Care and storage

- regularly disassemble and clean the internal elements of the screwdriver from carbon deposits, dust and dirt;

- if unstable operation occurs, carry out diagnostics. Check the wear of the brushes so that you do not have to change the engine armature;

- do not leave the instrument in high humidity rooms or under the sun. The same goes for the battery;

- keep the battery away from keys, coins, or other short metal objects. Accidental contact with the poles will short-circuit the battery. This could result in a fire;

- at the end of the day, take a clean rag and wipe down the tool. The cloth can be slightly moistened with water without using detergents;

- you need to store the screwdriver in a dry environment with a positive temperature. Use a case or other packaging to keep the tool free from dust.

Work with a screwdriver, observing the safety precautions and the rules described in the instructions. Choose the right rig. And then the tool will serve you for a long time.

How insert drill v drill and puncher

- 1 Varieties

- 5 How to insert a drill

- 3 What to do if the drill gets stuck

- 4 videos

Often there are options to appear difficulties are not tasks when working with a hammer drill for another drill. In the main, the discrepancy may lie in the inability to work correctly with drills. First, let's see some differences between cartridges not drills.

Device and purpose

The screwdriver is used for various construction and repair work, but its main function is to quickly screw in and tighten fasteners: self-tapping screws, screws, bolts, screws.

It helps you tackle a large volume of tasks in significantly less time than using a screwdriver.

Budget screwdrivers of low and medium power are used in the assembly, installation and dismantling of furniture, equipment, the construction of frame structures (partitions, walls, suspended ceilings) and other objects. Powerful hammering tool handles hole drilling.

In addition to the standard operations listed in the instructions for the screwdriver, it can be used for other tasks. Using a mixer nozzle, they are kneaded with thin solutions. Through a special adapter, the device is connected to an ice auger in order to quickly make holes.

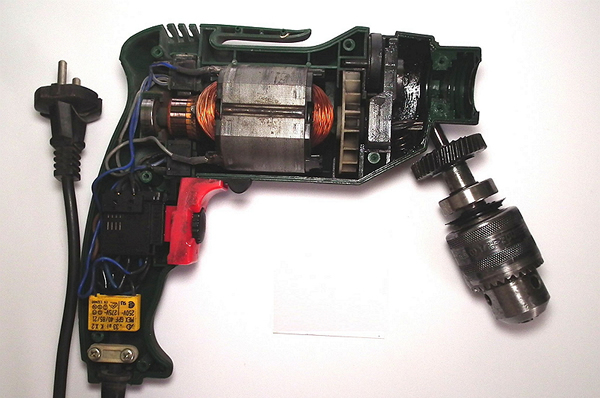

Most screwdrivers are made of plastic, which reduces the overall weight of the tool. Inside the case are located:

- engine. Depending on the type of device, it can be electric or pneumatic. The former are powered by a network or accumulator, the latter are powered by a compressed air tank or compressor.

- Reducer. Gear mechanism that transfers rotary motion from the motor to the spindle.

- Regulator clutch. Connected to a gearbox, it is used to adjust the screwing depth and torque.

- Starting capacitor. He starts the engine.

- Chuck. Bits, drills, socket heads are inserted into it. The most common quick-clamping three- or four-jaw.

- Power supply (battery) and / or power cord.

On the case there is a control panel with a power button, a speed switch. For work in the unscrewing mode, reverse is used. Additionally, the screwdriver can have a backlight, a fuse.

For newbies

So, let's start with the simplest case - inexperienced users. Screwdrivers have such a thing as a torque regulator. It looks like a scale around the front of the screwdriver, which is right behind the chuck. It contains numbers from 1 to 10, 15, 20 or even more - different models have different ways - and the last position on it is indicated as a drill.If you rotate this regulator and set it opposite a special mark so that one of the numbers is next to it, then when a certain torque is reached, the cartridge will no longer rotate, but will begin to click. If you put on the "drill", then the screwdriver will try to twist with all its might, as much as the engine power allows.

