How to choose?

When choosing a suitable model, first of all, you should pay attention to the brand of the walk-behind tractor. For the Neva and Neva MB model range, variations of 43-centimeter diameter are excellent, the depth of immersion of the spikes into the ground is 15 cm

For motoblocks of the Salyut brand, lugs of half a meter in diameter are needed, in which the depth of immersion in the soil will be at least 20 cm. For the Zubr, high products are needed - 70 cm in diameter.

Lugs are not required only for heavy motoblock units, their weight guarantees them stable movement on almost any surface. But if you decide to improve the permeability of your heavy model of a walk-behind tractor (weighing more than 0.2 tons), choose wide lug devices - with a diameter of 70 cm.

The choice of a suitable lug model also depends on the type of soil and the nature of the outside of the products. Their surface can be shaped like thorns or arrows. Consider when purchasing products that the low height of the spikes is not suitable for wet and loose soils - they are ineffective and easily clogged with soil. Arrow hooks are the most popular and are considered versatile.

When purchasing additional equipment for your unit, first consider options from the same manufacturer.

Pay attention to the cost - it depends on the manufacturer and modification

Grousers for a walk-behind tractor: what to look for?

The main factor in choosing a generic object is size. If a person wants to purchase lugs for a specific model of the unit, he should familiarize himself with the wishes of the manufacturer and follow them.

Since the Neva and Neva MB walk-behind tractors are especially popular among farmers and agronomists, we should use their example to outline the features of the universal lug wheels. For the products of these manufacturers, options with a diameter of 43 cm are suitable, because they are laid in the soil at a depth of 15 centimeters. Such dimensions will ensure maximum adhesion to the ground and trouble-free movement.

For absolutely all Salyut walk-behind tractors, wheels with a diameter of 50 cm will be relevant, the spikes of which are immersed in the ground by at least 20 cm. Naturally, each manufacturer has its own requirements for the lugs, therefore, you should carefully study the operating instructions for a motor-cultivator that has a motor-cultivator and do not ignore the wishes of the manufacturers.

An important point: heavy equipment does not need such additions, because its weight is already a guarantee of stability on almost any ground.

What are the grousers for the walk-behind tractor for?

Motoblock grousers are special devices that outwardly resemble ordinary metal wheels, supplemented with studded pads. The name itself indicates their main functional purpose - to guarantee perfect adhesion between the cultivator and the underlying surface - the soil. Thanks to these devices, the walk-behind tractor can move freely on any terrain, regardless of weather conditions.

In addition, the lugs for the walk-behind tractor perform other functions:

- contribute to better soil cultivation;

- simplify the transportation of both the walk-behind tractor itself and the loaded trailer connected to it on the off-road or on loose soils;

- increasing the weight of the unit, provide it with good balance and stability in space;

- allow the use of other attachment adapters, for example, for seedbed cultivation.

Purpose and varieties

The lugs are designed to increase the weight of the motoblock unit and improve the contact of the equipment with the ground, especially in areas with too wet and / or loose soil. They are a spike design that is fitted onto an axle instead of / over pneumatic wheels with soft tires.

Several lug configurations can be found on the market today. Distinguish between universal and special lugs. The first ones can be used on any walk-behind tractor, the main thing is to choose the right size. The latter are made for some specific brand (model) of the unit.

According to their design features, lug attachments are divided into those requiring dismantling of wheels with pneumatic tires and worn over the tires. The first type requires fixation on the wheel axle.

The use of lugs allows:

- it is better to process the soil layer;

- improve the cross-country ability of both the motoblock unit itself and the attached trailer with a load;

- to increase the stability of equipment due to an increase in its weight;

- hang other additional equipment.

