Friction ring for a snow blower with your own hands - Special equipment

Snow removal is usually done in many different ways.

Among them, two are most often found: cleaning the area with a snow blower and vigorous work with a shovel.

Of course, there can be no shortcomings in honest physical labor, in principle.

You honestly take a shovel, dress honestly, and also honestly do your job. The result is pure territory and satisfaction from the idea that the job was done just fine.

The pleasant pain in your arms and back assures you of this thought even more strongly, and with a pure heart and a sense of accomplishment, you put the shovel in place and return to your business. The next day, in the morning, you find that winter has come for a long time and thoroughly.

Snow fell during the night no less, and perhaps even more than yesterday - beautiful, of course, there is nothing to say. You honestly take a shovel, skillfully dress warmer, with the perfected movements of a real professional, you clean up the area covered with snow.

When everything is done, you, with the same wonderful sense of accomplishment and a little fatigue, put the shovel in place and return to the warmth to rest a little.

On the third day, there are views in the window that will take your breath away.

A real snowy desert, with its centuries-old glaciers, northern lights and an ecosystem in the form of polar bears and seals. Smoke is visible on the horizon - it means there, in the parking lot, some northern people.

You dress warmer, cast a scornful glance at the shovel, take out your gun, bullets and salt.

It's time to go and exchange what is in abundance on the farm for a piece of fresh venison.

At one point, you realize that everything could be much easier if you had a snow blower at your disposal. And to make your life easier, and simple snow removal, acquire this most useful technique as soon as possible.

Why does the structure wear out?

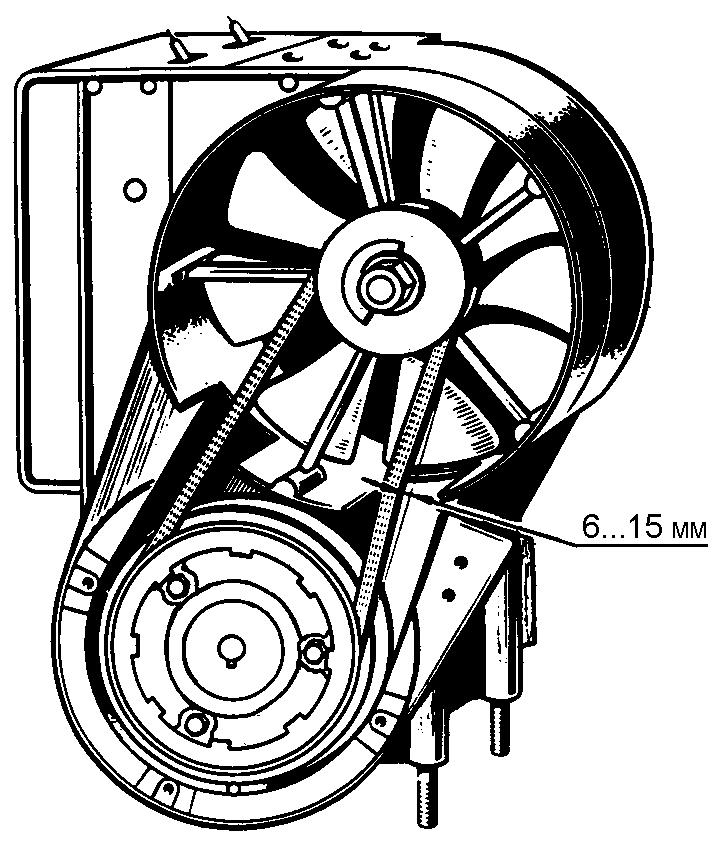

All manufacturers in their advertisements and even in the accompanying documentation indicate that friction rings have a large resource. But this only applies to a normal situation. If the rules for using the equipment are violated, the disk will degrade quickly. The same applies to machines that are operated correctly, but under very high loads.