True, it is worth noting that in two-speed screwdrivers at second speed, even in the "drill" position, if the torque reaches a certain value, then a protective system is triggered, which simply cuts off the current supply. At the first speed, the screwdriver will also try to twist "to the last".

And a beginner can start drilling or screwing screws, for example, when the torque regulator is on one of the numbers, or the screwdriver is at the second speed (and it is recommended to drill on it).

The drill can be clamped quite tightly, and as a result, when you start to release the drill or bit in the standard way (turning on the reverse, holding the chuck and pressing the start button), either the torque limiter or the protective system can work.

Therefore, in such a situation, you just need to put the screwdriver at the first speed and set the torque regulator to the "drill" position. On single-speed models, just set the torque adjuster to the drill position. Well, then, again, we unscrew it in the standard way.

How to replace the drill chuck with your own hands?

To mount the chuck on the drive shaft of the drill, a threaded connection or Morse taper is used. A visual inspection of an electric drill does not always help to suggest how to fix the drill chuck. The marking on the cartridge can inform about this: it is knocked out on its surface.

Replacing a Tapered Part View

The standard size of the Morse taper (according to GOST 9953–82) consists of 9 values: from B7 to B45. The larger the number after the letter B, the larger the diameter of the cone.

The markings on the chuck indicate the type of fastening

Thus, having found the marking "B" on the surface of the cartridge, we can conclude that this is a device with a tapered mounting base. With this method of attachment, the cartridge can be easily removed. It is enough to use a drift and a bench hammer.

Video: how to remove a chuck with a cone from an electric drill?

Replacing the Reverse Threaded Chuck

Two types of threads are used to secure the drilling chuck to an electric household drill using a threaded joint:

- inch (for foreign models);

- metric (from Russian manufacturers).

On an electric household drill, there are two types of threads using the threaded joint

On an electric household drill, there are two types of threads using the threaded joint

Markings of the following type are applied to the surface of the body of the threaded chuck: 1.5-13 1/2 - 20UNF or 1.5-13 M12x1.25.

The reversible threaded chuck has a left-hand thread for fixing. You need to know this nuance when removing a broken cartridge.

In order to get to the screw head, it is necessary to drown the cams in the collet to failure. Once the screw head is visible, use a hardened Phillips screwdriver to unscrew it clockwise to the right. Then clamp the hex key into the cams and hit it sharply in the counterclockwise direction. After the cartridge is ripped off, it can be easily unscrewed.

Video: how to remove the chuck from a reversible drill or screwdriver?

On other models, there are other options for fastening the cartridge to the thread. In some cases, the chuck is twisted entirely from the threaded end of the shaft. In other cases, the screw can be fixed with a special thin wrench using a narrow groove. The main difficulty is to move the cartridge from its place when unscrewing.

Sometimes this is very difficult to do. In any case, to remove the cartridge you need: a locksmith tool, the necessary skill and patience.

Mounting device - non-combat cartridge

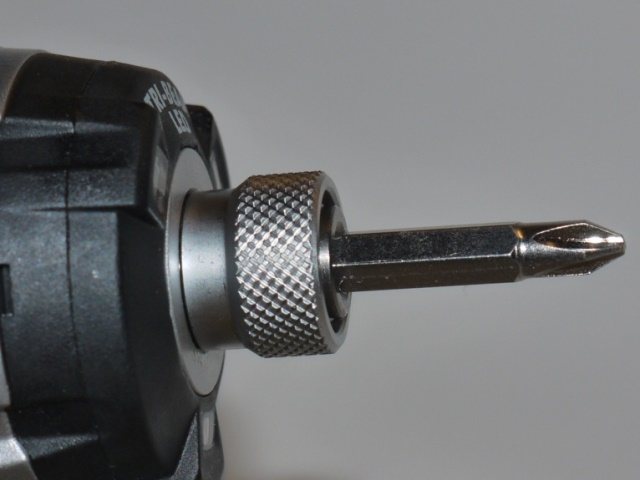

The chuck is the fastener in which the drill is fixed. The fasteners themselves are screwed onto the tool spindle. Most often, drills are equipped with a jaw chuck. This design is a hollow cylinder with metal "fingers" inside. When turning the adjusting ring, which is located outside the assembly, the "fingers" converge or diverge along the inner cone-shaped surface. In such a "fist" you can clamp both a drill with a cylindrical shank and a hex.