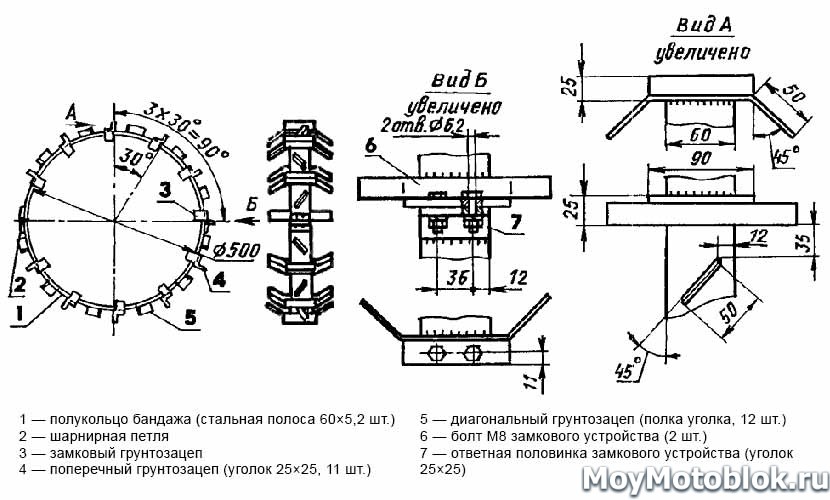

Complex lugs

The following design belongs to a number of complex ones, since it is not inferior to its factory counterparts in quality. We do such lugs with our own hands and they fit like a neva, fireworks and even a motor-cultivator. To make them, we need: half a wheel drive from a Zhiguli (you can cut the disc yourself), tractor tires, with a developed projector. After that, you should choose tires with the same advanced projector as the tractor. If you cut off the sidewalls, we get a closed ring.

The following design belongs to a number of complex ones, since it is not inferior to its factory counterparts in quality. We do such lugs with our own hands and they fit like a neva, fireworks and even a motor-cultivator. To make them, we need: half a wheel drive from a Zhiguli (you can cut the disc yourself), tractor tires, with a developed projector. After that, you should choose tires with the same advanced projector as the tractor. If you cut off the sidewalls, we get a closed ring.

The lugs that we received will be able to move along the dirt road without loosening it. On soft ground, the wheels will feel comfortable, but at the same time they will not move as boldly as the metal version.

Optimal dimensions

It's no secret that heavy machinery works the land better than light machinery. This is evidenced by the fact that people began to be interested in the question of how to make lugs for a car with their own hands. Even hard ground can be processed with such equipment, which a light tractor does not cope with very effectively. For such units, large lugs are required. To summarize, the design parameters will depend on the size of the walk-behind tractor.

Thus, the following popular walk-behind tractors can be distinguished:

"Neva". Walk-behind tractors are common, which adapt to any conditions. But in the case when the farm already has a Neva tractor, which by its characteristics is not considered universal, you can make soil cutters yourself. It should be borne in mind that the diameter of the device should not be more than 36 centimeters, and the width should not be more than 11.

MTZ. Even despite the fact that such units are Belarusian, the price for them is considerable due to the highest quality. You can focus on the price of 5,000 rubles or more. The bottom line is that the wheels of these motoblock models are quite large. It takes a lot of labor to make high-quality lugs

It is important that the dimensions are correct and that the triangular plates that engage the ground are carefully welded to the main lug wheel.

"Firework". Such a device is being assembled according to the "Neva" scheme.

"Centaur"

The wheels in such an apparatus are somewhat similar to the "Neva". But the first car has 11 centimeters longer wheels. If a grouser is made for "Centaur", then its length should be 450 millimeters, and width 110. It can also fit other models of motoblocks, including other manufacturers.

It is also helpful to make a lug extension. They are designed to increase the angle of rotation of the structure and the width of the potassium and counterweight.To do this, a slotted sleeve must be attached to the hub. An additional axle is inserted into such a sleeve, which is fixed with a bolt. Finally, you need to fix the soil cutter wheel on the axle.

Thus, there are many options for making soil cutters with your own hands without much labor and emptying the pocket for expensive factory models.

Originally posted 2018-03-28 15:28:41.

Self-production of hooks

- The easiest way, perhaps, is to make lugs from unnecessary disks from car wheels. With the help of a welding machine, an axle shaft is attached to the disks, on which bearings are then put on. Square metal plates are welded to the car rims so that they touch the rim edges.

- Then the plates are bolted to the rim. Further, teeth are made - steel hooks, which will enter the ground. For this purpose, you will need a steel plate, for example, a corner, which is cut by a grinder into parts, and from these parts the same teeth are welded that are made in the factory. The resulting hooks are placed on the wheel rim 15 cm apart.

- Homemade hooks can be made from an old gas cylinder. Two discs are cut out of it for wheel rims 5-7 cm wide and 30 cm high. Further, the same operations are performed as with car discs.

- To improve the operation of wheels with hooks, one more tooth can be welded from above to each hook and the teeth can be lengthened to 60 cm. An axis is made: a metal plate is attached to one rim, on which this axis will be placed.

