Photos of the best grinders

We also recommend viewing:

- The best woodworking machines for home use

- Review of the best types of drilling machines

- Knitting gun for fittings

- How to choose a soldering iron for polypropylene pipes

- TOP best miter saws

- How to choose a good circular saw

- Review of the best electric planers

- How to choose an electric riveter

- An overview of the most reliable chain saws

- The best handheld wood milling cutters

- Electric type construction stapler

- Best electric spray guns

- Which cordless screwdriver is better to choose

- Rating of the best blowers

- How to choose a renovator

- How to choose electric metal shears

- Which building hair dryer is better to choose

- Review of the best glue guns

- Rating of the best impact drills

- How to choose a mini drill

- TOP-best jigsaws of 2018

- Review of the best drills of 2018

- TOP best engravers

- Best cordless screwdrivers

- The best grinders

- How to choose a good electric hawk

- Review of the best models of electric trimmers

- Which construction vacuum cleaner to choose

- DIY power tool repair

- Review of the best soldering irons for home

- Review of the best rock drills in terms of reliability

- The best polishing machines

- Best Reciprocating Saws

- How to choose a good jackhammer

- Best screwdrivers of 2018

- Review of the best wall chasers

- How to choose a good impact wrench

Help the site, share on social networks

Types of grinders

The main field of application of hand sanders is the abrasive tooling of flat and curved surfaces of metal, wood, stone and plastic products. As such a grinding material, as a rule, there is an emery cloth based on fabric or paper, which moves at high speed over the surface to be treated. Depending on which type the grinder belongs to, these movements can be longitudinal, circular, reciprocating and rotational. In addition to models connected to a 220 V network, many brands offer cars with self-contained battery power. The performance of such a grinding power tool depends on the power of the electric drive, as well as on the area of the abrasive in contact with the processing plane.

The normative speed of the sandpaper movement depends on the type of sanding material and, in general, obeys a simple rule: the harder, the faster. Therefore, one of the most important technical characteristics of these devices, regardless of their type, is the ability to control the grinding speed. To do this, they produce grinding machines with an electric motor speed control, on which the linear speed of the sandpaper directly depends.

Tape

All belt sanders have an internal dust extraction system and the ability to connect an external vacuum cleaner.

For this, projections or holes are provided in it, and some manufacturers include special clamps in the delivery set. In this version, this sander can be used as a mini-grinder for sharpening locksmith tools, drills and knives.

Vibrating

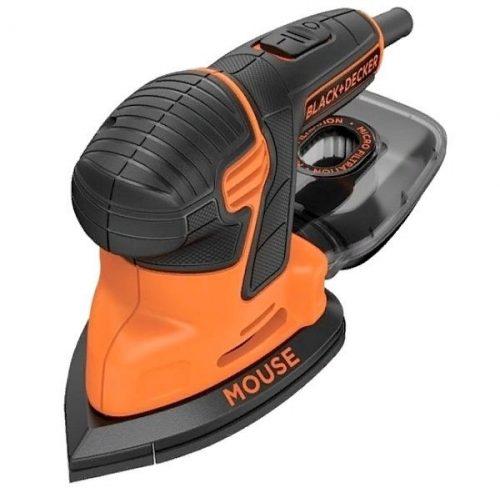

The design feature of vibration grinders does not allow them to process joints and corners, therefore, for such purposes, their type is used - delta grinders. The working surface of this grinding power tool is made in the shape of a triangle with an acute angle pushed forward, which makes it possible to process mating surfaces without dead zones.Delta sanders are mainly intended for processing in hard-to-reach places after basic sanding, therefore many models are produced in a cordless version.

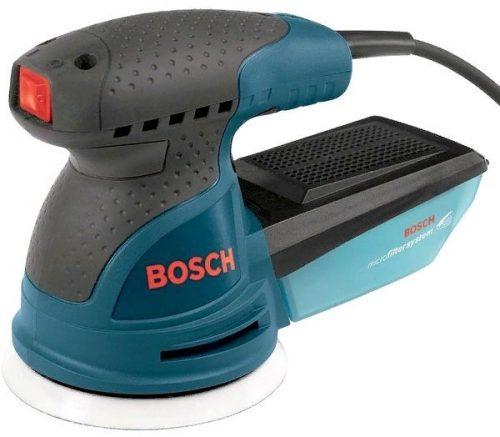

Eccentric (orbital)

Orbital sanders allow you to get the highest quality sanding and even polish paintwork. Therefore, in furniture, restoration and auto repair shops, eccentric sanders are used for finishing and polishing, and the rest of the types are used for cleaning and preliminary grinding. The performance and surface quality of orbital grinding depends on the surface area of the base, the rotational speed and the vibration amplitude of the disc. The lower the last indicator, the higher the quality and lower productivity. For most orbital sanders, it is fixed and ranges from two to five millimeters, but there are models with the ability to adjust this parameter.

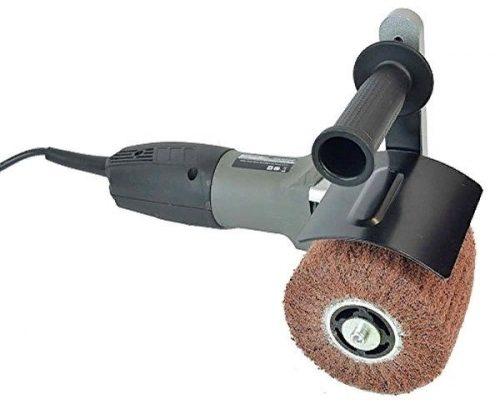

Brush

As a working tool in brush grinders, rollers with long metal or plastic bristles, as well as brushes with sandpaper lamellas, are used. In this embodiment, machines are used to remove oxides, rust and old coatings from surfaces before finishing. In addition, these machines use round or tapered abrasive cloth or felt mandrels that can be used for grinding and polishing.

Belt Sanders Rating

The working tool of the unit is an emery tape glued in the form of a ring. It is put on rotating rollers that provide movement. Due to the high power of the engine, the device quickly removes a layer of wood with large irregularities. They can also be used for processing metal, plastic, glass. When analyzing the nominees for the top, the site experts took into account the following characteristics of the grinders:

- Belt rotation speed;

- Power;

- The size of the processed area is determined by the length and width of the tape;

- Weight;

- The presence of a dust collector, which ensures the cleanliness of the workplace;

- Speed controller type;

- Functional;

- Energy consumption level;

- Cord length;

- Equipment;

- Price.

In the rating of belt sanders for wood, a description of 10 models is provided. Pros and cons are highlighted for each device based on user feedback.

The best chain sharpeners