How to get the perfect cut

A high-quality cut simplifies further work with the material

A high-quality cut simplifies further work with the material

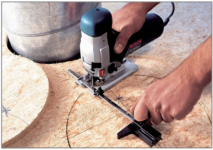

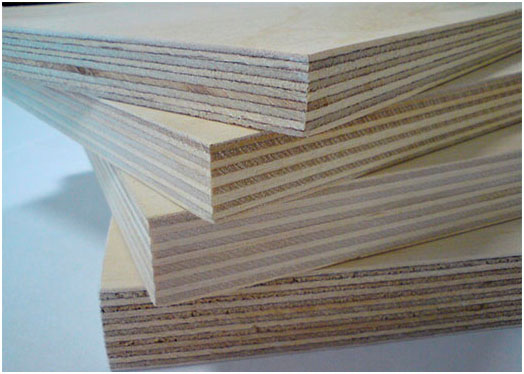

In order to get a perfect cut from the front side, you can use both a hand saw and use a power tool. There are several techniques to help you achieve a high-quality cut on plywood. Here is some of them.

Zero clearance

The principle of this technique is to keep the distance between the blade sole and the pressure plate as low as possible. This avoids breaking off the top layer of the plywood. This effect can be achieved by attaching a cover plate to the tool sole. The plate has a slot to keep the ability to cut along the intended line. Thanks to this, the teeth are guaranteed to cut small chips and do not break out the material.

It is important to exclude mechanical damage to the sheet surface overlay. The pad should be changed every 5 meters of cut

The use of pads made of more durable materials (metal, plastic or fiberglass) eliminates the need to frequently change pads, the surface of which must be pre-polished.

Adhesive tapes

To protect the back of the plywood, tape is glued along the cutting line. This method helps to prevent large pieces from breaking off, which is especially effective if the decision is made to use a hand or electric jigsaw. However, not all adhesive tape is suitable for this purpose. For example, masking tape in this case will be completely useless due to the small margin of safety.

Adhesive tapes - the best protection against chipping

Adhesive tapes - the best protection against chipping

Before you start sawing, tape-tape with fiberglass or aluminum reinforcement is glued to the surface. The requirements for its width are as follows: on both sides of the cutting line there should be a margin of 1.5-2.0 cm. It is better to pasting, pressing the tape with a dry cloth, avoiding the formation of wrinkles and gluing.

After the saw blade or electric jigsaw has stopped working, remove the tool after disconnecting it from the mains. Then proceed to peel off the tape

At the same time, great care should be taken so that sharp movements do not cause the separation of small fragments of the laminated surface, which inevitably form during cutting. Therefore, it is necessary to abandon the use of materials with a strong adhesive base.

When choosing such a tape, consider its adhesiveness and ease of cleaning from a rough surface.

Shape cutting technologies

Jigsaw

As we noted above, a jigsaw will come in handy if we are looking for how to cut a word out of plywood or make other parts of a complex shape:

We transfer the pre-printed drawings or templates to the workpiece using carbon paper.

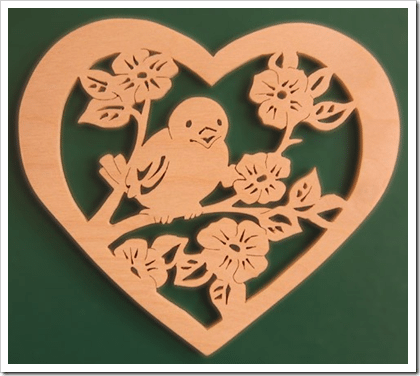

Curly carving with a jigsaw: photo of the finished product

Curly carving with a jigsaw: photo of the finished product

- If there are through sections in the structure, we make the starting holes with a thin drill.

- Insert a file or jigsaw blade into the hole. We fix the free end of the file with a fixing screw or clamp.

- We make a cut along the marked line, pressing the workpiece to the workbench. The saw moves either automatically (with electric curly jigsaws) or manually.

