Variety of impact wrenches: types and design features

Gear torque wrenches - torque multipliers

Simple manual mechanical multipliers have been known for a long time, and they are still successfully used in the auto repair: these are wrenches with a gearbox, which allows several times to increase the torque of the transmitted force.

The multiplicity of the gearbox and the transmitted force can be quite significant: the multiplicity is 3.5 - 60 and the force at the output is 700-10000 Nm.

Let's note an important thing: multipliers for car service (as a rule) are produced with a controlled moment, which is necessary for safety requirements. The types of drive of torque wrenches are different: from a hand lever (as in a meat grinder) - to the use of a pneumatic or electric drive

Input square for the drive: ½ "- ¾", at the output of the gearbox - square ¾ "- 1½".

More advanced versions of geared impact wrenches - with a built-in rotation drive: pneumatic, electric and battery torque multipliers are available - they are much more compact and more convenient to use. The main areas of application are industry, although they also have a place for the service of trucks and special vehicles.

Hydraulic impact wrenches

This is a very powerful technique with tremendous possibilities both in terms of torque and a variety of designs - but all of this is mainly for the industry.

There are hydraulic wrenches for truck tire fitting, but they are significantly expensive.

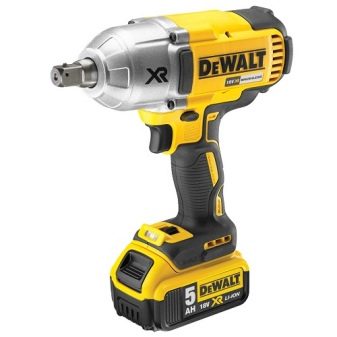

Electric and Cordless Wrenches

Electric network wrenches for car service are practically not produced - they are prohibited by safety standards: at the service station, the use of power tools with a voltage higher than 24V is not allowed. Electric impact wrenches on mobile trolleys are produced for service of cargo wheels.

They are made quite conveniently: Large wheels, balanced design and a powerful drive of 1.1-1.5 kW. Power supply 220-380V, output square 1 ″ and weight from 43 to 55 kg. They produce electric nutrunners for truck tire fitting in Sweden, Poland, Turkey and Russia.

Cordless wrenches for car service began to actively develop only recently - with the advent of more powerful new generation batteries. They have always lacked sufficient effort, but this segment is very actively developing and today there are already models on this market that can be selected.

A new generation of impulse (impact) wrenches appeared with a very decent torque up to 1000 Nm and a quick recharge up to 60 minutes.

The best thing about cordless impact wrenches is maximum autonomy: for work on the road, in mobile workshops and in the field, it is an indispensable tool.

But so far there are drawbacks: relatively low torques (for your money), limited operating time, relatively high weight and dimensions, high price compared to pneumatic impact wrenches.

Pneumatic wrenches

These are the most popular, inexpensive and most sophisticated tools in terms of design: it is difficult to come up with something better for the conditions of a car service.

Any motorist knows what a pneumatic impact wrench is, and it seems silly to write an article on this topic, but our 20 years of experience tells us what is needed - because there are always newcomers and mistakes that were 20 years ago are repeated today with constant persistence.

Specifications

Before you begin to study the rating of impact wrenches, you should know the characteristics that are usually taken into account when choosing these tools.

Torque

The measurement of this parameter is carried out in Nm (one unit is the effort from the use of a lever of one meter). Let's give an example: a human hand can make an effort equal to 9 Nm. For an electric wrench, this indicator can be in the range of 100-2.5 thousand Nm. In addition, the tool must fully meet the assigned tasks. So, the electronic regulation option will contribute to a more accurate adjustment of the wrench.

Expert opinion

Dmitry Levin

Wrenches with low power sometimes fail to loosen or tighten fasteners, and very powerful tools can be used to grind fasteners or cut threads.

Power supply

Most electric impact wrenches produced today can operate on both mains and battery power. This has an impact on autonomy, ease of portability, as well as the tightening force of the nuts.

Battery capacity

This indicator can vary between 2-5 A / h. It affects the autonomy of work, which can range from 30 minutes to three hours. It usually takes one to three hours to charge the battery.

It is advisable to choose batteries with a large capacity, as they will provide long-term trouble-free operation.

Cartridge

Available in hexagonal sockets as well as squares in various sizes. This has a big impact when choosing the right tooling.

It is important how the heads are fixed: with a ring, a ball or nothing at all. The used retainer prevents the tooling from falling out when the tool is lowered down

This is very important if the dismantling of structures is carried out at significant heights.

Which electric impact wrench do you use?

Percussion

Number of revolutions

The chuck can rotate at a speed of 800-9000 rpm, which affects the productivity of the tool. If the process is constantly repeated, the option of stepwise switching of speeds will not interfere, since it allows you to quickly switch to the required revolutions. There are electric wrenches with one to four speeds.

Impact function

A number of devices have the ability to perform blows that help to untwist or rip out old fasteners

When choosing a nutrunner for dismantling, special attention should be paid to this.

A good impact wrench with an impact function should have a pulse frequency of 2 to 3 thousand beats per minute.

Now you know what to look for when choosing an electric wrench

Parameter selection

To fully answer the question "how to choose a screwdriver", you need to tell about the technical parameters

The parameters of the batteries and the cartridge have already been discussed, there are some technical characteristics that you need to pay attention to

Torque

There is a line "Maximum torque" in the technical specifications. This is an indicator that shows how much effort a tool can develop. Measured in Nm (Newton per meter). For a household (amateur) tool or for a "clean" screwdriver, it is enough for the maximum torque to be 10-15 Nm. For a professional and universal (with a drilling function), it should be larger - in order to quickly and confidently do the necessary work even on hard materials or to drive powerful screws.

Number of steps

Different materials and different screws require different torques. It is changed using a special switch that allows you to change it from the minimum (1 Nm) to the maximum. The number of steps can be different. The more there are, the more accurately you can select the required effort.

This is not so important for cordless screwdrivers, but it is important for cordless ones - at more significant loads, the batteries are discharged faster. Therefore, it is important to choose the optimal mode

To track when the drill has reached a given torque, at the moment when this parameter is exceeded, the chuck scrolls idle, while emitting clicks. This mechanism protects the tool from overheating and is popularly called "ratchet". A useful feature that extends the life of a screwdriver.

Torque selection

How to choose a torque screwdriver? If you buy a tool for a certain type of work, you can focus on the diameter of the screws that will have to be tightened. This parameter is also in the technical specifications, but there is such a dependence:

These parameters are also useful during work - you can immediately set the required values, just slightly adjusting the value for a specific case. So, when working with drywall, a lower value is required - so as not to overtighten the screws and not to break through the cardboard. You will have to select the torque and depending on the type of wood - the screws go into the spruce with more effort than into the pine.

Spindle speed or speed

The torque must be provided with a sufficient spindle speed. For working with soft materials such as wood, the normal speed is 400-500 rpm, for working with concrete or metal, a faster rotation is needed - 1200-1300 rpm - this is normal.

So when choosing a screwdriver, look not only at the torque, but also at the spindle speed. They must be consistent. Only then will it be convenient to work with the instrument in different modes.

Number of speeds

There are screwdrivers that can operate at two speeds. These are mainly professional and semi-professional models. The speeds are switched depending on the density of the material with which they are working. You can try different speeds and propellers of different sizes.

Having two speeds - useful for professional models

The selection of the speed saves battery power. As a result, the tool lasts longer on a single charge. For household models, this is not the most necessary option, but it's nice to have it.

How does it work?

The layout of such a tool is similar to a standard electric drill device. The basis of the apparatus is an electric motor that transmits torque to a planetary gearbox. It transfers this value to the keyless chuck or hexagon socket. The device also contains all the elements traditional for drills and a screwdriver:

- speed regulator;

- load limiting mechanism;

- a system of gears, carriers and satellites.

A distinctive feature of the impulse screwdriver is the brushless motor device. In it, the rotor and magnets, as well as the winding and starter, are reversed, which should be taken into account when repairing or servicing. This mechanism reduces the wear of the main parts by up to 30%, and also allows you to significantly increase the load if necessary.

The power supply of the instrument depends on its configuration. Most often, the impulse screwdriver is equipped with a DC battery. For comfortable work, it is advisable to buy a device with a lithium-ion battery with a voltage of 16-18 V.

How is it different from a screwdriver?

Many believe that there are practically no differences and the wrench is just a kind of screwdriver. However, in reality this is not at all the case, and there are differences between the two tools. As mentioned above, a wrench is a tool that serves to twist and unscrew threaded elements. It is used in places where the nuts are rusted and hardly loosened. In addition, it easily handles tightening nuts in particularly difficult places.

A screwdriver is a tool with which you can not only screw in different screws, but also self-tapping screws, and various fasteners. It can be additionally used as a drill.And also, unlike a nutrunner, a screwdriver has a rod with a special nut head, which allows it to cope with the necessary tasks. In addition, impact wrenches have great power, weight and size.

Varieties

If we talk about the types of impact wrenches, then they can be divided into percussion and non-impact tools. It is worth considering these basic varieties in more detail.

- Pulse. In other words, this instrument can be called percussion and rotational. It allows you to make movements using a special attachment. Such tools are able to regulate the operation of the twisting element, as well as calculate how many blows are needed. At first, such a device makes rather long strokes, and at the end of the work they become short. In the end, the last blow will be the strongest, in this way it makes the connection quite reliable. This type of model is most often used by professional workers.

- Unstressed. This model is most often used for everyday work. It features high torque. Such a nutrunner costs several times cheaper than an impulse one.

In addition, nutrunners also differ in the type of drive. They are presented in several varieties.

- Gearbox. This model is mechanical. There is a cylinder with a reduction gear inside. It is also called a torque amplifier. Therefore, such models are considered torque wrenches. On one side of such a device there is a handle, by rotating which you can set in motion the rod itself with the head. Most often, these wrenches are used in order to "break" rusted nuts, for example, on the wheels of cars.

- Electric. This model is powered by an electrical network. It is distinguished by its low noise level as well as small dimensions. Such a tool is quite powerful, but at the same time it consists of a simple mechanism for switching the rotating head, as well as adjusting the tightening torque.

- Rechargeable. One of the main features of this type of model is its autonomy. It can be used both by professionals and at home. With this technique, even those nuts that have already become rusty can be unscrewed. These models also have a torque regulator that can go up to 500 Nm. The most popular are such wrenches, the impact frequency of which reaches up to 3000 per minute. For cars, wrenches are used that are powered by a 12 volt car.

- Pneumatic. This model is very often used in auto repair shops, as it consists of a metal case, and also has a connection system to the compressor. They are both percussion and unstressed.

- Hydraulic. Such a wrench will be needed in those places where a lot of effort is needed to unscrew the nuts. Its rated power reaches 10 thousand. In addition, this model differs in that it can be used under water.

- Petrol. The work of such a tool is provided by an engine that runs on gasoline.

In addition, impact wrenches can be divided into two types.

- Corner. They have a convenient pistol-like shape that allows them to be used even in awkward places. In these models, the spindle rotation axis is perpendicular to the motor axis, which makes it possible to cope even with rather dirty nuts.

- Straight. In such wrenches, the axis of rotation is parallel to the axis of the motor, which makes it possible to develop a torque of up to 4 thousand bits.

What it is?

Such a device is a device for working with different connections and threads. With its help, they can be unscrewed and twisted. In fact, it is an improved wrench. Its layout is pretty simple.The wrench is a bit like a screwdriver, it is similar in shape to a pistol with a slightly elongated body, inside which all the main components are located. In addition, such a unit has excellent characteristics. It consists of a torque element and also has a fast speed, battery or electric charging.

Each of its parts is responsible for certain functions, namely:

- cladding - nutrunners are made from metals, sometimes from polymers; the body itself unites parts, as well as units into a single whole;

- drive - it can be hydraulic, and electric, and mechanical;

- power amplifier - designed to increase torque;

- output shaft - provides reliability in holding the head.

Weight depends directly on what kind of work it will be used for. So, for household work, such small tools are suitable that will weigh no more than 3 kilograms. However, for more professional work, there are models with two handles. They are more massive.

Good luck

Close up and down AIST Rosemary:

Sauerkraut Burgundy burgundy Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð Ð ‡ РРРРРРРРРРРРРкР° Ð ° Ð ° Ð ° Ð ° Ð ° Ð ° Ð ° Ð ° Ð ° Ð ° Soon and so on and on and on.

Sauerkraut sauerkraut Bump, bump, bump, bump, bump, bump Flare, flip, flip, flare.

ЧÑоР± Ñ Ð¾ÑкÑÑÑиÑÑ ÐºÐ¾Ð »ÐμÑнÑÑ Ð³Ð ° йки ил и Ð ± оР»ÑÑ Ð³ÑÑÐ · овÑÑ Ð ° вÑомоР± ил Ðμй и коммÐμÑÑÐμÑкого ÑÑÐ ° нÑпоÑÑÐ ° нÐμоР± ÑоРRose, Rose, Rose, Rose, Rose, Rose, Rose and Rose Rose 3/4 Rose 1 Rose

Burgundy .

The difference between a nutrunner and a screwdriver

The electric screwdriver covers a wide range of jobs. It is used both for tightening (screws, self-tapping screws, screws) and for drilling low-density materials. The tool has a speed regulator and can be equipped with various types of chucks (keyless or jaw). Suitable for home and industrial work.

With a wrench, things are different. This tool is widely used in production for fast and high-quality fastening of parts, but more and more often it begins to appear in home kits of motorists. Can be fitted with a hex chuck or square with a friction ring. Impact wrenches are considered the most effective, although impulse-type models are very common. The main thing that distinguishes a wrench from a screwdriver is the increased power of the former. A wrench can tighten self-tapping screws, but it requires a fair amount of skill for this, since, with too much effort, it can tear off the caps or drive the fasteners deep into the board. The main everyday use of the nutrunner is to unscrew the wheels of the car and fasten the overall threaded structures. For this business, he is perfect.

The next difference is the cartridge. Unlike a screwdriver's clamping mechanism, adapters are required to use the drills or bits on the nutrunner.

Drive types

The most common models are electrically driven. Naturally, they require 220/50 AC mains. The network impact wrench is universal. They have a range of capacities, up to 6000 Nm and with a minimum of up to 40. Weighs up to nine kilograms - the more power, the heavier the unit.

Cordless wrench - from the car battery or its generator. Indispensable in places where there is no electricity network. But his Nm is low - up to 500 units. For the needs of motorists, and this is enough, so they constantly carry it with them, like a jack or "spare tire".

There are also impact wrenches that increase torque. Pneumatic is a type of shock-rotational. They work on a pneumatic supply source. They are straight and percussive. Very large Nm.

Hydraulic wrenches work at a service station, in a car company, together with an oil station that pumps fluid under high pressure. Withstand any frosty temperatures, have a crazy torque - 65,000.

Wrench multipliers. They have been known for a long time. Manual efforts increase the reducer several times. 3.5-60 Nm is enough for them, but it can be brought up to 60 thousand. In car service stations, personal garages, Nm is set in advance to avoid injury.

The difference between a nutrunner and a screwdriver

With a wrench, things are different. This tool is widely used in production for fast and high-quality fastening of parts, but more and more often it begins to appear in home kits of motorists. Can be fitted with a hex chuck or square with a friction ring. Impact wrenches are considered the most effective, although impulse-type models are very common. The main thing that distinguishes a wrench from a screwdriver is the increased power of the former. A wrench can tighten self-tapping screws, but it requires a fair amount of skill for this, since, with too much effort, it can tear off the caps or drive the fasteners deep into the board. The main everyday use of the nutrunner is to unscrew the wheels of the car and fasten the overall threaded structures. For this business, he is perfect.