Convenience and ease of use have made the cam mechanism popular. However, it is not without its drawbacks. One of them is the difficulty in working with small drills. A short piece can simply fall inward. You can still fix it by putting the drill in a horizontal position, but you cannot press on it hard during work. If another drill has been inserted into the drill, you can remove it by turning the adjusting ring in the appropriate direction. It is not always possible to do this manually, for this there is a special key that acts like a lever, increasing the effort. By the way, tightening the drill without a key is also not recommended - the larger the drill diameter, the more reliable the fastening should be.

When buying fasteners, make sure that it is rubberized - this way you will less injure your hands when fastening the tool.

Keyless fasteners, the second most popular, can be operated without a key. It is enough to insert the drill and turn the lever, often it can be done with one hand. The fixation of the drill, which this type of chuck provides, is quite enough for most jobs, however, compared to the classic version of the fastening, it is inferior in reliability, and it is more expensive. The main advantage of the quick-clamping fastening is the speed of changing the drill and the safety of the process, since such a chuck is devoid of teeth that can injure hands. The absence of a specialized key is also a significant advantage! Seasoned builders know how easily it is lost, so very often you can see the key tied with tape or electrical tape to the wire.

True, this does not add convenience, but there is at least some confidence that the key will not have to be looked for throughout the construction site. How to change a drill in a screwdriver? The scheme is absolutely identical - the cartridges for most drills are similar to fasteners on screwdrivers. Of course, the last tool cannot be a full-fledged replacement for a high-quality drill, if only because the fasteners are not provided for drills with a large diameter, and, as a rule, the rotational speed of a screwdriver is less.

Tool varieties: characteristic features

The screwdriver can be classified into the following varieties:

- Drill driver

- Wrench

- Cordless screwdriver

- Standard screwdriver

The principle of operation of the tools is similar to each other, but there are still differences in functionality.

The drill driver is able not only to tighten the screw, but also to drill a hole. The impact wrench is specialized in bolts and nuts. The third representative is a cordless screwdriver, designed exclusively for tightening / unscrewing fasteners with a cross head. The latter type is characterized by low power, in contrast to the above.

How to replace the chuck - update the drill

Most often, it is the cartridge that comes into disrepair first in the drill. Dismantling it at home is not easy, but possible! The fasteners are screwed onto the spindle itself, but in addition it is also secured with a bolt with a left-hand thread. In order to get it, you need to completely unclench the cartridge - it is inside. The whole difficulty of unscrewing it lies in the fact that many do not know about the left-hand thread, and trying to unscrew it, tighten it even more, rip off the cap and eventually carry it to the service.

By unscrewing the bolt, you can unscrew the cartridge itself, however, and this is not so easy to do.In some models, there are notches for a wrench at the base of the thread - in this case, you can fix the spindle and unscrew the fasteners using a lot of effort. The real difficulty arises when there are no wrench cuts. You will have to remove the housing cover to fix the spindle inside the drill. Difficult but doable.

Removing a cartridge is one thing. Finding a new one is completely different. In addition to the methods of clamping the drill, which are described above, different chucks also have different threads! The surest way not to confuse anything is to take an old cartridge with you and demonstrate it to the seller, or how to choose the right one according to the layout. When you have coped with this task, all that remains for you is to screw the chuck onto the spindle and tighten the bolt, which in our case is twisted counterclockwise.

An irreplaceable power tool in everyday life with a self-explanatory name, the screwdriver is actively used in construction work. The most common procedure with such a device is to replace the drill. Sometimes it seems that this process is very difficult and almost impossible.

