Adapter types

The angle adapter for the screwdriver is divided into two types: flexible and rigid.

The features of the first type include:

- the ability to penetrate the most inaccessible places;

- twisting tightly set self-tapping screws;

- widespread use in everyday life;

- not suitable for tightening metal screws.

The rigid adapter differs from the flexible adapter in the following characteristics:

- durable cartridge;

- suitable for professional activities;

- torque: 40-50 Nm.

The structure of these types varies considerably. A flexible one has a metal body, a bit gripper on a magnet, a flexible shaft. The rigid adapter is made of steel, two types of grips, magnetic and cam, there is a bearing.

How to do it yourself?

You can make such a product yourself, using a cable as a basis. It can be from a clutch, gas, or a speedometer. The braided wire is purchased or taken already available - it is almost impossible to make it yourself. It is threaded inside the cable.

One end of the future core is connected to the shank, for which a nut and welding are used. A chuck from a screwdriver is mounted on the second end

When using a homemade flexible shaft, it is important not to hold on to the chuck, but to the protective shell, that is, the cable

The choice of a finished product should be approached with great responsibility. The work performed with a flexible shaft is complex and time-consuming. A malfunction of one mechanism will lead to a malfunction of all the others.

When buying, you need to pay attention to the manufacturer of the product. A checked and properly made device will ensure high quality of the work performed

A hurried purchase will result in double spending. In addition, if the work needs to be done urgently, deadlines will be missed.

In the next video, you will find an overview of a flexible shaft for a screwdriver.

Shafts for petrol cutters

Electric and gasoline powered mechanical scythes use both flexible and rigid shafts.

Powerful brushcutters, capable of cutting tall, tough and dense grass and even small bushes, use rigid all-metal drives. Such devices are designed for continuous operation and have a high torque. They also have significant dimensions and weight and are worn on shoulder straps. A thick hard fishing line or powerful steel knives - two, three or four - are used as a working body.

The flexible drive is used in light, low-power and compact trimmers designed for finishing corners after a lawn mower or mowing grass on small lawns. These trimmers are held with one hand, and the flexible shaft is used in order to mow in the most comfortable position. The cutting element of such devices is a fishing line of small or medium thickness or a lightweight two-blade knife. If the device is overloaded, the flexible shaft can twist. In this case, the rupture, as a rule, occurs near the shaft-to-engine attachment point. If you cannot buy a "native shaft, then you need to select from the drives of a suitable length in the direction of the braid." Such drives can only rotate in one direction.

Before starting seasonal work and after changing the drive, remove the remnants of the old grease, rinse with gasoline or another solvent and fill the cavity in the handle with new grease. The type of lubricant is indicated in the user manual.

Operating tips

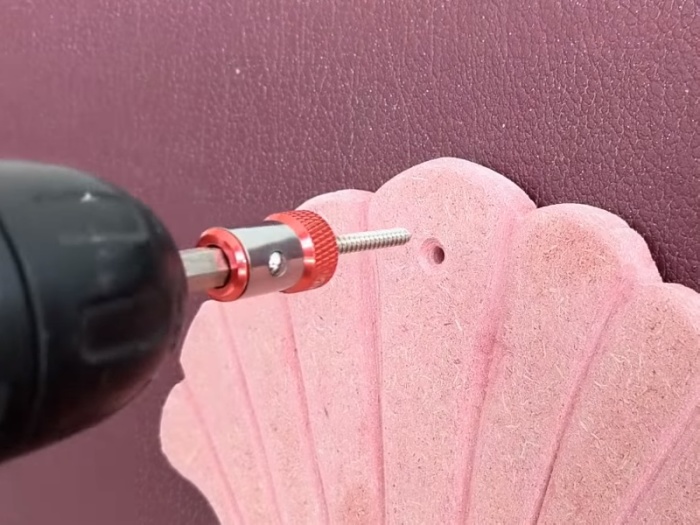

- Before you start using a screwdriver, you should choose the right attachment.It must correspond to the type of work and fit in diameter to the head of the fasteners.

- To insert the bit into a tool equipped with a keyless chuck, it must be pushed between the “cams”, gently turning the sleeve clockwise. If the design of the screwdriver has a key cartridge, then the bit is installed in a special socket and turned with a key until it is fully fixed in a clockwise direction. After the selected bit is set, the device can be connected to the network and proceed to direct work.