Dangerous effects arise when:

- changing gears on a moving snow blower;

- attempts to remove an excessively large layer of snow, especially snowdrifts;

- ingress of moisture inside the mechanism.

If the owner of the device changes gear without stopping the device, he will not notice anything bad at first. But the sealant, which is designed to protect the disk, will immediately undergo a strong blow. Even the strongest and most stable rubber cannot be designed to permanently absorb such shocks. It will wear out quickly under the influence of friction. As soon as the protective material breaks off, cracks, friction begins to act on the friction disc itself.

It will also collapse, albeit not so quickly. However, the result will be the same - complete degradation of the part. This will cause the snow blower to stop. Characteristic signs of wear are the grooves that cover the outside of the ring. Having noticed this sign, it is better to immediately discard the part and pick up a new one for replacement.

As for the dampness, everything is clear here - there is no chance of resisting it. By definition, a snow removal device will come into contact with water, albeit in a different state of aggregation. Liquid ingress will provoke corrosion.

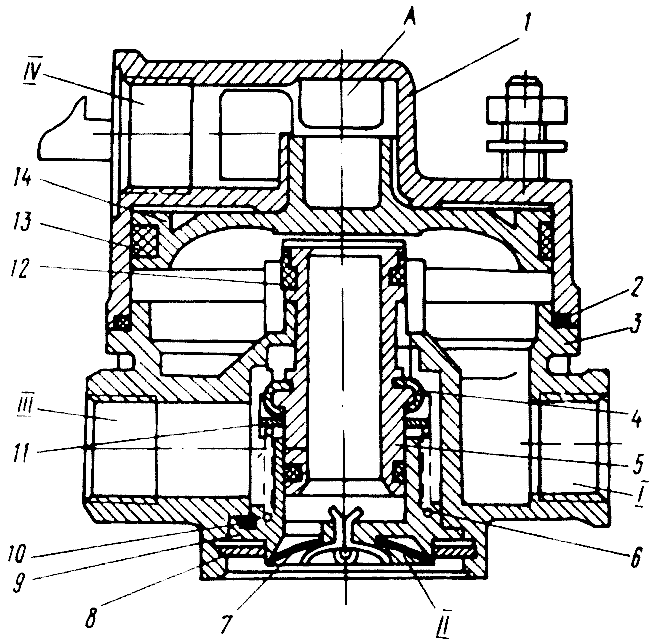

Principle of operation

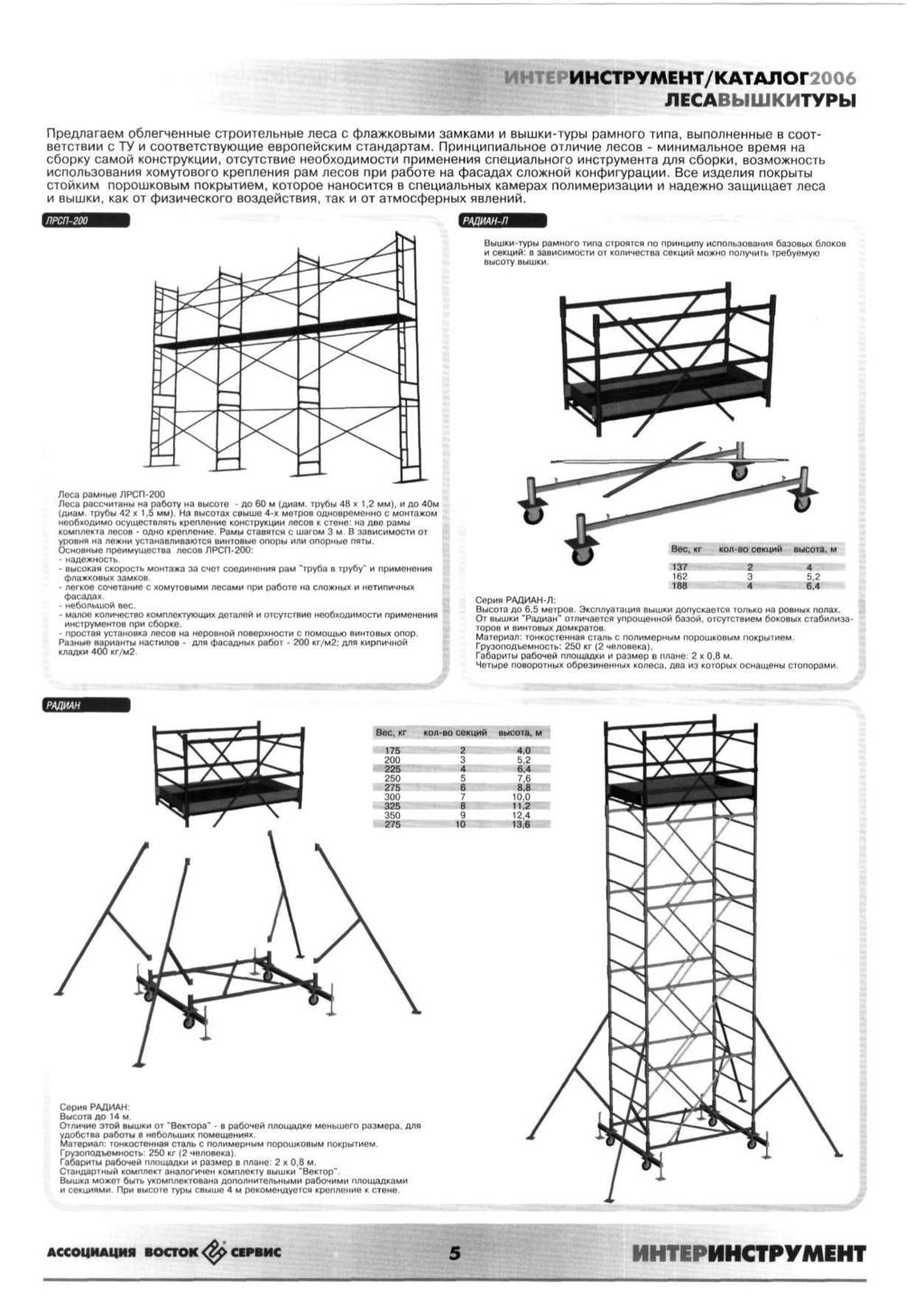

The principle of operation of snow blowers such as Husqvarna, forte qi jy 50, cmi 163, snow fox sf16353l, champion 656, lux 163 is very simple. But this is only at first glance. If you do not delve into the design features, then the snow simply gets inside and is thrown to the side, thus clearing the desired surface.

Principle of operation

