Violations of the rules of work

Safe mode of drilling involves adherence to certain rules, the disregard of which can lead to injury or damage to the tool. The chuck of the drill is in the greatest danger, taking on the main load upon contact with the surface. To avoid unpleasant consequences, it is not recommended to abruptly change the angle of inclination of the drilling. It is also necessary to limit the force applied to the drill, the drill of which is in the process of drilling. Overloading can cause the drill to break or jam in the chuck. For heavy-duty surfaces, use drills designed for the job.

Replacing the cutting tool

The "tail" of the screwdriver drill is fixed in the chuck. It comes in different sizes, just like the attachments. If the cutting tool is incorrectly installed, the screwdriver can damage the work process and harm your health. For example, due to the "wrong" drill, holes of different sizes with a damaged surface can be obtained. The sharp element will cause serious injury when it "leaves" the cartridge.

Most modern screwdrivers have jaw chucks. They consist of a cylindrical body as well as a sleeve and cams. When the sleeve rotates clockwise, the cams simultaneously press on the drill.

The process of replacing it is simple, but it has a number of individual characteristics. The whole process can be described as follows:

- it is necessary to select the necessary nozzle (bit) for the drill;

- then you need to take the cutting tool and install it in the center of the chuck (between the open "cams");

- after that, it should be fixed by turning the sleeve clockwise (with a key type cartridge, the key is installed in the recess);

- twist the sleeve until the attachment is secured.

It is not difficult to change the drill, but first you need to pull out the previous one. There are the following options for the development of the situation:

- standard removal of the drill (the chuck is not damaged);

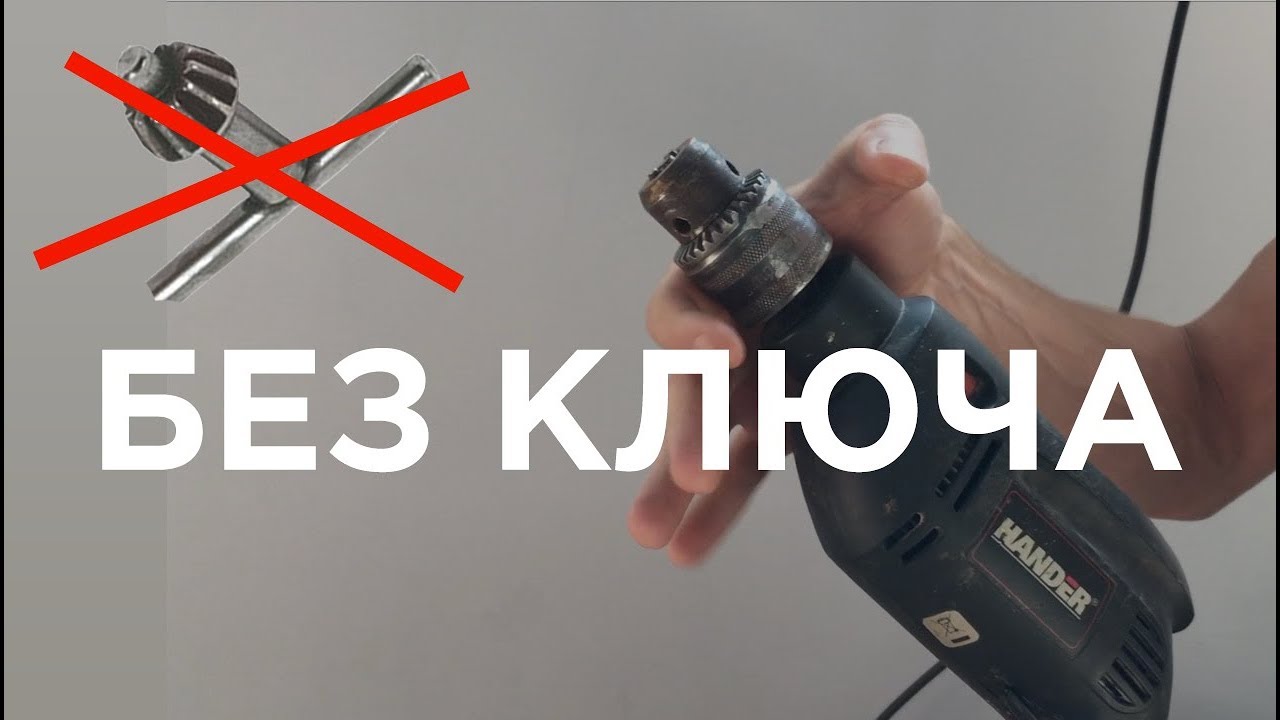

- pulling out the drill in the absence of a key;

- removing a jammed cutting element.

If the screwdriver is working properly, problems should not arise when replacing its working tool - the operation is elementary. To do this, you need to take the key, which is designed to loosen the cartridge, and insert it into the recess. Twist counterclockwise. Untwisting is carried out due to special teeth that are on objects. There is also another option for removing the drill. To do this, turn on the reverse rotation mode on the screwdriver, hold the outer case of the cartridge and press the "start" button. This way, the drill is easily released.

