Model range of Husqvarna walk-behind tractors

The Swedish company Husqvarna has been in the agricultural machinery market for over forty years. Recently, the brand entered the list of leaders in motor cultivators. This is primarily due to the quality of the products, as well as to the latest technologies that are used to create models.

Due to the power of the units, it is possible to use various additional equipment. Attachments from the manufacturer can also be found on the market. For example, a cart for a walk-behind tractor, which is slightly inferior in size to a tractor and has a large cross-country ability.

The entire model range of equipment is divided into series, which have their own distinctive features. It is worth considering that walk-behind tractors need good service, since special systems were used when creating the structure.

In this video, we will consider the Husqvarna walk-behind tractor:

Each model is suitable for use in its area, but there are also multifunctional models. These options include the popular TF 338 unit.

TF 230

The TF 230 belongs to the 200 series, but it differs in the form of sufficient power and practicality. It is used for small areas. The model has a gasoline engine version, which stands out for its reliability. The unit has all the necessary protection, as well as an adjustable handle.

The variant has low fuel consumption, which, with a 3.6-liter tank, allows for long-term operation without refueling.

TF 324

The Husqvarna TF 324 is used in medium-sized plots. There is a powerful gasoline engine with a working volume of up to 163 cubic meters. cm.

There are two gears, one of which is reverse. It is used for maneuverability and better cross-country ability. The overall dimensions of the equipment are small, which makes storage and transportation convenient. The engine is installed from the manufacturer Briggs & Stratton.

The reduced noise level is also considered an important difference.

TF 338

Husqvarna TF 338 is one of the most successful models. The main features of the unit:

- original Husqvarna Engine, which supports 92 and 95 gasoline;

- there are many additional functions that simplify the operation process;

- there is a reverse motion for greater cross-country ability and no getting stuck off-road;

- the handle is adjustable in height, which is convenient when transporting. It can also increase productivity;

- maintenance-free gearbox of autonomous type. There is enough lubricant for the entire period of operation;

- the basic package includes several protective side elements;

- wide wheels of pneumatic type allow to increase cross-country ability;

- manual start allowing all-season use based on reliability;

- the clutch actuator is protected by a completely sealed cover.

Thanks to its good power and efficient operation, the walk-behind tractor takes leading positions in the form of mini-tractor equipment.

TF 334

The TF 334 is a professional vehicle with 6.5 hp. The weight of the unit reaches 56 kg in the absence of attachments. The accessories of the cutters go deep into the ground by 0.3 m. There is a steering column that is adjustable for the height of the operator.

All other equipment is considered standard and includes all equipment, including protective guards, which are installed to protect the driver.

It is considered one of the quietest and most maneuverable models. Very convenient to operate in a small area.

TF 335

The TF 335 has a four-stroke petrol engine with 6.1 hp. It is used on an area of up to 1 hectare. The chain-type gearbox has three gears, the list of which includes one return, that is, reverse.

The set includes 6 cutters. There is also a protective cover and all additional protective shields. There is a possibility of connecting various options for agricultural equipment.

TF 545

The Husqvarna 545P is suitable for large areas and difficult terrain. There is an air filter with which the service interval is increased. With the help of a walk-behind tractor, you can perform work of any complexity. It is also possible to use any attachments, including heavy ones. The standard cutting depth is 30 cm with a width of 1.1 meters.

The model is distinguished by its quality and durability.

The procedure for connecting additional attachments

For the rational installation of attachments, special accessories are used: suspensions, wheels, brackets. Before installing additional attachments, first remove the engine from the cultivator. To do this, remove the casing, unscrew the nuts and bolts of the fasteners, remove the V-belt. Next, remove the throttle lever, then remove the motor and install the bracket and suspension.

