Peculiarities

Many car enthusiasts think that purchasing an electro-hydraulic jack is a waste of money, because such equipment is quite expensive compared to other types. This type of jacks manufacturers are positioned only as an automobile.

Consider all the advantages and disadvantages of such a purchase. Let's start with the merits.

- Easy to use. The driver needs to connect the device to the vehicle's on-board network and turn it on by pressing a button. As you can see, there is no need to additionally pump air or fluid to lift the car. This option is ideal for people with disabilities and women.

- The design characteristics of the device allow it to be used on an uneven surface or in the presence of other unfavorable factors.

- Small size.

- Low noise level.

The electro-hydraulic jack also has some drawbacks, and some are quite significant.

- High price. As we noted above, compared to their non-electric counterparts, electric ones are an order of magnitude more expensive. The reason for this is one - a lot of electronic components.

- The lifting capacity of no more than 4000 kg significantly limits the use of the tool for large machines.

Exploitation

The jack is used only when the engine is off, the parking brake is locked and the chocks are installed.

The body of almost every electrically driven device is made of plastic, therefore it requires careful use. Shocks and high temperatures are not allowed. To avoid injury, lift the jack only by the handle.

Avoid intensive work of the equipment, moisture ingress on the jack. Connect it to the network only when you are working with it. If oil leaks, the machine must be turned off to avoid fire.

The ease of use of the electric hydraulic jack outweighs the disadvantages. It will be appreciated by both beginners and experienced drivers. The main thing is to find a model that fits the parameters of your car.

The video below explains in detail about the electro-hydraulic jacks.

General characteristics

Electric jacks are mechanisms for lifting cargo, functioning from the car's cigarette lighter or its own battery. 12 volts are enough to power the electric jack. Such a lifting mechanism is able to function even when the car engine is running, which is very much appreciated by motorists. This allows the jack battery to be charged from the mains of the vehicle being lifted.

Electric jacks are characterized by ease of use, the ability to perform their duties from a battery or a vehicle generator, excellent qualities when used in extreme conditions. The current consumed by the jack is 20 A.

Species overview

Currently, there are portable, mobile and stationary jacks, they all differ in design, principle of operation and dimensions. Consider what varieties exist and in what area of application they will be especially effective.

By construction type

There are several types of lifting devices that differ in design configuration:

rhombic;

By way of control

Hoisting mechanisms also differ in the type of drive they use. There are the following types of drives:

Mechanical jack - lifting the load is done by using a foot or hand lever.

How the device works

As already mentioned above, the principle of operation of the unit is to power an electric jack with a 12 volt electric drive using a socket or cigarette lighter that is located in the car. Some motorists consider it reckless to buy a Craft jack, and in order to change this categorical point of view, it is recommended to familiarize yourself with the advantages and disadvantages of the jack.

As for the advantages, they are represented by ease of use, since it only requires the installation of a mechanism under the vehicle, its connection to the network and control using a remote control

Due to its good stability, the electric jack can be operated even on uneven surfaces, which is also important .. Not every driver can afford to buy an electric pump due to its high cost

Its design includes various mechanical parts, wires, microcircuits, sensors and other components that are included in the cost of a one-piece design. A significant disadvantage is the fact that the assembled electric jack has a rather large size and weight, which minimizes its ease of use.

Not every driver can afford to buy an electric pump due to its high cost. Its design includes various mechanical parts, wires, microcircuits, sensors and other components that are included in the cost of a one-piece design. A significant disadvantage is the fact that the assembled electric jack has a rather large size and weight, which minimizes its ease of use.

The main characteristics of an electric jack that you should pay attention to when choosing

Electrical products cost slightly more than hydraulic or mechanical lifts, so their choice should be approached responsibly. It is strongly discouraged to give preference to cheap models, since there is a risk of acquiring a fake, which will soon become unusable.

The most important characteristic that you need to pay attention to right away is the carrying capacity of the device.

A separate item is worth noting the maximum lifting height, which is represented by the distance between the surface and the machine in the raised position. Another important parameter is the ground clearance or the pickup level, which is necessary in order to determine the distance of the jack under the machine.

Experts have established another bonus feature - the versatility of the lifting mechanism, which is responsible for the ability to lift all vehicle models. This parameter is secondary and not very much in demand, because it is he who contributes to the fact that the cost of a universal electrical structure increases significantly

You also need to pay attention to the size and weight of the unit.

Lift construction

Anyone who has ever seen a car can imagine what an autojack is like. It must be included in the set of the necessary tools for any machine. A good chauffeur will always check its availability before leaving, because when changing the wheels, you need to raise the car. Often, looking into the trunk of a new car, you can see the simplest and most unreliable diamond-type lift. Then it becomes necessary to replace it and buy a more modern instrument, which is divided into several types in terms of the design form:

Anyone who has ever seen a car can imagine what an autojack is like. It must be included in the set of the necessary tools for any machine. A good chauffeur will always check its availability before leaving, because when changing the wheels, you need to raise the car. Often, looking into the trunk of a new car, you can see the simplest and most unreliable diamond-type lift. Then it becomes necessary to replace it and buy a more modern instrument, which is divided into several types in terms of the design form:

- Rhombic.

