Subtleties of choice

The most important consideration for selecting the optimal band saws is the impeccable quality of the emerging boards. Any "dips", "waves" and so on are categorically unacceptable. In terms of power, these devices are divided into:

- professional;

- semi-professional;

- homemade.

The semi-professional product is recommended for small businesses and ancillary workshops. Such a tool can work for quite a long time, including when cutting hard material. But if you need to process large-diameter frozen forest, only professional devices are suitable. The cutting depth also plays an important role. It is directly proportional to the motor power

You also need to pay attention to the kerf width. The width of the processed boards depends on this indicator.

The machines installed in large industries can cut workpieces up to 61 cm wide. It is required to check the degree of sharpening of the teeth, which affects the evenness of the cut. Saws that allow you to change the speed of work are clearly better than the regular versions.

But we must remember that a household tool rarely has such a function. The payment for auxiliary options is not very significant, but they are reflected in the convenience of work immediately. The ability to quickly tension the blades reduces the time wasted, and also reduces the labor intensity of the work. It is also advisable to choose versions with millimeter scales. They increase the accuracy of the cut, especially if there are 2 or more stops.

Application and selection of tape machines

You can't do without a band saw for wood, if you need:

- straight / curved cutting of wood, wood-based panels (fiberboard, particleboard, MDF), furniture boards;

- sawing logs into boards;

- cutting boards into lamellas;

- rough cutting of parts;

- non-standard woodwork;

- economical sawing of expensive lumber.

Sawing a tree

Choosing the right machine for band sawing wood is easier if you decide in advance for which operations it is needed. It is also necessary to decide which additional functions will be in demand, and which of them can be neglected.

- The main thing is the quality of the incisal edge. Plus a saw blade made of solid steel - it stays sharp for a long time and retains a streak even when working with artificial wood blades. Minus - if the saw is already dull, then it must be changed, it will not be possible to sharpen it again. Advantages and disadvantages opposite to hard blades have blades made of softer nickel steel. These tapes can be sharpened many times, divorced and even welded if they break. However, nickel saws also dull faster.

- Cutting depth - that is, the maximum material thickness that the band saw can handle. For a small workshop, a value of 150 mm will suffice. Sawing thickness of 300 mm or more is suitable if massive parts are to be sawed into thin parts on the equipment.

- Sawing speed. It is recommended to select the maximum speed for the tree.

- During operation, sawdust accumulated on the drive pulley can cause the saw band to slip. Stationary scrubbing brushes sweep away wood waste to prevent pulley contamination. For the same reason, a closed bearing design is desirable.

Wood band machine

Unlike multifunctional carpentry machining centers, wood band saws are relatively inexpensive equipment, which is why they are chosen for medium and small scale production.

We select the machine

Which band saw equipment for metal is preferred - directly depends on the materials that will be cut and on the cutting conditions

Let's list what you need to pay attention to first of all before choosing a machine

- Correctly selected cutting edge metal. Cutting steel - alloyed and unalloyed - requires carbon blades.For work with cast iron, as well as alloys containing titanium and nickel, carbide materials are used. For cutting abrasive materials - high-strength diamond saws. For heavy-duty sawing - bimetallic high-speed cutting.

- The power of the electric drive and the presence of speed control. For household and occasional metal cutting, machines with a weak engine are usually used. But for large-scale production, productivity depends on the power of the drive of the main movement and on the feed rate of the workpiece. Therefore, these parameters can be decisive.

- Management - manual or automatic. In manual operation, the operator independently raises the cutting frame and clamps the workpiece in a vice. In case of automatic, the wizard sets the program. Further actions - fixing the workpiece in a hydraulic vise, feeding into the cutting zone, raising and lowering the saw frame - occur automatically. Hand-held machines are in demand for cutting light metals in small industries. Automatic - for serial sawing in large enterprises.

- The degree of rotation of the frame / table / vice for angular cutting of metal.

- Cooling. The metal being processed and the cutting mechanism itself get very hot during sawing, so a coolant, usually water or water emulsions, is supplied to the place of greatest friction. An additional plus of such cooling is that metal sawdust is washed off, and not carried far from the cutting site.

- It is desirable to have such a function as an automatic stop after the end of the through cut.

- The overall rigidity of the structure. The more stable the machine is and the better it resists vibration, the more accurately it is able to cut metal.

Few companies will allow themselves to choose and buy a machine, regardless of its price. The cost of the equipment is determined by its purpose, dimensions, the name of the manufacturer and the number of resellers.