If you do not have a special key, the drill can be removed using a Phillips screwdriver or a nail. It must be inserted into the recess on the chuck and half of it fixed. We twist the opposite part of the cartridge by hand. However, if such untwisting does not work, then we take a gas wrench or a vice - these tools will help to increase the rotation of the cartridge. If the previous options for pulling out the drill failed, then you should resort to "heavy artillery". In some cases, external damage makes it difficult to get the drill. In this situation, it is necessary to relax the "cams" with the help of gas keys and a vice. We completely clamp the cartridge with the keys and rotate (unscrew).

A radical option in the most hopeless situation would be to twist the cartridge from the screwdriver.To do this, it is necessary to squeeze it in a vice and forcefully knock out the cutting tool from the inside using a punch. Naturally, after such a procedure, the screwdriver should be taken to the repair. Summing up, it is worth noting that the procedure for inserting a drill into a screwdriver is quite simple and even someone who has never done this can handle it. The main thing in this process is to follow the recommendations.

About, how to insert a drill into a screwdriver, see the next video.

What to do if the key is lost?

If the key is missing, it will be difficult to remove the drill. The easiest option is to deal with the problem with brute force. The parts of the clamping device hold right and left hand and rotate in opposite directions. However, if the chuck is tightened too tightly or the drill has been used for a long time, it is unlikely that it will be possible to unscrew the thread.

To enhance the applied impact, use various tools or homemade devices. Here are some ways:

Experienced craftsmen loosen the fastening of the cartridge with a few tangential blows with the edge of the right palm. At the same time, the drill is held with the left hand in the position of the drill from itself. The disadvantage of this method is that the palm can be injured from habit. And even with a tightly tightened (and even more so a behavioral or jammed) mechanism this way can not be handled.

A metal shaft is selected, the diameter of which allows it to be inserted into the hole on the chuck. In this capacity, you can use a nail, an old drill, a hairpin. The main thing is that the metal is strong enough and does not bend from the applied effort. The screwdriver is inserted into the slot of the chuck and acts as a lever (while the support goes to the shaft). It is enough to slightly loosen the thread, and you can pull out the drill by untwisting the mechanism with your hands.

The cartridge is clamped in a vice or held tightly with a gas wrench. The shaft is inserted into the hole, and then, applying muscular effort, the mechanism is unwound or twisted.

The effectiveness of the described folk methods is significantly less than when using a factory turntable. But once or twice it is possible to tighten or loosen the locking mechanism in this way. After finishing work, you need to purchase a new key in the store.

Why are sparks in a drill dangerous?

An electric drill, like any other power tool, requires systematic maintenance. Spare parts wear out during operation, the lubricant dries out.

Drill brushes require regular replacement. One of the manifestations of the problem is that at normal voltage in the network, the electric motor does not work. A bright signal is the formation of an all-round fire on the manifold. The sight is beautiful, but dangerous. In order not to ditch the anchor of the drill, they are changed. It is advisable to buy original ones, not Chinese ones. With them, the tool will last much longer.

Photo: brushes for electric drills

Graphite drill brushes

The design of the drill allows you to replace the brushes yourself. There are models in which there are installation windows for brushes on the body. The replacement is simple:

- Unscrew the plugs from the installation windows.

- Take out the worn out brushes.

- They put in new brushes.

- Tighten the plugs.

Other models require minimal drill disassembly:

- Unscrew all screws on the housing. Remove the cover. It is more convenient to leave the screws in their "native" places.

- Take out the brush holders, take out the worn brushes from them.

- Insert new brushes, pressing the spring firmly into place.

- Reinsert the brush holders, tighten the electrical contact of the lead wire well.

- Close the housing cover, tighten the screws.

How to free a two-sleeve chuck

Unlike the key, this type of chuck has no gear and, accordingly, no stop. Its rings are relatively smooth. In this case, the ideal solution is the removable magazine holder, which often comes with modern drills. You will also need a hammer:

- Grasp the upper sleeve (ring) closest to the drill with the holder and fix it as securely as possible.

- Hold the drill in a vise, clamp, in your hands or between your knees.

- Hit the handle of the "magazine" with force in the direction in which the upper clutch is normally untwisted.

One blow is enough - the ring moves and the drill is released quite easily. To facilitate sliding, it is permissible to drip a little oil or grease between the chuck jaws or under the clutch.

Existing types of fastening

The chuck on the shaft of any drill, screwdriver or hammer drill is attached in two ways - using a threaded connection or on a cone. A type of threaded connection is the use of an additional locking screw.

Threaded fastening implies that an identical thread is made on the drill shaft and on the inner channel - metric or inch. Therefore, in this case, during the repair, the question is raised how to unscrew the cartridge. The type of thread and its main parameters are marked on the body. For example, the designation 1.5-15M13x1.2 is embossed on the case, which means the following:

The principle of removing the drill chuck.