Hitch

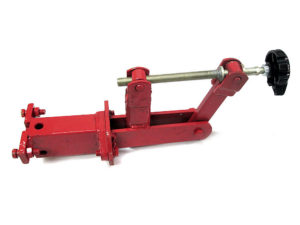

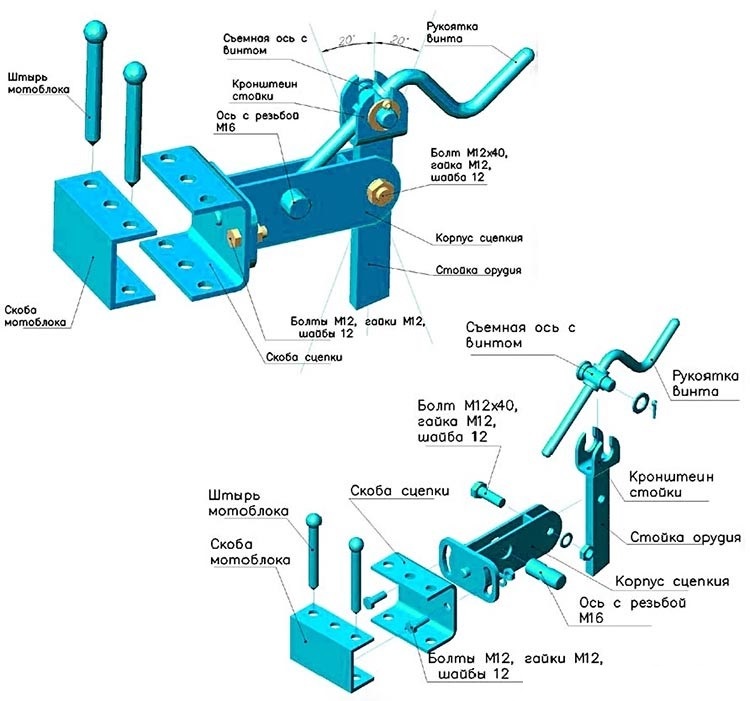

Universal hitch STs-00010

Universal hitch STs-00010

To connect various additional mounted attachments in the cultivator, two types of coupling mechanisms are used: adjustable and non-adjustable. Non-adjustable couplings fix the hitch without the possibility of adjusting the angle of movement, cheaper in cost. Adjustable devices provide the required angle of attack.

Trolley hitch diagram

Trolley hitch diagram

Trailer

The cart is attached to the suspension by means of a kingpin, and instead of rotors, drive wheels are installed, after removing or lifting the transport wheels. In this case, the coulter is removed.

Motor-cultivator Mole with a trailed cart

Motor-cultivator Mole with a trailed cart

Pumping unit

The pump is connected to the bracket, in this case the belt is the drive. As with connecting a trailer, it is necessary to install wheels instead of cutters, and remove or fix the transport wheels in the uppermost position.

Pumping unit for the Krot motor cultivator

Pumping unit for the Krot motor cultivator

Cutters

Soil milling cutters plow the soil without turning the soil layer. The standard diameter is 33 cm. They are mounted on the cultivator shaft.

For processing light and medium soils, one or two pairs of cutters are used; for processing virgin lands, 3 nozzles can be installed on each side.

Milling cutter

Milling cutter

Some owners create their own cutters to increase the tillage depth. There are unique homemade products with a diameter of almost 0.5 m.However, as experience shows, such improvements are not advisable both from the point of view of the technical capabilities of the Krot motor-cultivator and on the basis of the peculiarities of the agricultural technology of soil cultivation.

Before plowing, the transport wheels are raised, and the opener is installed on the trailed bracket. Thus, the attachments will provide forward movement with simultaneous soil cultivation, and the opener will regulate the level of immersion in the soil.

Cutters "Hound's feet"

Cutters "Hound's feet"

Different types of cutters are used depending on the quality of the soil. For heavy, dense soils, the crow's feet model is the best option, for less hard soils, conventional saber cutters are suitable. They can be made in various shapes - three-lobed and four-lobed.

Plow

The plowing of the garden can also be done with a plow; for its installation, the following manipulations are carried out: the cutters are removed and metal lugs are installed in their place, the opener is removed. At the rear, a reversible plow is connected by means of a special hitch.

Hiller

Similarly, to carry out the hilling of crops, metal lugs are installed, and in the back of the Mole cultivator, a hiller is installed.

Rotary mower

For mowing grass on lawns or for making hay, the transport wheels are reinstalled on the gearbox shaft, and the pulleys of the mower and cultivator are connected by a belt drive.

Rotary mower

Rotary mower

All attachments are supplied with passports with technical documentation, so it will not be difficult for owners to carefully familiarize themselves with the connection features of various types of additional attachments.