Band saw applications

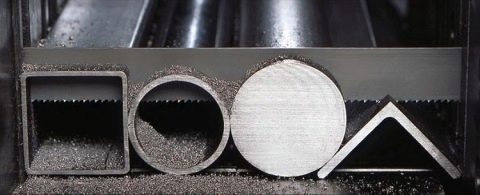

Band saw machines are used to perform the following operations:

- For sawing a wide variety of hard materials - metal, wood, rocks and so on.

- For cutting workpieces, which are sheet materials, round metal products, pipes, corners and so on.

- For dividing frozen food products.

- For working with materials of increased strength.

- For cutting workpieces that are heavy or large.

In this case, the band saw machines, depending on their scope are subdivided into household and industrial models. Household options are used in home workshops.

Industrial machines are powerful production units, which, in turn, are subdivided into metalworking and woodworking equipment, depending on the type of material being processed. And each of these types consists of a large list of models that differ in key technological characteristics.

1 Blades for bandsaw machines - types and designs

For modern metal-working band saws, the market offers blades made of carbon steel, as well as bimetallic blades with a spring base and teeth made of carbide or high-speed steel. The variety of design versions of band saws and the use of optimal cutting modes allow for a sufficiently high productivity and significantly reduce the cost of metal processing on band saw equipment in comparison with other methods of dividing cutting of workpieces.

Made from quality high carbon tool steel, band saw blades are designed to handle a wide range of unalloyed and alloyed alloys.However, in terms of their operational and technical performance, they are significantly inferior to bimetallic band saws, which are more widespread, especially with high-speed steel teeth. The base of these blades is made of special spring steel, which provides the saws with strength and durability.

The cutting (working) part of the teeth is made of high-speed alloy M42, which is analogous to 11R2M10K8. This steel, alloyed with cobalt and molybdenum, has high (up to 950 HV) hardness, wear and red resistance. A reliable connection of the base with the cutting teeth is ensured by electron beam welding and allows using bimetallic blades in the most difficult industrial conditions. Saws of a new design, with a combined tooth pitch, are most applicable for cutting products of variable cross-section, profiles, pipes.

The variable pitch can significantly increase efficiency and stability, reduce vibration of the cutting process of various workpieces with a variable cross section.

Carbide tooth band saws are used for the most difficult cutting conditions. They are used on rigid double-column and high-performance bandsaw machines when cutting difficult-to-machine materials:

- rare earth metals;

- non-ferromagnetic alloys;

- iron casting;

- alloys such as Hasteloy, Inconel, Monel;

- other alloys with a high titanium and nickel content.

Choice

Despite the fact that outwardly the design of the tape seems simple, it has many distinctive features that indicate which task the canvas does the best and what it is intended for. These include the number and shape of the tooth, as well as the cutting speed and setting option.

Number and dimensions of teeth

When looking at a blade for a band saw, you need to pay attention to the number of teeth on the side of the cutting edge. It is no coincidence, since the evenness of the cut depends on it.

The more of them, the easier it is to make an even cut on a part with thick walls. If the density of the teeth is low, then this is reflected in the working load supplied to the parts (it decreases). When there are a lot of cutting teeth, in the process of work, stress is distributed over the entire area of the blade.

As for the size of the teeth, everything is simple: the smaller they are, the shallower the cutting depth. For example, if the blade has small cutting edges, it is better to work with thin-walled sheets predominantly. Standard teeth are designed to work primarily on thin workpieces. Such canvases can be used if a curly cut is needed. When a deep cut is required, it makes sense to buy the coarse teeth version.

Step

Not everything is so simple here: in order to buy the correct option, you need to correlate the step with the parameters of the counterpart on the machine itself. Here you can take into account that a blade with a large and constant pitch is produced for cutting small thin parts (rare teeth will not cope with a large thickness). If you need to cut a large sheet, it is worth buying a tape, the teeth of which are close to each other. In the case of working with soft material, it is advisable to purchase a tape, the teeth of which are variable.

Wiring

Depending on the type of band saw blade, the teeth can be positioned differently. They have a slight deviation to the sides relative to the plane of the ring-shaped tape itself. The quality of the cut and the degree of vibration during work with this or that material depend on the wiring. In addition, the grinding speed of the tool itself depends on this.

Divorce can be standard, group and wave-like. In the standard version, the teeth are located alternately in both directions, and the third one looks to the center.A blade with this wiring is used for cutting out dimensional metal sections on horizontal equipment, as well as for contour sawing and cutting raw materials on machines equipped with a vertical feed.