- Lugs can be made from any round workpiece. The main thing is to choose the right width and diameter of the future wheel with hooks. The dimensions of the wheel are determined functionally, that is, based on the purposes of use on the walk-behind tractor.

For "Neva"

The walk-behind tractor of each brand has hinged options that are more suitable for its design than others. It is better, of course, to purchase a universal walk-behind tractor, for which almost all canopies are suitable. Wheels with lugs Ø 340 × 110 are produced for the Neva.

The walk-behind tractor of each brand has hinged options that are more suitable for its design than others. It is better, of course, to purchase a universal walk-behind tractor, for which almost all canopies are suitable. Wheels with lugs Ø 340 × 110 are produced for the Neva.

By design, these lugs are slightly larger than the homemade ones we have described. Follow the instructions above, but select other rim sizes. The height of the wheel for the "Neva" hook should be 340 mm, the width of the self-made device - 110 mm.

For "Centaur"

Grousers for a walk-behind tractor of this brand differ only in size. Above, the dimensions were described, which had to be guided by, converting the old wheels into lugs for the "Neva". The same scheme is used to make wheels with large hooks. The wheel height is chosen 450 mm. The wheel width should be 110 mm, as for the Neva. Such hooks are suitable for the Centaur 2060 and 2090 walk-behind tractor and units with similar parameters. The factory version will cost about $ 30.

For "Zubr"

The motoblock of this brand is a heavy professional equipment, and the best available attachment can be installed on it. In order for the Zubr to go into the ground perfectly, it needs lugs. The standard fixtures that fit it have a 200mm bar and a 700mm height. Wheels of this width are suitable only for heavy walk-behind tractors and, in addition to the Zubr JRQ78 and 79, they also fit the Centaur 1070D, Aurora 101 and Aurora 81, Zirka LX1080D and 1090. In the factory version, the distance between the hooks is 14.5 cm. The wheel hub has a diameter of 60 mm. They put on the walk-behind tractor using an additional hub.

Purpose

The most common options for using lugs (iron wheels) are walk-behind tractors, mini-tractors and motor-cultivators. Despite the fact that some modern mechanisms and devices have these hinges in their own basic configuration, more often they still need to be purchased separately from the unit or made with your own hands.

Iron wheels are used in situations where it is required to increase the coupling of equipment with the ground, thus increasing the traction force and the ability to overcome obstacles. So, motor vehicles equipped with iron wheels behave much more stably on loose and loamy soils. This enables the unit to perform thorough soil tillage without the danger of getting stuck or burrowing in it. The use of iron wheels for cars and mini-tractors significantly increases their cross-country ability in muddy conditions.

However, the possibilities of operating lugs with road and agricultural machinery do not end there. In a slightly different form, these devices are used to more firmly fix the greenhouses on the soil, as well as additionally to tie the wood foundation to the ground. The device of construction lugs is somewhat different than that of wheel lugs. They are rods of iron reinforcement up to a meter long with a plate welded at one end.

general information

- By design, these devices are spiked wheels. Today, there are many different device transformations, and you should choose them wisely. To a greater extent, the quality of work determines the weight of the unit. The most functional sheds can be hung only on heavy walk-behind tractors or medium-weight units. If it is of high quality, the unit does not give the desired result, you need to additionally purchase wheels with lugs for it.

- Standard fixtures are metal wheels with spikes that bite into the ground and engage the walk-behind tractor. To make devices with your own hands, you will need to know their device, which will be seriously helped by drawings and diagrams. You will need to determine the diameter of the canopy, choose the material of manufacture, and, of course, select the necessary tools. The first thing you need is a welding machine and a grinder.

- The first step is to determine the size of the fixtures. Their height and width depend on the tasks for which the hooks are mounted on the walk-behind tractor. You also need to take into account the requirements for the mass of devices, because the wheels are put on with them to improve the adhesion of the walk-behind tractor to the ground. For this, wheels of solid weight are needed, which may not be enough for a walk-behind tractor. The minimum wheel weight is 20 kg. If necessary, weights are hung on the soil hooks. This is necessary to achieve the best results, or it is used when the weight does not reach the norm.

Self-production of the simplest elements

There are several techniques for making homemade iron wheels. Let's talk about different options that differ in the degree of complexity and the scale of the required activities.

The simplest method to make something similar to industrial iron wheels is to modernize ready-made factory elements. For this, "anti-slip strips" are made, which are put on the wheels.

Let's consider the process of their creation.

- Take a 2-3 mm iron sheet.

