Snow blower won't start - how to solve the problem?

In order to repair a snow blower in the event that its engine does not start, you need to determine the possible causes of the breakdown.

There may be several of them:

- gasoline remaining in the fuel tank - if in the spring, after the last snow removal from the fuel tank of the snow blower, all fuel residues were not drained, then after approximately 9 months of rest of the car, the fuel remaining in its tank will completely lose the properties required for engine operation. The octane number of gasoline will drop sharply and all useful additives will disappear from its composition. Such gasoline will not be able to start the engine of the snow blower, therefore, if the equipment does not start, the first thing to do is to inspect the fuel tank. The remaining fuel will need to be drained, and then refueled with fresh gasoline;

- throttle flap - when starting the snow blower, many people forget to move the throttle lever to the position required for operation. If the engine is started at the same time, it will work under very high loads, not receiving the required air. Over time, this will lead to damage to the internal combustion engine. The only solution to this problem is to constantly monitor the position of the lever;

- poor quality engine oil - it is necessary for the constant lubrication of moving engine parts. Oil all the time lends itself to increased friction, due to which it loses its useful properties. The use of low-quality oil completely leads to the lack of starting the internal combustion engine. In order to prevent damage to the motor, you need to use only specialized oil that has all the necessary components and additives;

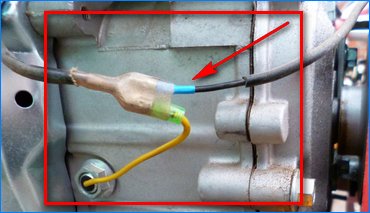

- problems with the ignition system - if the engine of the snow blower does not start, then the reason for this may be poor wiring contacts. It is possible that the wires broke due to a shock or began to melt as a result of a short circuit. Another reason is the wrong magneto coil clearance. Due to the incorrect position, the coil will not be able to deliver a spark, as a result of which the fuel will not ignite. You also need to check the ignition spark - it is possible that oil has filled it, as a result of which carbon deposits have formed on its upper part. Cleaning the candle or replacing it completely will help solve this problem;

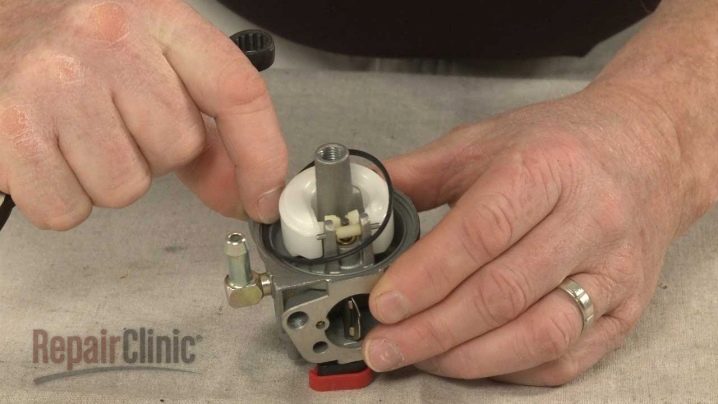

- breakdown of the carburetor - this important unit of the snow blower is responsible for preparing and supplying fuel to the engine cylinder. If you regularly use low-quality fuel to refuel the car, this will lead to a malfunction of the carburetor. In this case, you will need to clean the mechanism from carbon deposits and dust. To do this, the carburetor must be disassembled and washed. Once it is dry, it will need to be reinstalled on the snow blower. Next, you need to adjust the carburetor. In this case, it is necessary to act strictly according to the algorithm specified in the operating instructions. If the carburetor has been set correctly, the snowplow engine will start almost immediately.

What kind of breakdowns can cause engine failure?

There are other breakdowns that make it impossible to start the engine in winter. Among them, the following stand out:

- gasoline that was not drained from the tank for the summer;

- the throttle valve is in the wrong position;

- cheap engine oil is used;

- the carburetor does not work;

- problem with the ignition system.

