Stages of work

The work on cutting with a jigsaw on a tree takes place according to a certain scheme, several stages are observed.

Preparatory

We start by inspecting the plywood - it should be flat, without knots and notches. It should be dry, free from lumps and swellings.

Then they create a sketch of the work - the stencil is attached with tape or buttons to the surface. At the beginning and end of the lines, at key points and intersections, punctures are made. Complex drawings and patterns are transferred to plywood through copying.

When transferring a picture, the direction of the fibers should be taken into account - the cuts should be perpendicular to them.

Sawing with a hand jigsaw

The hand jigsaw is held by the handle, straight, positioning the file perpendicular to the surface. When working, do not press hard with the tool on the surface - the pressure should be minimal. Movements should be smooth, effortless - the instrument sinks down almost under its own weight. When the jigsaw moves up, sawdust is ejected, so you cannot bring the surface close to your face.

Basic concepts to get started with a hand jigsaw.

Sawing with a jigsaw

The work takes place according to certain rules:

- the saw blade is attached to the turned off tool;

- before work, the tool is tuned - the frequency and amplitude of movement of the canvas are selected;

- sketches are attached at eye level. the workplace should be equipped so that hands and back do not get numb during work;

- cut out the contour of the product;

- move the jigsaw smoothly, without strong pressure and jerks;

- for through cuts, make holes with a drill and then insert a jigsaw file there;

- for cuts at an angle, the jigsaw platform is shifted to the desired angle;

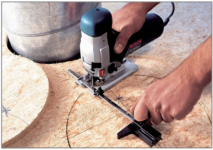

- to cut a circle, turn off the pendulum stroke, drill a hole for the file and work with a compass-stop.

Working with a jigsaw is traumatic. For novice craftsmen, simple plywood works are suitable.

Classification

Electric table jigsaws can be classified according to different criteria.

Appointment of the jigsaw

According to the purpose of use, household (home), professional and industrial stationary jigsaws are distinguished. Home and professional machines differ in their functionality. Household jigsaws are designed for simple household chores and perform a minimum of functions. Their power does not exceed 500 watts, and the duration of continuous operation is about 30 minutes. To cut thick material, you need a professional machine. Its engine power is in the range of 750-1500 watts, which allows sawing wood blanks with a greater thickness (up to 13 cm), as well as processing any kind of material. In addition, professional jigsaws are designed for a longer service life, and their operating time without interruption is about 3 hours. Industrial stationary jigsaws are powerful mechanisms that can function for about 20 hours, withstanding enormous loads.

By type of food

By the type of power supply, jigsaws are distinguished that are connected to a stationary power supply (network) and that run on a battery (rechargeable). Networked jigsaws have much higher performance. Desktop machines are only networked. Battery powered jigsaws can be used where there is no fixed power supply.

By the nature of the design

With a reciprocating or pendulum mechanism.Pendulum jigsaws have a higher performance and a longer service life of the device. This mechanism allows the saw blade to deflect from the workpiece during cutting. As a result, sawing is carried out when the blade moves in two directions: vertical and horizontal.

With lower support. These jigsaws are the most widely used. The work table consists of two parts: upper and lower. The cutting and cleaning mechanism is at the top, and at the bottom is the control module, electric motor, transmission device and switch. On such a device, you can work with material of any size.

Two-slide jigsaw. It has an additional rail at the top of the working table, which makes it easier to work with small parts.

Hanging jigsaws. Jigsaws of this type are not equipped with a solid frame, therefore they have great mobility. During processing, the saw blade moves, and the material to be processed is stationary. The working mechanism is fixed to the ceiling, which allows you to work with materials of various sizes.

Jigsaw with a degree scale. Such a stationary jigsaw is used to perform precise work using drawings.

There are also specialized jigsaws - devices adapted to work with a certain type of material, for example, for sawing foam or fiber materials with a thickness of about 30 cm. There are also special types of jigsaws designed to perform any specific operations. To cut out small-sized workpieces, electric mini-jigsaws are used, which have small dimensions.

The band jigsaw is a multifunctional device with a powerful motor. It is used to obtain even and neat cuts in wood parts of various sizes. They are very easy to use and have high speed. To perform artistic cutting, both electric jigsaws and hand-held ones are used - this way you can achieve a more accurate reproduction of the pattern.

Advantages over a saw

It seems that both tools do the same job, but the result is different.

It seems that both tools do the same job, but the result is different.

- The jigsaw provides a smooth cut, which is especially useful when further sanding and polishing of surfaces is required. The saw, as a rule, gives a rough cut, which must then be processed in several passes.

- Replaceable jigsaw blade allows you to quickly replace it, the blade tension during operation practically does not have to be changed.

- A jigsaw is much safer than a saw and often causes only scratches, but a saw can seriously damage clothing and skin.

If the jigsaw is made by yourself, for this they take a small amount of raw materials, in addition, it is cheaper than a conventional saw.

Of course, these two tools are designed for different jobs. For example, a large log with a jigsaw with its thin blade, of course, is not sawed. Even a small tree is not worth trying to cut with it. Under heavy loads, an electric tool can overheat and burn out, and the blade can burst. But for a large saw, the log is not a threat.

Tool selection

Many manufacturers today offer their own models, and each can have a lot of nuances in the design, and therefore there may be difficulties when choosing.

Many manufacturers today offer their own models, and each can have a lot of nuances in the design, and therefore there may be difficulties when choosing.