- Using an angle grinder, a rectangle is cut out, which should be several centimeters wider than the contour of the tire and coincide with its circumference.

- The edges of the strips are folded inward to prevent sideways jumping and injury to the machine operator.

- The preparation of the lug component begins (for this purpose, sheet iron with a thickness of at least 0.04 centimeters is required, which is bent at an angle of 120 ° and cut into identical pieces).

- With a welding machine, the resulting elements are welded to the strips, keeping the same distance between them.

The same operations are performed for the second wheel. To tighten the structure, you will need bolt ties, which are also welded. Violation of the dimensional relationships between the studs (plates) on different wheels can provoke the fact that when moving forward, the unit will tilt to the right or left.

Manufacturing of lugs with a more complex design

In addition to methods for making the simplest lugs, there are also methods for making more complex structures. To work on the production of the latter, you need to prepare:

- Steel sheet, 3 to 5 mm thick - you need to make a central disc from it;

- Steel strip, 5 mm thick and 50 mm wide - it will be required to make the outer hoop. You will need 6 hoops - they will make the wheel heavier and more durable;

- Another steel plate, with a thickness of 8 to 10 mm - you need to make a hook from it;

- Bulgarian;

- Drilling machine or drill;

- Welding machine.

All parts should be connected to each other by arc welding, since a gas torch will not be able to heat metal of a given thickness. The manufacturing algorithm is as follows:

- First, lengthen the axles of the walk-behind tractor - this is required due to the fact that the width and diameter of the lugs are larger than the place where the standard wheels are mounted;

- Be sure to provide for the possibility of adjusting the position of the track, since in the future you will process the garden with rows of different widths. When moving the lug wheels, you will be able to adjust the position of the attachment being used and the width at which the lugs will be located. Since the mass of each wheel is about 10 kg, reliable grip and high stability of the walk-behind tractor on the ground will be ensured;

- Next, start making the lugs themselves. To do this, make 2 spoke-shaped center discs from profiled steel sheet;

- After that, weld 3 outer hoops and hooks to the end parts of the structures;

- Weld steel plates to the hoops. They should be located on the hoops diagonally in the form of a snake;

- Sharpen each plate for better traction.

The made lugs will provide maximum grip and help to remove even the thickest weeds with ease.

When using lugs, do not forget that they are only intended for work in the garden. Do not use devices for moving the walk-behind tractor on concrete or asphalt, as the teeth of the product will bend and quickly become unusable.

Both the simplest and more complex designs are suitable for use on motoblocks Salyut, Agat, as well as Neva MB-1 and MB-2.

What we call wheels - in the case of a walk-behind tractor, are lugs. In the overwhelming majority of factory designs, the equipment is equipped with conventional wheels with embossed off-road tires.

This is done in order to be able to use the traction force for the transport of goods on ordinary dirt roads.

Important! The use of a walk-behind tractor (even factory-made) on public roads is prohibited. Even if it has quality factory wheels installed

Therefore, many owners of small agricultural machinery make lugs for a walk-behind tractor with their own hands. In this case, it is only necessary to fit the landing nest to the hubs of the factory motor plow. When changing the mode of use, simply mount the desired wheels.

If the walk-behind tractor is used only in the field, ordinary rubber tires are not needed. And for a mini-tractor of your own production, you do not have to make ordinary wheels at all. In this case, homemade lugs for the walk-behind tractor will be the only set.

The design is not new, the first tractors were produced without rubber tires. The wheels were metal, and powerful transverse or diagonal plates of thick steel were installed on the driving rollers.

Combined design

If the technique is homemade and the soil is not too difficult, the wheels should be appropriate. Hooks can be made using tractor protectors.

If the technique is homemade and the soil is not too difficult, the wheels should be appropriate. Hooks can be made using tractor protectors.

We take the halves of the rims from the Zhiguli car. Choosing tires with good tractor tread.We cut off the sides, we get a rubber closed ring with a good tread. We open the halves of the rims and twist them firmly after the tires are laid. With such lugs, it will be possible to move along a compacted dirt road without fear of loosening it. On soft soil of a plowed field, the wheels will not let you down, but the tractive effort will be less than in the case of the metal version.

If it is necessary that not only the wheels are tenacious, but also additionally loosen the soil in the rut, knife-type hooks are made. You can create a homemade rim to attach them, or weld them onto the rims. The only drawback of the knife design is that it does not allow you to move the walk-behind tractor in the usual way.

