Selection principles

When choosing a tool, you need to consider:

- Electric motor power. The higher it is, the more opportunities open up for the master.

- The presence of a power regulator. It is necessary when you need to cut different materials frequently.

- The ability to adjust the angle of the saw blade. This additional function will allow you to use the tool in hard-to-reach places.

- Platform material. If it is plastic, any fall could cause it to break. On sale you can find models with metal soles.

- The length of the cable. The bigger, the better.

- File type. You need to buy several types of equipment in advance, a paste for cooling the metal.

When choosing a tool, you need to hold it in your hands in order to feel how comfortable it is. On some modern models, a laser designator is installed, a flashlight that illuminates the working area. These are optional functions, but they facilitate the workflow and allow you to make even cuts.

Jigsaw

Advantages and disadvantages

The advantages of jigsaws:

- The workflow is facilitated.

- No need to buy expensive industrial equipment to cut metal blanks.

- With the help of a power tool, you can make even cuts.

- Compared to stationary units, with a jigsaw, you can cut parts in hard-to-reach places.

Disadvantages:

- High price of power tool accessories.

- Over time, the files become dull, break. You need to regularly buy new rigs.

- In order not to spoil the metal on the cuts, it is necessary to use a special cooling lubricant.

A jigsaw is necessary for builders, installers who work with metal, wood, plastic.

Manufacturers and cost

In hardware stores, you can find tools for cutting metal, wood, plastic from companies:

- Makita is a Japanese manufacturer of power tools. Produces high quality products.

- DeWalt is an American company that produces professional construction tools. The price is justified by quality, power, reliability.

- Bosch is a German manufacturer that produces tools for professionals and hobbyists.

- Skil is a German manufacturer that produces power tools for the construction industry. The products of this company are of good quality.

- Hitachi is a concern of 1100 companies that develop equipment for large enterprises and produce power tools.

Among budgetary manufacturers one can single out Interskol, Diold, Zubr.

Jigsaw brand "Makitta" (Photo: Instagram / joyridertools)

Geometric parameters of the cutting edge

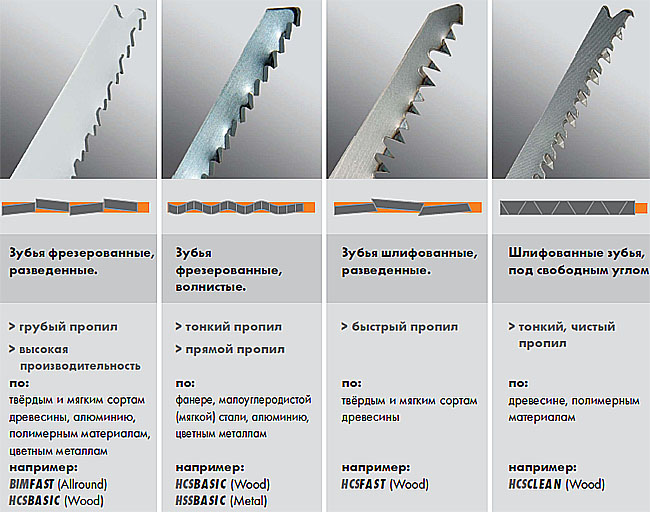

Upon careful examination of the blades, we draw attention to the fact that they have different geometric features of the sawing surface, differ in teeth and setting. Increased tooth set-up results in a wider cutting line

The work is done quickly and the quality is reduced. There are the following types of jigsaw attachments:

- Classic milled saws. Each subsequent tooth is bent in the opposite direction. This makes it possible to quickly cut material with low quality. Allows to cut wood of different density, plastic products and non-ferrous metals.

- With wave-like wiring. Several teeth are smoothly bent in one direction, then a similar amount is deflected in the opposite direction. The sawing edge is wave-shaped. This is a jigsaw tooling for laminated chipboard, wood, plywood and plastic products, as well as non-ferrous metal.

- Sanded saw blades with classic retraction.Dilution of teeth and their grinding is done. This allows you to perform high-quality sawing of wood products, fiberboard and chipboard structures.

- Conical grinding. The teeth are not set apart, but they are ground. Designed for laminate, wood and polymer structures. Allows you to make a thin, neat incision.

Each of the above nozzles has its own superiority for performing tasks of a narrow direction.

Marking

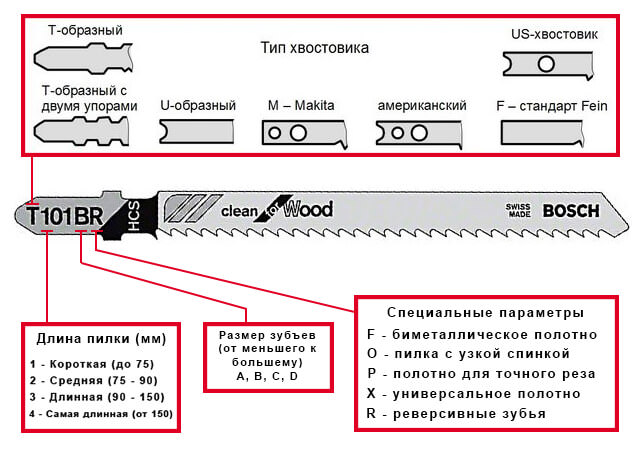

There is no single labeling system, and each manufacturer is free to create his own version of information presentation.

There is no single labeling system, and each manufacturer is free to create his own version of information presentation.

All the necessary information about this blade is applied to its lateral surfaces and allows you to understand the purpose, features and other parameters of the file. There is a predominant way of designating the parameters of the canvases, developed by the specialists of the Bosh company.

It consists of letters and numbers that represent the following characteristics:

- The first letter is the type of shank (T - T-shaped, U - respectively, M - Makita, etc.).

- The number indicating the length of the file (1 - up to 75 mm, 2 - from 75 to 90 mm, 3 - from 90 to 135 mm, 7 - over 150 mm).

- The letter denoting the size of the teeth (A - small, B - medium, C and D - large).

- The last letter carries additional information (F is a blade made of a bimetallic alloy of special strength, P is a clean cut, O is a narrow rear part of the blade that makes it easier to cut curved shapes, X is a progressive notch pitch, R is reverse teeth).

On the neck of the web there is information about the metal from which it is made, and on the side surface - the material that can be processed with it.