- To reduce or, conversely, increase the rotation speed of the nozzle, you need to weaken or increase the impact on the trigger button.

- When the fastener is tightened, the limit sensor will automatically be triggered and the device will stop working.

- When unscrewing the screw, the bit must be placed in the slot, while first setting the rotation of the bit to work in the opposite direction.

- If during operation it is necessary to remove or change the nozzle, you must first turn on the reverse mode. When the bit is turned in the opposite direction, the hand grips the ring holding it, and the bit is easily removed and replaced with another.

Operations performed with the engraver

If we talk about buying an assistant for delicate work, then it is worth choosing a reliable tool that itself costs a decent amount, even if a limited number of attachments are sold with it. Additional accessories can be purchased later additionally:

- the use of grinding and polishing wheels helps to achieve a flawless smooth and shiny surface;

- brushes are used to remove rust from material and grind seams that are difficult to reach with standard tools;

- a nozzle in the form of a cutting wheel will allow you to get miniature pieces of workpieces and smooth out their torn edges;

- a set of thin drills will come in handy when shaping the smallest holes;

- cutters will help to process hard-to-reach surfaces; abrasive devices are also used for this;

- a compact tool with the help of feather-shaped attachments will provide an opportunity to easily make the openwork ligature of miniature writing and make minor restoration repairs, and will make it possible to make elegant souvenirs.

For the convenience of performing operations, various additional elements are sold:

- rubber pads will allow you to better hold the device during operations;

- so that more attention can be paid to the work, and not to keep the button in the working position, a button locking mechanism is provided;

- a flexible shaft for the engraver will allow you to transfer the torque to the nozzle;

- in order to easily and conveniently change nozzles, there is a spindle lock button in the design.

The work of an engraver is akin to that of a jeweler, of course, not always requiring miniature precision. But the criterion for the quality of work has always been the use of solid and durable tools. The engraver belongs to the same type of tool, the direction of activity changes with the use of different attachments. The category of engravers includes both a drill in a dental office and a manicure machine in a hairdressing salon. Engravers of inscriptions and drawings on the surface of natural granite and marble also use this compact and affordable device for creating monuments and crafts.

Selection guide

The selection of the nozzle includes a determination with several parameters:

1. The maximum size of the hardware that this model can twist. Depends on the torque that the chuck is able to transmit. There is a table that will help with the choice (the data describe the possibilities of working with medium-strength steel)

| Hardware diameter, mm | Torque, Nm |

|---|---|

| 8 | 12 |

| 12 | 20 |

| 16 | 30 |

| 21 | 60 |

| 50 | 180 |

2. Method of connecting the working bit to the chuck. Magnetic gripper and collet three-jaw chuck. The first option is more practical, but less reliable. The second provides the most durable grip.

Different firms are represented on the market, with significant differences in price and quality. Inexpensive, affordable nozzles from China and Taiwan are designed for the picky user. At a rotation speed of more than 300 rpm. they begin to vibrate and warm up. The magnetic fastener is only suitable for single-sided bits. After a short operation, the nozzles begin to run out radially, which negatively affects the working qualities.

Firms AEG and Dewalt produce more reliable bits with acceptable torque values and a strong connection for the bit. They are designed to operate at 400-600 rpm.

Professional equipment from the USA by Milwaukee is aimed at the fastidious consumer. Huge rotation speed 1600-1800 rpm, combined with the possibility of drilling.

The angle screwdriver attachment helps to facilitate repair work, furniture assembly, wall mounting, and other daily tasks. The main thing is to correctly determine what is required from the tool. Then choose the model you need without overpaying for unnecessary functions and follow the instructions.

Design

Such an adapter has special requirements regarding bending stiffness. In the center of the structure there is a special cable or wire rod. They are made from materials that can withstand torsional stress. At the heart is a metal core on which the wire is wound. There can be several layers.

The safety of the tool is ensured by a rubber sheath, it is also an additional protection of the core from damage and retains the lubricant inside. In relation to the rotating rod, this shell remains stationary. On the one hand, there is a cartridge on the adapter, through which you can change the attachments. On the other hand, there is a union nut or fastening fittings, through which fixation takes place with a screwdriver.

How to choose an adapter?

Battery-powered screwdrivers are the most common device in construction. Its main "plus" is mobility. Depending on the model of the screwdriver, the battery receives a voltage of 14 to 21 volts. The "output" turns out from 12 to 18 volts

When choosing an angle adapter for an 18 volt socket screwdriver, pay attention to the following recommendations:

- nozzles (steel P6 and P12) are suitable for working with metal screws;

- in the available models, as a rule, a tribe made of modern plastic is used;

- The adapter is light in weight, but the torque is limited to 10 Nm;

- a steel gearbox is able to increase the torque up to 50 nm;

- the more solid the size of the bit extension, the higher the performance of the screwdriver;

- the possibility of "reverse" expands the functionality of the device (we not only tighten, but also unscrew the screws).

When choosing an adapter, we look at the maximum screw size and adapter model, as well as the method of connecting the bit to the chuck. The magnetic grip is practical, but the three-jaw chuck will provide maximum clamping strength.

Today the modern market is saturated with different models of adapters for screwdrivers, they differ in quality and price. In most cases, inexpensive Chinese nozzles with a rotation speed of 300 rpm, quickly heat up and emit vibration. Magnetic fasteners are suitable for single-sided bits.

Work

Externally, a flexible shaft is almost indistinguishable from a thick cable, only its surface is often corrugated. The flexible shaft is equipped with tight articulated joints, which retain their immobility during operation. You can see how when the screwdriver is turned on, only the tips begin to move.

The user can hold the adapter in his hand and twist or twist the self-tapping screws without fear of damaging the palm. Some models have a limit when using self-tapping screws, and it reaches 4 * 70 mm.If this indicator is, for example, 4 * 100 mm, then after overcoming 80 mm inside the timber, the flexible shaft simply folds into a loop and cannot complete the task. If you try to continue working, then the cable inside simply breaks off near the nozzle. The ultimate load is 6 Nm.

Information for fishermen

The angle adapter for the screwdriver is designed not only for tightening screws and screws, but is also widely used by fishermen. An adapter for an ice ax for a screwdriver helps in drilling "holes".

The use of an attachment that allows you to rotate the ice ax with a screwdriver gives the lover of fish hunting the following advantages:

- easy ice drilling;

- a sufficient number of holes in a short period of time;

- when discharging the screwdriver, the ice ax can be operated manually;

- slight noise;

- an adapter for an ice ax for a screwdriver is compact and convenient.

The main purpose of the device is to transfer rotations from an electrical device to an ice ax. Most modern adapters are equipped with a special handle for a secure hold of the tool. The design of the adapters is different, the simplest is a sleeve made of metal. With a more complicated design, the adapter is attached at one end to the auger part of the drill, and at the other end to the chuck.

Installing an adapter for an ice ax under a screwdriver will not be difficult:

- unscrew the bolt that connects both parts of the drill;

- in place of the "top" of the drill we mount the adapter;

- the hex shank is fixed into the screwdriver chuck.

Some disadvantages of adapters for ice axes for a screwdriver are still present. A powerful charge is required for a long and productive tool. As a rule, screwdrivers of 18 volts and a torque of up to 70 nm are used for drilling ice. Unfortunately, not all batteries perform well at low temperatures. Extra batteries must be taken care of and kept warm. Fishermen need a more powerful tool that costs a lot of money.

A way out of the situation will be the use of an adapter with a reducer (a set of gears, which are located in the crankcase, is designed to adjust the speed of rotation of the shafts). This element will allow using an inexpensive screwdriver for the drilling process. The gearbox will take on some of the load from the chuck and the tool mechanism, and will also help save the battery power of the device.

For information on how to make an ice screw adapter for a screwdriver, see the next video.

Let’s block ads! (Why?)

Rules for working with an engraver equipped with a flexible shaft

There are a number of rules to follow when using a Flexible Shaft Engraver for a variety of materials.

What needs to be done before starting work

Before starting work, choose nozzles. All of them should be at hand, so that later you do not waste time looking for them. While the device is off, it is better to hang it on a special hook that comes with most modern models.

