How to choose the right lugs for a walk-behind tractor?

Not only the effectiveness of their use, but also the ease of movement of the walk-behind tractor depends on how correctly the lugs are selected.

When buying accessories, you should pay attention to the following factors:

- Sizes of lugs - suitable dimensions of products directly depend on the class of the agricultural machine. For heavy motoblocks, choose products with a diameter of about 70 cm. Medium and light units can be completed with lugs with a diameter of about 25–40 cm;

- The type of soil to be cultivated - the most versatile are lugs, to which arrow-shaped spikes are welded. Their grip part is shaped like corners, so they show excellent grip even on very loose soil;

- Possibility of mounting weighting materials - for operation on loose soil, some lug manufacturers provide for the possibility of installing additional weighting materials, which make the use of products more effective, especially when working with light walk-behind tractors. As a rule, weights are in the form of durable metal containers that can be filled with stones, sand or any other available material, and then installed on the lugs.

When buying lugs, be sure to consider each of these factors. So it will be much easier for you to choose the most effective fixtures for mounting on a walk-behind tractor.

Interesting: Manufacturing Guide caterpillars on the walk-behind tractor from improvised means

What are the grousers for the walk-behind tractor for?

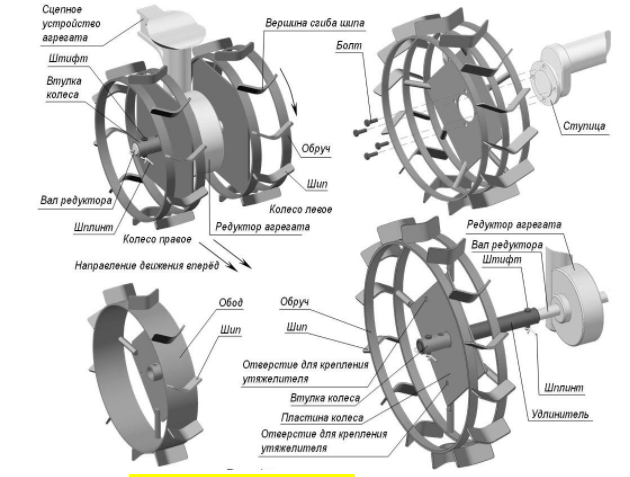

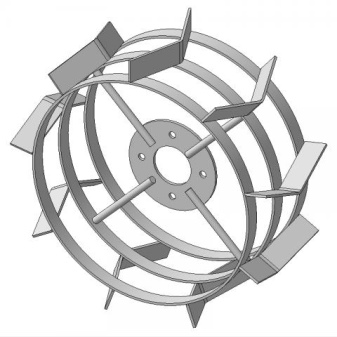

Motoblock grousers are special devices that outwardly resemble ordinary metal wheels, supplemented with studded pads. The name itself indicates their main functional purpose - to guarantee perfect adhesion between the cultivator and the underlying surface - the soil. Thanks to these devices, the walk-behind tractor can move freely on any terrain, regardless of weather conditions.

In addition, the lugs for the walk-behind tractor perform other functions:

- contribute to better soil cultivation;

- simplify the transportation of both the walk-behind tractor itself and the loaded trailer connected to it on the off-road or on loose soils;

- increasing the weight of the unit, provide it with good balance and stability in space;

- allow the use of other attachment adapters, for example, for seedbed cultivation.

Anti-skid chains and bracelets: which is better

The analogs of chains for cars are bracelets, which are a pair of sections of chains fixed to the wheels with belts. The chain sits over the top of the tire and the belt sits in the hole between the disc. In this case, the bracelet, unlike the chain, is firmly tightened on the bus, which allows the chain to be located in one place.

To increase efficiency, it is recommended to attach at least three anti-skid bracelets to one wheel

Usually, three bracelets are mounted on one wheel, which is enough to reach a hard surface, while creating friction and repulsion of the car. Unlike chains, bracelets have the following advantages:

- Speed and ease of installation. If it is recommended to install the chains only before overcoming a snowy or swampy area, then the bracelet can be installed even when the car is stuck.

- Compact, as they do not take up much space in the trunk, unlike chains.

- No need to jack up the wheel.

- Versatility. If the chains are designed for a specific wheel diameter, then the bracelets are suitable for all wheel sizes.

- Unlike chains, bracelets are several times cheaper.

- Long service life.

Like chains, bracelets are classified as hard or soft. Some of the cheapest options for bracelets are plastic products. They are suitable for all types of cars, from small cars to SUVs, so every driver can afford them.

Bracelets, like chains, are divided into hard and soft

How else are chains different from bracelets? Numerous observations of drivers show that the chains have better grip on the road surface, which has a positive effect on the flotation parameters. Chains can be used to overcome snowy and icy areas until they end. Bracelets can only be used for short-term use up to 5-10 km.

