Engine is jammed

This is a separate issue that can be encountered after downtime. The kick starter cord won't stretch, but don't despair, it's the carburetor. Minor blockages can cause the float valve needle to not fully close the valve and the fuel cock to open during standstill. Thus, during the time the gasoline filled the cylinder. First you need to turn off the tap, then unscrew the candle and, pulling the cord, drain the gasoline from the cylinder through the hole for the candle. Then you will have to disassemble the carburetor, clean it, blow out the jets, assemble and install in place. In this case, the candle will be flooded, so in any case it will have to be ignited.

Can the starter be turned for a long time?

Yes, you can do this, but be prepared for the following problems:

- Dead battery. Each unsuccessful attempt to start reduces the battery charge. In order for the battery to recover the expended energy, you need to start the car and let it run for some time. But if it fails to start, then soon the battery will simply run out. Then it will need to be charged, asked to light up or try to start from the pusher.

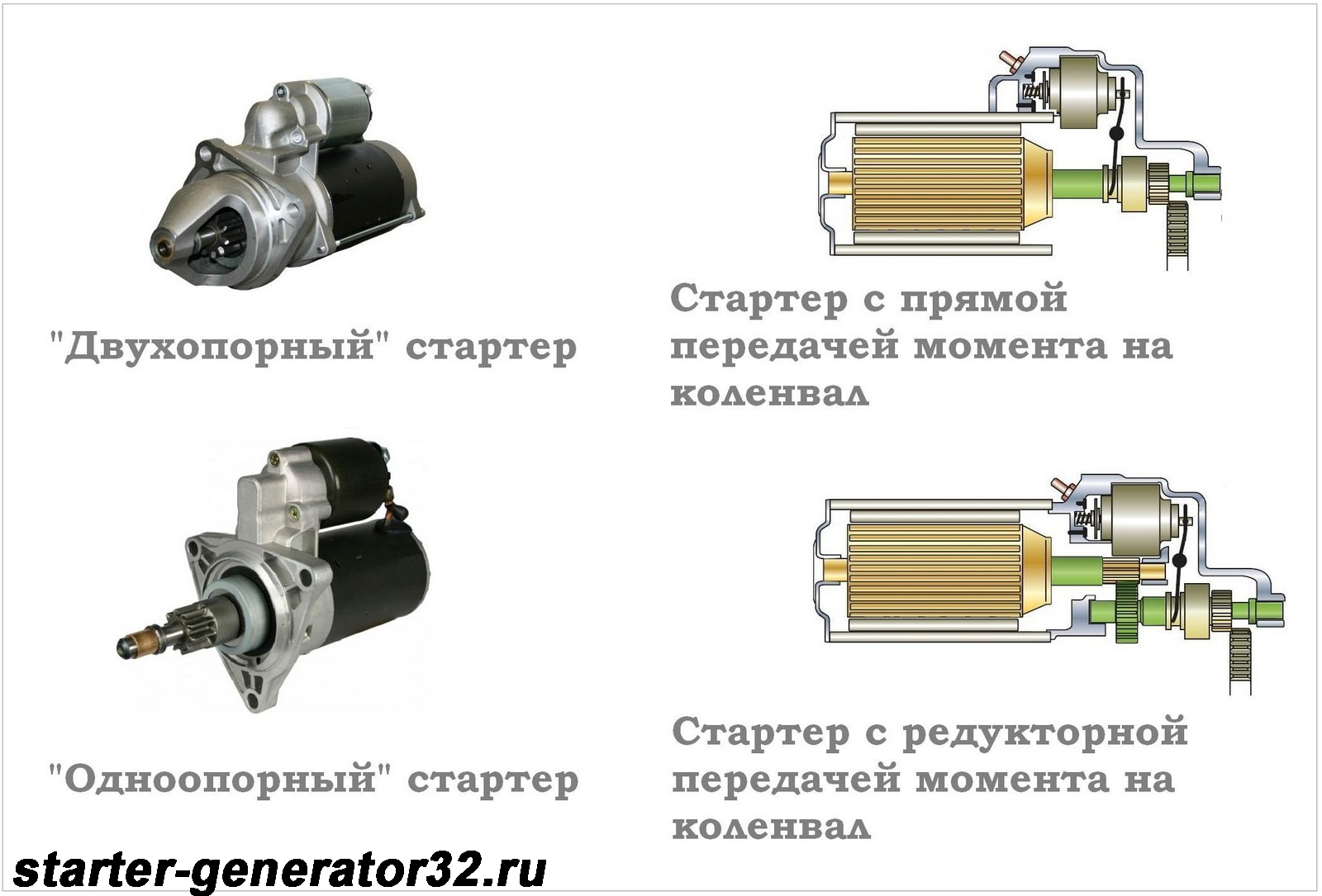

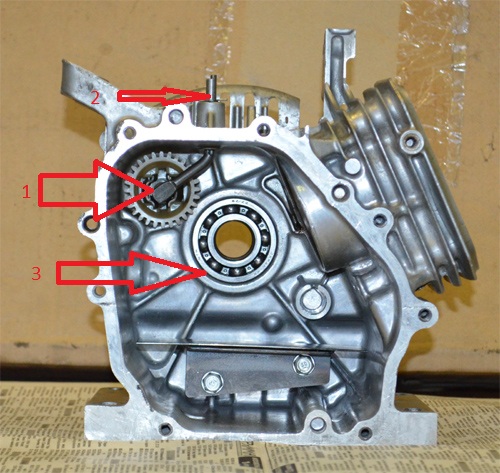

- Starter breakage. Excessive starter operation leads to overheating. And this is very bad for its details. Very often they break down, and then it is impossible to start the car at all. The bendix also suffers, which engages with the crankshaft. If it fails to start, the splines or bearing may suffer. So if you twist the starter for a long time, get ready to replace it.

What the statistics say

It is enough to turn to the experience of hundreds of owners of gas generators to draw a laconic conclusion: the most popular time of the year among power source engines that break down is winter time. The point here is not at all in omens, but in the most ordinary natural factors in the form of dirt, snow and low air temperatures, which reign supreme on the street in the winter season. The latter factor is especially felt if your generator is powered by a four-stroke engine. Due to the fact that oil in such engines is supplied separately from gasoline, it tends to freeze at sub-zero temperatures. Therefore, if you find yourself with a similar device in the above conditions, be sure to bring the device into a warm room or warm up the gas tap in some other way. In no case do not use an open fire (do not put it by the fire) for these purposes, preferring an ordinary hair dryer.

Under those circumstances when the weather conditions do not cause any suspicion, but the power source still stubbornly refuses to work, should pay attention on the following possible origins of the problem

Generator won't start

You need to start checking from the simplest to the most complex, for example, by checking the presence of gasoline itself in the tank.

Checking the oil level

Modern gasoline generators have an oil level sensor in the crankcase. If there is not enough oil, the ignition will not turn on. The level is checked with a dipstick built into the lid on the crankcase. If the oil level is low, it must be topped up and started again. If the level is sufficient, or if the engine does not start again after adding oil, continue the diagnosis.

Low quality gasoline

This is almost the most common reason a generator engine won't start. After idle time, a sludge forms in low-quality gasoline and water separates.This can lead to clogging of the filter or water in the working emulsion enters the cylinder and does not ignite.

