Popular models

Protective covers for a vacuum cleaner for angle grinders are available in a huge range. Moreover, each of their types can differ not only in design, but also in functionality. Several models of attachments are very popular with masters.

Bosch 2605510224. This casing is suitable for grinders of various brands with discs 115 and 125 mm. It is equipped with a special ring brush that allows you to work with a fiber attachment and a grinding wheel. The size of the nozzle is 200 × 190 × 80 mm, its weight is 0.3 kg. The cost is low.

- STOMER 98299441. This device is made in the form of a semicircle. It is installed on angle grinders with 230 mm discs. The main advantage of the nozzle is the presence of a guide, which is responsible for adjusting the shaking depth. The size of the casing is 320 × 160 × 240 mm, the weight is 2.71 kg. It can also be purchased at an affordable price.

- Mechnik Air Duster. This variant is suitable for tools with 125 and 230 mm diamond discs. It is distinguished by its low price and the ability to connect to medium-power vacuum cleaners (up to 1.6 kW). The casing is lightweight and easy to install.

- Blastrak. This is a professional vacuum cleaner cover that can be attached to grinding tools with 125 and 180 mm discs. The nozzle is characterized by variable elasticity, it is more rigid at the points of attachment with angle grinders and soft at the edges in contact with the floor.

- Metabo GED125. This casing deserves special attention. It is recommended to purchase it for processing concrete and stone. The nozzle is completed with a special branch pipe that allows you to attach it to the vacuum cleaner.

Every craftsman, whether he is a professional or an amateur, cannot imagine his everyday life without an angle grinder, or, among the people, “grinders”, “ushma”. It is practically the main power tool in most jobs and many people try to buy it first. A grinder is not the safest type of tool, therefore knowledge of safety rules and special parts are required to operate it.

Every craftsman, whether he is a professional or an amateur, cannot imagine his everyday life without an angle grinder, or, among the people, “grinders”, “ushma”. It is practically the main power tool in most jobs and many people try to buy it first. A grinder is not the safest type of tool, therefore knowledge of safety rules and special parts are required to operate it.

They are designed to ensure the personal safety of the worker himself and those around him, as well as to quickly and efficiently perform the assigned tasks. What is meant by the phrase “special parts”? Various types of protective hoods with dust extraction.

When buying a grinder, you can find a protective casing in the kit, but this accessory, if you can call it that, will not be able to keep the room where the work is done from dust. For this reason, many people buy or make themselves a casing for a grinder for a vacuum cleaner.

When buying this nozzle, you will need to familiarize yourself with the information about what type of work it is intended for and what size of the disc the casing is made for. The advantages of such a purchase include the adjustable depth of penetration of the disc, the reliability and durability of the casing. The disadvantage is that this accessory is by no means cheap.

When buying this nozzle, you will need to familiarize yourself with the information about what type of work it is intended for and what size of the disc the casing is made for. The advantages of such a purchase include the adjustable depth of penetration of the disc, the reliability and durability of the casing. The disadvantage is that this accessory is by no means cheap.

Canister

If you don't have welding skills or your wife flatly refuses to issue permission to damage the pan, then there is a third option, how to make a protective casing with a dust extraction, which also wonderfully connects to the vacuum cleaner tube. What is needed for this?

Find a canister in your garage, closet, or a neighbor's. From it, with a construction or ordinary knife, you will need to cut structural holes with your hands, in accordance with the grinder's shaft and the location of the disk on it. It would be nice to remember about safety precautions. Why? Trite - to preserve the integrity of the hands

Moreover, it is important to choose the right knife. It should be with a high-quality handle and sit well in the hand without slipping

After that, it is necessary to fix the tube of the vacuum cleaner with the neck of the canister so that it becomes like a nozzle. How? Cut the neck lengthwise and put on the clamp in order to tighten the vacuum cleaner tube afterwards

It is important to remember that in order to achieve good suction of the vacuum cleaner, it is necessary to ensure that all parts of the casing are snug against each other.

Causes of dust formation

The grinder is a versatile tool. With its help, using various attachments, you can cut metal, stone, porcelain stoneware and tiles, process wood and other materials. But one of the disadvantages is the formation of a huge amount of dust.

The grinder is a versatile tool. With its help, using various attachments, you can cut metal, stone, porcelain stoneware and tiles, process wood and other materials. But one of the disadvantages is the formation of a huge amount of dust.

Works causing the formation of large amounts of small debris:

- Slitting grooves on the walls. Work is carried out on plaster, and cement and sand have a fine fraction. The height of the passage of the channels is at the level of one and a half or two meters. From this height, the dust settles evenly over the entire area of the room.

- Sanding of wooden structures. Before painting or varnishing, wood products are subject to mandatory removal of cellulose fibers that are formed during the sawing process. Cellulose is thin, light and hangs in the air for a long time.

- Removing old paintwork. Remove old paint before applying fresh paint. A flap emery wheel is used. The paint he removes turns out to be fine.

- Cutting floor and decorative ceramic tiles. Sintered ceramics have a fine grain structure and they penetrate everywhere.

- Scraping parquet or wood floors. Leveling the floors is done by removing the top layer. Irregularities have different heights and therefore, in addition to shavings, a lot of wood dust is generated.

At the end of the repair, dust has to be removed from all possible cracks and cavities. To protect neighboring premises from construction dust, protective screens made of polyethylene film or light fabric are installed in the doorways. Also, special devices are used that you can make yourself.

Complicated way

The second option will require an iron or aluminum pan. All actions take place in stages and does not require special skills in the manufacture of additional equipment for the ear. Nevertheless, some tool is worth buying in order to do everything as accurately and efficiently as possible. Yes, and I would not want a self-made protective element to cause injury.

Cutting according to pre-measured values of the shape for the grinder casing

It is important to remember the saying - measure seven times and cut one. Why? It is unlikely that the spouse will be happy if, in order to save money on equipment for the ear, you have to spend money and buy a lot of new dishes.

From the remains of the pan, teeth are cut to the size of the grinder's twisting sleeve

It is tightly fixed on the grinder with a special clip purchased in advance in the store.

A cone is made from the same pan to the size of the vacuum cleaner tube so that it can be tightly attached to the shape of the casing. It is worth realizing that this can take a lot of effort.

It is necessary to cut a plate that exactly repeats the shape of the future casing. And, accordingly, combine all the parts into one structure.

The advantages of a pan casing include the fact that there is no need to spend a lot, and you do not need to have special welding skills. The negative aspects of this option include the scrupulousness of the assembly of the entire structure and, again, the inability to adjust the depth of the cutter.

Peculiarities

The casing for the angle grinder for a vacuum cleaner is a special attachment that allows you to protect the master from the effects of dust, which, when working with a grinding tool, flies out from under the disk. Many hardware stores offer respirators for protective purposes, but these devices are ineffective. After a few hours of work, they begin to clog up, which means that they cannot cope with their functions. In addition, respirators are not designed to remove dust from the work area. Therefore, if repairs are carried out in a residential area, which has decorative trim and furniture, it is necessary to use a grinder with a dust extraction.

In most designs of grinders, a dust collector is provided.Thanks to him, dust is immediately collected from under the working surface of the device, without polluting the room. Such models are characterized by high suction power. They protect not only from dust, but also from debris. Additionally, a protective casing made of durable material is installed on the dust removal mechanism. It is able to withstand intense mechanical stress and, during surface treatment, collect various fractions, including fine dust particles, and pieces of metal or concrete.

The protective cover for the vacuum cleaner has two main functions.

- Dust protection. It prevents the spontaneous spread of debris in the work area. The dust protection element also traps small and large pieces of debris that are formed during surface treatment. In addition, this device also protects the tool itself from getting into the outer part of the body of various particles, which adversely affect the functioning of the rotating parts and can further damage them.

- Adjustment. The casing is not only responsible for dust removal, but also allows you to adjust the operation of the wheel.

Since cleaning is carried out with a vacuum cleaner connected to the nozzle, when installing the cover, make sure that the diameter of the dust tube and the hole of the nozzle match. The nozzle in the form of a flexible hose should fit exactly into the hole and slide over the casing without any backlash.

It is recommended to use a cover for a vacuum cleaner in the following cases:

- For grinding concrete and chipping walls, floors. This type of surface treatment produces a lot of dust. In addition, most of the work is done at a height, and debris falling from above can settle throughout the room. To increase dust protection, it is necessary to choose an aerodynamic or sanding casing that is suitable for powerful models of grinders and withstands well loads.

- When cutting tiles. Such work is always accompanied by a large amount of dust, which not only pollutes the room, but is also harmful to human health. For this process, experts recommend choosing a cut-off or universal casing.

- For scraping wooden floors. This process is quite time consuming. It provides for the treatment of surfaces of large areas, after which a lot of debris and dust are generated. Thanks to the protective cover, scraping is quick and efficient, since the master does not need to be distracted by cleaning the working area. It is installed on the angle grinder using special fasteners.

The cover for the vacuum cleaner can be sold as a complete set with the tool, or separately. At the same time, many craftsmen make a protective device with their own hands in order to secure the working process. A homemade casing does not differ in functionality from the factory one, but it may be slightly inferior in performance. Self-made casings are able to protect the craftsman from injury, preventing particles of the processed material from flying away. But if the financial possibilities allow, then it is better to purchase finished products, since they are of high quality and allow you to expand the capabilities of the device.

Self-production

Making a casing for a grinder for a vacuum cleaner with your own hands is not difficult. You just need to approach the problem with fantasy. There are many materials for manufacturing:

- aluminum pan or plate;

- plastic oil canister;

- plastic bottle with a volume of 5 liters.

Standard casing

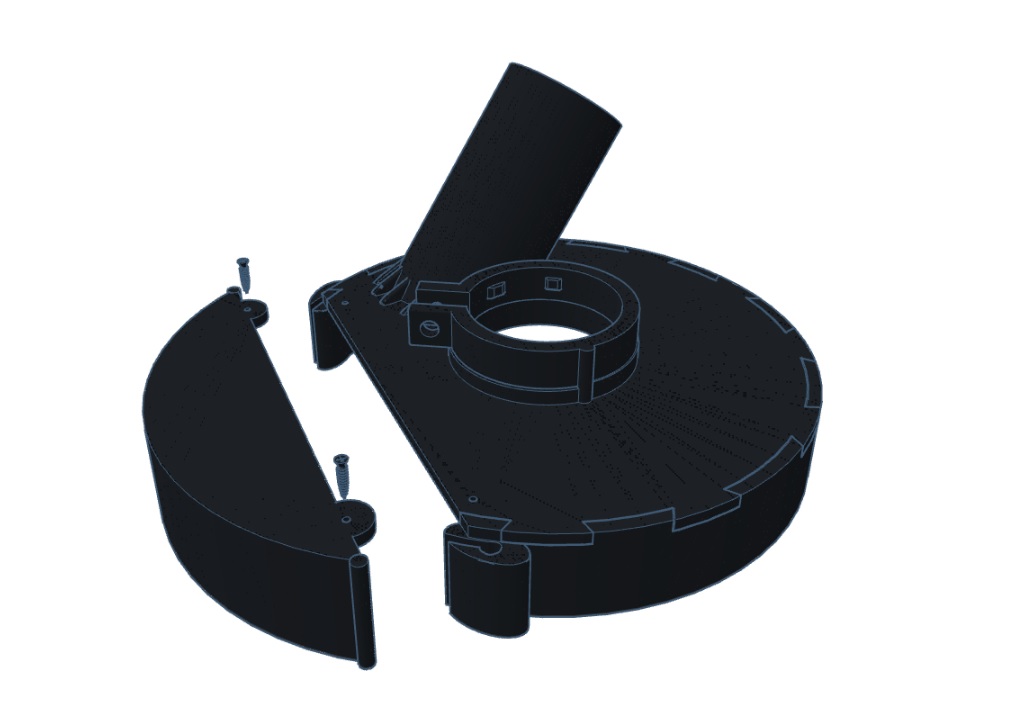

A less costly manufacturing method is to use a standard protective device. It only needs to be attached to the side cover and pipe. To make a side cover, you can take a piece of galvanized steel and then proceed as follows:

- Cut strips 15 mm wide and 30 mm long from galvanized steel to make corners. Then bend them at right angles in the middle.

- In the lateral open part of the casing, drill holes with a diameter less than the thickness of the screws. Fasten the previously made corners through these holes.

- Cut out the side cover from the zinc plating.

- In it, closer to the edge, drill a hole for the branch pipe.

- The branch pipe can be made by rolling a sheet blank into a pipe. The edges can be fixed together with self-tapping screws or clamps.

- One edge of the nozzle must be cut in several places. And unbend these sectors.

- Insert the pipe into the cut-out cover and secure with self-tapping screws.

- Also screw the resulting structure to the corners with self-tapping screws.

- Fix the structure to the grinder.

- The connection to the vacuum cleaner is made by means of a corrugated hose. For a secure connection, you must use a clamp.

That's it, the angle grinder with a casing for the vacuum cleaner is ready to work.

Plastic canister model

After changing the oil or pouring antifreeze into the car, plastic canisters always remain in the garage. Thick walls and ebb in the corners allow you to keep the shape well without deforming. In addition, the size of the canister neck is almost the same as the hose of the vacuum cleaner.

Before cutting, you should decide on such a parameter as the immersion depth of the cutting disc. The installed dust extractor will prevent immersion. You can take the standard casing as a basis.

- First, apply a marker with a marker.

- Use a sharp construction knife to cut holes and cut off unnecessary parts. The holes for the grinder are recommended to be made on both sides. This is necessary in case it becomes necessary to change the direction of rotation.

- The hose is connected to the neck with a clamp.

- The dust extractor is fastened to the angle grinder with a clamp with an adapter ring.

- To close the unused mounting hole, you need to cut out a circle with a larger diameter and fasten it with self-tapping screws.

Tile cutter attachment

To cut ceramic tiles requires constant supervision. And the exhaust hood for the grinder closes the view completely. A transparent material is needed to make the casing.

To cut ceramic tiles requires constant supervision. And the exhaust hood for the grinder closes the view completely. A transparent material is needed to make the casing.

A 5-liter transparent bottle of bottled water is suitable as a blank. The nozzle of the vacuum cleaner enters the neck. A hole for the fit is cut with a stationery knife.

The bottom of the bottle is cut off so that the disc is exposed to the required height. The structure is fixed to the angle grinder with a clamp or screws. The large volume of the bottle does not allow dust to scatter, and the casing simultaneously acts as a dust collector.

The angle grinder is considered a multifunctional tool. In addition to many advantages, it has one significant disadvantage - it generates a large amount of dust during cutting and grinding of the material. To free themselves from long-term cleaning of the room after working with a grinder, craftsmen use devices equipped with a vacuum cleaner. The main element of any of these devices is the protective cover. It can be easily matched to any angle grinder model. The main thing is to be able to correctly attach the part to the exhaust system.

Installation instructions

To improve the efficiency of the protective cover, it must be correctly positioned and secured. The installation process is simple, even a novice wizard can handle it. Connecting the nozzle is as follows:

- first, you should close the standard grinder casing with an aerodynamic one, for this it is resting on the thrust bearing;

- then the casing is clamped onto the studs, it is fixed with screws, ensuring symmetry to the disk;

- a vacuum cleaner hose is connected to the exhaust pipe, it should freely pass into the hole in the casing;

- the installation process is completed with a control check of the fasteners, since work can only be started when the casing is securely fixed.

To learn how to make a dust extraction casing for a grinder with your own hands, see the next video.

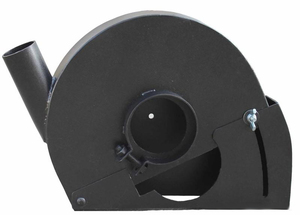

Types of casings

In shops selling electric tools, you can find a protective casing for angle grinders with a dust extraction. Most manufacturers make them for semi-professional and professional equipment of well-known companies.

The purpose of this additional equipment is to efficiently remove dust from the processing area by means of the grinder itself. Fastening is carried out to regular places using a clamp.

The exhaust outlet is the same size as the suction hose of the vacuum cleaner. Outside diameter - 65 mm. The hole diameter is 59 mm. The dimensions of the dust extractor correspond to the circle to be installed. For example, the Messer 10-40-441 casing is designed for a circle with a diameter of 180 mm. And its dimensions are 245x230x100 mm.

The big disadvantage of purchased equipment is the high price. So, the minimum cost for an exhaust hood for a grinder for a vacuum cleaner fluctuates around 3,000 rubles, which is comparable to the cost of a budget angle grinder.