When you know what chains and bracelets are, you can conclude:

- If you are planning a long road on swampy, snowy and icy terrain, then it is recommended to use chains.

- Bracelets are used only when planning rare trips around the city or outside of it in bad weather. Even if during the trip you forget to put on the bracelet, you can do it at any time, even if the car gets stuck.

Do-it-yourself grouser extenders for a walk-behind tractor

Extensions are used to increase the width of the potassium, as well as for the ability to freely turn the wheel relative to the axle. In order to make this kind of extension cord in a walk-behind tractor, it is necessary to screw a sleeve with a slot onto the axle. An axle is inserted into the sleeve, which is fixed with a bolt. Well, the final one is to fix a wheel with a grouser on the axle. This mechanism is very simple and anyone who has at least some relation to technology can do it. There is such an extension cord in the mall costs from 800 to RUB 1000

Material from the section "How to make lugs according to drawings

»Photo site, drawings and diagrams of walk-behind tractors

, motor cultivators and attachments to them. For those who searched the Internet for publications on the topic “Diagram of the device of a homemade wheel with a bandage

", As well as photos and pictures upon request"Making lugs for a walk-behind tractor with your own hands

».

For making lugs with your own hands

There are many different options and designs for rubber wheels of a walk-behind tractor. We offer you an original, but still quite laborious method of making a bandage with grousers for rubber wheels. This method is suitable for those who have old, unusable rubber tires (factory or for a homemade walk-behind tractor with car wheels, the main thing is that the sides of the tire are intact). In principle, in such a way, it can be done both to the car and to the tractor. To make a bandage with lugs from a tire, it is necessary to make identical and uniform cuts around the entire circumference in the old rubber slope as shown in the diagram: first you need to calculate and mark everything well, and then, using a breakdown, make holes in the tire sidewalls at the corners of the marked cuts from which and start cutting. Cutouts are best done with a scalpel or a knife made from a braid, periodically smearing it with grease or soap. The best option is to make cutouts with a grinder. Then you cut off the bead rings of the tire, since you no longer need to install it on the disc. A self-made tire with cutouts will need to be put on the rubber wheel of the walk-behind tractor. To do this, a wheel with an identical tire is disassembled (it is necessary that it is not new, but with good wear). On the tire removed from the wheel of the walk-behind tractor, a made blank with slots is put on (this operation is not easy and time-consuming).And in the slots you insert low channels welded from thick metal, you can not in each, but through one slot (for large wheels, you can use small factory-made channels, but this issue must be determined in advance, because the width of the notches depends on this and especially the width of the rubber sections to be left, which should be equal to the width of the channel flange). The inserted metal channels will play the role homemade lugs on motoblock wheels

... The main thing is to correctly calculate the ratio of the elasticity of the rubber left on the tire and the weight of the inserted channels, so that they are not too heavy and do not pull the tire rubber. Instead of channels, in the manufacture, you can use homemade metal brackets of any shape convenient for you. After dressing, the wheel is skidded back, inflated and walk-behind tractor on rubber wheels with grousers

ready for use. Given the high labor intensity of the work, it will be much easier to make an ordinary metal or lug from metal. But for someone, due to the lack of the necessary metal or the presence of old tires, this option will also be interesting.

With the help of a walk-behind tractor, you can do a lot of different work if, in addition to the unit, there are appropriate attachments. The main task of any walk-behind tractor is soil cultivation: plowing, hilling, possibly planting and digging potatoes with a certain canopy. Plowing requires cultivator lugs. They are reliable assistants to each owner of the unit, and you can make lugs for a walk-behind tractor with your own hands within a few hours. Lugs are a fairly common attachment that allows you to increase the weight of the equipment and provide better grip of the walk-behind tractor with the soil.

Varieties

The modern agricultural machinery market presents a wide selection of various wheel models, which are classified according to several criteria. The main criterion for distinguishing lugs is their design.

There are two types of wheel lugs.

The first is a product made in the form of one or more welded metal rims equipped with cone-shaped spikes or corner plates welded at a certain angle. Such a structure is installed instead of native wheels, and the fastening takes place using special brackets. The advantages of the species include high efficiency. when working the land, and good cross-country ability of the unit. The downside is the need to "change shoes" the walk-behind tractor, which is a rather lengthy and time-consuming process.

The second type is represented by lugs made in the form of metal nozzles, which are installed on top of ordinary wheels and do not require mounting on the axis of the walk-behind tractor. Structurally, such models can be made in the form of chains or rims equipped with metal spikes. Outwardly, such models vaguely resemble conventional anti-slip chains for cars.

This type of lug is especially popular with SUV owners and has worked well on bumpy slushy roads with a lot of mud and clay. The advantage of this type of lug is quick installation and low cost in comparison with metal wheels. The disadvantages include a slightly lower cross-country ability and the need for additional use of weighting materials.