To check, unscrew the screw on the carburetor and open the fuel cock. If the gasoline is dripping, then it is clean. It is only necessary to drain 10-15 ml of gasoline to remove condensate from the float chamber. If the gasoline does not drip, but only drips, then the blockage is most likely in the faucet filter. To clean the filter, it is necessary to drain the fuel from the tank and disassemble the tap. The filter is a round mesh. It must be cleaned and flushed with gasoline. Then put everything back together, and start again.

To do this, close the throttle valve, open the fuel supply cock and let it stand for 1 minute. Then, at idle (without turning on the ignition), we pull the kick starter string a couple of times to pump the carburetor. Next, turn on the ignition and start the engine. Open the throttle immediately after starting. If the generator does not work this time, the spark is probably not sparking.

No spark

To check if the spark plug is giving off a spark, you need to unscrew it, connect the high voltage wire and put it in such a way that the thread touches the block body (ground). Then we turn on the ignition and, watching the candle, pull the kick starter cord.

If there is a spark, then the reason is most likely a lack of compression. Most likely, the rocker arm in the timing belt is poorly locked, so the valves do not close completely. This will also be accompanied by a slight effort when starting (pulling the lace). With normal compression, the lace is pulled out rather tightly. It is better to solve such a problem in a service center. Although it occurs extremely rarely and mainly in generators of dubious origin.

If the candle does not sparkle, then there may be 3 reasons:

- the candle has gone numb;

- little oil in the crankcase;

- breakage of the oil level sensor.

Since the oil level has already been checked, 2 probable causes remain. The easiest way to check is to replace the spark plug with a new one (of the appropriate brand) and repeat the spark experiment. Damage to the oil level sensor is unlikely, but if there is no spark even with a new spark plug, then you can disconnect the wire from the sensor and start again.

In the absence of a new candle, you can "bring back to life" the old one. Its contacts must be cleaned of carbon deposits with fine sandpaper and calcined over gas. In the field, you can ignite a candle in a tin can, pouring a tablespoon of gasoline over it and scorching it.

Now we re-test the spark plug, screw it back in and start the generator.

Parking up to one month

A serviceable car after such a parking should start without any problems, since a discharged battery becomes the main malfunction of the car in such situations. Therefore, one must take into account its seasonal peculiarity. Even in cold weather at -15 degrees, idle time for 10 days often leads to battery discharge. In warm weather, the battery can only be discharged from leakage current, the rate of which should not be more than the permissible one. Signs by which it becomes clear that the engine does not start due to the battery are as follows:

- When the ignition is on, the indicators on the instrument panel are off.

- A small click is heard when trying to start the motor.

- The starter motor slowly rotates the engine crankshaft.

