What it is?

Cultivators are machines whose purpose is to cultivate the land and level the plot. Subdivided into steam and row crops. The former prepare the soil before sowing, and the latter process them. With the help of cultivators, loosening, weeding, harrowing, irrigation, as well as hilling of agricultural crops are carried out.

There are mechanisms with passive and active cutters. In accordance with the type of drive, the mechanisms are divided into manual, conventional and cultivators with an aggregate, which is often a tractor. From the outside, it looks like a small harvester.

Cultivators can be used for several purposes. Here are the main ones: lancet, ploughshare, disc, milling, as well as forestry and motor-cultivators. Its purpose is power cultivation of the land.

As a rule, cultivators are equipped with compact engines of various types: diesel, gasoline, as well as powered by a network or a battery. The widespread use of aggregates is characterized by the specifics of the purpose. On this basis, they are divided into light, medium and heavy and, accordingly, semi-professional and professional.

LLC "Vederstad"

Offers a model range of the TopDown series: TD-300, TD-400, TD-500, TD-600, TD-700, TD-900 with a working width of 3 to 9 m, respectively.

TopDown stubble cultivators are designed for basic cultivation of medium to heavy soils without rotation. They crush crop residues; cut the root system of weeds and plant debris; loosen the lower layers of the soil; level and compact the surface layer of the soil. The working bodies of the stubble cultivator are two rows of cut-out discs with a diameter of 430 mm, three rows of chisel-shaped tines, one row of paired leveling discs, a row of rollers with a diameter of 600 mm. Additional equipment of the front working area with a finger spring harrow is possible, which ensures the distribution of crop residues across the working width of the equipment. General view of the Top Down TD-400 stubble cultivator manufactured by Vaderstad-Verken AB, (Sweden)

The tillage depth of the stubble cultivator is from 5 to 25 cm, infinitely adjustable by the hydraulic system during operation from the tractor cab. In the same way, depending on the need, the necessary combination of working bodies is established: all working bodies are involved; disc system and roller; a system of loosening arms and a roller; disc system and loosening tine system without roller. The degree of soil compaction is regulated in the range from the pressure by the weight of the rollers themselves to the pressure by the weight of the entire machine. You can also remove the rollers completely to leave the soil open for a longer period, for example in wet conditions. The cultivators are optionally equipped with the BioDrill system, designed for sowing green manure seeds and applying granular mineral fertilizers.

Classification of cultivators.

1. By appointment.

According to their purpose, cultivators are divided into four groups:

- for continuous processing;

- for inter-row cultivation (tilled) soils;

- special purpose;

- universal.

Cultivators for continuous tillage quickly prepare almost any land plot for further sowing. The working machine in motion performs disking, chopping and digging of plant residues, leveling and compacting the soil (using a chopping roller with a 3-row tooth harrow). The bottom layer of the soil must remain intact, the depth of cultivation is adjustable.Units of this group are designed for weed control and loosening of the soil during its preparation for sowing, as well as for the care of fallows.

Cultivators for inter-row soil cultivation are in demand on those areas where row crops are grown. During the growing period, plants carry out 2-4 inter-row treatments. Row spacing 45-90 cm, sometimes more. The purpose of such cultivation, in addition to the destruction of weeds by cutting and sprinkling with earth, is to carry out root dressing of plants and loosening the earth.

Special cultivators are used in garden and forest plots and as anti-erosion cultivators. Such units in the operating mode must eliminate at least 98% of weeds and loosen the soil without transferring wet layers to the surface.

Universal cultivators perform two or more tillage procedures at once. The actual task for this series of machines is to plow stubble to a shallow depth and prepare the optimally loosened soil in several passes. In order to warm up the soil as quickly as possible before pre-sowing treatment, these cultivators are used to loosen and ventilate it. This should mainly be done in the spring, because the amicable emergence of spring (yielding crops in the year of sowing) crops predetermines the thermal regime of the soils.

2. By the type of coupling with the tractor.

By the type of docking of cultivators with a tractor, they are distinguished: trailed and mounted.

The trailed cultivator in action is easy to maintain and adjust. The big advantage of the unit is the ability to quickly align it in the longitudinal and transverse lines due to the speed and simplicity of the adjustable levers. Rigid coupling of the unit with the tractor ensures raising and lowering of the structure parallel to the surface of the cultivated area during crossings and turns.

Rhythmic lifting of the structure relative to the tractor hitch is carried out by a device that aggregates the drawbar of the machine with its inner wheels. Ease of use, practically non-existent clogging of the working bodies by plant residues gives savings in time and money when performing work. Example - KPS-8PM, KPS-6. 0

The mounted cultivator for continuous cultivation is designed to loosen the soil with incomplete crushing of hard clods of soil, eliminate weeds and evenly mix the fertilizer with the soil. A group of such mechanisms has proven itself in moisture conservation - stubble cultivation with the intention of protecting the soil from moisture loss.