The next classification criterion is the compatibility of the lugs with various equipment. On this basis, special and universal devices are distinguished. And if the former are designed for a specific model of agricultural or road equipment, then the latter are compatible with most of them, and can be installed on almost any unit.The advantage of specialized samples is a higher efficiency and versatility, and the advantages of station wagons include their practicality and the ability to use in relation to any technique. In addition, such models are much easier to sell if they are not needed.

Weighting the body of the walk-behind tractor

In some cases, the weight of the wheel weights is insufficient. Since it is not recommended to overload the axle, weight is added to the unit body. This can be done in different ways. The best option is to fix the removable steel frame directly on the walk-behind tractor. The base can be a frame, a gearbox, or a niche for installing a battery.

The increase in the mass of the body is carried out in the following sequence:

- Determination of the center of gravity of the unit. Creation of a wireframe project.

- Welding to the casing of the gearbox, and to the steering wheel bracket of the walk-behind tractor - bolts with a diameter of 12 mm and a length of at least 10 cm.

- Welding the frame from the corner. Making mounting holes in it for bolts.

- Fitting the frame to the frame. Drilling holes in it corresponding to the location of the holes on the frame.

- Cleaning the frame from dirt and rust. Painting the product and fixing it to the frame.

- Manufacturing of cargo to the size of the frame. You can find the necessary parts at the scrap metal collection point, where the material will be immediately cut into fragments of the desired size.

The fastening of weights to the walk-behind tractor is carried out by welding or bolted connections. The second option is more time-consuming to implement, but more practical in the long run. The need to remove additional load arises when transporting the unit or performing light work when excess pressure on the ground is contraindicated.

How to do it yourself?

Soil wheels can also be made at home, without spending extra money on the purchase of finished products. There are several fairly successful methods of making this equipment.

The first method is to remake old tires. To do this, you just need to "dress up" them in a structure that will prevent slipping.

To do this, you will need:

- welding machine;

- saw for metal;

- metal sheets with a thickness of 2-3 mm;

- metal sheets with a thickness of 4-5 mm.

From sheet metalwhich is thinner, you need to cut 2 strips slightly wider than the width of the tire. The length of the strips should be such that, when twisting them into a ring, the wheel fits freely inside them. Pull the strips into rings, fix with bolt pins. In this case, it is desirable to bend the long edges inward.

From a thicker iron sheet, cut the blanks for the hooks, then bend them along the middle at an angle of 90 degrees and again - across at an angle of about 120 degrees. You should have a kind of beveled corners in the middle.

Then weld them to the base of the lug at regular intervals. This is a very important point, because if the identity of the distance is not observed, the walk-behind tractor will wiggle from side to side.

The second method is even easier to execute. You will need:

- 2 discs from the wheels of a Zhiguli car;

- a sheet of steel of sufficient thickness (4-5 mm);

- welding machine;

- angle grinder;

- electric drill.

A strip of metal must be welded onto car wheels - the ring base of the lug. Strong teeth are already installed on it.

Cut triangular blanks of the same size from the sheet and cut the corners. Weld them neatly perpendicular to the metal strip, keeping equal spacing. The dimensions of the teeth depend on the mass and size of your walk-behind tractor.

Approximate dimensions of lug devices for various brands of motoblocks

Walk-behind tractor brand

Lug diameter, mm

Width of lugs, mm

Self-made lug devices are attractive primarily because you design them for a specific walk-behind tractor, that is, they will ideally fit your device. You save your money, because often additional attachments (which include lugs) are quite expensive, especially for motoblock units of foreign, in particular, European production. It is also worth noting that not only car wheels, but also motorcycle wheels and even gas cylinders - any round metal parts of a suitable size are suitable for the manufacture of home-made lug devices. To make the teeth, you can use corners 5-6 cm wide (cut into pieces of a suitable size), cutters or a thick sheet of steel.

Use parts made of metal alloys with high strength characteristics, and pay more attention to the teeth of the lugs, because the main load when immersed in the soil goes to them. To increase the service life, paint the finished products with paint for metal products or cover with an anti-corrosion compound

To increase the service life, paint the finished products with paint for metal products or cover with an anti-corrosion compound.

You can learn more about how to make grousers for a walk-behind tractor with your own hands.

Soil lugs for the walk-behind tractor are useful devices that allow you to clear the area for sowing from weeds and, at the same time, increase the stability of the agricultural machine on loose soil. Today, these simple products have earned great popularity not only among the owners of large farms, but also among summer residents who have small land plots at their disposal.

Soil lugs for the walk-behind tractor are useful devices that allow you to clear the area for sowing from weeds and, at the same time, increase the stability of the agricultural machine on loose soil. Today, these simple products have earned great popularity not only among the owners of large farms, but also among summer residents who have small land plots at their disposal.