You will need to charge the battery using a special device for charging car batteries, or seek help from outside drivers. To start the motor, you need starting clamps - "crocodiles", as well as knowledge of the rules for performing "lighting" from an external power source. If your car has a manual transmission, then it can be started from the "pusher".

Significant effort is required to start a diesel engine, therefore, not all cars equipped with a diesel engine can be started in this way without consequences, so it is better to refuse this method.

Why is it dangerous to turn the starter for a long time when starting the engine

Starting the engine is a process in which the starter and the battery are directly involved. It is they who suffer the most with a long start of the motor. Accordingly, the following problems are possible:

- Battery discharge. Each attempt to start the engine consumes battery power. In this case, if the attempt is not successful, then we can assume that the battery is consuming its “idle” charge. In order for the battery to charge, the engine must start and run for a while. Several unsuccessful attempts to start the engine, and you will get a discharged battery, which will need to be charged from the station, or start the engine by “lighting” other cars;

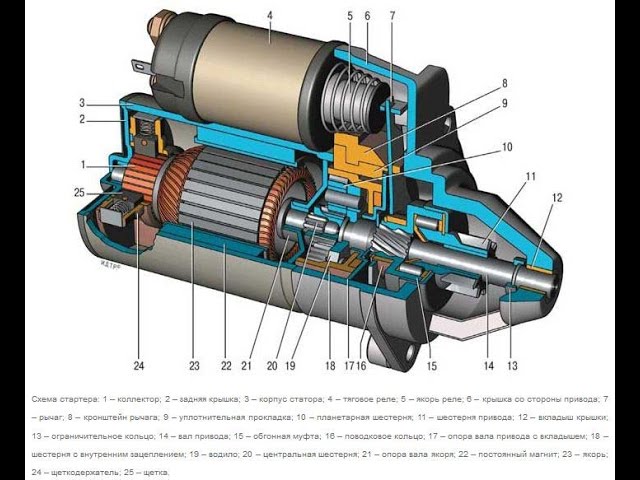

- Failure of the starter. With a long scrolling of the starter, it begins to overheat, which can adversely affect its components and lead to complete failure of the part. Also, do not forget about the bendix, which, when trying to start the engine, is fed to the crankshaft. If the motor does not start, there is a high risk of damage to the splines on the bendix or bearing. If you constantly have to turn the starter for a long time when starting the engine, over time this will lead to its failure and the need to replace it.

Most often, you can solve the problem with a long cranking of the starter when starting the engine without contacting a service center on your own, thereby preventing early failure of the starter.

When should you go to the workshop?