Consider an ordinary electric jigsaw with a standard set of functions:

- Cutting regulator, which is available in almost every modern model. It provides speed control and allows you to select your own for different materials.

- Fastening the canvas. Various models provide for the presence of screws or thumbs, but the simplest option today is fixing with a clamping lever.

- The multi-stage pendulum allows you to increase the service life of the blade, since after the cut it changes its position, so the sawing occurs in one direction.

- A rotating mechanism that allows you to cut material at any angle to the vertical, and you do not have to twirl by hand and twist the mechanisms. In almost the same position, it is possible to make any contour or image.

- The cooler serves to cool the electric jigsaw motor, which allows you to use the tool without interruption and maintain its performance under prolonged load.

- Angle lock - at an angle when rigidly mounted, it helps to make a cut, which is useful for furniture makers and others to get a fairly accurate cut.

Professional models, like simple ones, will help to cut wood no more than 7 cm thick or metal up to 4 mm thick, and their cost will be much higher. But they have a much longer service life, and they wear out more slowly.

The cost also determines the amount of available fluctuations. An indicator of 3000 is enough, it may not be useful anymore, but it will affect the cost.

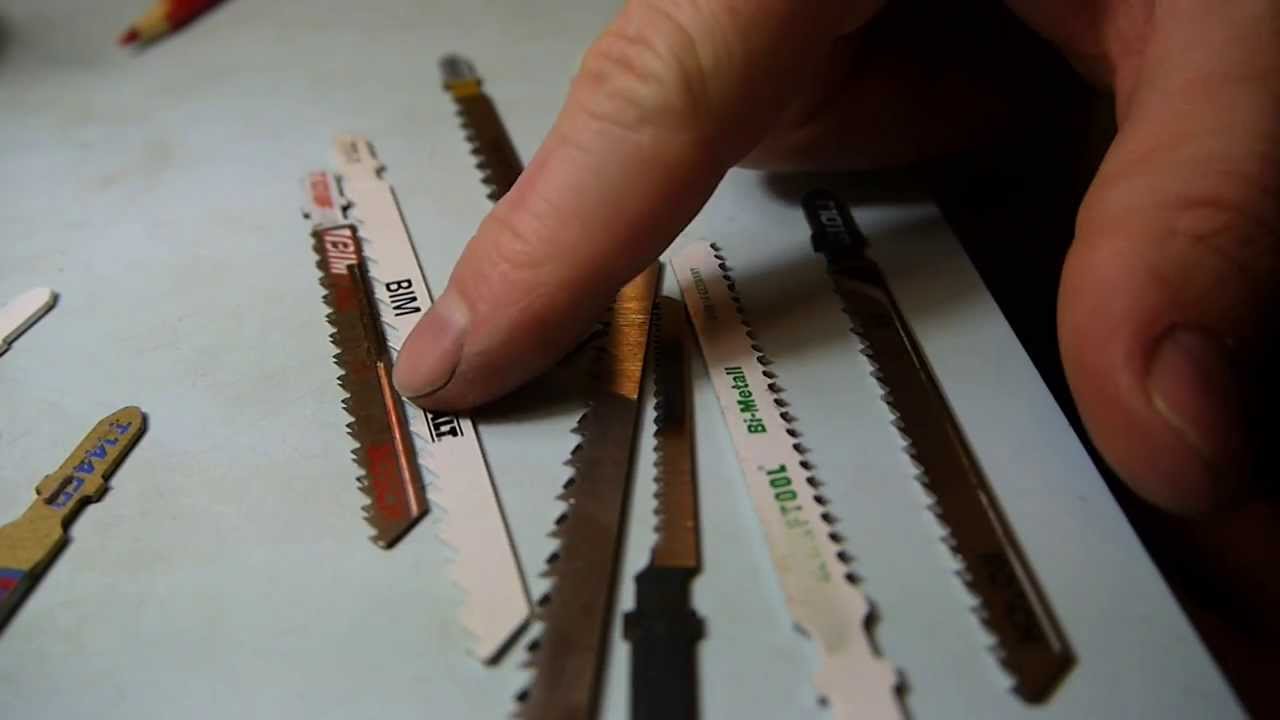

Selection of canvas

The jigsaw is universal primarily in that it is possible to replace the working blade. A new canvas made of a certain metal will allow processing not only wood, but also other materials.

The jigsaw is universal primarily in that it is possible to replace the working blade. A new canvas made of a certain metal will allow processing not only wood, but also other materials.

There are several main directions in which canvases are made:

- for wood;

- for metal;

- mixed type.

Typically, metal is cut with a blade with a large number of teeth per unit of length (TPI - Teeth Per Inch). Mixed teeth have a rather complex shape.

The set and ground teeth provide high cutting speed and large vibrations. Untreated teeth are used to ensure a smooth cut. When there is no wire, the processing speed is reduced. Wavy milled teeth are used for light shearing requirements.

Shank type

How to choose the right jigsaw file? Attention is drawn to the shank design. There are two main types:

- The T-shaped shank was developed by BOSCH. She was the first to develop and introduce it into mass production. The company ranks among the leading manufacturers of electrical equipment. Makita Corporation, Hitachi, Metabo, and other manufacturers have also adopted this tip design. It ranks at the top of the popularity rating.

- The U-shank is next in the ranking. This is a representative of American manufacturers. Such designs are completed with a tool with screw and shoe clamps.

There are two more types of shank for vintage Makita and Bosch electrical appliances. Now they are not produced, they are rare to meet. Each jigsaw has its own saw fixation, for which only one of the specified types of shank corresponds.