Gasoline that remains in the fuel tank after several months of inactivity is no longer usable and therefore the snow blower will not work on it. The octane number drops, all the necessary additives evaporate.The problem is solved very simply: you need to change the fuel, for which you drain the old one and fill in the new one.

Each starting instruction indicates in which position the throttle valve should be. If this condition is not met by the user, then it is also impossible to get work from the motor, since there is no required air flow. Even if the equipment starts, the engine breakdown is not far off, since it begins to experience a load several times higher.

Poor quality oil is also the reason that the engine not only does not start, but can also fail. As a result, expensive repairs will be required in the future, since the main elements work with high frictional force, and without lubrication they simply wear off.

If none of the above is observed, then you should check the contacts. A break in the wiring or an incorrect gap at the coil leads to the lack of the necessary spark, respectively, the ignition of the combustible mixture also does not occur.

We must not forget about the carburetor - one of the most important components of the design of a snow blower. He is responsible for the supply and preparation of the combustible mixture. It is regularly required to clean the unit from carbon deposits, to prevent dust accumulation in it.

For information on how to properly start the snow blower, see below.

How to start a snow blower? For many, the question will seem strange, because there is nothing easier than following the instructions that come with the purchased equipment. Buyers do exactly the opposite. First they try to start the car, break it down, then they fix it. To avoid such incidents, let's figure out how to start a snow blower.

Subtleties of repair

Let's take a look at the DIY repair process using the Craftsman snow blower as an example. If his starter has failed and he needs to be replaced, then the old cord is cut off first. The knot inside the starter is untied, after which the entire mechanism must be rotated for seven full revolutions against the sun. A screwdriver should be inserted between the ribs of the mechanism so that it does not start a return movement. Next, you need to stick a new cord into the hole intended for it and tie it tightly. Then carefully remove the screwdriver, without letting go of the cord, but holding it. The winding of the cord onto the reel will happen by itself, with the help of the return movement of the starter mechanism.

Sometimes snow blowers may experience abnormal vibration. Then you should make sure that everything is in order with the engine mount. Most likely, they need additional tension. Also, sometimes there are problems with the gearbox. This means that you will need to replace the gear located inside the mechanism. This gear can wear out and cause problems and you will not know how to start your snow blower.

For the time being, the equipment worked properly, and now it has begun

malfunction. What could be the reason, and will it be possible to return it to

operation? - Only specialists can answer all these questions.

If the equipment does not start, first of all it is worth evaluating everything

the simplest possibilities of its malfunction. So, for example, it is necessary

make sure that there is fuel in the tank, or that the equipment is connected to

power supply. Along the way, it is worth remembering: how long has the equipment been carried out,

after all, clogged fuel filters or an old plug can create just such

Problems. In this case, it will be possible to return the equipment to operation immediately after

how you carry out all maintenance work that

probably should have been done earlier. If you do not have enough time for this

skills, or you do not want to do such work yourself - you can

contact our workshop and receive such services in a full range.

If all these points are normal, but the technique is still

refuses to work normally - we are talking about a more complex breakdown, diagnose

and which must be corrected already in a professional workshop. So,

problems can arise with piston rings, due to which compression falls

engine. The carburetor may also be faulty - it often turns out

so that it needs to be cleaned, gaskets changed, and so on, which is again better

to do in the workshop. Starter, engine and many other elements can create

in case of damage, it is such a problem in operation, and it is a competent

a specialist will be able to quickly determine what kind of problem is

deal this time.

When contacting our service center with such a problem, you

you are guaranteed to receive fast service, and only

professionals. All services will be provided with a guarantee, and they will cost

not expensive at all. In addition, in any case, we will advise you and help

You will avoid such technical problems later on.

Correct operation and maintenance of the snow blower is a prerequisite for efficient operation and a long service life. When buying new equipment, first of all, you should read the operating instructions and prepare for the first use, only after that you can start working.