After all the arc elements have been cut through, we remove unnecessary areas and process the finished part with a file or sandpaper. Finished hole

Finished hole

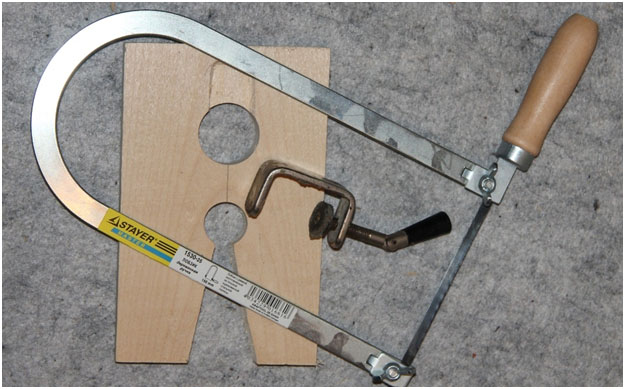

Fraser

The furniture router is great for cutting thick plywood. Of course, a complex shape cannot be made with its help, but cutting an arc or a circle is easy:

- The standard ruler, which is part of the router, is fixed in the center of the circle using a self-tapping screw.

- If the length of the ruler is not enough, you can assemble a simple bracket from a metal profile or wooden planks.

- Rotating the cutter along a fixed radius, we select the groove around the circumference, resulting in an almost perfect hole.

Router bracket: can be used to cut almost any disc diameter

Router bracket: can be used to cut almost any disc diameter

In this way, you can cut not only circles, but also individual arcs - for example, in order to make grooves for furniture brackets.

With improvised means

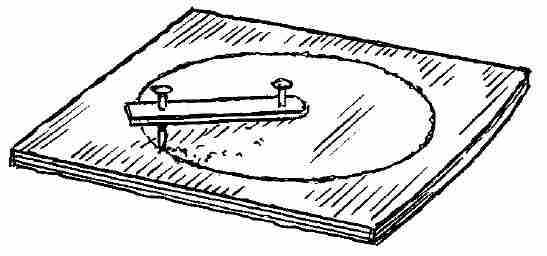

For curly elements, it is advisable to have special devices, but any craftsman may need to make a round hole in a glued veneer plate. Below we will show you how to cut a circle out of plywood when you have nothing at hand, well, almost nothing:

- For cutting out of plywood, a wooden plank with two nails is used.

- One nail is driven through the bar into the workpiece, exactly in the center of the hole being made.

- We drive the second nail into the bar in such a way that the point comes out on the seamy side by at least 5-10 mm. The distance from the first nail should be equal to the radius of the hole to be made.

- Rotating the bar, draw a furrow on the plywood with a tip, deepening it with each revolution.

- A sturdy cord can be used instead of a stick. The principle of operation remains unchanged.

Threading with nails The sharper the nail used, the faster the hole will be made. It should be noted that although the price of such a device is low, it should be used only when other methods are not available: the edges still turn out to be far from ideal.

Threading with nails The sharper the nail used, the faster the hole will be made. It should be noted that although the price of such a device is low, it should be used only when other methods are not available: the edges still turn out to be far from ideal.