However, in fact, replacing a drill in a screwdriver will not be difficult, the main thing is to follow the instructions step by step and pay attention to the details.

How to change a drill in a drill - we do it ourselves!

It is far from always possible to get the drill out of the chuck in the usual way - as a result of a strong load or improper fixation, it can jam the chuck. How to get the drill out of the drill without damaging the fasteners and tools? First of all, try to cool the cartridge well. Sometimes this is already enough for the cams to release the drill a little, and you can pull it out.

Read the same

The most proven way to remove a jammed tool is to tap the cams.

... For this, the free end of the drill is fixed in a vice, a wooden bar is applied to the chuck, through which tapping is carried out. From such a vibration cartridge

may loosen your grip and release the tool. This method is useful both for owners of classic fasteners and for owners of quick-release fasteners. Extraction is sometimes possible after lubricating the drill with machine oil or the popular WD-40 grease.

The latter method is better, because the sprayer will quickly reach the desired points of contact between the drill and the chuck. In any case, after lubrication, you will need to wait a little for the substance to penetrate deeper. Sometimes, in especially difficult cases, the problem is solved only after dipping the entire cartridge in machine oil or vegetable oil. If neither one nor the other is at hand, you can make a "bath" of your drill and gasoline. Hold on cartridge

in the liquid you need at least an hour. By combining methods, the jammed drill can be removed even faster.

Instrument care instructions

The screwdriver needs minimal maintenance. In order for the tool to work properly, you need to adhere to the recommendations specified by the manufacturer, do not use it for tasks that are not indicated in the data sheet, do not overload too often. Periodically, the inside of the chuck and rotating parts should be lubricated with machine oil.

Store the tool in a dry place away from heat, moisture and sunlight. After each use, wipe the case with a clean dry cloth to remove construction dust from it. If drops of mortar have fallen on the screwdriver, you can clean it with a well-wrung out soapy cloth.

If you follow the rules of operation, do not use the tool for tasks that exceed its capabilities, you can significantly simplify the implementation of repair and construction work. In order for the screwdriver to work for a long time and not fail at the wrong time, you need to take care of it in a timely manner, monitor the condition of the parts and recharge before use.

Video: How to Insert a Drill Into a Bosch Drill

Pulling out and installing the drills is much easier and faster when using the quick release chuck. In it, the sleeve is manually rotated. To limit the cam force, they are often equipped with locking elements.

Before inserting the drill, first make sure the drill is in working order and disconnect it from the power source. Only then can you start training.

Types of eyeless cartridges

Mounting the working tool on the hammer drill

As stated above, the hammer should be checked before installing the drill. To perform such a test, the perforation mode is set for non-live drilling. If you hear and feel that the engine runs smoothly and without bumping when you press the start button on the device, this means that the hammer can be used as intended after drilling or drilling.

To attach a cylindrical shank drill to a hammer drill, use a cam adapter

Before inserting the drill into the hammer drill, the shank of the working tool must be treated with a special grease that will protect it from corrosion. The procedure for installing drills in a drill is as follows.

- The hammer drill is installed on the back of the floor or other hard surface.

- The movable part of the clamping device is retracted.

- The tool is inserted into the punch as far as it will go. In this case, the drill or drill bit to be inserted into the drill must be held vertically. If you do not comply with this requirement, you may experience breakage or even breakage of the tool, which can also lead to malfunction of the drill bit.

Press until it clicks, then pull out the drill if it fails. everything is fine

Due to the fact that the chucks on modern rotary hammers differ in a rather simple principle of operation, questions about how to get a drill from a hammer drill, as a rule, do not arise.

After removing the used tool from the rotary hammer to replace it with another, it is recommended to immediately clean the shank from grease and construction dust. The drill bit you intend to insert must also be cleaned and pre-lubricated. A tool replaced in this way will not damage the impact mechanism and will last much longer.

Lubrication extends the life of both drill and drill

With a hammer drill, you can not only get a drilled structural element, but also perform processing with a special chisel. You can also set the device mixer as a working organ.