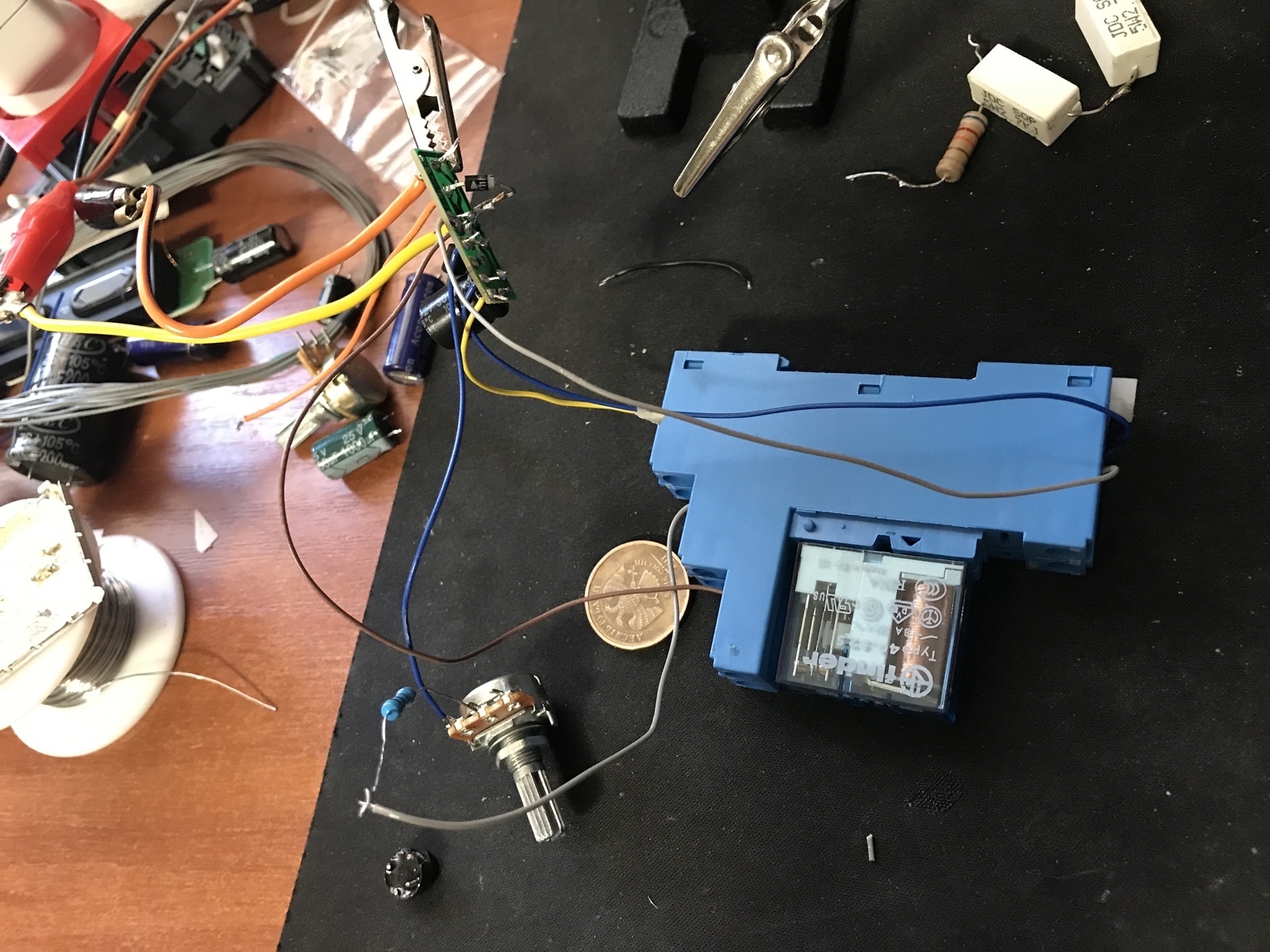

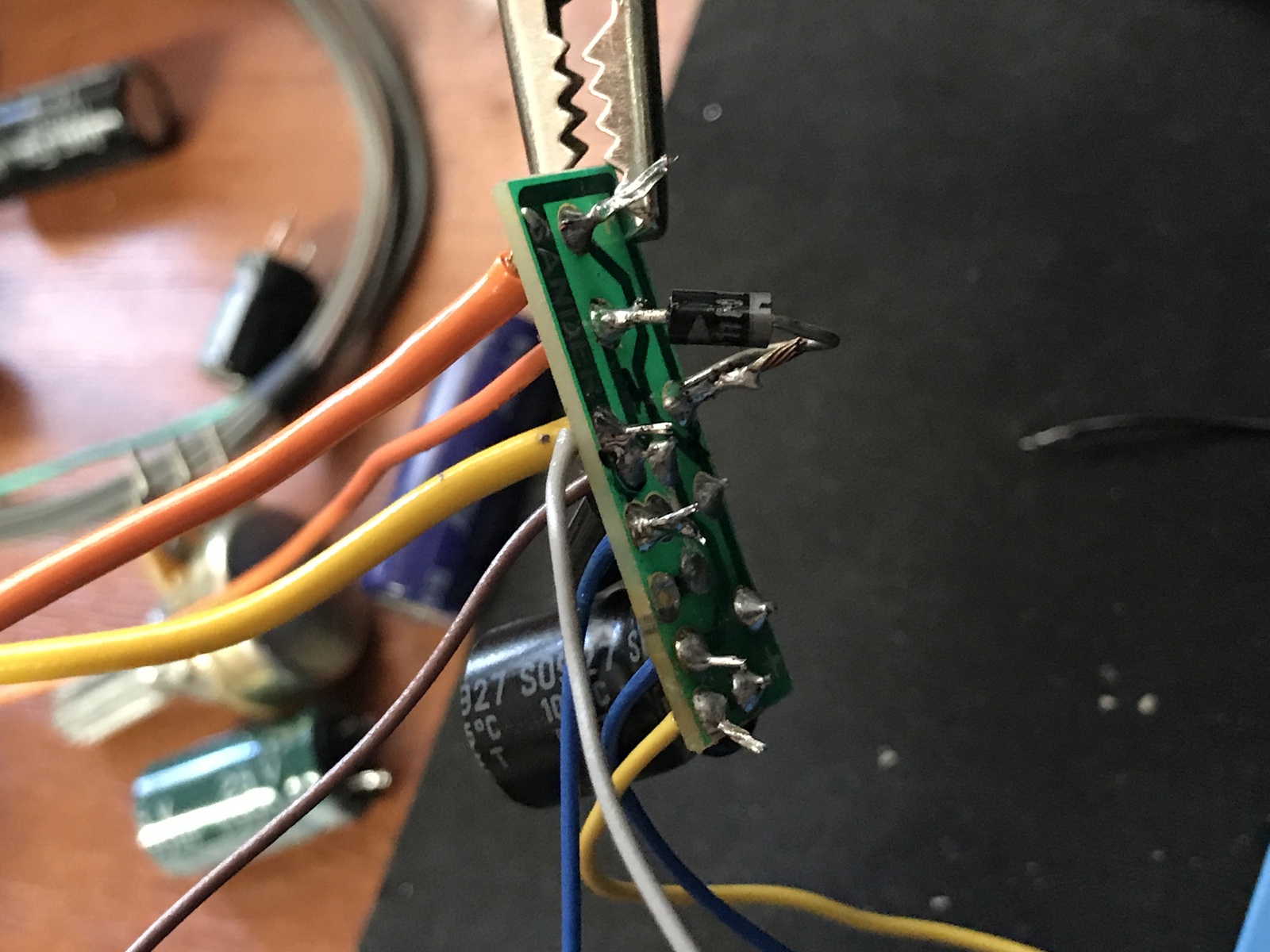

A number of faults, alas, are quite difficult to fix with your own hands, without sufficient qualifications: for example, a faulty inverter converter or voltage regulator can be repaired only with a good understanding of the principle of operation and circuitry of such devices. Not every owner of a gas generator will take up the engine bulkhead, although this is not as difficult as it might seem.