For correct operation, as well as understanding how to maintain the equipment, you need to understand at least in general terms what the snow blower is made of. The main and most expensive part is engine

... It can be electric or gasoline. The first option does not require special attention, so this article will focus on liquid fuel options.

The second important element is screw

... It is he who collects the snow and, with the help of a special branch pipe, throws it aside. The auger can be metal with shear bolts or plastic. The advantage of a metal auger is that in the event of a breakdown, the bolts are simply replaced with new ones. They are usually not expensive. The second option itself is cheaper, but in the event of a breakdown, the entire auger changes.

The principle of operation of the snow blower is very simple: the engine drives the auger, which shovels the snow and throws it aside.

In fact, the job of a snow blower is to lift the snow from the surface to be cleaned and throw it aside with a powerful jet, where it will not interfere.

Advice! The snow blower must be serviced when it is first put into operation, as well as in preparation for conservation for the summer and before the start of a new season.

Launch system malfunctions

If, when checking, the candles turned out to be wet, but the engine does not start, then it will be much more difficult to detect the malfunction:

- may malfunction the ignition system;

- due to depressurization of the connections, air leaks may appear;

- the air damper in the carburetor may be under-closed;

- breakdown of the carburetor.

Failure of the ignition system is an unpleasant moment, but you should not panic and immediately call a specialist. First turn out and inspect the spark plug. If you find carbon deposits on it, clean it with emery, rinse it with gasoline and let it dry completely. Very often, after such a procedure, the motor starts to work normally.

If the motor still won't start and you feel skilled enough, check the electrode gap. The required value is indicated in the manufacturer's instructions, but due to constant vibration during operation, it may change, and the walk-behind tractor may stall on the go. Adjust the gap to the desired value by bending the side electrode.

The rest of the problems of the ignition system cannot be dealt with on the fly. If the insulators of the candles or electrical wiring are burnt out, then they need to be replaced. You can also close the STOP button to ground, and until the short circuit is removed, the engine will not start.Also, the reason that the engine does not start can be a violation of contacts in the angles of the spark plugs or a violation of the gap between the magnetic shoe and the starter. Finally, the starter itself may be damaged and will have to be replaced.

Another common reason why the motor of the walk-behind tractor “chokes” or stalls under load is air leaks. If this is due to the leakage of the carburetor connections, then you must first tighten the spark plugs and tighten the mounting bolts, and then check and, if necessary, replace the gaskets. The engine will "gag" even when the carburetor choke is open. To fix the problem, it needs to be adjusted, making sure that it walks freely without distortions and jamming.

If the walk-behind tractor does not gain power normally, it is worth checking its muffler. Over time, the products of fuel combustion clog the muffler, forming a thick layer of carbon on its walls, so it must be periodically cleaned. To do this, the muffler must be removed by plugging the outlet with a clean rag, rinsed first in gasoline, and then by washing with detergents to remove carbon deposits, and finally to dry with a hairdryer.

Sometimes the walk-behind tractor stalls during operation and from elementary overheating. If, with the throttle fully open, you press the throttle and the engine loses speed instead of accelerating, then this is a clear sign of overheating. The walk-behind tractor must be stopped and allowed to cool completely, and then started again.

This is not the whole list of reasons why your still recently perfectly serviceable walk-behind tractor can stall even under light load. Almost all units of the walk-behind tractor are subjected to significant loads during operation, therefore minor malfunctions and breakdowns are not uncommon. Therefore, upon discovering that something is wrong with the walk-behind tractor: extraneous noise, twitching, strong vibration, etc. - stop the engine immediately. And only after the motor has cooled down, you can start troubleshooting. But this is already a topic for another conversation.

How to start a snow blower - procedure for vehicles with electric and manual starter

Most of the breakdowns of snowplowing equipment are associated with its improper use. Especially often snow blowers fail as a result of an illiterate start. A number of important mechanisms that are responsible for the smooth start of the engine and other components of the machine suffer from this.