But there is still a difference, and it will be visible already during operation - all the disadvantages and advantages will be understood only then. In order not to have to face certain difficulties already in working with a snow blower, examples of designs of different types of snow blowers are given below.

A single-stage, or auger snow blower, rakes and throws snow with only the auger. Such a device is compact - often such models consist only of a bucket with an auger inside and an engine that does all the work.

For more information about the operation of the auger snow blower, see the video:

There are also options that are equipped with only blades that shovel snow like a broom.

Such models are usually light in weight and size. Often they are equipped with low-power electric drives - such snow blowers are designed to remove snow no more than 11 centimeters thick, but they cope with the task perfectly.

Single-stage snow blowers are also produced with gasoline engines, however, they are more noisy than electric ones and require constant maintenance. Before use, make test runs, clean from dirt and dust, but this is optional, constantly monitor the oil level.

These snow throwers are available in different versions, with two-stroke and four-stroke engines. The difference in cost and maintenance is again oil and fuel. Starting a single-stage petrol powered snow blower is another story.

There are two options to choose from - starting with a rope and an electric starter.

Snow blowers are not equipped with batteries, therefore, to start from the button, you must first connect it to the mains. Need a socket. And for greater efficiency, the electronic start is duplicated by the first option - there is a cable available, in case the button does not work.

A two-stage snow blower does not fundamentally differ from a one-stage snow blower, but it still has its own characteristics. They also have an auger that rakes in snow. Then it falls on the rotor with blades, which throws it out through the chute.

The main difference between the designs of a two-stage cleaner and a simple one, which has one stage, is that the auger in this case does not touch the ground. Snow falls first into the bucket, and only then onto the auger itself.

Also, they are equipped with wheels and a powerful frame, so that they can be used for cleaning a large area with minimal effort and time. All two-stage snow blowers come in three classes. Consumer, semi-professional and professional.

Consumer goods have a good price. They are available and sold in absolutely all stores of the corresponding profile. This is the most popular product - you can always purchase parts that are out of order for them. Semi-professional snow blowers are more expensive.

But this technique is much more powerful than the consumer one, and the materials from which they are made are better than those of cheap materials. This technique breaks down less often and lasts longer. Major repairs are generally a rarity. Professional snow blowers are a rare guest in stores.

This is a tricky technique that costs a lot of money. But this technique copes with the work, there is nowhere better. She removes snow very quickly and very cleanly. They provide absolutely everything, from the start in the worst weather, to almost a coffee maker for the driver.

How to change the friction disc on a snow blower?

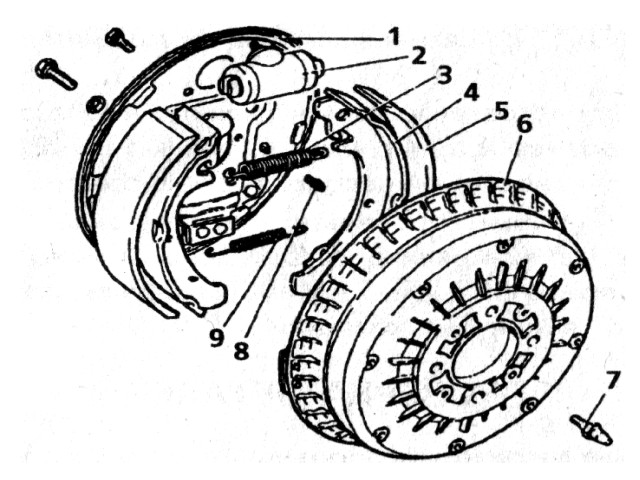

It is not possible to restore a worn out friction disc.Therefore, if an element is found to be broken, it will need to be replaced immediately.

To do this, you must act in this order:

- If the snow blower is working, then its engine will need to be turned off and wait until the motor has completely cooled down;

- Next, you need to carefully unscrew the standard spark plug from the internal combustion engine, and also drain the remnants of the fuel used from the fuel tank;

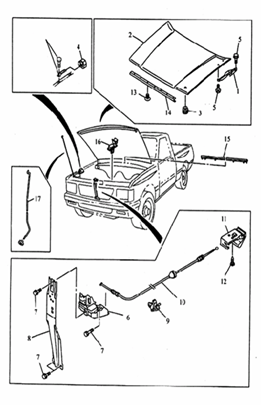

- Then you will need to remove all wheels of the household snow blower and unscrew the factory pins on it;

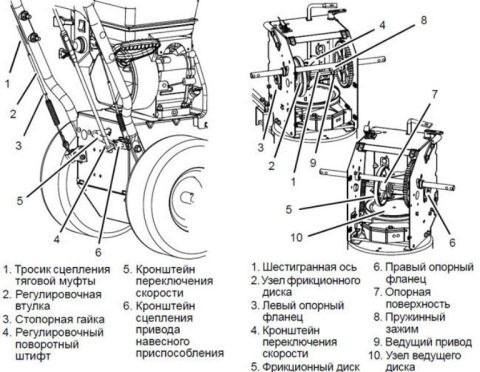

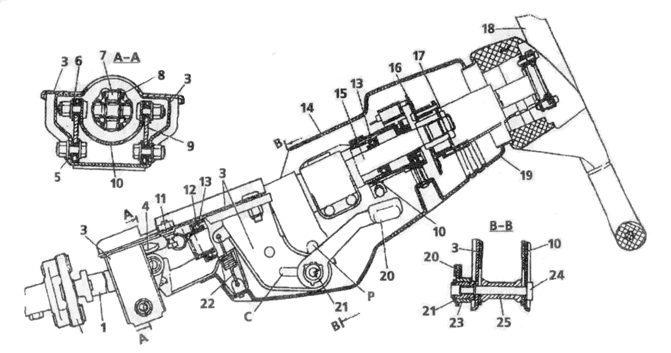

- After that, you need to unscrew the hex screws with a wrench and carefully remove the top cover of the transmission housing. Next, you need to remove the pin from the built-in spring clip.

Fixture manufacturing and replacement

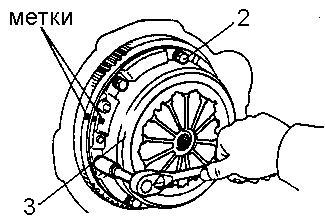

It is almost impossible to "reanimate" the friction ring. But there is no need to be afraid - changing a wheel is quite simple. The first step is to turn off the engine and wait until it cools down. Pulling out the spark plug, pour out all the fuel from the gas tank. Further:

- remove the wheels one by one;

- remove the pins of the stoppers;

- unscrew the screws;

- dismantle the top of the checkpoint;

- remove the pins from the spring clips holding them.

The next step is to remove the support flange. It blocks access to the friction device itself. The remains (fragments) of the worn out disk are removed. Instead, they put a new ring, and the snow blower is assembled (repeating the manipulations in the reverse order). A newly installed disc must be carefully checked by warming up the engine and walking around the area with a snow blower in idle mode.

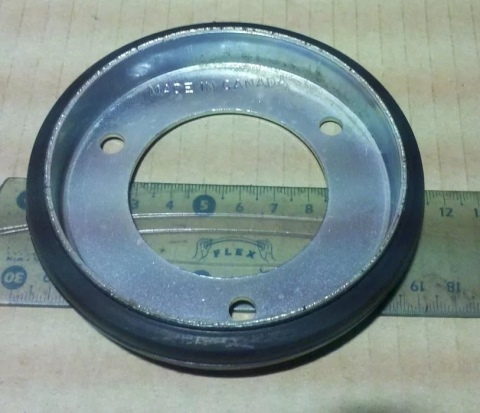

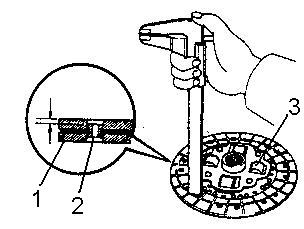

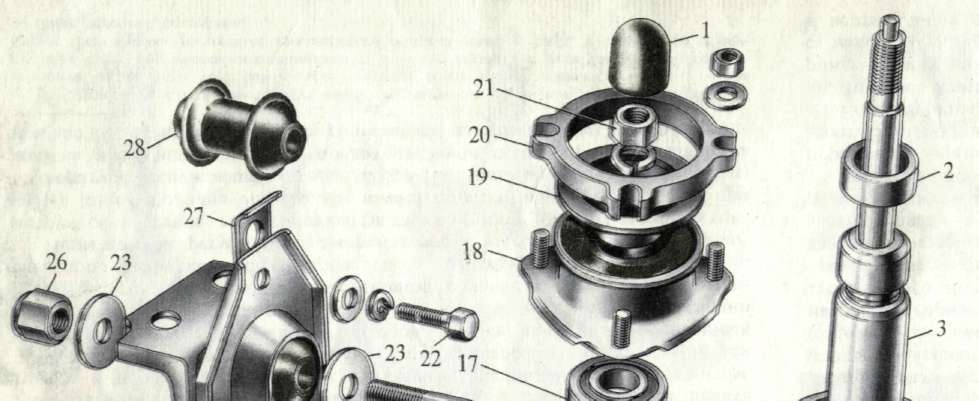

The purchase of friction discs is not always profitable. It is often more economical to make them yourself. But you need to understand that homemade elements can be made completely even only after many hours of hard work with a file. Billets will have to be made of aluminum or other relatively soft alloys. The outer contour of the old ring will allow you to prepare the circle.

In this circle, you will have to prepare the most even hole. The easiest way is to use a drill. Relatively thin drills are fixed in it. When several channels have been made, the bridges separating them are removed with a chisel. The remaining burrs are removed with a file.

When the disc is ready, a seal is put on it. Polyurethane rings of the appropriate size will be required, for example, 124x98x15. "Liquid nails" will help to put the ring on the disc more firmly. Installing self-made discs is done in the same way as in the case of industrial products.

Additional details and nuances

If the disc is made according to all technical rules, during a test run, each gear change is made without the slightest extraneous sounds. But even minor knocks give a reason to redo everything from scratch. Usually it takes about 2 minutes to check. As for the polyurethane protective elements, the harder versions are often painted blue. The 124x98x15 clutch wheels mentioned above are the most common format.

In terms of elasticity, polyurethane bypasses any metals. However, it is not sufficiently resistant to strong heat. Therefore, the operation of the snow blower is permissible only with a strictly limited load on the clutch.

What is important, the ring of any model is adapted only for strictly defined modifications of harvesting equipment. You need to be interested in compatibility in advance

Important parameters when choosing a factory product are both the diameter of the inner hole and the outer section. Of course, it is advisable to choose the products of the same company - it is safer and safer this way.

For information on how to independently replace the friction ring on a snow blower, see the video below.

Friction ring for snow blower

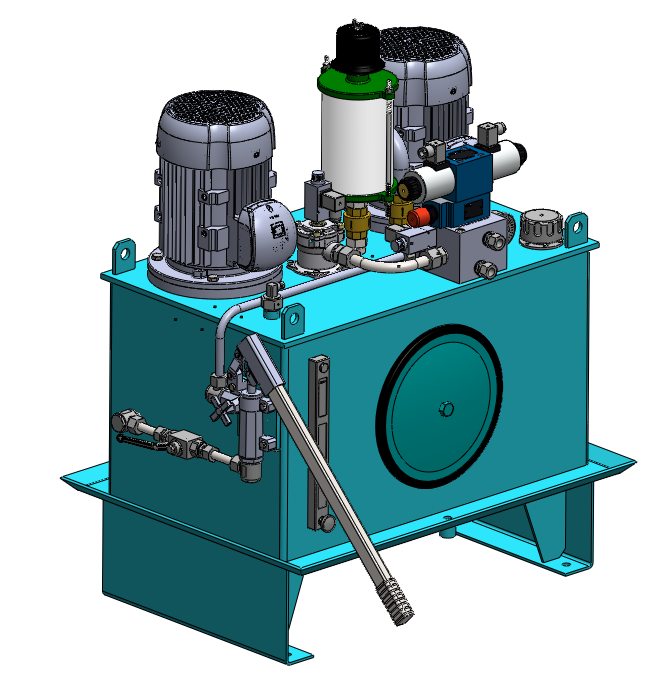

Modern snow blowers are equipped with a mass of elements that, during operation, are subject to increased wear.

One of them is a friction ring for a snow blower.This seemingly simple detail performs a rather important function.

Therefore, its timely replacement must be treated with special responsibility.

DIY snow blower friction ring

It is quite possible to make a friction disc with your own hands. When processing the walls of the element, care must be taken that it can be easily installed in the transmission of the snow thrower.