In this case, it is worth contacting a specialized repair shop. You can find out the coordinates of workshops in your city on the Internet or in stores selling gasoline tools.

There are many such workshops in large cities, here are only a small part of them:

| Town | Workshop | Coordinates |

| Moscow | "Electrobenzotechnika" | 13 centers in Moscow and 18 in Moscow Region (495) 783-58-33 |

| "Southeast" | Maryino, Stavropolsky passage. possession 199 (499) 390-93-49 | |

| St. Petersburg | Lenremont | 7 workshops (812) 344-44-44 |

| "Benzomix" | st. Uchitelskaya, 23, ATOLL business center, office 154 (812) 385-54-30 | |

| Nizhny Novgorod | "Machines" | st. Rodionova, 24 (831) 412-92-48 |

| Novosibirsk | RemCity | st. Topolova, 3 (383) 303-41-77 |

| Vladivostok | "Gas unit" | st. Dorovolskiy (4232) 273-273-9 |

The video shows the repair of a Chinese-made gas generator

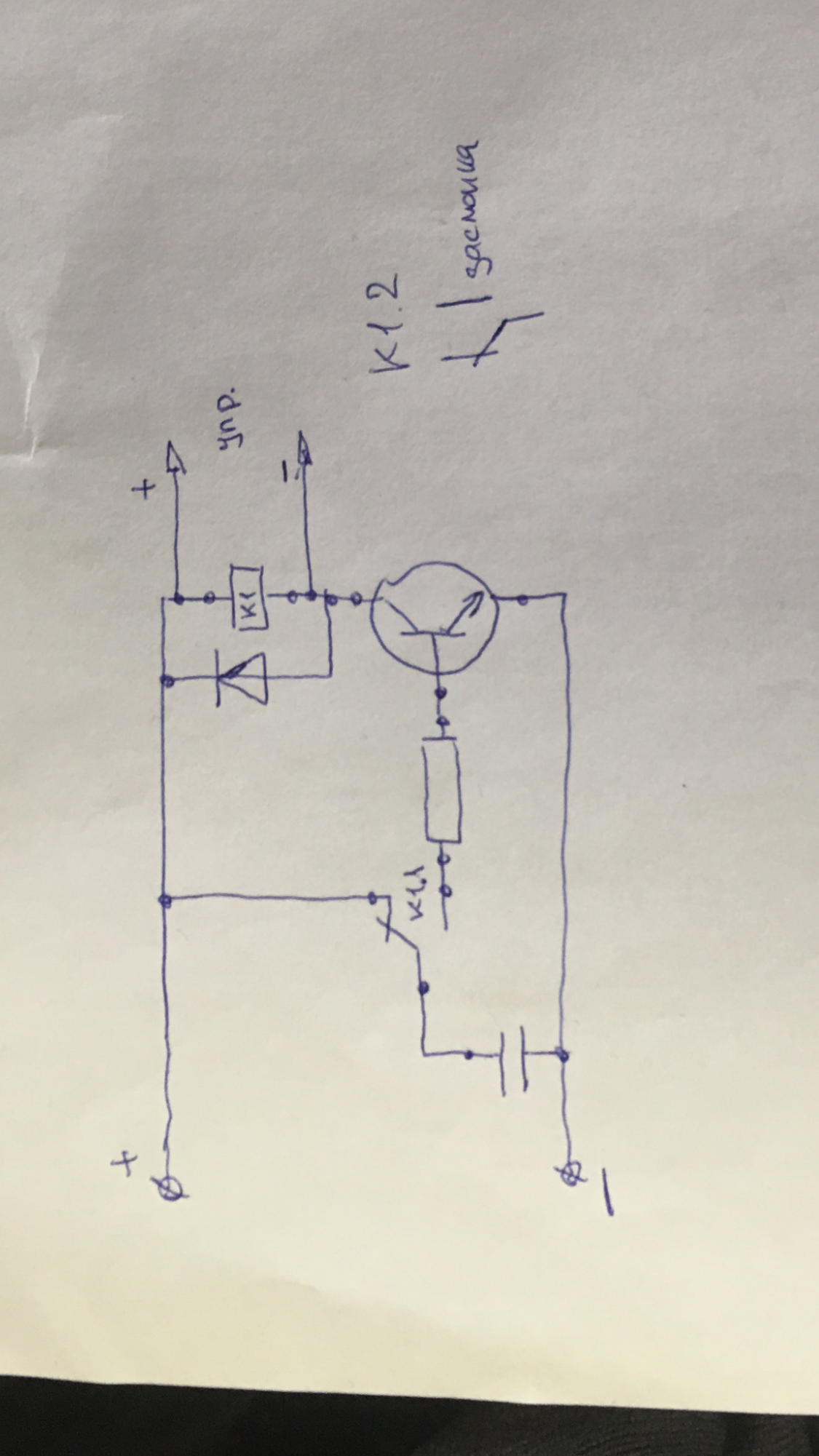

Starting the engine without a starter with automatic transmission by closing method