In order to prevent premature breakdown of equipment, you need to turn it on correctly. If the snow blower is equipped with only an electric starter, then it is required to start it in the following order:

- First, you need to move the snow blower fuel valve lever to the "On" or "On" position;

- Then it is necessary to fix the cap from the high-voltage wire on the top of the spark plug motionlessly;

- You will then need to move the throttle lever to the Closed or Choke position. To do this, you need to move it all the way to the right;

- Next, you need to move the starting switch lever to the "On" or "Enabled" position. After that, it is necessary to press the pump several times for manual pumping of fuel;

- Then you need to press the starter button located on the snow blower body and hold it until the engine starts. It is not recommended to keep your finger on the button for more than 10 seconds. If the engine does not start, it is better to wait a few minutes and press the starter button again;

- Once the snow blower motor starts, you will need to move the throttle lever to the "Run" or "Open" position. After that, it is necessary to give the engine some time to warm up. After 5-7 minutes, you can start cleaning the snow.

To start a snow blower with a manual starter, proceed as follows:

- The first step is to check the amount of engine oil.Then you need to move the locking levers of the auger and wheels to the fully lowered position;

- Then you need to move the fuel feed lever to the "On" or "Enabled" position;

- Next, you need to motionlessly fix the cap of the high-voltage wire to the spark plug;

- After that, the throttle lever must be moved to the “Closed” or Choke position;

- The start switch will need to be moved to the "On" or "On" position;

- Then you need to press the manual fuel pumping button 3-5 times, and slowly pull the starter rope towards yourself until you feel resistance. After that, you need to pull out the cable with a sharp jerk so that the snow blower engine starts;

- You will then need to move the throttle lever to the “On” or “Open” position and allow the engine time to warm up.

Repair sequence

1. Check the integrity of the wire going from the (On / OFF) button on the walk-behind tractor control levers to the spark plug.  Checking the integrity of the wire

Checking the integrity of the wire

2. Remove the spark plug and clean the contact with sandpaper. We check the gap between the contacts.  Unscrew the spark plug

Unscrew the spark plug

Having unscrewed the candle, I found carbon deposits - apparently the quality of gasoline is not very good.

3. We screw the candle back.  The walk-behind tractor does not start - we purge the fuel supply system

The walk-behind tractor does not start - we purge the fuel supply system

A murmur was heard in the tank. After this operation, the walk-behind tractor sneezed and started up.

I think the fuel filter had to be flushed as well. there may have been a blockage in it that was blocking the access of a sufficient amount of fuel to the combustion chamber. In any case, at the moment the walk-behind tractor has started up and is working, and I hope you can also start the walk-behind tractor, if it does not start. ...

The easiest ways to revive the walk-behind tractor:

This problem can occur with both old and new equipment. In this case, you will need to troubleshoot the motor block engine.

One of the possible reasons is the absence of a spark between the electrodes or its breakdown (breakdown). In this case, it is necessary to replace the spark plug with a new one.

If there is a spark but the engine will not start, check the spark plug insulation. If the candle is wet, the tip (or rather its insulator) may be faulty. Remove the shield and replace with a new tip.

Frequent breakdown of the walk-behind tractor - pops and the release of flame from the muffler (while the engine does not start). Deformation of the flywheel key may cause this. Replace it by disassembling the starter ratchet. Open the clutch housing, remove the flywheel, remove the old key, install a new one and tighten the housing.

If the starter cord is pulled out without force when starting, the cylinder seal may be worn out or the gasket between the filter and carburetor may be incorrectly installed. To eliminate, replace the seals and check that they are properly secured.

The walk-behind tractor also stalls after winter or after a long downtime. In this case, no gasoline flows into the carburetor. The cause of the malfunction is the locking of the locking needle. Sediments and tarry formations accumulate around it and prevent it from opening when the engine is started.

Poor quality or inappropriate gasoline can cause engine malfunction. In this case, the spark gets wet and requires replacement of the tip. If you smell an unusual fuel smell, replace it. If the walk-behind tractor does not start well and stalls?