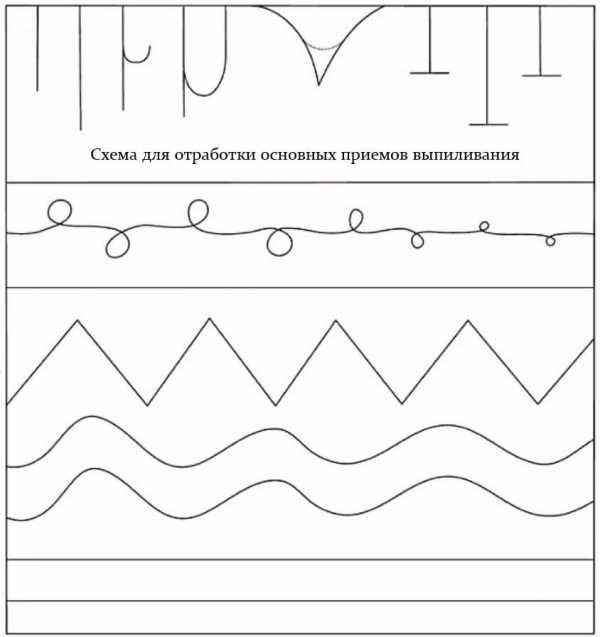

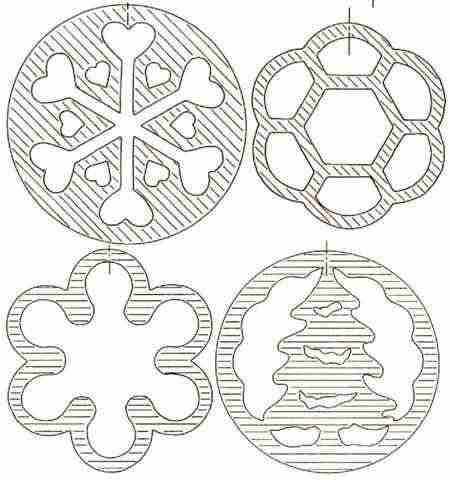

How to cut patterns?

The most difficult, but beautiful is the artistic cutting of patterns. To create an ornament, you need to transfer the stencil to plywood. In order to make a stencil, use whatman paper, paper or the remains of wallpaper. Large pieces of furniture can be placed on a Whatman paper or a cut of wallpaper, for small items a simple A4 sheet is suitable. On a sheet with a pencil, you need to create a drawing or take a ready-made one, then you need to duplicate it with a brighter pencil or felt-tip pen to make it easier to transfer the drawing to a wooden blank. In order to make a pattern or ornament using a hand and electric jigsaw, you must:

- draw or find a drawing on the Internet that you will translate and cut;

- transfer this pattern to the workpiece;

- cut out a drawing - large elements can be made with a jigsaw, small elements only with a hand jigsaw;

- remove the rest of the paper if you glued the stencil to the plywood;

- process the edges;

- clean the product from dust and shavings;

- cover with varnish, stain or paint.

There are the following options for transferring a picture to a workpiece:

- simple drawings can be transferred with an awl, and then connect the lines with a pencil;

- you can use carbon paper;

- glue the drawing on the plywood with glue or double-sided tape, and after work remove the rest of the paper.

Artistic jigsaw cutting involves training and skills that require patience and hard work to learn. Start with simple patterns, gradually increasing the complexity of the patterns. Openwork products are very elegant and beautiful, and they are also an inexhaustible space for creativity and imagination. Curly cutting will require more work with a hand jigsaw than with an electric one, as mentioned above. Manual jigsaw allows you to make small elements in the picture

Particular attention should be paid to the corners, which can provoke cracks or breakaway of the corner.

Features of work

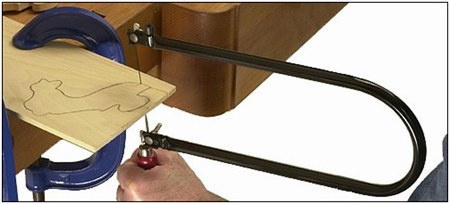

A jigsaw is a tool that allows you to cut various elements out of plywood and create ornaments. The thin, serrated blade makes various cuts, lines and allows you to create wood ornaments. The jigsaw is also used in construction, but in this article we will focus specifically on cutting out decorative elements.Jigsaw cutting has a number of features. There are many variations of this tool. The two main varieties are hand jigsaw and electric jigsaw. Initially, a hand-held jigsaw was invented. This design consists of an arc and a blade. The blade is secured with clamps that allow you to change the tension. The frame includes a handle.

The clamps can be positioned to rotate. This allows you to change the plane and create complex thread features. The jigsaw blade and its entire structure are subject to wear and tear, so the file must be changed frequently. Craftsmen who work with hand tools have many spare files to replace. A jigsaw is a power tool. There are mechanisms in the body, there is a handle on the body, the sawing element is located in the front part at the bottom of the body. Sometimes there is a foot to help cut smoother. There are models with attachments used to facilitate sawing, edge leveling.

When working with a jigsaw, you should familiarize yourself with the parameters that are spelled out in the instructions in order to know exactly how to use the tool for cutting patterns. Such a tool differs from a manual jigsaw in the fastening of the file, its thickness and weight. The jigsaw has more weight and less accuracy, but significantly higher productivity.

Sawing purposes and suitable tools

Depending on the purpose of sawing, we select what can be used to cut plywood most efficiently. Among the tools used for work are the following:

- electric circular saw;

- hand saw;

- electric jigsaw.

Consider the features of using various tools for cutting plywood and in which cases it is more expedient to use this or that device.

Hand saw

When cutting plywood with a hand saw, physical effort has to be made due to the high density of the material. This tool is used when it is necessary to cut a sheet of plywood into equal pieces.

Hand jigsaw - the best helper in the processing of plywood sheets

Hand jigsaw - the best helper in the processing of plywood sheets

A hand jigsaw is considered the best tool and allows you to decide in advance how to cut plywood without chips, saving yourself the need to purchase electrical tools. With its help, you can make a small number of elements of complex shapes. Having certain skills in working with a jigsaw, you can make a neat cut, however, due to the high labor costs and low productivity, this method cannot be called optimal.

Plywood hand saw

Plywood hand saw

If you don't have power tools or a simple jigsaw at hand, then you should resort to using a simple hand saw. To cut the sheet conveniently and avoid chipping, the tool blade must have a large number of small and well-sharpened teeth. The angle of inclination of the saw to the plywood sheet must be sharp. It is recommended to avoid jerking and make steady movements with strong pressure.

Circular Saw

Plywood sheets can be cut into various shapes using a circular or circular saw, but the main purpose of these tools is to create rectangular cuts. It is very difficult to get a neat cut when cutting material because the rotational speed of the discs is very high. In this regard, preference should be given to those cutting wheels that have small teeth and are used for working with wood. When processing plywood, it is good to use cut-off wheels designed for sawing chipboard.

Fine-toothed cut-off wheel to prevent large chipping

Fine-toothed cut-off wheel to prevent large chipping

Tip: when cutting the plywood sheet, make sure that the pressure on the sheet is low and the rotational speed of the disc is low.

Circular Saw

Circular Saw

When making furniture or repairing it, you often have to choose how to cut laminated plywood.To get a clean cut, it is necessary to select discs or blades with frequent and fine teeth. The angle of their sharpening, as well as the shape, is of great importance. It is advisable to select discs with a positive sharpening angle and a different shape of the teeth (there is an alternation of trapezoidal and straight teeth). If the disc has negative sharpening angles, then it is necessary to reduce the speed, otherwise the wood will burn.

A relationship has been established between the size of the chip and the saw teeth: small ones leave less damage than large ones. The set of teeth has an impact on the cleanliness of the cut plywood. Best results are obtained with minimal wiring. You can check this parameter using a regular ruler. Sawing a thick sheet with a disc with a minimum set of teeth should not be, since the increased friction will cause it to burn and pinch the disc.

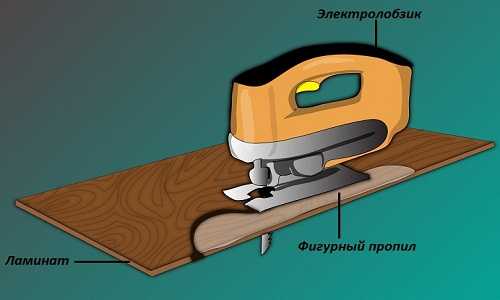

Electric jigsaw

Sawing any plywood is best done with an electric jigsaw. When working with this tool, use small files, cut the blade, pressing the jigsaw and avoiding jerky movements. At the end of the process, the ends of the material are processed with sandpaper.