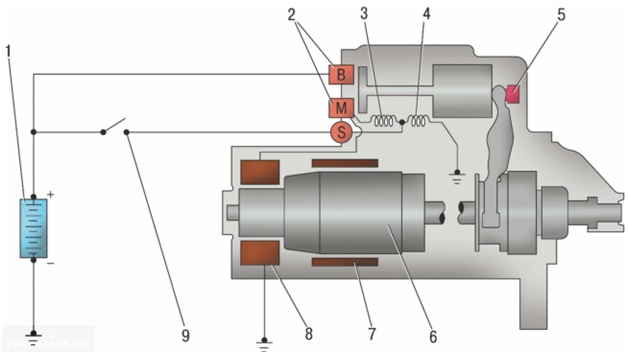

For a competent start of the engine by closing the starter on cars with an automatic transmission, it is necessary to take into account the electrical diagram of the connections of its components. A typical mistake of motorists when trying to close the starter is to bridge the two output terminals of the contacts with a screwdriver. In this case, the electric motor is triggered, but the traction relay remains disconnected and the overrunning clutch is not connected. It is not recommended to short-circuit the starter power leads directly.

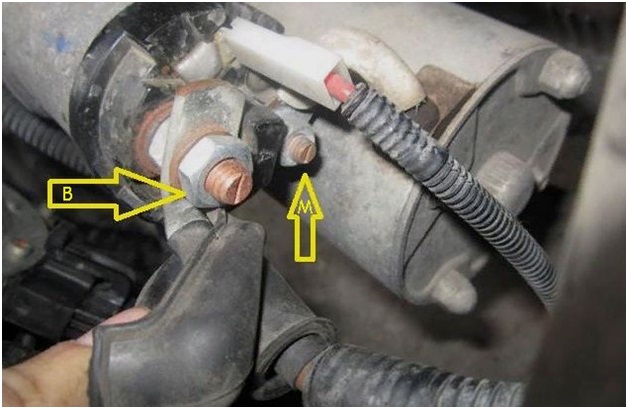

Any starter has three positive contacts "B", "M", "S" and one negative contact - 8, which is always connected to the body. The "B" terminal is always under DC voltage from the battery. Procedure:

- Before closing the contacts, you need to find the "S" terminal. On modern starters, it looks like a protective petal casing.

- Carefully trace the difference between contacts "B" and "M" - permanently connected "B" is marked "+12".

- To start the starter, contact "B" and terminal "S" are closed.

- The closure is performed for a short time and only after connecting the "neutral".

- It is forbidden to close contacts "B" and "M"!

On domestic cars, it is easy to find the necessary starter terminals: for example, a traction relay with the designation of contacts on a VAZ 2114 looks like this:

The output contact "B" is here covered with a rubber protective casing, and the terminal of the traction relay "S" is located under the plastic plug, which must be removed before closing.

The contact is closed with a screwdriver with the ignition connected:

On foreign cars with automatic transmission, the "S" terminal looks different: it is often made in the form of a threaded terminal with a copper tip and white wire insulation. It is convenient to close such a contact with an open-end wrench:

When closing the contacts, observe safety precautions: the traction relay of the car at idle consumes from 30 to 100 A, and the starting current can reach 600 A. It is necessary to work with insulating gloves, in case of "sticking" a screwdriver or a key, immediately remove the minus terminal from battery. The 12V starter operating voltage is not dangerous, but fuses or wiring can be burned out if errors occur.