After starting, the walk-behind tractor periodically turns off with the appearance of pops. Make sure the candle is dry. If a conductive substance appears on it, this can cause the absence of a spark between the electrodes. The plug can be replaced with a new one or the old one can be cleaned. To do this, it is washed, blown and ignited.

The engine started for a few seconds and then stalled again. Check the sump for patency. If the tap is clogged, it must be blown out and cleaned (using gasoline).Water can also enter the fuel. In this case, it must be drained and filled with a new one.

Preparation for conservation and after its completion

Preparing your snow blower for warm storage involves a number of procedures.

Long service life and personal safety while cleaning requires knowledge of how to use the device on different surfaces and how to remove snow in different conditions.

Cleaning from flat surfaces

eg asphalt, is carried out at the minimum auger height. If uneven surface

- not tamped crushed stone, then you should set the height equal to the size of the stone.

When working on slopes

it is worth remembering that a slope of 5 degrees leads to the fact that the technique slides down a little, and with a slope of more than 20 degrees, it can tip over to the side. Therefore, in the presence of a slope, cleaning is carried out up and down along its surface.

Fresh thin layer of snow

If the thickness of the cover does not exceed half the auger, and the snow has fallen recently, then the self-propelled model can be cleaned at maximum speed

... In the case of a drive, the operator should simply select the optimal travel speed, but not more than 5 km / h, since otherwise the range of snow throwing will decrease, and you can slip on the ice if it is hidden under the snow.

Advice! The best option for turning the chute is 30-40 degrees. This makes it possible to increase the throwing distance of the snow in comparison with the right angle of the turn.

Fresh deep snow

If the snow is deep, but also fell recently, that is, it did not have time to freeze and pack up, then the speed of movement should be chosen small. On a self-propelled version, it is best use second and first gear.

Deep fresh snow is removed in two stages:

- the top layer is removed;

- the remainder is removed.

Here is an important point: you need to remove 20-30 cm of snow (in length) so as not to trample the one that lies under it.

Self-propelled units can handle snow that can be up to 90 cm thick, manual units are designed for a thickness of no more than two auger diameters.

Caked snow

Removing wet and ice-covered snow is not much different from removing deep fresh snow, with the only difference that move very slowly

, and move forward less than 30 cm at a time. This is necessary in order to reduce the load on the gearbox. If there is an ice cover, the machine must be lifted above its surface and, as it were, thrown from above in order to crush the ice with a weight and finally grind it with an auger.

Advice! When working with wet snow, the auger should be thoroughly treated with WD-40 fluid.

When cleaning around your home, avoid places where bushes, rocks, curbs or other elevations may be hiding. Do not direct the gutter towards the house, as some models throw snow with such force that it can break a window.

Malfunctions of gasoline and diesel garden walk-behind tractors

A garden walk-behind tractor is a very useful thing in the household. With a good walk-behind tractor, work on personal plots goes much faster. But walk-behind tractors, like other household equipment, sometimes break down.

The most common malfunctions of garden motoblocks:

- the walk-behind tractor stalls under loads;

- the walk-behind tractor works intermittently;

- the walk-behind tractor smokes, stalls, the muffler makes unusual sounds;

- the walk-behind tractor will not start;

- the walk-behind tractor starts up, but quickly stalls;

- the walk-behind tractor stalls when heated.

Fault: the walk-behind tractor stalls under loads

If the walk-behind tractor functions normally for several minutes and then stalls, the reason usually lies in a fuel supply failure or problems in the ignition system.

To find out what is the reason for the malfunction of the walk-behind tractor, you must first check how the fuel is supplied:

- take out the candle and inspect - if it is dry, then there is not enough fuel;

- check if there is enough fuel in the gas tank of the walk-behind tractor;

- make sure that the fuel valve is open - a closed valve can be a simple reason that the walk-behind tractor stalls.