Justified is the use of mounted cultivators when cultivating the soil after plowing for the fall for sowing spring crops, flax, corn, sunflower, peas, and beets. Cultivation is carried out at an angle to the direction of plowing. The specificity of the cultivator is that, with a set of working accessories in one pass, it gradually implements all the main procedures for pre-sowing cultivation. Example - STEP KN - 3, 2.

Was this article helpful? Push the buttons!

Varieties of models

Motor cultivator factories offer hundreds of different models to users.

Motor cultivator factories offer hundreds of different models to users.

But answering the question why such equipment is needed, we can confidently say that such equipment allows you to quickly, efficiently and effortlessly plow the land and carry out other agricultural work.

To choose a cultivator, one of the best units for small areas is the Centaur MK 10-1, Carver T -650 r and AL-KO Farmer MH 5001 R models.

Centaur MK 10-1

One of the most popular Chinese cultivators are machines that are produced under the Centaur brand. The company manufactures a large number of ultralight and lightweight models. In this regard, users have the question of how to choose a cultivator for a summer residence.

One of the most popular Chinese cultivators are machines that are produced under the Centaur brand. The company manufactures a large number of ultralight and lightweight models. In this regard, users have the question of how to choose a cultivator for a summer residence.

10 acres can be easily processed using the ultra-light MK 10-1 model. It is designed for cultivating soil in small areas. It is often used for soil plowing, weeding between rows.

Specifications:

- motor power - 1.7 horsepower;

- engine type - gasoline;

- tank volume - 1.5 liters;

- weight - 10 kg.

I have been living in the countryside for many years. For weeding narrow row spacings, I purchased a Centaur MK 10-1 cultivator. Its main advantage is that, due to the high speed of the cutters, it turns the soil perfectly.

Evgeny Lutskiy, p. Yakovlevka

Carver T-650r

The Carver model is a medium-class gasoline cultivator with a four-stroke engine type and one cylinder. The motor power is 4.80 kW at 1400 rpm, and the engine displacement is 169 cubic meters. The machine comes with 6 cutters, which provide a maximum plowing depth of 33 cm, and a tillage width of 30 cm to 80 cm.

The Carver model is a medium-class gasoline cultivator with a four-stroke engine type and one cylinder. The motor power is 4.80 kW at 1400 rpm, and the engine displacement is 169 cubic meters. The machine comes with 6 cutters, which provide a maximum plowing depth of 33 cm, and a tillage width of 30 cm to 80 cm.

The transmission of the machine has a reverse with one gear forward and backward and a single-stage gearbox.

About a year ago I bought a Carver T -650 r. I plowed my six hundred parts in 60 minutes. In the store I found out that, despite the country of origin, there are any spare parts for the model.

Sergey Loginov, Tula

AL-KO Farmer MH 5001 R

This cultivator sits somewhere between light and medium. The main difference is the original transmission.

This cultivator sits somewhere between light and medium. The main difference is the original transmission.

Here, a hypoid gear reducer is used, as in the axles of modern cars.

This solution made it possible to make its casing narrow, so it has less resistance when buried in the soil.

This makes it possible to walk not on freshly plowed land, but a little to the side. There is no need to bend down to engage reverse - the lever is mounted on the right handlebar.

AL - KO Farmer MH 5001 R is a very comfortable model. The machine is easy to drive, easy to turn and avoid obstacles on the ground. The unit is low maintenance.

Anton Udovik, Samara

Models

In this category of goods, Belarusian units from "Kubanselmash" have proven themselves well.

In the model range:

- KSO-4.8;

- KSO-6.4;

- KSO-8;

- KSO-9.6;

- KSO-12;

- KSO-14.

The equipment of the KSO series is used for soil cultivation before sowing, as well as plowing. On average, the cutters of these cultivators are capable of sinking into the ground to a depth of 10 cm. The technique is used in different regions of the country, regardless of the climatic zone. Their effectiveness can be traced even on soil that is prone to erosion. Supplied complete with double tandem roller and leveling bar. A single roller or a three-row spring harrow can be supplied as required.

The KSO-4.8 cultivator is capable of cultivating up to 4 hectares of land in an hour of operation, its working width is four meters. The working depth is adjustable by the operator and can range from 5 to 12 centimeters. The speed at which the equipment is moving is 12 kilometers per hour. The total weight of the structure is about 849 kilograms.

KSO-8 is used for steam treatment or pre-sowing. The manufacturer can complete his unit with an additional device for mounting the harrow tines. The cultivator frame is made of a shaped tube with thick walls, thanks to which it was possible to create a technique with the necessary margin of safety. The cultivator has replaceable bushings made of polyurethane. The preset loosening depth can be adjusted from 5 to 12 centimeters.