When spring loosening together with traditional nozzles, the width of the soil processed per pass will double, which will save a lot of time.

How to make from Zhiguli disks?

1 way

More complex elements can be created on the basis of a metal sheet or car disks. The exact adaptation can only be made in accordance with the drawing. Some make the drawing on their own, others use a ready-made version.

To create such products, they take:

- 4mm steel, which will serve as the discs of future iron wheels;

- metal 8mm sheet, which is necessary for the area to be submerged in the ground;

- electrical tools (welding machine, angle grinder, electric drill).

The manufacturing process is pretty simple:

- An angle grinder cuts 2 equal-sized workpieces in the shape of a circle, in the center of which holes are drilled for the studs and the hub.

- A jagged frame is made along the outer edge (no more than 100 millimeters in height).

- The second sheet of metal dissolves into triangles with rounded corners.

- The triangles are welded to the scalloped frame.

2 way

In this case, a complete set of disks is required. One pair can be fitted with tires and used for driving on asphalt, while the other can be made as classic lugs.

Let's consider the order of operations.

- We dissolve a metal corner with a shelf of 5-6 cm into pieces wider than the available discs.

- In the middle of one side, using an angle grinder, cut out a platform in the form of a triangle. It is with this part that they will begin to touch on iron wheels. Using a gas burner, we heat the corner and bend it a little. We "grab" with electric welding to strengthen the workpiece.

- Along the outer rim of the car disc, we weld the spikes from the corners at regular intervals (a step of 15 centimeters would be ideal), directing the pointed part in the direction of the motor vehicle.

- The same steps are repeated for the other disk.

How to make lugs with existing factory wheels

The easiest way is to put the structure on the tire like snow chains.

It is enough to take sheet metal with a thickness of 2-3 mm, and cut a strip that will be slightly wider than the tire profile. The preload is provided by a simple tie made of bolted studs. The edges of the strip should be folded to prevent slipping under lateral loads.

The lugs are cut from thicker sheet steel (4-5 mm). They need to be bent in the middle at an angle of 120 °. The blanks are then welded to the strips at regular intervals.

Important! The lug distance must be the same on both wheels. Otherwise, the equipment will be sidetracked during work .. Therefore, before starting work, you should use ready-made drawings, or develop a layout yourself

Therefore, before starting work, you should use ready-made drawings, or develop a layout yourself.

Such lugs can be made with your own hands in a couple of evenings. If you use a regular smooth tread on a homemade walk-behind tractor, the device will turn the equipment into a real off-road vehicle.

We will acquaint fans of small-scale mechanization with various types of structures, and varying degrees of complexity.

Specifications and dimensions

Grousers for agricultural machinery are metal wheels or overhead rims equipped with a powerful tread that goes deep into the ground and reliably adheres the equipment to the ground. Highly hardened steel is used as a material for their manufacture, due to which the devices are practically indestructible and can serve for more than a dozen years. An important working parameter of lugs for walk-behind tractors and mini-tractors is their diameter and weight.

It depends on these indicators how well the unit will perform its work on plowing the land, removing weeds, hilling various crops and removing snow. So, the minimum weight of the simplest metal wheels should not be less than 20 kg, otherwise the use of this equipment will lose its meaning, and the benefits from it will be minimal. If the lugs, often homemade, do not reach the above standard, then they are used in combination with weighting agents, the presence of which provides the equipment with the necessary weight.

In addition to the weight of the lugs, the size of the lugs is also important. The diameter of the factory models ranges from 300 to 700 mm, and the width ranges from 100 to 200 mm. The most popular are the Patpiot 490001070 models and the device for the Celina, Kaskad, Kadvi and Neva walk-behind tractors.

The dimensions of these devices are 400x180 and 480x190 mm, respectively. The models are suitable for most domestic machines and are used for plowing soft soils, removing weeds and cutting furrows. The Patriot S-24 model, weighing 11 kg and measuring 390x120 mm, is no less popular. It can be used to loosen the ground, fight weeds and remove snow. More overall devices measuring 500x200 mm can be used in combination with a plow, and samples of 700x130 mm are used with potato diggers and flat cutters.

Grousers for motor cultivators have more modest dimensions than models for walk-behind tractors. Thus, Tarpan and Neva, popular among domestic farmers, weigh only about 5 kg, have a diameter of 280 mm and a width of 90 mm. Such devices are used for loosening light soils and working with single-row hillers.