Domestic workers also often have questions about how to insert a drill into a screwdriver or how to replace a cartridge with an impact drill. The first question is easy to solve, since the design of the screwdriver uses cartridges of the same design as for drills and hammer drills. But the question of how to correctly replace a cartridge with a perforator must be approached with skill: it is not easy to carry out such a procedure without certain knowledge and skills.

A Few Tips for Using a Drilling Tool

To avoid the risk of harm to your health from flying tools or concrete chips, drilling operations must be carried out with all precautions. To ensure this safety, goggles, gloves, ear plugs or earplugs

Naturally, all work must be carried out in special clothing, in which there should be no hanging elements that can be wound around the drill.

Rest regularly to prevent overheating of the power tool used for drilling.

It is very important to insert the drill correctly (this must be done until the tool stops)

Two ways to compress a thin cartridge if the jaws reach the shank slightly

If the drill gets stuck in the wall while drilling, it should be removed without removing the tool from its surface.To do this, remove the drill from the punch and insert another one with which you want to start breaking the wall around the drilled hole in it.

If the drill cannot be removed from the drill or hammer drill, it should be clamped in a vise and then pressed with a hammer using a wooden washer to press the jaws of the clamping mechanism. This can be helped by oil, a few drops of which are poured into the key cartridge.

How to use a screwdriver

Today it is difficult to imagine renovation, construction or home improvement without electronic assistants, one of which is a screwdriver. Its importance cannot be overestimated; it significantly improves the quality of work and saves time. The scope of its application is not only major repairs and construction work, but also various everyday situations that arise in our life. For example, assemble or disassemble a cabinet, change the lock, drill a hole in the wall, and much more. Let's take a look at how to use a screwdriver.

Today it is difficult to imagine renovation, construction or home improvement without electronic assistants, one of which is a screwdriver. Its importance cannot be overestimated; it significantly improves the quality of work and saves time. The scope of its application is not only major repairs and construction work, but also various everyday situations that arise in our life. For example, assemble or disassemble a cabinet, change the lock, drill a hole in the wall, and much more. Let's take a look at how to use a screwdriver.

Screwdrivers are cordless and mains powered. Cordless screwdrivers are preferred as they can be easily operated without worrying about having a functioning socket. The removable battery is easily attached from the bottom of the screwdriver handle and is recharged via the AC adapter. It is best to choose a screwdriver with two batteries, this will avoid long interruptions in work: while one is charging, you can work with the second. Today there are two most common types of batteries: nickel-cadmium and lithium-ion. Nickel-cadmium, unlike lithium-ion, has a memory effect and therefore, before putting it on recharge, it must be completely discharged, otherwise its capacity, on which the duration of work between recharges depends, will gradually decrease.

The screwdriver is sold in various configurations: only a tool or with a set of different attachments (bits). How to use a screwdriver to change a bit or insert a drill? Replaceable tips are fixed in the three-jaw chuck of the screwdriver without the use of additional tools, only by hand. For convenience, the cartridge has a rubberized ribbed surface, turning it counterclockwise, we expand the cartridge socket and insert the nozzle, and to fix it, we turn the cartridge clockwise.

The screwdriver has an adjusting ring immediately behind the chuck, which controls the speed of the torque and stops the chuck as soon as the screw is screwed in. Depending on the model, the screwdriver has several levels of control (from 6 to 22), which allows you to choose a mode more suitable for performing a certain type of work and not spoil the surface of the material. Let's take a look at how to use a screwdriver to find the right torque speed for a tree, for example. To begin with, we set the minimum level of control and start work, if the self-tapping screw has not yet been twisted and the sound of a ratchet is heard, that is, the sound of a running engine, then it is necessary to increase the speed of the torque. And so on until the self-tapping screw completely enters the wooden surface. After that, you can continue working without worrying that we will rip off the self-tapping slot or it will go into the depths. This approach allows you to work more efficiently and save battery power.

Article read 1191 times (a).

More from this heading: