Technical characteristics of tedders (GVR - 6)

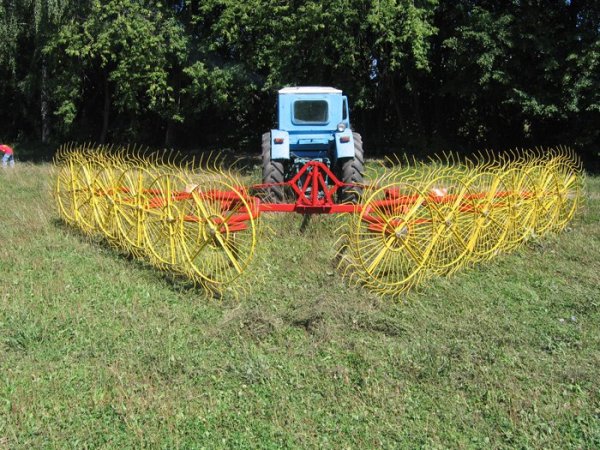

Rotary models are used in agriculture when processing cut grass. The trailed structure covers the surface of the cultivated area of 6 meters. The efficiency of this unit is 7 hectares of field for 1 hour.

The structure weighing 1000 kg in working condition has dimensions that differ from the dimensions in the condition of transportation to the field work site. The recommended speed is 20 km / h while driving.

The fields are processed at a speed of 12 km / h. This speed does not affect the quality of the hay being processed. For drying and scattering herbs, use a pair of rotors with rods in the amount of eight pieces. Factory production has provided 3 teeth on each rod for a strong hold.

The mower model does not move without the help of a wheeled tractor, it works through the hydraulic system

Wide design, the utmost attention of the tractor driver is imperative, for safe use

To compensate for the loads arising during movement, springy units of long-term use are installed. The constructive solution of the system is designed for efficient operation in fields with complex ground surfaces.

The trailer interacts with wheeled tractors. The tedders are serviced by one operator, for processing swaths in the fields. (GVR - 6) will not cope with wet grass, the moisture content of which reaches 85%, there are other models for tasks of this kind.

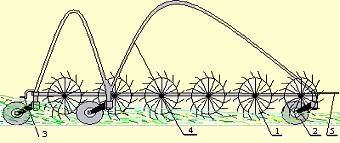

Device (GVR - 6)

The unit for drying and folding hay consists of a special rake for collecting swaths into swaths, tedding and pressing dry grass and straw.

- The mower consists of two rotors, the arrangement is horizontal in accordance with the cultivated area.

- The equipment is equipped with support wheels.

- High quality metal frame for durability.

- Hitch and drive mechanism.

The rotor device consists of a long rake, a treadmill and a mechanism that drives the system. Timely maintenance, replacement of worn out, but not yet out of order parts will increase the efficiency of this unit. Any technical device requires constant maintenance.

Principle of operation and regulation (GVR - 6)

Operation (GVR-6) begins with preparatory work.

- First, attach the rake trailer to the tractor crossbar and fix it.

- When attaching the safety cable to the tractor crossbar, it is necessary to hook the rake onto the spoke.

- We attach the cardan shaft to the vehicle.

- Remember to connect the rake hydraulic system to the tractor system.

Having brought the unit into working position, you can go to the processing of hay. Using the adjustment lever, we raise the rake system and move to the processing site. The adjusting lever makes it possible to lower the wheels in case of poor grasp of grass from the surface of the field or raise when grabbing the ground.

Parts catalog with diagrams and numbers - download / read PDF

The rake's fingers pick up the grass as it moves. The grip takes place from the bottom of the base in the middle part, the fingers release the hay. The mass of dry grass is constantly in motion, passing the length from wheel to wheel, reaching the last, creates a swath. The loosened grass is quickly dried when blown by the wind.

By changing the position of the treadmill, the direction of the grass mass is changed accordingly. Turning to a horizontal position creates windrows. Passing over the swath, the opposite action takes place again, scattering wet hay to dry out.

The width of the roll is adjusted with guy wires.For tedding, the section of the implement requires minor modifications. The grass mass will not pass from wheel to wheel, it just stays on the field. The movement of the section along the roll results in wrapping and shearing.

