Features of the device, work, difference from gasoline

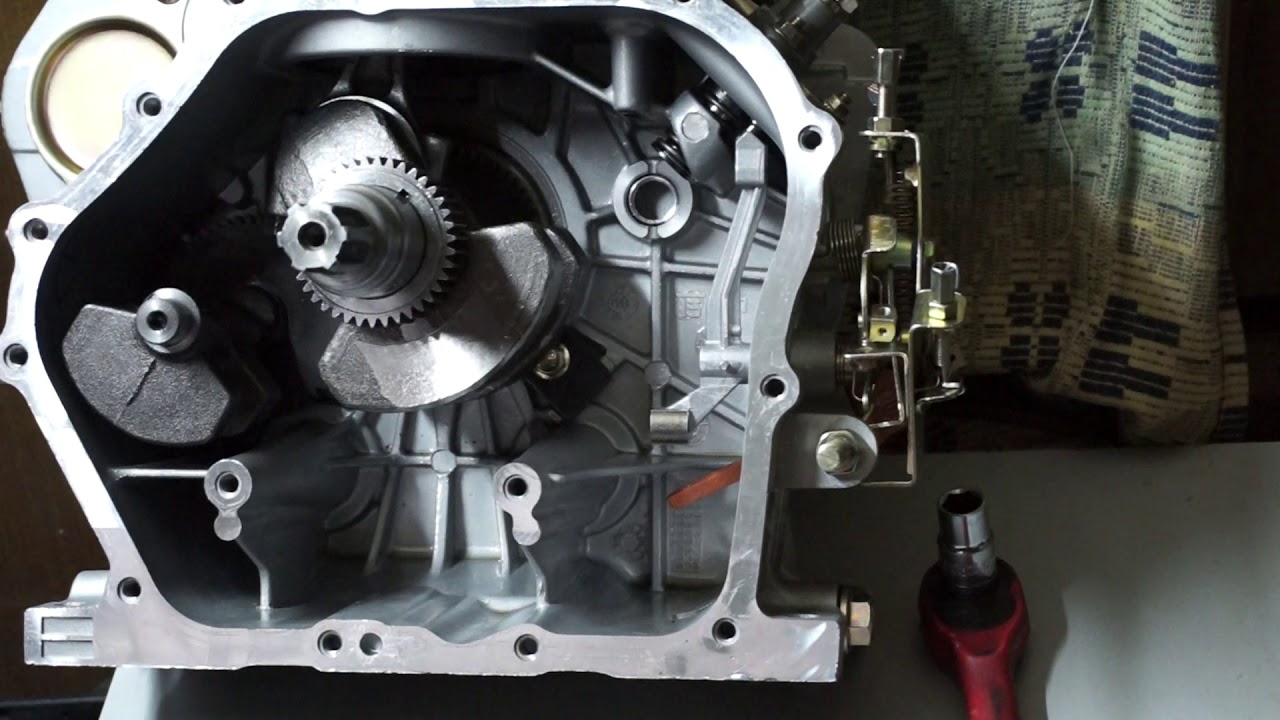

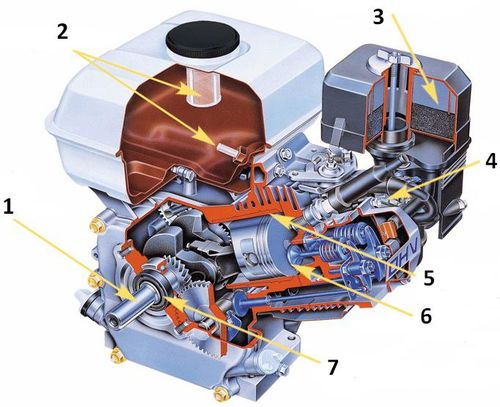

The design does not differ much from gasoline counterparts, but it has its own characteristics. On small agricultural machinery, the simplest models are used, unpretentious in work and more high-torque, since they give out high power even at low speeds. The main parts of the motor:

Block and engine head. The most massive parts on which all the main parts are fixed. They are made of cast iron, since other alloys will not last long under high loads. The crank mechanism is almost indistinguishable from standard solutions. The difference is in greater weight and strength, since during operation the compression ratio in the combustion chamber ranges from 19 to 24 units. In petrol versions, the indicators are from 9 to 14. Reinforced valves for air intake and exhaust gases. Fuel is supplied by a nozzle that evenly sprays diesel fuel throughout the volume. There is no spark plug in the design. The combustible mixture is ignited by the high pressure. An explosion occurs, so the parts are massive and strong to withstand the stress. The fuel pump must generate high spray pressure. This ensures even combustion of the mixture.

The air filter cleans the air from dust, this is important for a walk-behind tractor, since it usually works in dirty conditions. If you do not change it in time, the wear of the parts will be much higher.

The task of the fuel filter is to remove all impurities and water from the diesel fuel, otherwise the nozzle will clog and you will have to clean or even change it.

For all the simplicity of the design, the principle of its operation is much more complicated. If in gasoline versions the mixture is formed in the intake manifold, then fed into the cylinder and ignited with a candle, then in diesel versions, the process is completely different:

- The same four-stroke scheme is used as in multi-cylinder car diesels. This ensures smooth operation, stable rpm and reduces vibration.

- Air is fed into the cylinder. As it contracts and the pressure increases, the temperature inside rises to 800 degrees.

- At the very end of the stroke, diesel fuel is supplied from the nozzle under high pressure. It is sprayed into tiny droplets, fills most of the combustion chamber, and ignites spontaneously almost instantly.

- The mixture is prepared in a short time. To make it burn quickly and without residue, the nozzle injects diesel fuel under pressure, which is several times greater than the air pressure in the cylinder. The space is limited by the cylinder walls at the sides and top, the piston crown at the bottom.

- At the moment of ignition, the pressure inside is very high. Therefore, the diesel runs louder and harder than the gasoline counterparts. But the difference between the two options is minimized and does not affect the comfort of work.

Due to this principle of operation, the motor delivers high power even with a lean mixture. And this helps to save fuel and allows you to work normally even at low speeds. Unlike the petrol version, it is not necessary to add revs when the load increases. The system can be called simple and reliable; with proper care, the resource is at least 3,000 operating hours.

How to remove the engine from the walk-behind tractor

To dismantle the power plant, the walk-behind tractor is placed on a flat surface and cleaned of dirt. The protective shield is removed, the accelerator cable is disconnected from the carburetor plate. Then loosen the bolts that secure the attachment bracket and loosen the drive belt stop pins.The 4 screws fixing the motor are unscrewed. The motor turns to the left.

The belt is removed from the crankshaft pulley. After that, the power plant is considered disconnected from the chassis. If necessary, you can replace the fasteners. In some models, the fenders are pre-removed to facilitate access to the bolts that fix the motor to agricultural equipment.

Installing the engine

When installing the engine on a walk-behind tractor, you need to be careful and follow the sequence of actions. Errors will lead to a decrease in the service life of the unit, rapid wear of parts and cause malfunctions.

The following conditions must be met:

- correctly transfer the torque from the power plant to the transmission;

- accurately connect the motor to the gearbox or frame of the walk-behind tractor;

There are special installation kits that can help you avoid mistakes when assembling equipment. Such kits consist of the following parts:

- Adapter plate. It is inserted between the engine and the gearbox.

- Hubs. Installed on the engine crankshaft.

- Fasteners. Provide secure fixation of the power plant.

When using such a kit, a sequence of two steps is required - fix the motor to the mounting plate and slide the pulley onto the crankshaft. With the help of such a set, it is easy to install the engine on walk-behind tractors, both domestic and foreign.

Motor problems

Engines running on different types of fuel (gasoline or diesel) have a different resource. For engines using diesel fuel, it is much larger, but it is gasoline units that are popular, due to the lower cost and ease of operation and repair.