The procedure for manufacturing a part is as follows:

- First you need to find a solid piece of aluminum. A part of any metal is also suitable, the main thing is that the material is soft and easier to process;

- Next, you need to take an old faulty friction ring and cut a circle from the workpiece used along its outer contour. If a grinder is used for this, then the workpiece along the outer contour will need to be cleaned of burrs;

- The most difficult stage in the manufacture of a disc is cutting a hole along its inner contour. Most often, a drill is used for this. With its help, in the center of the workpiece used, you will need to drill several adjacent holes. The bridges remaining between the holes can be cut off with a chisel. As a result, the extra pieces of the disc will fall off and the operator will have an almost finished workpiece. Its inner walls will need to be thoroughly cleaned of burrs.

After manufacturing, you will need to put on a sealing rubber ring on the friction disc. To do this, it can be cut out of dense household rubber by carefully cleaning its inner and outer edges from irregularities.

Next, a homemade disk must be installed on the snow blower and tested. A sign that the job has been done correctly will be the absence of knocking sounds when shifting gears.

Friction ring for snow blower Link to main publication

Peculiarities

The friction ring for a snow blower is subject to very heavy wear. Therefore, it often breaks down in a short time. Meanwhile, the efficiency of work largely depends on this ring. Without it, it is impossible to synchronize the spinning of the wheels with each other. The breakdown is most often manifested in the fact that the gearbox sets one speed, and the device works at a different pace or changes it chaotically.

By default, most manufacturers equip their snow blowers with aluminum clutches. Products with steel parts are found much less frequently. Regardless, the ring is shaped like a disc. A rubber seal is put over the disc element. Of course, the reliability of the rubber used is critical.

Helpful hints and warnings

In order to make it easy and pleasant to work, and the equipment worked properly and for a long time, it is worth observing some operating rules. With due attention to simple things, they will make life easier in return:

- To ensure that fewer stones and other objects fall into the chute that can damage the snow blower, the area for cleaning must be carefully checked.

- When working with this technique, always protect your eyes first. It is also not advisable to leave any parts of the body open.

- It is best to wear protective clothing and non-slippery shoes during cleaning work. Never start work if you have any part of your clothing hanging or dangling.

- Never make adjustments or other manipulations with parts of the snow blower with the engine running.

Working safely with a snow blower

In order to keep the snow blower intact for longer, and even more so to avoid unnecessary repairs, first of all, you should pay attention to minor details:

- Snow removal is much more effective if you start it right after it has fallen

- The snow that is thrown out of the gutter did not fly against the direction of the wind, because, in this case, it will again be in the same place from which it was removed. Do not do like this.

- The gasoline engine must be left idling before and after work. At first, it should warm up, because it stood without work for a long time - in this case, it will be possible to avoid unnecessary deformations of the metal.

- At the end of the work, this will make it possible to melt all the adhered snow and ice, which then can simply freeze up in places where it was not possible to clean them.

Why does the friction ring wear out?

During the operation of a household snowplow, several factors negatively affect its friction ring at once.

These include:

- a sharp change in speed without first stopping the machine - the first to suffer from this is the rubber seal located above the ring. He is not able to protect the disc, since initially, in its normal state, the rubber is quickly erased. As soon as the seal is torn off, the friction ring for the snow blower will be under the blow. Over time, the part will also wear off or split into parts, which will lead to a complete stop of the machine;

- improper operation of the snow blower - you need to remember that the wheels of the snow blower will slip in the snowdrifts or pits. They will begin to create a high mechanical impact on the element. Because of this, grooves and burrs will quickly appear on its surface;

- using a snow blower in conditions of high air humidity cannot be solved in any way, since snow and moisture are constant companions of the snow blower. Acting on the disc, dampness destroys it, therefore the operator is required to identify the worn-out element in time and immediately replace the element.

To extend the life of the part, you need to properly operate the snow blower and exclude its prolonged use under high loads. This will save not only the disk, but also other important parts of the machine from premature failure.