How the jack works

Having figured out what elements the jack consists of, it's time to find out how this device works. In fact, there is nothing complicated here. The work is based on the principle of communicating vessels:

- The first step is to place the device on a flat, hard surface.

- Next, you need to click on a special lever. But first you need to make sure that the valve on the device is in the closed position.

- When the jack with the load reaches the desired height, the lift is stopped. In the opposite situation, when it is necessary to lower the system, use the valve of the apparatus, which is smoothly rotated counterclockwise.

Thus, the main operating element in this device is a special lever that provides oil pumping. During movement, it begins to act on the piston, which, in turn, produces a lift. The oil cannot go back, since the discharge and suction valves interfere with this.

Jacks can be used for more than just lifting loads. With their help, you can perform pressing, bending, and other related work. When solving such problems, a protective thread must be installed. For more accurate operation, you can calibrate the force. Special pressure gauges allow you to select the appropriate pressure.

Jacks can be used for more than just lifting loads. With their help, you can perform pressing, bending, and other related work. When solving such problems, a protective thread must be installed. For more accurate operation, you can calibrate the force. Special pressure gauges allow you to select the appropriate pressure.

This is how jacks work. It is the same for all devices, regardless of their design. Anyone can learn to handle such a mechanism. Of course, the first time, certain difficulties are possible. However, if you find out in advance about the features of a particular type of jacks, then everything is greatly simplified.

Review overview

Very often, when it becomes necessary to purchase a particular product, the consumer gets acquainted with the reviews of buyers and already experienced users. And this is correct, because it is a person who is not interested in selling such equipment who can tell truthful information from personal experience. Having carefully studied the reviews of people who have experience in using Zubr jacks, we can conclude that with the right choice and operation, this equipment has no drawbacks.

Further in the video review, an overview of the sliding hydraulic jack "Zubr Professional 43050-3_z01" is presented.

How to choose a quality tool: what to look for

Minor details can be ignored, but some points need special attention. One of the important criteria is the carrying capacity, since each model is designed for a certain weight of the load.

It is strictly forbidden to exceed the value indicated in the technical passport of the lift, because this can lead to a breakdown of the machine or to the failure of the hydraulic jack itself.

It is also necessary to pay attention to the lifting height, large models are often designed for 40-50 cm. This value will allow you to replace the wheel, as well as provide access to the handbrake cable. With regard to the height of the pickup, this parameter indicates how many centimeters is the distance between the bottom of the vehicle and the ground

Note!

The lifting speed is influenced by the working stroke of the jack. This is the distance between the maximum lift height and the pick-up point.

The larger the stroke, the better.

Many car enthusiasts claim that it is best to buy a 5t jack from branded and popular manufacturers.

But such a statement is a delusion, since the most important thing in purchasing a mechanism is to pay attention to the parameters, as well as to study the information contained in the accompanying document.You can judge the quality of the lift by the material from which it is made, and by the reliable fixation of all connections.

It is not at all necessary to overpay just for a well-known brand of lifting mechanism. After all, there is no guarantee that equipment from a foreign manufacturer will be better than a domestic analogue, even if the difference in their cost is significant.

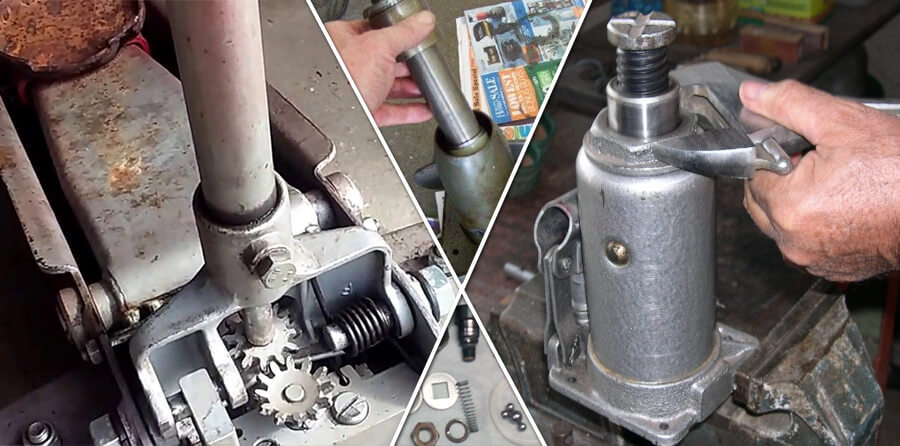

Jack installation example

Important!

Before buying, you need to decide on the purpose of using the lift - for operation only in the garage or for a complete set of machines.

Thus, it is imperative to take into account the lifting capacity, lifting and picking heights, as well as the purpose of use and intended purpose.

If the jack is planned to be constantly carried in the trunk, then it is recommended to give preference to compact and lightweight models. Experienced motorists advise you to transport and store a 5 ton hydraulic jack in a bag, package or special case.

Features and working principle

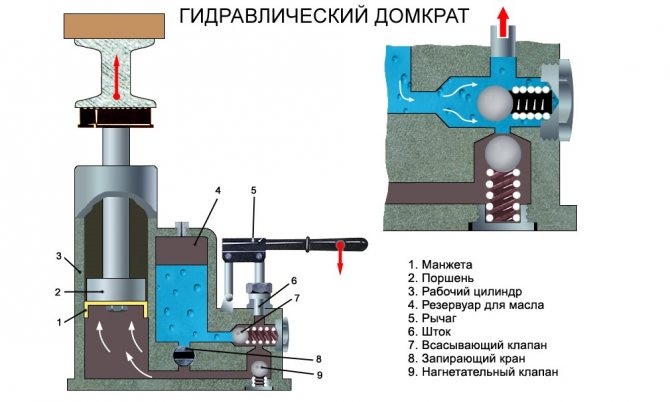

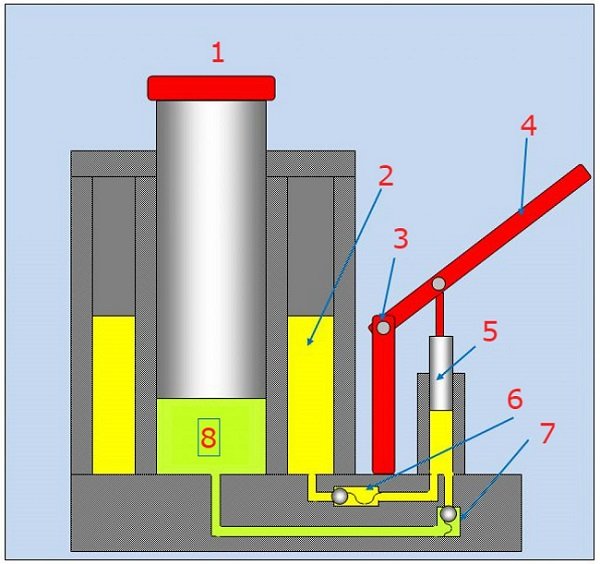

The 10 t hydraulic jack is a heavy lifting mechanism, which consists of:

- hulls;

- piston;

- fluids with a hydraulic valve;

- working chamber;

- stock;

- lever.

The construction is made of high quality material of extra strength. Due to its special properties, the device does not corrode. The body is both a cylinder for the piston and a place for the fluid. The difference between a hydraulic jack and a mechanical jack is that the hydraulic tool is able to lift the load from the lowest height.

There are two-piston models. The fluid that is used to work in such a mechanism is called oil. When the lever is pressed, the oil flows into the working chamber. The oil quantity is regulated by means of the restrictor valve.

The basic principle of a hydraulic jack is to create pressure on the fluid that pushes the piston. In this regard, there is a rise. If it is necessary to lower the load, open the hydraulic valve and the liquid will flow back into the tank. The main feature of the mechanism is the use of an incompressible fluid and a high coefficient of lifting force with little effort on the handle. Low working force is provided by the high gear ratio between the cross-sectional areas of the cylinder and the pump piston. Besides smooth operation, the hydraulic jack has a high efficiency.

How the hydraulic jack works

The principle of operation of a hydraulic jack can be considered on the example of a popular device manufactured by "SHAAZ". The functioning of this lifting structure is based on the principle of communicating vessels, but first the lift must be installed in a room withfirm and level surface... Next, you need to press the special toggle switch, after making sure that the jack stand and its valve are closed. Before proceeding with the operation of the mechanism, the instructions for the use of a hydraulic jack 5t manufactured by OJSC "ShAAZ" should be carefully studied.

Hydraulic lift device

Hydraulic lift device

When a mechanism with a vehicle or other load reaches the required height, the lifting process must be stopped immediately. If it is necessary to lower the system, the toggle switch of the jack should be rotated slowly counterclockwise... The main working element of the lifting structure is represented by a special lever, thanks to which the working fluid is pumped. During pumping, the oil acts on the piston, due to what and the load is lifted. The return of the working fluid is completely excluded, since this is prevented by the parts represented by the suction and discharge valves.

On a note!

Experienced experts say that bottle jacks can be used for more than just lifting vehicles. Repairs such as bending and pressing are also carried out with this device. But in order to solve such a problem, you must first install a protective thread on the jack and calibrate the force. It is recommended to use special pressure gauges to select the correct pressure.

Best rolling jack

The mechanism must meet all the characteristics required by motorists and workers of service stations. The best rolling jack can be chosen only by checking the technical parameters, equipment, product quality. Some of the advantages and disadvantages of rolling jacks from the best manufacturers are listed below.

- Matrix Master 51028 - A well-known brand of rolling jacks. The compact device allows you to lift loads up to two tons. The lifting height is 385 mm, the pickup is 13 cm. The locking mechanism will allow you to safely perform work, the weight of the tool does not exceed 13 kg. As disadvantages, it is possible to single out a price that is high to competitors and a gear mechanism that is difficult to maintain.

- Santool 110103-002 hydraulic type of mechanism allows for easy work. A distinctively low price, reliability allows the use of a sliding hydraulic jack for a long time. The presence of a case and a weight of the device of only 6.5 kilograms makes the device mobile. The disadvantages include the lifting height - 300 mm, this will create problems when lifting off-road vehicles, it is recommended to use a support under the threshold.

- Skyway S0180201 - a simplified design allows you to lift a load weighing up to 1.8 tons. A distinctive feature is low weight and cost. The hydraulic device can be installed on vehicles with a ground clearance of 125 mm or more. The lifting height is limited to 300 mm, but this is sufficient for passenger cars weighing up to 1800 kg.

- AIRLINE AJ-3F-500 is a more powerful hydraulic jack capable of lifting vehicles weighing up to 3 tons. The rolling device is more likely to be used in a garage or service, since the weight is more than 32 kg. Transporting a lifting mechanism with such a weight in the trunk is not comfortable and does not make sense. The advantages include a lifting height of 500 mm, lifting speed, reliability.

- Sorokin HobbyLine520 is not an expensive rolling jack with average parameters. The height of the roll is only 125 mm, the weight is 6.5 kg. The lifting of the platform is limited to 300 mm, the lifting capacity is 2 tons. Of the shortcomings, it is possible to note the absence of a suitcase and a substrate; in principle, they can be purchased separately, of the desired shape and configuration.

Many car owners want to get an answer to the question of which is the best trolley jack of 2 tons. A variety of models allows you to choose a mechanism according to the required parameters, operating environment. Models with reduced weight and dimensions are optimal for transportation in luggage racks.

The use of a sliding lift in a garage or an amateur service station is not advisable, you need to pay attention to more professional equipment

Good

Poplar poplart popcorn

- lokl ± lokllllÑ ÑÑÑl¾l²l½Ñ l¼lÑl »l;

- open and close;

- l ± li l l l l l l l l l h;

- saucer and saucer, sardine Heart, heart, heart, heart, heart, heart, heart, heart, heart ;

- bushy bush;

- green tea;

- saucer (saucer) REMOTE 200 ROTARY 200).