Main characteristics

Motoblock "Neva" is used for secondary tillage. The design provides a shank that pierces the soil, catches it and turns it over. From a constructive point of view, technology refers to machines that use the rotary movement of discs or teeth. The rotary cultivator of this range is a perfect example.

Tillers are used before sowing or after the crop has begun to grow to remove weeds. Thus, the disturbance of the soil layer near the plants, controlled by the operator, kills unnecessary plants, uproots them. Serrated Neva products are often similar in shape to chisel plows, but they have different purposes. The technique works close to the surface while the plow is deep below the surface.

All units of the company can be described as compact equipment with a low center of gravity.

All models are equipped with a Subaru engine, and with it an electronic switching system is installed. All units have a front wheel for transition, and compact dimensions allow transporting the walk-behind tractor in the trunk of a car.

The wattage may vary depending on the model. This figure ranges from 4.5 to 7.5 horsepower. The working width is from 15 to 95 cm, the immersion depth of the cutters is up to 32 cm, most often the volume of the fuel tank is 3.6 liters, but on some models it reaches 4.5 liters.

The gearbox is installed in Neva walk-behind tractors, three-stage and V-belt. Such equipment works on AI-95 or 92 gasoline, other fuel cannot be used.

In some motoblocks there is an engine with a cast-iron sleeve, in the design of a simpler technique, one forward speed and the same backward. There are multi-speed units in which you can switch between three speeds. Most motoblocks are capable of replacing a small tractor; they can not only cultivate the soil, but also transport various loads. Such a technique is capable of accelerating from 1.8 to 12 kilometers per hour, respectively, the models have a different engine.

On average, a semi-professional engine is designed to work without breakdowns up to 5 thousand hours. The case, made of aluminum, protects against moisture and dust.

The maximum weight of the walk-behind tractor reaches 115 kilograms, while this model is capable of carrying loads weighing up to 400 kilograms.

PLOW TO A MOTORBLOCK FOR TWO BODIES. Dimensions and workmanship

Obviously, the equipment should be adjusted for the track width as well. For this purpose it is necessary to check how the plow coulter is positioned. Its right edge should be in line with the inner edge of the right wheel. So the plow will cut the ground evenly and simply roll it off. The entire walk-behind tractor will go easier.

What, in fact, is how they plow the ground with a walk-behind tractor, let's talk a little below. At the beginning, let's find out what other preliminary measures, besides hanging the wheels and the plow, need to be done.

Before starting the operation of loosening the soil, it is worth pulling an approximate cord along the first row of the plot. Seasoned plowmen are completely different and skip this step. Beginners should certainly perform this operation. There is that during plowing, at least some plow leads a little to the right. Therefore, it is very difficult to make the row completely even. The cord will help you stay on course.

Starting from the second, what remains to be done for our client, you can do the rows without using additional guides, since the wheel of the walk-behind tractor will go along the furrow.

What you need, the walk-behind tractor is prepared. Now proceed to the actual procedure of loosening the soil in this area.To make fewer turns, it is worth plowing the land with a walk-behind tractor along the long side of the plot.

The handle of the walk-behind tractor should be slightly turned at the base to the left. In this case, it is possible to walk on the not yet plowed strip, which, of course, is even more convenient.

And well, now it is necessary to figure out how the earth is plowed with a walk-behind tractor correctly. This procedure is performed in this way:

- The tiller is installed at the beginning of the strip and goes along the stretched cord.

- If the row is passed, they turn around in such a way that the right wheel of the walk-behind tractor is opposite the furrow of the already plowed strip.

This is interesting: Do-it-yourself potato planter for a walk-behind tractor - we describe in order

Gearbox tools

Please note that you must not forget to change the oil in the gearboxes. If this moment is missed, after a while the additives lose their properties.

To increase their service life, their performance must be protected with oil. Failure to replace it in a timely manner can cause the product to foam, as a result of which the gearbox will jam.

Before changing the oil, you need to check the previous level, then remove the dipstick and clean it with a soft cloth. The monoblock gearbox must be filled with oil at a medium level.

Oil is the key to long-term operation of the gearbox. In search of the best product, be sure to read the instructions

It is important to consider the conditions under which it will be used. The most popular is the oil of the Motul trademark, which is used by almost all owners of motoblocks