The jigsaw will facilitate sawing and make a high-quality sheet cut

The jigsaw will facilitate sawing and make a high-quality sheet cut

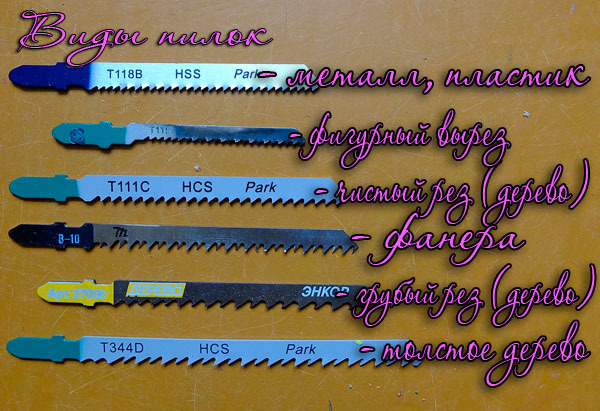

You should not buy low-quality tools, because after a 5-meter cut, there is a strong bluntness of the cutting edge, which causes chips. The lack of setting and the opposite sharpening of the adjacent teeth and the small width allow you to make a complex figured cut. But these qualities of fine cut files make the blades brittle.

Plywood saw blades - the key to successful cutting of material

Plywood saw blades - the key to successful cutting of material

Finish cutting of plywood can be done using blades for working with metal parts. The size of the teeth of such saws is minimal, which greatly slows down the cutting speed, but allows you to achieve the highest quality. Since the width of the metal files is large, it is possible to carry out a figured cut only with a large bend radius (0.6-0.8 m).

We saw laminate and chipboard with a jigsaw

Select a reverse cut file to cut these materials. True, this increases vibration, but the quality of material processing does not suffer in any way. Some craftsmen use standard wood blades, but in this case, you should work on the back of the workpiece.

As with woodworking, when sawing laminate and chipboard, the maximum speed of the saw should be set. But the function of the pendulum stroke should be turned off, otherwise the file will "break" the edges of the part. When working, we recommend that you firmly press the sole of the jigsaw to the surface to be treated, avoiding lateral forces.

In their reviews, many craftsmen, when cutting laminate and chipboard, recommend using an anti-splinter liner. This is a specific device that fits into the grooves on the sole of the jigsaw. It is designed to resist chipping. In each specific case, it is necessary to make a test cut and select an anti-splinter liner with the required parameters. Ideal is the insert in which the cut exactly matches the thickness of the saw blade mounted on the jigsaw.

Which jigsaw to choose

In order for a hobby to bring joy and not to have to correct and tweak something every five minutes, one should approach the choice of an instrument with all attention and responsibility.

Despite the seeming simplicity of the design, the manual jigsaw has many nuances that must be taken into account when buying.

- Frame material. Better to set the strip metal jigsaws aside. They tend to twist and warp the blade during cutting. The metal tube frame is free from this drawback, it holds its shape perfectly and is noticeably lighter.

- Lever. Be sure to check how firmly the handle is attached to the frame. If she keeps jumping off, the process will turn from pleasure to torment. Over time, the sawing masters change the cylindrical handle, turned on a lathe, for an individual one, carved from soft wood, taking into account the anatomical features of their hand.

- Clamps. Reliable retention of the saw during the sawing process is not only a matter of convenience, but also of safety. Good clamping pads are provided with perpendicular notching systems to ensure that the shanks of the web are retained.

- The lugs should have wide, high and comfortable ears. Avoid wing nuts that are stamped from sheet metal or replace them immediately with tall wing nuts with the same thread.