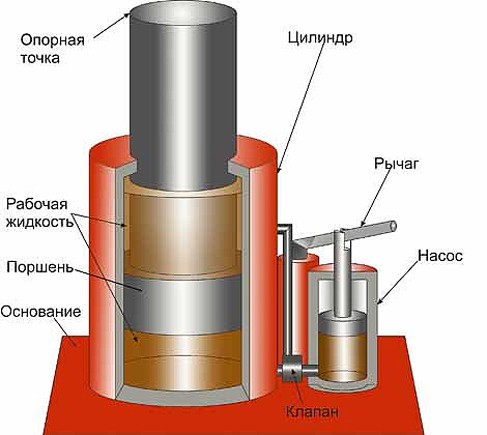

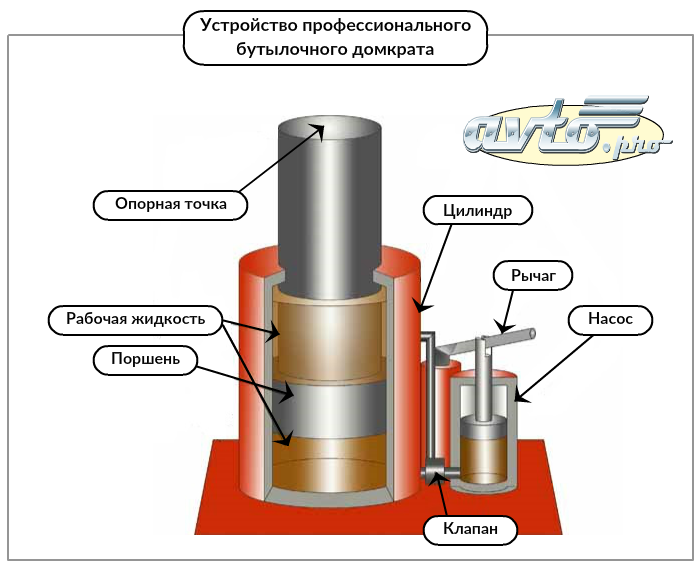

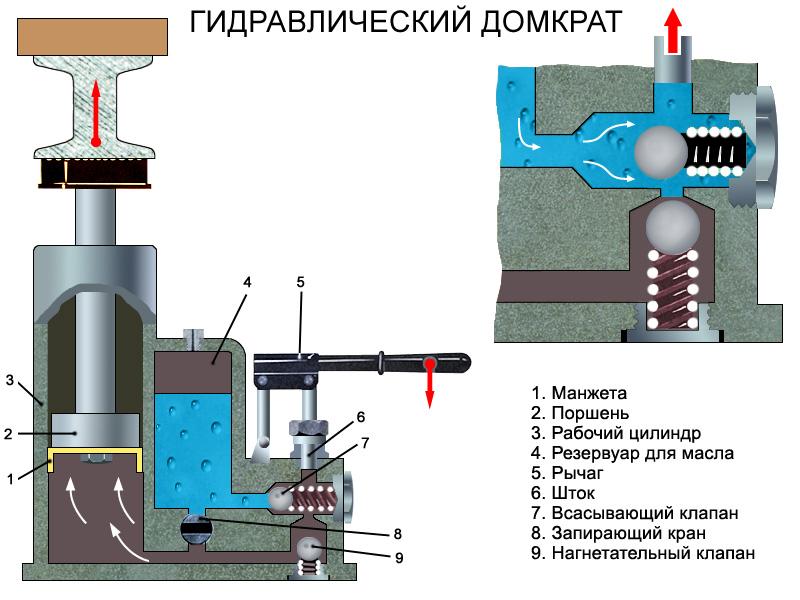

Features of the design of the hydraulic bottle jack

Bottle hydraulic jack

Experts consider the design of the hydraulic lift to be unique and original. As for the elements of which it consists, their list is as follows:

- handle and cylinder;

- pump and valve;

- screw;

- storage tank;

- stock.

There is a suction valve on the tank nozzle, which prevents water from getting back into the cylinder if the pump toggle switch is in the lowered position. There is also a discharge valve on the cylinder nozzle, which prevents liquid from leaving the reservoir, even if the pump plunger is in the raised position.

Note!

The valve is opened with a special screw that relieves the pressure in the jack, after which the load is lowered to the ground. In general, this mechanism is considered to be proven for more than one dozen years .. Due to the fact that the bottle pneumohydraulic jack is distinguished by the presence of a quick-release coupling half, it can be connected to a pumping station or to a pump

As for the main elements of the lift, they are represented by a body, a working fluid (hydraulic oil) and a retractable plunger or piston.

Due to the fact that the bottle pneumohydraulic jack is distinguished by the presence of a quick-release coupling half, it can be connected to a pumping station or to a pump. As for the main elements of the lift, they are represented by a body, a working fluid (hydraulic oil) and a retractable plunger or piston.

Hydraulic bottle jack device