they will quickly become unusable. Also, it will not be very comfortable to work with such a device, since there will be no reliable fixation of the part.

You should also decide with the manufacturer. The following companies are engaged in the production of vice: Wilton, Stanley, NEO, Delo Tekhniki, Cobalt, Caliber and some others. Here the choice depends on purely individual preferences. Of course, the size of the device is an important criterion when choosing. It all depends on what parts are planned to be processed. Naturally, small vices simply cannot withstand heavy and bulky parts, and it will be extremely inconvenient to fix small ones in massive vices.

For locksmith vices there is GOST 4045-75. It applies to those models with jaw widths from 63 to 200 mm.

An overview of the curved precision vise is presented in the following video.

Advantages and disadvantages

The popularity of manual vices, not only in production, but also in everyday life, is due to a number of indisputable advantages of this simple tool.

- Manual yews are characterized by the absence of backlash, which increases the accuracy of processing parts.

- Due to its small size and low weight, the hand vise does not require a working space and easily fits in a pocket of trousers or a work apron. They do not need to be attached to a workbench and can be carried with you at all times.

- Despite its small size, the mini-vice is highly durable and is a full-fledged locksmith tool. For their manufacture, carbon steel is used - a metal with high strength and wear resistance and a long service life.

- The handles of modern models are covered with santoprene - a material that provides good grip between the palm and the tool and does not allow the vice to slip out of the hand. In addition, in contrast to the metal surface, the santoprene handles are warm, which makes it possible to work in the cold.

- With the help of a hand vise, a wide range of works with small parts is carried out, which is why they can be safely attributed to a universal tool.

- Compared to stationary samples, manual vices are not expensive, which makes them even more popular, especially among home craftsmen. Moreover, manual models are the only type of vice that is suitable for correct work with metal tiles and aluminum profiles.

Along with the obvious advantages, manual vices still have disadvantages. These include the inability to work with large and medium-sized parts, as well as the presence of special teeth on the jaws of some models, which can damage parts made of soft material.