Cultivators KSO-6.4 have a working width of 6.4 meters. The role of the eye is performed by longitudinal and transverse rectangular pipes. The speed of movement of equipment is up to 12 kilometers per hour, while the width of capture of the paws is 13.15 centimeters. The depth to which the cutter can be immersed is up to 8 centimeters.

KSO-9.6 has similar characteristics, its speed and depth of immersion coincide with the previous model. Spring struts with reinforcing plates are used as working bodies in the design of the equipment. The cultivator's share has a working width of 10.5 cm, if a duckfoot share is installed, it must be completed with an equalizer.

Cultivators KSO-12 have a working width of 12 meters.The power of the power unit inside is 210-250 horsepower, so that the equipment can speed up to 15 kilometers per hour. The working depth is similar to other representatives of this series - 8 centimeters.

The KSO-14 has the largest working width, it is 14 meters. The immersion depth of the knives is maintained, engine power up to 270 horsepower forces, although the speed remains at around 15 kilometers per hour.

For an overview of cultivators for continuous tillage, see the next video.

The hand cultivator is a great choice for small beds

On each site there are narrow land plots, for example, between trees, where electric and gasoline cultivators with their rather decent working widths simply cannot make their way. In such cases, small hand cultivators can be of great help. These are the most inexpensive and easy-to-use models that even a child can handle.

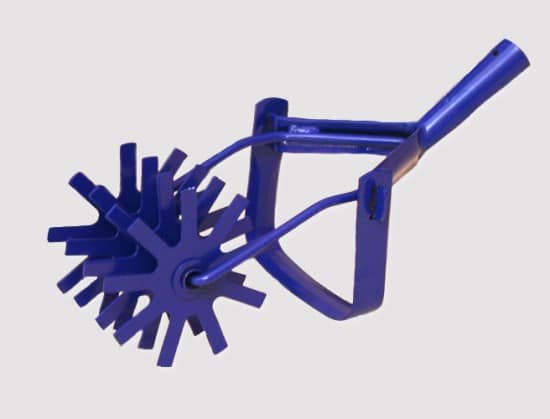

For loosening soft soils, a rotary (disc, star) manual cultivator is perfect for giving. The grip width of such a product depends on the number of toothed discs. The set for rotary models includes the necessary tool - a weeder knife, which cuts the grass and turns its roots out of the ground.

Unfortunately, the hard earth is too tough for the rotary technique, for these purposes a cultivator-ripper with sharp curved teeth is used, which forcefully “eat” into the ground and break dense inclusions and crust.

For soil in containers and pots, there are also hand cultivators - small ones with short handles. Narrow mini-cultivators are also perfect for loosening the soil on alpine slides.

How to set up a cultivator correctly?

In order to exclude burrowing of the cultivator and a number of other common problems, the owner of the equipment must perform a number of steps to prepare and configure it.

These include:

First, the cultivator must be placed on a thick plank and the factory wheels removed from it. Instead, you need to fix one set of cutters on the left and right sides.

One set of cutters includes 8 cutting knives - this number of elements gives the best result when processing soil;

When installing the cutters, pay attention to the position of the knives. They should only be directed forward.

The working part of each of the knives should not be sharp. Otherwise, the cultivator will not move forward, but will start burrowing into the ground. In addition, sharp cutters will cut the stems of the weeds, rather than wind and pull them along with the roots;

Further, the equipment will need to install the shackle necessary for mounting the opener;

The coulter is a bar with holes made in it. It is necessary for precise adjustment of the position of the cutters during the cultivation of the site;

To fix the opener, it must be installed in a shackle and secured with cotter pins and a sleeve. For this, the second hole is selected. The counting is carried out from the bottom of the opener. Thus, the cultivation depth will be 20 cm. This is quite enough for high-quality soil cultivation and the elimination of large weeds;

To increase the depth of cultivation, the opener must be lowered down and attached to the shackle through the upper hole of the element;

To reduce the plowing depth, the coulter should be raised up and fixed to the shackle through its lower hole.

Having installed and configured the working equipment, you can start operating the cultivator. To accurately determine the plowing depth, you should make a control run of the equipment over the site.

At this time, you need to pay attention to the work of the cultivator. If its engine vibrates strongly and smokes, it means that the equipment lends itself to excessive loads.

In this case, you will need to set the coulter to a shallower depth and check the cultivator operation again.

After the first tillage has been completed, the opener should be switched to deeper plowing mode. This arrangement will allow for high-quality processing of the site, and not harm the working mechanisms of the cultivator.

It is often difficult for novice farmers to figure out how to plow with a cultivator on the fly. The most common problem is the machine sinks deep into the ground and cannot be manipulated by the operator.