Construction and classification of tractor rakes

Structurally, tractor rakes are working elements fixed on a metal frame frame, designed for raking up hay and tedding it.

The working elements are driven by the power take-off of the traction machine or work by rotating their own wheels.

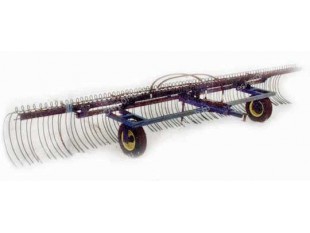

The position of the frame of trailed devices is changed by adjusting the drive wheel.

The mounted rake systems are raised and lowered by hydraulic drives connected to the hydraulic circuit of the base tractor.

Aggregation of devices with tractors, including MTZ machines, is carried out using a trailed mechanism (trailed units) and a hitch of the base machine (mounted rake).

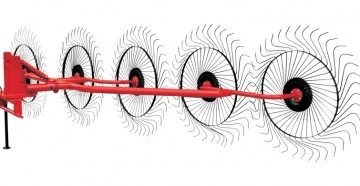

By the number of sections of the working bodies, the rake units are divided into multisection units used to perform a large amount of work and single-section devices for processing small areas.

Depending on the shape of the working bodies and the principle of their operation, the rake units are divided into:

- Transverse, swath-forming units located perpendicular to the direction of movement of the base chassis with a different number of sections and a variable working width. Machines of this type are equipped with sections of working elements, folding during transportation, with cylindrical teeth fixed on hinges. When performing work, the cross-type rake mechanism copies the soil surface of the treated area.

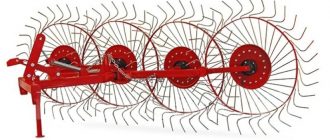

- Wheel-finger rake, consisting of identical independently working sections symmetrically located in the left and right parts of the frame. Each of the sections consists of working bodies made in the form of a wheel with metal fingers and supporting pneumatic wheels. Units of this type are used both for raking grass into swaths and for tedding it during dry mowing.

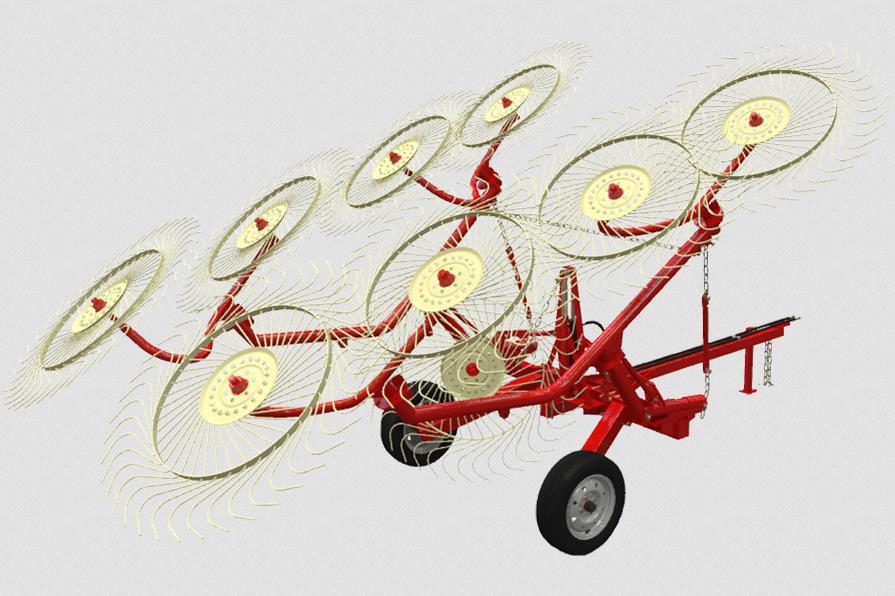

- Rotary rake systems are devices with the greatest functionality with an automatically variable grasp width and height of the working bodies, designed for raking, tedding grass and haylage and laying them in swaths. During operation, the unit uses rotary working elements with cylindrical teeth fixed to the frame.

Device and purpose

The tedder rake replaced the conventional rake, which was used to rake the grass after mowing. With their appearance, it was possible to mechanize the hay harvesting process and completely eliminate the use of heavy manual labor. Structurally, the tedder rake is a two-section wheel-finger design, in which the sections are able to work both together and separately. Each unit consists of a frame, support wheels and rotating rotors, which are the main working parts of the unit. The rotors are fastened to the frame by means of tapered bearings, and the torque required to rotate them is transmitted using the propeller shaft of the tractor. The support wheels are set in motion due to adhesion to the ground while the tractor is moving.

Each of the rotors is equipped with raking fingers made from high strength steel. Depending on the model, the number of rotor fingers can be different - from 32 to 48 pieces. The rotor wheels are fastened by means of a spring suspension, which prevents mechanical damage to the working elements and prolongs the service life of the unit. The rotors are located at a certain angle in relation to the line of movement of the tractor, and thanks to the rotating adjustment lever, they can be raised or lowered to the height required for more efficient work.The same lever is used to transfer the unit to transport mode, when the rotors are lifted high above the ground so as not to damage during movement.

Price

The new unit will cost the buyer 75-80 thousand rubles, depending on the region. The lowest prices are in Ryazan and Chelyabinsk, the closer to Moscow and the region, the more expensive. Used ones can be purchased for 50 thousand or less. Do not be afraid of low prices for used rakes. As mentioned above, even with a serious breakdown, you can cope yourself by returning the device to its working position.

The domestic manufacturer has proved by his own example that our technologies may well compete with Western developments. Simplicity and reliability - that's what lies at the heart of GVK-6. For entrepreneurs and farmers who value their time and money - a must purchase.

User manual

When working with a tedder rake, a number of recommendations should be followed.

- The attachment should be carried out with the tractor engine off.

- Before starting work, it is necessary to check the connection between the rake and the tractor, as well as the presence of a safety cable fixed to the tractor crossbar. You also need to make sure that the hydraulic system is tight and the propeller shaft is in good working order.

- During stops, the gear lever must be in neutral and be sure to turn off the power take-off shaft (PTO).

- It is forbidden to leave the tractor with the engine and PTO engaged, as well as with the parking brake turned off, unattended.

- Adjustment, cleaning and maintenance of the tedder rake should be carried out only with the tractor engine turned off.

- On bends and difficult terrain, the speed of the rake should be reduced to a minimum, and for particularly sharp bends, it is imperative to turn off the PTO.

How the tedder rake works, see the next video.

Let’s block ads! (Why?)

The use of a tedder rake

After mowing, you should prepare the grass to turn it into hay. This means that it is necessary to form windrows, turn over from time to time, collect in bales or rolls. Factory or home-made rake tedders collect the cut grass in swaths and, if necessary, turn them over to dry. To use hay-harvesting equipment, walk-behind tractors, mini tractors, tractors and even horses are used. It is much more efficient than working with a hand tool. You can perform the following operations:

- raking of the mown plant mass;

- tedding grass;

- wrapping and spreading swaths;

- doubling of the located rows of rolls.

Manufactured do it yourself rake for a mini tractor have a number of advantages. The device is more efficient than hand tools, easily transported to the storage area and takes up little space. Affordable price, and also there are no problems with the purchase of spare parts.

Manufacturers and modifications of the "GVK-6" rake-tedder

At this time, the GVK-6 tedder rake is manufactured at the PKU IK-2 enterprise, at the correctional colony No. 2 in the city of Ryazan (Voroshilovka village, area of the Krasnoye Znamya plant). For some time now the trade name has been changed to "rake-tedders" rakes "GVV-6" Katyusha ". This is a lightweight version of the tedder rake. It is distinguished by its more compact dimensions and lighter weight than that of the modernized modification "GVK-6M", which is now produced by the Sol-Iletsk Machine-Building Plant (LLC "SIMZ").

Rake-tedders in transport position.

This enterprise is located in the city of Sol-Iletsk, Orenburg region. From its very foundation, in 1944, and up to our era, it has specialized in the production of trailed hay harvesting equipment. And also, in addition to her, produces tractor trailers.

The largest distributor of the GVK-6M trailed unit is the international association BelAgro.It includes 34 branches - large centers for the sale of agricultural machinery and spare parts for it, as well as service, located in Belarus, Ukraine, Russia and Kazakhstan.

Tedder rake price analysis

You can order and purchase a model (GVR - 6) for processing haymaking in the online store. It is beneficial for the user to buy these products directly from the manufacturer. The design undergoes pre-sale preparation, paperwork, technical passport in the first place.

Who has the conditions for self-assembly, you can read how to make a tedder rake with your own hands

Estimated price in the range of 140,000.00 to 147,000.00 rubles. There are proposals to purchase the unit on the secondary markets, these are used models. Many structures are in excellent condition, they can work for many more years, with a decent technical inspection. The cost of used units ranges from 78500.00 to 112456.00 rubles.

Buyers are provided with several payment options for purchased rake tedders, in any convenient way, these are:

- in cash;

- loan processing;

- the possibility of leasing.

Holdings and large farms engaged in cattle breeding, purchase a device for mowing and drying, a profitable investment. Agricultural machinery is designed to facilitate human labor - this is the main task of the manufacturers and developers of this unit.

Popular models

The domestic market of agricultural equipment is represented by a large number of rake-tedders. Among them there are both foreign units and Russian-made devices.

The most popular of them is the GVK-6 model. The product is manufactured at the enterprise of the correctional institution No. 2 in the city of Ryazan and is actively exported to neighboring countries. The equipment can be aggregated by means of wheeled tractors of classes 0.6-1.4 and fixed to them like a conventional hitch. A feature of the GVK-6 tedder is its ability to work with damp grass, the moisture content of which reaches 85%. For comparison, Polish and Turkish counterparts can only cope with 70% humidity.

The length of the unit is 7.75 m, width - 1.75 m, height - 2.4 m, and the working width reaches 6 m.The width of the rolls is 1.16 m, height 32 cm, density - 6.5 kg / m3, and the distance between two adjacent rolls is 4.46 m. In the working position, the device is able to move from speed up to 12 km/ h, and during transportation - up to 20 km / h. The GVK-6 model is distinguished by its high productivity and processes an area of up to 6 hectares per hour. The weight of the rake is 775 kg, the cost of one section is 30 thousand rubles.

The next popular model GVR-630 comes off the assembly line of the Bobruiskagromash manufacturing plant. The unit is also used in the form of a tractor trailer, and is connected to the tractor through a hydraulic system and a power take-off shaft. The working unit of the device is of Italian origin and is presented in the form of an asymmetric collapsible frame with two rotors mounted on it. Each rotor has 8 tine arms fixed to it with a hub. Each tine arm has six right-angle tines. The height of the rotors above ground level is adjusted by means of a hydraulic drive located on the left rotor wheel, which allows for raking of fields with a slope and difficult terrain.

The principle of operation of this model is somewhat different from the principle of operation of models of other brands and consists in the following: with multidirectional rotation of the rotor wheels, the teeth collect the cut grass and put it in rolls. When the direction of rotation is changed, the machine, on the contrary, begins to stir the mowing, thereby increasing air exchange and accelerating the drying of the grass. The model features a large working width of up to 7.3 m and a high raking capacity of 7.5 ha / h.This is 35% higher than the average of most other models. In addition, the device is very maneuverable and, in comparison with other models, can reduce fuel consumption by 1.2 times. Such a rake weighs 900 kg, and their cost is within 250 thousand rubles.

You should also pay attention to the swath former GVV-6A manufactured by the Bezhetskselmash plant, located in the Tver region. The model is highly appreciated by Russian and foreign farmers, it competes with Western models in the modern market

The unit is capable of processing 7.2 hectares per hour and has a fairly high operating speed of 14.5 km / h. The gripping width of the device is 6 m, and the roller width during raking is 140 cm. The weight of the device reaches 500 kg, the cost is about 100 thousand rubles.

Modifications

GVK-6.0A

This device is made in one of the correctional institutions in the city of Ryazan (PKU IK-2). It is distinguished by its compact size and light weight - less than that of other modifications. Its speed is slightly lower than that of the base model. Let's give the data in the table:

Characteristics of the side rake of the GVK-6.0A tedders:

| Specifications | Indicators | Unit measurements |

| Raking grip | 5,8 | m |

| Tedding grip | 6 | m |

| Performance | 58600 | m2 / h |

| Speed (working) | 10,1 | km / h |

| The weight | 0,596 | T |

| Transport dimensions (length, height, width) | 7.32x1.81x2.3 | m |

| Raking dimensions | 5.8x1.63x6.65 | m |

| Tedding dimensions | 3.9x1.63x7.6 | m |

GVK-6.0AB

One of the earliest models of these rake-tedders, produced at the Sol-Iletsk machine-building plant. This unit is quite heavy - it weighs almost a ton. It is his characteristics that are given in the general table of parameters.