- 1.5 and 15 - the minimum and maximum diameter of the drill shank in mm;

- M13 - metric thread with a diameter of 13 mm;

- 1,2 - thread pitch.

If an inch thread is used, then the designation UNF is entered, and the diameter is indicated in inches (for example, 1/2). When replacing the chuck, it is imperative to check that the markings correspond to the dimensions of the mount. Today's drills are mostly inch-threaded to meet international standards and expand interchangeability.

For secure fastening, a locking screw is installed on the shaft inside the device. This screw has a left-hand thread, i.e. in order to unscrew it, you need to turn it clockwise.

The second method of mounting the chuck on the drill shaft is based on the use of a Morse taper. In this case, the end of the motor shaft is made in the form of a cone. The inner channel at the bottom end has a similar conical part. The chuck is simply forced onto the taper of the shaft. The marking of such elements has several meanings: B10, B12, B16 and B18, where B means the use of a Morse taper, and the numbers are the maximum drill shank diameterthat can be fixed in this chuck. This mounting method is quite common, especially in screwdrivers.

Preparation for work

Before starting work appropriate training should be provided. To determine whether a tool is ready for a task, there are several conditions:

- When the drill is started with the power cord, it must be connected to the mains;

- If it operates with a battery, then it must be connected and charged;

- A drill is inserted and fixed inside the drill.

To check that the drill is working, you need to click on the power button. If the chuck is spinning fast enough, there is enough charge and you can start working. If it rotates very slowly, then the battery is discharged and needs to be recharged.

Concrete fixtures

The dimensions of the drill for a concrete hammer drill may be different. This indicator depends on what diameter the hole needs to be obtained. But all drill bits for stone, brick and similar coatings have a hard tip. It is made from a special alloy, which gives it higher characteristics. The drilling of such coatings is carried out by means of a percussion-rotary motion.

The dimensions of the drill for a concrete hammer drill may be different. This indicator depends on what diameter the hole needs to be obtained. But all drill bits for stone, brick and similar coatings have a hard tip. It is made from a special alloy, which gives it higher characteristics. The drilling of such coatings is carried out by means of a percussion-rotary motion.

If conventional nozzles have a shank in the shape of a cylinder, then a drill for a hammer drill comes in other shapes. To drill a small recess in the concrete surface, use a drill in the form of a screw with a carbide tip. Large holes are cut with a tungsten carbide bit at the edges. Diamond tools are also popular for their durability.

For granite surfaces, it is customary to use pobedit-based nozzles. Such a tool has different softness, respectively, it is used for different surfaces.For ceramic tiles, a lance-shaped drill with a tungsten or victorious tip is an excellent solution. For glass, it is recommended to use a crown with a special coating on the edges.

How not to lose your key?

In order not to face empty-handed unfinished work, it is important to properly organize the workspace. Such an organization will allow you not to lose sight of the key every time after changing the tool.

The easiest way to protect yourself from loss is in your own workshop. Here you need to create a permanent place to store the turntable and always put it there. In this case, the storage place should be convenient enough and at hand:

- Many manufacturers supply their instrument with an eyelet for attaching a turntable. It is placed either under the handle or near the fork. By inserting the key into this hole, you can rest assured that it will not get lost. The only drawback is that over time, the mount wears out and breaks.

- The keyhole is made of insulating tape. It is attached to the power cord. The attachment point is usually located 50-60 cm from the handle. So the turntable will not interfere with your work and will always remain at hand.

- Having attached a ring to the key, you can hang it on a hook next to the workbench.

If in the process of work it turned out that the spinner from the clamping mechanism was lost, the main thing is not to panic. With the help of folk methods, it is quite possible to release the chuck, get or change the drill, and finish the job.

For newbies

So, let's start with the simplest case - inexperienced users. Screwdrivers have such a thing as a torque regulator. It looks like a scale around the front of the screwdriver, which is right behind the chuck. It contains numbers from 1 to 10, 15, 20 or even more - different models have different ways - and the last position on it is indicated as a drill. If you rotate this regulator and set it opposite a special mark so that one of the numbers is next to it, then when a certain torque is reached, the cartridge will no longer rotate, but will begin to click. If you put on the "drill", then the screwdriver will try to twist with all its might, as much as the engine power allows it.

True, it is worth noting that in two-speed screwdrivers at second speed, even in the "drill" position, if the torque reaches a certain value, then a protective system is triggered, which simply cuts off the current supply. At the first speed, the screwdriver will also try to twist "to the last".

And a beginner can start drilling or screwing screws, for example, when the torque regulator is on one of the numbers, or the screwdriver is at the second speed (and it is recommended to drill on it).

The drill can be clamped quite hard, and as a result, when you start to release the drill or bit in the standard way (turning on the reverse, holding the chuck and pressing the start button), either the torque limiter or the protective system can just work.

Therefore, in such a situation, you just need to put the screwdriver at the first speed and set the torque regulator to the "drill" position. On single-speed models, just set the torque adjuster to the drill position. Well, then, again, we unscrew it in the standard way.