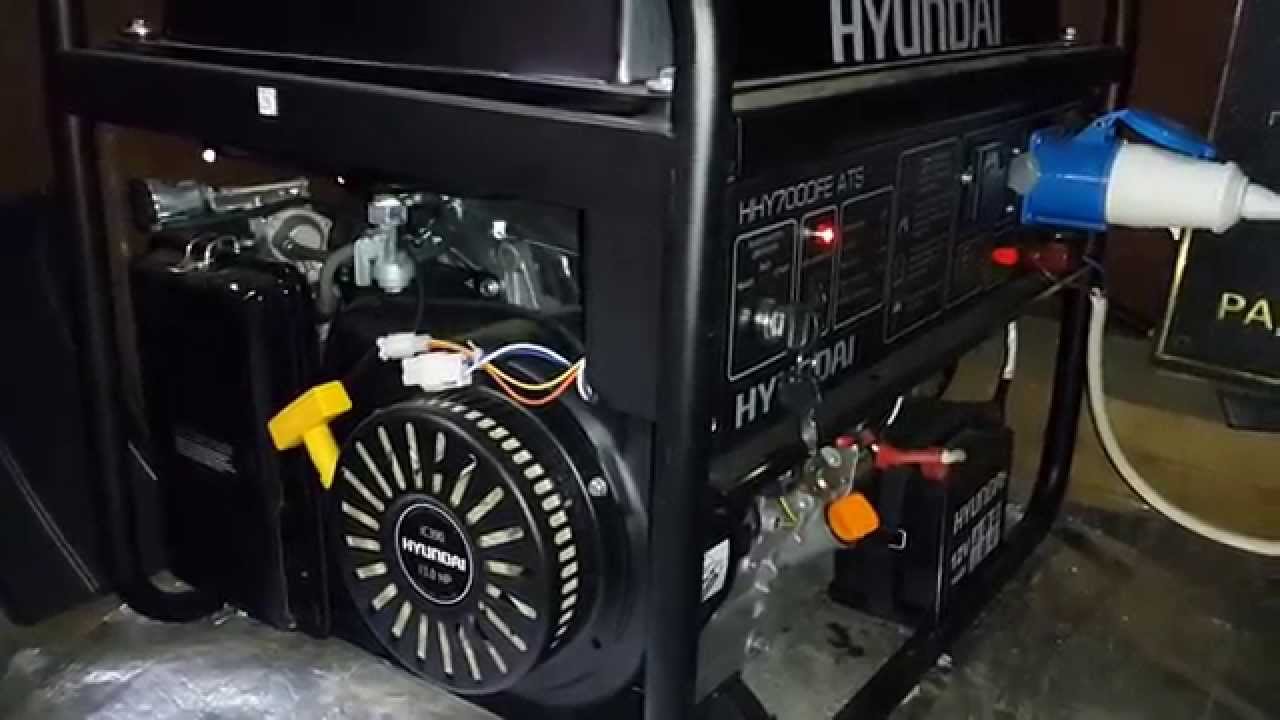

Starting the generator after conservation

Actually, this operation is carried out, like a normal launch, only the preparatory stage deserves special attention:

- before starting, it is necessary to fill in engine oil and install a new oil filter recommended by the manufacturer;

- install a charged battery;

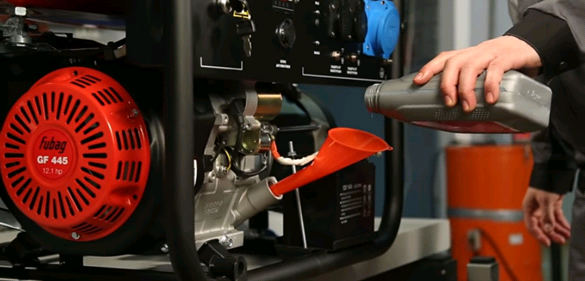

- fill the generator with fuel.

If you have not used the power plant for a long time and put it on storage, then in case of resumption of work, it is necessary to properly prepare the device. Before preserving the equipment, according to our recommendations, you drained all liquids from it, removed dirt and dust, and then packed it in a box and left it in this state for several months. But when summer comes, the season of construction work, or they often start to turn off the light, you have to remember the installation and put it into operation.

How to prepare generator to work after long-term storage, we will tell in this article.

First you need to get the unit out of the box and carefully wipe it off dust. No matter how you pack it, dust always ends up on the device, so it should be removed. If it has accumulated in hard-to-reach places, for example, on the grate, then you can use the compressed air of the compressor. After completing this procedure, install the structure on a flat surface and carefully inspect all visible parts, especially rubber hoses. Indeed, in the process of storage or rearrangement, they could be damaged or bent.

Tips for preparing equipment for operation

- If by external signs everything is normal, no violations were noticed, then you can proceed to the following activities. If you notice that the hose is bent or cracked, then it is better to replace it with a new one.

- Next, you need to check the state of the air filters after a long stagnation. If the equipment was in the house, covered with a plastic bag, then it may be in excellent condition, but if you forgot to change it before preservation, then be sure to replace it with a new one or clean this one.

- In the case when you have gasoline equipment, be sure to repeat the manipulation where it is necessary to lubricate the engine cylinder. To do this, remove the high-voltage wire from the spark plug, unscrew it with a special key. Then take a new syringe and take 20 milliliters of lubricant into it and pour it into the plug hole. Cover the hole using ordinary cloth and turn the starter several times by hand, while making sure that the ignition is turned off. This will help distribute the oil evenly throughout the motor.

- While the spark plug is unscrewed, look carefully at it to see if carbon deposits have formed on the threads. If you notice it, it's best to replace it with a new one. Then you can safely refit the spark plug.

- When all preparations are made, you can try to start the generator. First, let it run for ten minutes at idle speed, and then gradually connect the consumers.

- Watch the technician carefully so that there is no oil leakage or the smell of a burnt wire. The fact is that if the station is located in a room with high humidity, then the wiring could become damp. You should also check the readings of measuring instruments such as an hour meter and voltmeter.