Prevent the chips from sticking to the surface of the tool by first covering it with a layer of paraffin. It should be borne in mind: if the design of the tool does not provide for forced ventilation, you can work with it for no more than 15–25 minutes, and then you must give it time to cool naturally. By doing so, you will save your engraver from premature failure.

Holding the engraver with your hands, try not to cover the ventilation slots with your palms.

Mode change

It is necessary to change the speed with which the tool of an engraver equipped with a flexible shaft rotates, both when changing the operations being performed, and when switching to processing a different material. At low speeds, softer materials, such as plastic, are processed.If such materials are processed at high speeds, this can lead to intense heating of the tool and melting of the edges of the workpiece. At medium speeds, metal products are processed, at high speeds - from solid natural stone.

How to properly care for your engraver

Like any other technical device, an engraver equipped with flexible drive shaft, needs proper care. Correctly and regularly performed, such maintenance will not only allow using the device at its maximum power, but will also significantly extend the period of its trouble-free operation.

In the process of processing, carried out with the help of an engraver, the blades of its fan are actively clogged with dust and small particles of waste material. For such a fan to work effectively, it must be regularly cleaned using a soft cloth dampened with soapy water. Under no circumstances should various solvents and aggressive detergents be used for these purposes, which can lead to premature damage to the fan blades.

To clean and lubricate the insides, the tool has to be disassembled. This infrequent procedure requires certain repair skills.

The technical condition of the attachments used with the engraver must also be checked regularly. Worn nozzles should be immediately replaced with new ones, as they can cause increased vibration of the device, which will ultimately lead to its premature failure.

It is very important to pay constant attention to the technical condition of the flexible drive shaft of the engraver. On the shaft cover, which is made of polymer materials, there should be no serious mechanical damage that can lead to premature shaft failure. After each use of the engraver, it is advisable to clean its drive flexible shaft of dust and other contaminants, wipe and, if necessary, lubricate the tips with which it is connected to the electric motor and the working attachment.

After each use of the engraver, it is advisable to clean its flexible drive shaft from dust and other contaminants, wipe and, if necessary, lubricate the tips with which it is connected to the electric motor and the working attachment.

Liquid oil is used to lubricate the inner cable

During work, care must be taken that the flexible shaft does not bend too much. Both during storage and during operation, it is necessary to protect the flexible shaft from mechanical damage.

Bracket for receiving a drilling machine

The multifunctional bracket helps you convert a standard hand drill (corded, battery powered) into a stationary drill press. The body is made of heavy-duty aluminum alloy. Massive, allows you to securely install the drill for subsequent drilling. The fasteners are designed to fit all modern power tools.

The sole is equipped with a vice, which allows you to fix the workpieces in the desired position, to avoid their displacement while drilling holes. The adjustable bracket allows you to set the desired height, taking into account the dimensions of the tool itself. For comfortable work, a rubber grip is provided that smoothly lowers the drill.

Multifunctional bracket for drill and screwdriver

| Price | RUB 2,077.21 - 2,345.32 |

|---|---|

| Rating | 4,6 |

| Reviews | 115 |

| Orders | 188 |

| Delivery to RF | Free of charge |

Purpose

A flexible shaft for a drill is a special attachment capable of transmitting torque from the electric motor of the drill to a tool that is not aligned with it. Thus, it becomes possible to force the tip with a drill to rotate, which is in a completely different plane with respect to the axis of the electric motor, and also to change its position as soon as necessary.Due to the design features, the shaft is easily bent in the desired direction and allows you to work in hard-to-reach places where it is technically impossible to get close with a standard drill.

Externally, the flexible shaft is an elongated bendable nozzle, one end of which is fixed to the drill using a tip, and the other is equipped with a collet clamp designed to fix the cutter, bur or drill. Thanks to the flexible shaft, there is no need to hold a heavy drill, which allows for quite delicate and painstaking work. For example, using this device, you can drill holes with a diameter of 1 mm or more, clean the part in a hard-to-reach place and tighten the screw where it is impossible to get a drill or screwdriver that is not equipped with additional equipment.

With the help of a flexible shaft, you can turn parts from various materials, engrave any surfaces, or use it as a grinding machine. Moreover, engraving with a shaft is especially convenient. This is due to the small thickness of the working tip, into which the bur is installed, and the ability to wrap your fingers around it like a ballpoint pen.