GVK-6M

This modern modification is produced by several enterprises: the Sol-Iletsk Machine-Building Plant (SIMZ LLC), as well as the Belagro group of companies, which unites several manufacturers from Russia, Belarus, Kazakhstan and Ukraine. Their products differ slightly in weight. The model from LLC "SIMZ" has 725 kilograms, and the analog from Belagro has 775 kilograms. Dimensions - in the table:

Characteristics of the GVK-6M tedder rake:

| Specifications | Indicators | Unit measurements |

| Transport dimensions (length, height, width) | 2.4x1.75x1.75 | m |

| Raking dimensions | 6.6x1.65x6 | m |

| Tedding dimensions | 7.6x1.65x4.1 | m |

In the video, the GVK-6 tedder rake is in operation:

Device

On the main support frame, there are two sections - left and right. These sections can be used simultaneously or separately. The mechanism moves across the field on support wheels - each section is equipped with three wheels (for movement), as well as five impellers fixed in the direction of travel. These wheels, which are equipped with a governor, have tilted, spring-loaded pins.

On the main support frame, there are two sections - left and right. These sections can be used simultaneously or separately. The mechanism moves across the field on support wheels - each section is equipped with three wheels (for movement), as well as five impellers fixed in the direction of travel. These wheels, which are equipped with a governor, have tilted, spring-loaded pins.

The rotating control arm will allow the wheels to be lowered if the implement is not picking up all the grass from the field, or to raise them if the rake is buried in the ground. Also, with the help of the lever, the rake is transferred to inactive mode (for transportation). In this position, the angle of the fingers changes so that they do not touch foreign objects. This mode allows you to quickly switch without changing the working angle and other settings.

The principle of operation of "GVK-6"

The impellers of the rake-tedder are set in motion due to their adhesion to the field surface. When driving on a swath, the impellers begin to rotate, and their fingers pick up the mowed grass mass when moving. Due to the location at an angle to the direction of movement, the withered grass, after it is captured by the first wheel, constantly moves sideways, for the entire amount of this capture, being transmitted to the second, third, etc. impellers.

Grabbing the blades of grass is carried out at the bottom, at the very base, and in their middle part, the fingers release the hay. After the passage of all the GVK-6 wheels, a uniform and voluminous swath is formed on the swath

And, no less important, the roll is well loosened, breathable and therefore dries very quickly. Swath width can be adjusted by front and back guides

Rake-tedders in position for raking hay into a swath.

This is swathing. As for the work on tedding hay, this requires a slight change in the position of the sections of the agricultural unit. So that when the "GVK-6" moves across the field, the grass mass collected by the fingers does not flow to the next impeller. And it loosened up, fluffed up and remained lying on the swath. And if the section of the rake-tedder moves along the finished roll, then it moves and turns over.

The rake-voroshilox mechanism works at a rather high speed - in an hour "GVK-6" processes up to 6 hectares.

An important point: most of the analogs of this unit (for example, Polish or Turkish production) cannot cope with tedding of raw grass (the maximum allowable moisture for them is, at best, 70%). While the "GVK-6" value of the maximum moisture content of the grass to maintain effective work is 85%.

Maintenance of the GVK-6 tedder rake is extremely simple. To ensure their smooth operation, the minimum effort of one operator will be sufficient. The unit quickly and effortlessly hooks up to the tractor, turns into any of the working positions (for raking, tedding, windrow turning). Fingers change easily and in an extremely short time.

Advantages and disadvantages

Like any agricultural equipment, the tedder rake has its pros and cons. The advantages include the simplicity of the equipment in operation, as well as its undemandingness to routine maintenance. A long service life of the units is also noted, reaching ten years. In addition, one can note the high reliability and strength of the structure, which is based on a powerful drawbar and a sturdy frame, as well as the ability to conveniently adjust the position of the rotors and quickly switch to the inoperative position, which is achieved thanks to the hydraulic mechanism. The performance of the tedder rake depends on the model and averages 7 ha / h.