If the problem is a malfunction of the gasoline walk-behind tractor in the ignition system, it must be re-adjusted as follows:

- remove the cover protecting the ignition system;

- turn the engine flywheel until the contacts open in the magneto;

- using a feeler gauge, measure the distance from the anvil to the hammer;

- turn the flywheel to the maximum compression of the piston;

- turn the flywheel again until a knock appears, indicating the operation of the freewheel;

- turn the flywheel in the other direction so that its mark coincides with the mark on the walk-behind tractor;

- set the distance from the break contact to the cam at 0.3 mm;

- fix the cam with a screw that is located above the element;

- install the cover into the walk-behind tractor body.

If the adjustment is made correctly, the walk-behind tractor will not stall during operation.

Fault: the walk-behind tractor works in jerks, intermittently or at reduced power

If a walk-behind tractor on a gasoline or diesel engine began to work intermittently, you must immediately turn off the unit and start troubleshooting.

Continuing to work with a faulty walk-behind tractor means bringing it to more serious breakdowns.

What to do:

- if the engine of a gasoline walk-behind tractor makes return movements, it is necessary to flush the pump and fuel supply hoses and replace the fuel with a better one;

- when the walk-behind tractor works in jerks due to incomplete warming up of the engine, it is necessary to turn off the engine, let it cool completely, start and warm up for ten minutes;

- if the engine power has dropped, it is necessary to check and clean the filter system;

- if the ignition magneto is worn out, replace the part with a new one.

Fault: the walk-behind tractor smokes and stalls, the muffler makes unusual sounds

Possible causes of the malfunction:

- too much engine oil in the fuel;

- the ignition is incorrectly set;

- the fuel in the engine cylinder does not completely burn out.

Troubleshooting methods:

- if there is an excess of oil, drain the fuel, flush the fuel pump and hose system, add new fuel;

- check the correctness of the gap between the electrodes;

- if it becomes obvious that the fuel does not completely burn out, disassemble the piston system, rinse and dry the cylinder, adjust the carburetor correctly.

Fault: the walk-behind tractor starts up, but quickly stalls

Such a malfunction occurs if there are problems with the contacts. What to do:

- clean the candle;

- check the integrity of the wires;

- set the correct distance between the electrodes.

Fault: the walk-behind tractor stalls when heated

This problem occurs due to excess air entering the carburetor. With such a malfunction, the gas trigger should be squeezed halfway. After starting the engine, before starting work, it is necessary to gas well.

If you cannot cope with the malfunctions of the garden walk-behind tractor, the walk-behind tractor stalls, the walk-behind tractor does not start, contact the Alfa-Rost walk-behind tractor repair shop in Rostov-on-Don. We guarantee high-quality repair of gasoline motoblocks using original components that can always be found in our warehouse.

Engine maintenance and first start

When putting the motor into operation for the first time, pour gasoline and oil

... If there is oil from the factory, then it is not necessary to drain it, but after five hours of operation, you need to fill in a new one. After that, check the recoil starter rope: it should rotate easily and not jam.

To check the performance of the engine, you need to measure the compression: its normal value is from 9 to 12 atmospheres.

At the first start-up, the value is as low as possible, the reason for this may be piston rings that are not lapped in. The problem should go away by itself after 5 hours of operation, if this has not happened, then there is a defect in the motor, and it is best to return the equipment immediately under warranty.Low compression means that the engine is not capable of delivering full power.

To start the snowblower for the first time

, you need to carry out a series of consecutive actions.

- Fuel is pumped using a special button.

- The operating mode switch must be set to on.

- The carburetor lever for fuel supply must be moved to the position - open (to the right as far as it will go, the lever is lower).

- The upper one blocks the air flow, it also needs to be turned all the way, while the air supply will be stopped.

- The throttle lever is set to the maximum position.

- If the starter is manual, then you need to smoothly and firmly pull the starting cable. If electric, then you just need to press the desired button. If the engine does not start, the procedure must be repeated.