Usually, of all faults, two main types can be distinguished:

- startup problems;

- problems with smooth operation.

Fuel system problems

The first step is to check the spark plugs. If they are dry, it may mean that gasoline is not getting to the engine. The main reasons will be: lack of fuel, the supply valve was closed, the hole in the tank plug is clogged, unnecessary objects get into the fuel system.

For service you should:

- refuel the walk-behind tractor;

- unscrew the fuel supply valve;

- clean the gas tank cap;

- remove all gasoline from the tank, after removing the fuel cock, and wash it with clean fuel. Then purge the jets in the carburetor using the fuel pump.

When the candles are still wet

The following faults are distinguished:

- Carbon deposits on spark plugs. They should be cleaned with a rough surface and washed.

- The gap between the electrodes is increased or decreased. You need to adjust it to the required size.

- The insulation of the wiring is damaged. It is usually replaced with a new one.

- There was a short circuit of the ground to the STOP button.

- The starter of the ignition system is faulty.

The rubber seals on the carburetor may also loosen, causing air to be sucked in. It is necessary to tighten the bolts, spark plugs and inspect the gaskets between the cylinder and the plug head.

Another option for poor engine starting is that the carburetor choke does not close completely.

The candles in the walk-behind tractor should not be wet

If the compression is broken, it will also be difficult to start the engine. The reasons are: carbon deposits on the valves, the inlet valve is deformed, or the piston rings are already worn out.

Malfunctions in the course of operation usually manifest themselves when the nodal connections of the engine, undergoing overloads, fail, which leads to malfunctions.

When the engine began to pick up and reduce speed by itself, this is possible by loosening the traction and fastening the levers. To eliminate it, simply adjust the control drive.

If the engine loses power, it means that it is overheated.In this case, the motor can jam, which happens when the oil level in the crankcase is low, a nadir forms on the connecting rod head, or the oil sprinkler has become unusable.

Selection rules

When buying equipment, first of all, you should decide on its class and power. The larger the area of the land plot to be processed, the greater the load on the walk-behind tractor. This means that the heavier and more powerful unit will be required.

You also need to consider the width and depth of plowing. Even for units of the same class, they can be very different. The wider the ripping strip, the faster the device will cover the required area.

If you do not want to limit yourself to simple loosening, then you definitely need to purchase equipment equipped with a power take-off shaft. This makes it truly versatile.

You also need to decide on the transmission. For small areas that will not create a serious load on the device, a belt is also suitable. For more complex tasks, it is better to choose a chain or gear.

Expert opinion

Vasily Kuznetsov

If possible, it is better to check the equipment (or a similar model) right in the store. This will allow you to see how it works, as well as identify shortcomings and defects in advance.

Before buying, be sure to inspect the unit for build quality. Everything should be well connected to each other, there should be no backlash, loose bolts and similar problems.

Specifications

The motor or engine for the walk-behind tractor is the main unit. All agricultural work is done in our time with the help of small and large mechanization, manual labor is unproductive.

Gasoline engines are very popular, their advantage is as follows:

- reliability;

- low cost;

- easy to repair and set up;

- not as noisy as diesel units.

The first units are of excellent quality and reliability, but prices are usually above average. Chinese engines are inexpensive, but reliable enough, although their quality sometimes leaves much to be desired. The most popular engines from the Land of the Rising Sun are Honda and Subaru. Of the Chinese engines, Dinking, Lifan and Lianlong have proven themselves best.

Honda

Engines of this corporation, designed for motoblocks, are in demand on all five continents. Units with a volume of 12.5 to 25.2 cm³ are sold in millions of units annually (4 million per year). These engines have low power (7 HP)

Most often in the Russian market you can find such series as:

- GX - engines for general needs;

- GP - household engines;

- GC - universal power plants;

- IGX - complex motors equipped with electronic units; they are able to solve complex problems, including the processing of "heavy" soils.

The engines are compact, robust, lightweight and suitable for agricultural machinery of a wide variety of formats. They are usually air-cooled, have a vertical shaft layout (sometimes horizontal) and are often supplied with a gearbox.

The engines are installed on devices such as:

- motor pumps;

- generators;

- walk-behind tractors;

- lawn mowers.

Subaru

The engines of this company are made at the level of world quality standards. In total, there are three types of four-stroke power units from this manufacturer, namely:

- EY;

- EH;

- EX.

The first two types are similar, differ only in the valve arrangement.

Dinking

Very good motors, because they are not inferior in quality to Japanese ones. They are compact and reliable. The company from the Middle Kingdom is actively expanding its product line. Due to their low value and good quality, the engines are in high demand.

Usually Dinking are four-stroke units that have good power and low gas consumption. The system has a complex of reliable filters, air cooling, which allows it to work for a long time without preventive maintenance.Variations in power - from 5.6 to 11.1 liters. with.

Lifan

Another engine from the Middle Kingdom, which is in good demand in Russia. This corporation is developing progressively, actively introducing various innovations. All motors are four-stroke with a two-valve drive (four-valve models are rare). All cooling systems on the units are air-cooled.

Engines can be started manually or with a starter. Power plant power ranges from 2 to 14 horsepower.

Lianlong

This is another manufacturer from China. All products comply with the standards adopted in the European Union. The enterprise is also actively working for the Chinese defense industry, therefore it has modern technologies. Buying engines from Lianlong is the right decision, because they are reliable. Many models were designed with the participation of Japanese specialists.

Attention should be paid to the following distinctive qualities:

- fuel containers are well sealed;

- cast iron frame increases engine resource;

- carburetor adjustment is convenient;

- the unit is distinguished by the simplicity of the device, while the price is in the middle segment.

Briggs & Stratton

This is a company from the States that has proven itself well. The units are trouble-free, they work for a long time without preventive maintenance. The I / C series is especially famous. The motors are distinguished by low fuel consumption, good performance, they can be found on almost any garden equipment.

Vanguard

These motors are popular among the owners of large agricultural land. The equipment operating on such power plants belongs to the professional class, meets all international standards, while the noise background and vibration level during operation are minimal.

Adjustment of valves

To adjust the valves on walk-behind tractors, you need to prepare tools:

- spanners;

- screwdrivers;

- a stylus or razor blade.

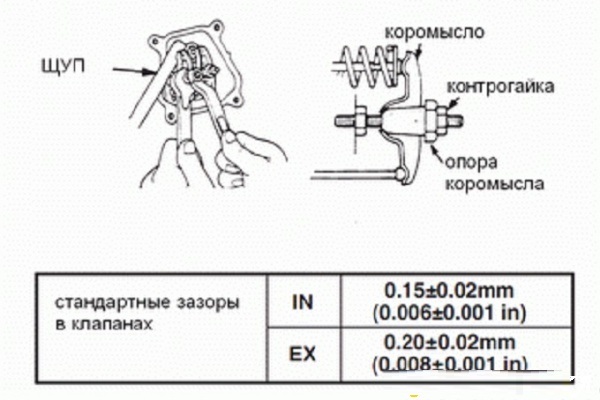

Some engine types may require other additional tools. Adjusting the valves means setting the optimal valve clearances for the engines of walk-behind tractors. In the instructions for the unit, the size of the gap is indicated. The device of the engines on each model of the unit is different. But in general, the sequence of actions is as follows:

- the engine cover is removed;

- the valve cover is removed;

- adjustment is made;

- the valve box cover is installed;

- the casing is installed.

The valve is easy to find under the valve cover. Check the size of the gap with a feeler gauge. Most often, the clearance of the intake valves is 0.15 mm, the exhaust valve is 0.2 mm. With the correct clearance, the dipstick fits freely under the valve. If so, then everything is fine. To adjust, loosen the nuts and insert the dipstick again. Adjust the gap, tighten the nut. Check the clearances again. If results are normal, install the valve cover and shroud.

The valve is easy to find under the valve cover. Check the size of the gap with a feeler gauge. Most often, the clearance of the intake valves is 0.15 mm, the exhaust valve is 0.2 mm. With the correct clearance, the dipstick fits freely under the valve. If so, then everything is fine. To adjust, loosen the nuts and insert the dipstick again. Adjust the gap, tighten the nut. Check the clearances again. If results are normal, install the valve cover and shroud.

Before making adjustments, it is recommended to let the engine run and then cool it down. The valves on the Agro walk-behind tractor are adjusted in a slightly different way.

Procedure:

- warm up and then cool the engine a little;

- remove the oil bath from the air filter;

- remove the flywheel cover;

- align the “0” mark on the flywheel with the mark on the cylinder;

- the valve box cover is removed;

- clearances are checked;

- clearances are adjusted;

- all nuts are tightened;

- the cover and casing are installed in their places.

Roughly the same scheme is used to adjust the Patriot and Agros walk-behind tractors. For the Cascade unit, proceed as follows:

- remove the cover;

- remove the valve cover;

- turn the flywheel until the intake valve is pressed;

- measure and adjust valves;

- put the cover with the casing in place.

The same method can be used when adjusting valves on Ural and Centaur units.

Varieties

Depending on the possibility of connecting attachments, the technique is:

Depending on the weight and power, the units are divided into:

- ultralight;

- lungs;

- medium;

- heavy.

Ultra-light equipment includes small and not heavy (up to 20-25 kg) devices. They are ideal for processing summer cottages with an area of 10-15 acres. The main advantage of this type of equipment is its compactness, which facilitates storage and transportation of the unit. Also, ultra-light units are very maneuverable, easy to work with. They are well managed.

Lungs have a relatively low weight (up to 50 kg) and are usually no more powerful than 5 l / s. They are capable of performing a small amount of work with not very intense loads. Overheat quickly enough. Because of this, they are most suitable for summer cottages, small household farms.

Expert opinion

Vasily Kuznetsov

Due to its power, the result of the work of a light and ultra-light machine is close to the result of manual soil cultivation with a shovel.

Medium diesel motoblocks have a greater weight (up to 100 kg) and an engine with a capacity of up to 8 l / s. Often their design provides for reverse gear, the ability to shift gears. Designed for processing large land plots. They cope well with loads, they loosen solid soil well.

Usually, a power take-off shaft is installed on medium-sized devices in the category of equipment, which allows the use of various attachments. On the lungs, it is most often absent.

In fact, they are a two-wheeled mini tractor. Typically, the power of such equipment is 10 l / s or more, and the weight exceeds 100 kg. They have good performance, are quite hardy, all models can be used with attachments. Thanks to this, they are well suited for the processing of large land plots, including professional ones, in farms.

Depending on the type of engine cooling, walk-behind tractors can be distinguished with:

The first type has special ribs on the cylinder, onto which air is forcibly injected. This is a simple design that rarely breaks down and costs less. In the latter, the cooling system is similar to that of an automobile and uses antifreeze. They are more expensive, but much less likely to overheat.

What kind of cooling does your walk-behind tractor have?

Air

The technique can be launched:

- manually;

- with a starter.

The unit transmission can be:

- belt;

- chain;

- gear.

The manual version is less convenient, but somewhat cheaper.

Belt transmission is the cheapest and easiest to maintain. However, under severe loads, it slips, the belt stretches over time.

The chain transmission is more reliable. The most effective and reliable gear is considered. It is installed on heavy machines that are subject to significant stress.

The wheels of the unit can be:

- pneumatic - the traditional version with air-inflated tires;

- monolithic - instead of pneumatic tires, they are monolithic, without air inside.

The first option is easier, but has slightly worse cross-country ability. The second goes better on "virgin soil", but has a greater weight.