If everything is fine and the equipment works great, then it is completely ready for use.

Possible problems

Unfortunately, gasoline generators can fail after long periods of inactivity. And not all users understand what the cause of a system malfunction may be. Accordingly, they leaf through the operating instructions in an attempt to find a solution to the problem. But the design of a gasoline generator is not so complicated, and you can find a malfunction without special knowledge. To begin with, you should consider the sequence of operation of the generator system. Free flow of fuel and the presence of a spark are required to start the engine.

To check the flow of fuel into the cylinder, it is necessary to unscrew the spark plug and inspect its electrodes. If they are dry, no fuel is supplied. Wet electrodes indicate gasoline intake. In some cases, it happens that the candles are flooded with fuel when the generator is factory. The spark seems to be there, but it is not possible to start the engine. This situation occurs after a long stagnation of the generator. To solve the problem, it is necessary to wipe the spark plug electrodes dry and screw it back in. Next, you need to check for a spark. To do this, you need to insert it into the mouthpiece and connect the external electrode to any metal element of the engine.

Only it is necessary to connect at a distant distance from the screwing point. Otherwise, the spark that appears may ignite from gasoline fumes from the cylinder. After the spark plug electrode is attached, you need to pull the starter. If there is a spark, then everything is in order. If a spark does not appear, you will have to look for a solution to the problem on a more global scale, since the absence of a spark indicates worn out candles or a malfunction of the generator's electrical system. Further, it is proposed to familiarize yourself with several ways to troubleshoot problems in the absence of a generator plant.

- In the presence of incoming fuel and a spark, it is necessary to wipe the spark plug and then tighten it. And start again according to the rules of the instructions.

- If the candle turns out to be dry after unscrewing, you can make a technical injection. This will require a syringe of 1 or 2 cubes. Gasoline is pumped into it, which is subsequently poured into the cylinder. Then the candle is quickly twisted, a mouthpiece is put on it, and a plant is made. With this approach, the engine will start on the 1st or 2nd try. But with further work, it may stall. If, nevertheless, the generator stalls, you will have to contact the service center.

- If suddenly there is no spark of the candle, and it was not possible to get it by replacing the mouthpiece, then the electrical system of the generator needs to be repaired. And only a specialist can repair the device.

Often, users, faced with a non-working generator system, begin to disassemble it and view the internal state. However, experts first of all recommend checking oil level and fuel availability... In some cases, the generator stops working when the air filter is clogged. It is not so difficult to clean it with your own hands, and to establish its location, it is enough to look at the operating instructions.

A similar solution to the problem if the fuel filter becomes dirty. It also needs to be cleaned or replaced. If suddenly the generator engine does not start after the performed manipulations, the problem is probably the contamination of the carburetor.

In the next video, you will see how to properly start a gasoline generator.

DIY gas generator repair

The elimination method should be followed during repairs. Here we mean the following. We start checking the device:

Visual inspection of the gas generator - maybe there is mechanical damage, fluid leaks, etc. Let's see if there is enough oil. With the help of the starter, we turn the motor to find out about the compression resistance and external noise. We start the engine.

When this did not work out, we proceed to the spark. We are trying a new candle with which we turn the engine. When we don't get sparks anyway, we disconnect the wiring from the oil sensor relay and change the spark plug cap. When, after that, there is no spark, then proceed to the ignition switch and the power button. Their serviceability indicates problems with the ignition coil.

There is a spark - we start the engine. If it stalls at startup or functions with the damper closed, you need to clean the carburetor. Some claim to have cleared it, but the problem persists. Correct (and not just ...) cleaning involves complete disassembly of the element and the use of special substances. Then it is necessary to install the carburetor properly and adjust the rods, damper springs and speed control

When after that it does not start again, then you should pour a little gasoline into the combustion chamber using the place where the candle was screwed.

Pay particular attention to the tank. If there is rust in it, this is bad.

Even if the entire fuel system is well cleaned, then, after a short time, rust will go to the jets and under the carburetor needle. As a result, the problem will resume. If the corrosion is insignificant, then you can pour a special substance into the tank and leave it for 10-12 hours; then drain and rinse with gasoline. You can install a new fuel filter, but only replacing the tank will really help solve the problem.

If you did not succeed in fixing the tool yourself, contact our company for a gas generator repair.

The quality of the oil in the car has decreased, why

Modern engine oils have a long shelf life. But after the oil enters the engine, its shelf life changes. Since modern oils have many different additives, during the direct operation of the engine, oils are exposed to very high temperatures. This leads subsequently to the so-called “stratification” effect of the oil. It does not manifest itself during constant operation of the engine, because during its operation the oil is constantly mixed and agitated. But when the car is idle, a sludge forms in the oil, and it loses almost all of its properties.

It is highly discouraged to start the engine with such oil, as this can damage it. If the vehicle is out of service for a long time, the engine should be flushed, and the oil and filters should be replaced.

Recommended: What to do if the engine oil smells like gasoline