- Screw.

- Roll-up.

- Rack and pinion.

Selection Tips

When choosing a jack with an electric drive, you yourself need to pay attention to such aspects

- Vehicle weight.The model of the jack will depend on this parameter, since each type is designed for a certain carrying capacity, and exceeding the maximum value will lead to damage not only to the device, but also to the car.

- Ground clearance. The functionality of a jack depends a lot on its height range - the wider it is, the better the equipment should be.

- Brand. To buy an electro-hydraulic jack for the first time, it is better to take products of a well-known brand in the middle price category. Such manufacturers, as a rule, give a guarantee for their products, there is no doubt about the quality of the components and the reliability of the characteristics indicated in the product passport.

At the moment, the equipment of the German company Varta, the American company Turbo and the jacks of the domestic manufacturer Sorokin have proven themselves very well on the market of jacks with an electric wire.

DIY electric jack repair

Poor performance of an electric jack can be caused by the fact that the microcircuits wear out over time and become unusable. At the same time, the rod is not able to rise to the height level that was specified by the manufacturer in the technical documentation. Chips that have become unusable can be easily replaced with new parts.

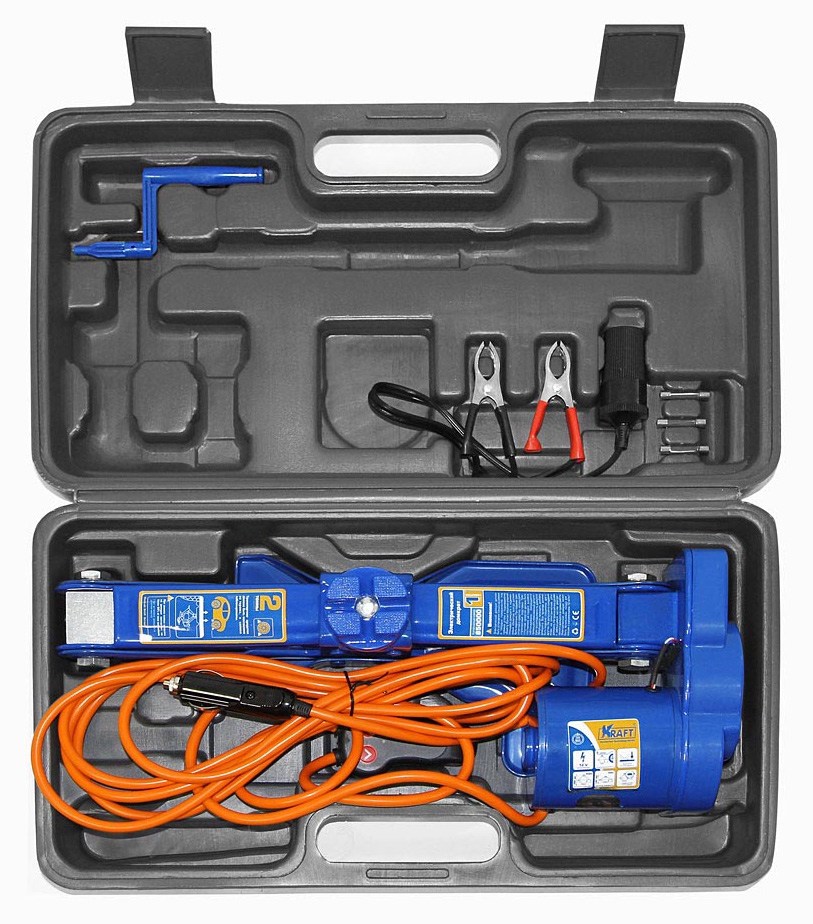

Repair tool kit electric jack

Repair tool kit electric jack

Another breakdown is represented by the fact that an inexpensive electric jack sags under the load that is applied to it. The air accumulating inside leads to the fact that the gaskets and microcircuits allow liquid to pass, instead of which air bubbles enter the working cylinder. To eliminate such a malfunction, it is recommended to carry out repair work, replace all spare parts and microcircuits, acquiring a case with tools for this.

Before carrying out repair work, an electro-hydraulic automobile jack must be disassembled with a wrench and drain the liquid that is in a special reservoir. If the structure does not have a filler hole through which the oil is drained, it should be done through the check valve. The lower rubber ring must be carefully inspected and then checked for leaks in the housing. As for the slave cylinder, unscrew it and see if it is affected by rust formation.

Important!

Rusty parts are recommended to be unscrewed and cleaned with sandpaper. To make sure that the plunger and O-rings are working, they also need to be unscrewed and checked for damage and dents.

If iron shavings are noticed inside the device, it is washed with water, and then collected in the reverse order.

An electric car jack 12 V is a specific device that is gaining momentum on the market every day. Despite minor drawbacks, many motorists prefer to opt for this type of lifting structure in order to repair their vehicles.