In the group cutting profile, the teeth look alternately to the right and to the left. The speed of rotation of such a blade is higher (in comparison with other analogues). In addition, it does not create colossal loads on the workpieces and has a high cut quality. In a wave set, the teeth look alternately in both directions, but at the same time several elements can look in each direction at once. This layout is useful for cutting thin materials and small workpieces.

Cutting speed

The usefulness of the blade for solving the planned tasks depends on the cutting speed and feed. And here you will have to build on the type of material being processed. To choose the right option, you need to build on the choice of a specific manufacturer, since each tooth must cut off chips of a specific thickness from the workpiece being processed. The blade is selected based on the characteristics of the band saw equipment, since each machine has its own cutting speed and material feed.

The principle of operation and capabilities of the band saw machine

The main element of the drive mechanism for most models of band saws is a belt, which is stretched over two flywheels. The belt starts moving immediately after turning on the machine - from this moment it is already possible to load the workpieces and perform their cutting.

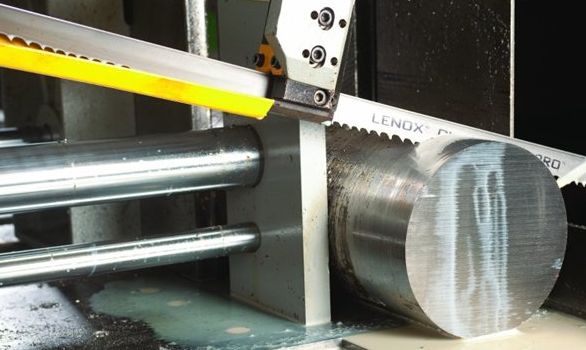

The metal band saw is designed in such a way that during the cutting process, an even distribution of pressure on the workpiece is ensured, which makes it possible to obtain very accurate cuts with the help of such equipment. Conveniently, cutting with a band saw can be performed both perpendicular to the axis of the equipment and at an angle not exceeding 60 degrees. Obtaining a cut at an angle is ensured either by changing the position of the cutting blade itself, or by turning the movable frame on which this blade is fixed, or by turning the working table.

During operation, the cutting blade gets very hot, which can eventually lead to its failure. To prevent this from happening, a cutting fluid (coolant) is supplied to the cutting site, which not only protects the working blade from rapid wear, but also prevents metal dust and sawdust from entering the surrounding air. As such a liquid, ordinary water or a special composition can be used, which provides not only cooling of the tool, but also its constant lubrication.

Individual companies involved in the production of band saws equip their models with special brushes, with the help of which the working blade is constantly cleaned of metal shavings and dust. Thanks to this simple addition, it became possible to obtain a smoother cut, provide reliable protection for the operator, and significantly extend the service life of the tool.

The metal band saw can be equipped with several basic types of saws:

- from carbon steel - for cutting unalloyed and alloyed alloys;

- from bimetallic alloys, which are used for special cutting modes;

- from carbide materials - for cutting metals that are difficult to process (cast iron, alloys with a significant content of titanium, nickel);

- diamond-coated - for cutting abrasive materials.

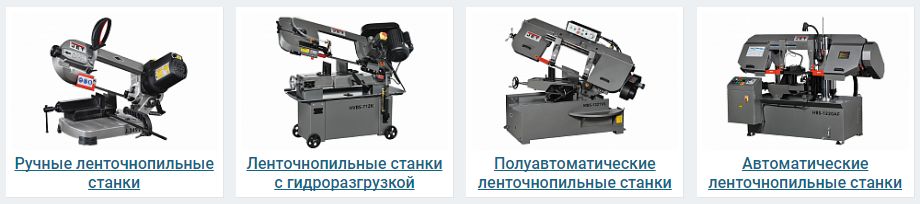

Automation degrees

The manual metal band saw is similar in design and mechanism to a cantilever one. In this class of band saws, the saw bar is moved by the physical effort of the worker or by the dead weight of the frame itself. Their advantages:

- Quite a low cost of both the equipment itself and its maintenance and operation.

- In most cases, cutting can be done at an angle of up to sixty degrees.

Disadvantages:

- The manual method of lowering the saw frame causes the saw to vibrate during operation, which reduces the service life of the machine.

- In most cases, there is no visual control of the degree of stress on the saw itself and the mechanisms responsible for cleaning the working platform.

- When working manually, it is necessary to periodically adjust the blade drive pulleys.