- After the engine has started, the air supply must be opened. For this, the upper lever is returned to its original position.

When the engine is running, it is not necessary to immediately remove the snow, it is important to check its operation. For this, the device is left in a wound state for 5 hours.

From time to time you need to listen to how it works: the revolutions should be the same.

Advice! You can check the engine by the noise: if it is monotonous, then everything is working properly. If there are interruptions or a metallic knock, then there is a defect, and the engine should be turned off immediately.

If everything is working properly, then the engine needs to be turned off, and when it cools down (after 2 hours), the compression can be measured. At a normal rate, the engine needs to be warmed up and the oil in the engine changed.

Snow removal equipment repair - unit repair methods

In various models of snow blowers, there may be other breakdowns associated with the design features of these snow blowers. For example, repairs to Craftsman snow blowers often focus on troubleshooting the outlet chute. In this case, the first thing to do is to make sure that the safety bolts and the worm gear are intact. To do this, you will need to dismantle and disassemble the gearbox of the unit. This is done in the following order:

- First, detach the bucket from the machine frame;

- Next, carefully pull out the gearbox;

- Then remove and check the "worm" which is located on the shaft. Most often it is cut off the mechanism;

- To fix the problem, buy a new "worm" and install it instead of the old part.

For Patriot snowblowers, one of the most common problems is the lack of starting the engine. In such cases, experts advise to immediately check the engine compression. If this indicator is within 6-8 atmospheres, then the problem can be eliminated by replacing the old starter cord. To do this, you need to act in this order:

- Remove the protective panels and unscrew the return mechanism;

- Cut off the old cord and untie the knot inside the starter box;

- Turn the mechanism 7 full turns counterclockwise and fix it with a screwdriver;

- Insert the new cord and tie it into a tight knot where the old cord was attached;

- Release the return mechanism and it will rewind the cord itself.

If this does not help, then you will have to buy a new engine for the snow blower.

Owners of Profi brand snowblowers often have to figure out why their unit is not moving forward. The reason for this may be hidden in the gearbox of the machine. To quickly fix the problem, it is necessary to disassemble the assembly and replace the damaged gear inside it.

Owners of Energoprom snow blowers often do not know what to do with excessive vibration of equipment motors. First of all, you will need to check the reliability of the support frames and mountings for the engine of the unit. It is often sufficient to simply tighten the fastening bolts tighter and the problem will disappear immediately.

First use on snow

The first snow removal with a snow blower should be carried out on a dry deck with a thickness not exceeding the diameter of the auger. Before starting cleaning, you should wait 2-3 minutes for the device to warm up. The next moment is direction of the gutter in the right direction

... There is an interesting nuance here: the snow is thrown forward twice as far as to the sides. After that, you can start the auger and begin work. The first time it is best to stop after 20 minutes to check the gearbox again. It should be lukewarm or cold. A high temperature is a sign of a defect. In this case, the work must be stopped and the equipment must be returned to the seller.

If the snow blower is working properly, the area can be completely cleared. After the end of the cleaning action, do not immediately turn off the engine and stop the auger. It is recommended to wait 3-5 minutes to allow them to dry. Then you can turn off the device.

Advice! Before you go to rest, you need to remove all the adhering snow, otherwise it may freeze up and cause problems the next time you start.

Design features

The device of all snow blowers, regardless of the engine and type of movement, is similar. In addition to the engine, which can be electric or gasoline, there is a bucket. This is a device inside which the auger shaft is fixed (if the machine is equipped with an auger). How wide the bucket is, determines how large an area the snow blower can cover in one pass. The auger is a metal shaft, plus screws attached to it. They are attached towards the center of the shaft, as they have to rake in snow.

The outlet pipe looks like a pipe, it throws out the snow mass at a distance of three meters. The pipe can be made of metal or plastic. As for the undercarriage, the snow blower can be on wheels or on tracks. An important part of the snow blower is the rotor, which is located inside, crushing the snow and directing it to be ejected towards the outlet.