Most often, such manual devices for cutting metal on a band saw machine are used by small industrial enterprises.

Semi-automatic metal band saws, in which the mechanisms are driven by a hydraulic drive. From manual work, the operator only needs to feed the blanks.

Work with a workpiece in a semi-automatic machine is done as follows:

- After starting the band machine, the workpiece is automatically held.

- A specific cutting speed and pressure is provided by a special hydraulic cylinder.

- The lifting of the saw bar after reaching the lower cutting point is done automatically.

Automatic machines are used mainly in large factories for cutting a large number of workpieces. The main advantage of this device is that there is no need for the use of physical efforts - the worker only has to put the part in a vice and set the required parameters for processing.

If the need arises, then tape machines of this type are easily transferred to manual control mode.

Video: JET MBS-56CS - metal band saw.

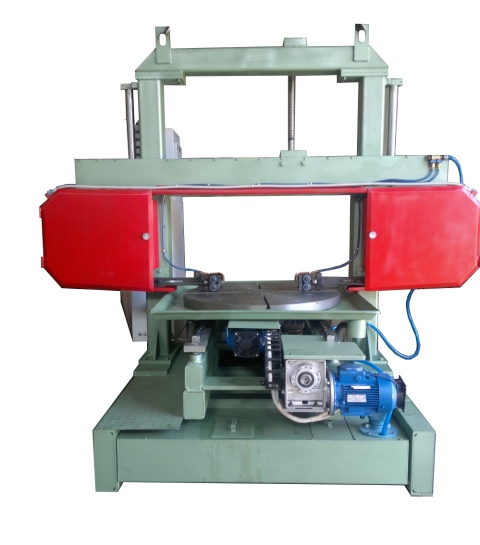

Bandsaw Automation Degrees

Band sawing machines, the production of which has been established, including by Russian enterprises, can have varying degrees of automation.

Manual

The lowering of the saw frame, which is made in the form of a console, in such machines can be carried out either by the efforts of the operator serving them, or by the weight of the frame, then such machines are called gravitational. To regulate the feed rate of the frame, to ensure its lifting and fixation at the starting point, a special hydraulic cylinder with a bypass valve, which is called hydraulic unloading, is used. The operator fixes and marks the workpiece, he also sets the lowering speed of the saw frame.

Hand-held machines are most often used in small industries. The advantages of such equipment include:

- low cost, ease of use and maintenance;

- the ability to cut at an angle.

Hand-operated table band saw HT150M

The hand-held machines also have a number of disadvantages.

- The methods for lowering the saw frame often do not avoid vibration during the cutting process, which significantly reduces the life of the cutting blade.

- In manual machines, it is often impossible to visually control the degree of tension of the web, and there is also no mechanism for cleaning it.

- There is a need to regularly check and adjust the pulleys that drive the cutting blade.

- It is impossible to control and regulate the pressure exerted by the cutting blade on the part. The hydraulic cylinder in the mechanism for lowering and raising the cutting blade allows in a very small range to change only the speed of its lowering.

Manual band saw Pilous ARG 130 Mobil

Semi-automatic

The following technological operations are automated in semi-automatic band saw machines: lowering and raising the saw frame, clamping the workpiece in a vice and releasing it after the end of the cutting process. The operator's task when operating such a machine is only to place the workpiece in the clamping mechanism. Cutting a workpiece in semi-automatic machines is as follows:

- automatic fixation of the workpiece after starting the band saw;

- cutting at a given speed, at which the pressure on the part and the force exerted on it are provided by a special hydraulic cylinder;

- automatic lifting of the saw frame and release of the workpiece after the cutting blade reaches the lower cutting point.

Semi-automatic metal band saw YOURTIME

Semi-automatic bandsaw machines, which can have single-column, double-column and console versions, are used to equip small-scale production.

Automatic

To equip large industrial enterprises where there is a need to cut a large number of the same type of workpieces, automatic band saws for metal are used. Such machines, which can be single-column, two-column, cantilever, vertical and portal types, allow the following technological operations to be performed in automatic mode: fixing the workpiece in a vice, lowering and raising the saw frame, changing its tilt angle and rotating the table, adjusting the cutting force, pressure and the feed speed of the saw frame. If necessary, these bandsaw machines can be transferred to manual control mode.

Automatic machines can operate in a three-shift mode and perform the same type of operations (cutting long workpieces into fragments of a given length) without the presence of an operator.

Automatic double-column band saw cut-off machine PMS 530/530 ACN