Major manufacturers of trailed mini excavators

In the last couple of years, new brands with original products have appeared on the Russian market, which until that moment had experience in selling in European and American markets. We are talking about manufacturers of trailed excavator equipment. The common thing that unites such equipment is the ability to transport it using any vehicle with a towbar, van, light truck. Once delivered to the destination, the excavator can be moved with a bucket or manually rolled back by the operator.

Among the equipment of this type are Landformer excavators from Germany, which have found their application in agriculture, as well as in companies involved in electrification, gasification and installation of local sewerage. It is known about the experience of using this machine and for cleaning the river channel (by attaching it to the pontoon). The Landformer trailed mini-excavator weighs only 465 kg. The standard equipment of the novelty includes a bucket 25 cm wide (less than the width of a sheet of A4 paper). Additionally, the machine can be equipped with buckets 35 and 60 cm wide. This wheeled mini-excavator of the trailed type has a maximum digging depth of 2.1 m. Productivity - 1 cubic meter in 10-12 minutes. If necessary, the motor can be replaced with a more powerful one. The main condition for this is the compatibility of technical characteristics.

Another manufacturer is the British company Powerfab, which offers customers a trailed TD1 model. This equipment appeared in Russia about a year ago. Excavator weight - 750 kg. The stability of the trailed mini-excavator is provided by four hydraulic stabilizers. The engine of the machine is diesel, with a power of 9 kW. The maximum digging depth is 2.4 m, the digging force is 2 tons. A wide range of attachments is available.

Benefits of earthmoving sheds

Mounted excavators are equipped with an autonomous control system. Swinging, raising and lowering the boom is done using the hydraulic system and levers. All actions of the auxiliary equipment are highly accurate. At the same time, the price for such devices is very affordable. Depending on the performance and the country of the manufacturer, it varies between 40,000-130000 rubles.

The advantages of mounted excavators are as follows:

- High power and performance. Removable equipment is not inferior in these indicators to combined tracked and wheeled vehicles.

- Compactness and light weight. The devices are folded and packed in a car trailer or commercial van. The weight of the canopies varies between 350-450 kg, which allows loading and unloading them manually or using a simple lift.

- Easy to manage and maintain. There is no need for special education and certification to use earth-moving equipment. It is enough to read the instruction manual.

- The speed of bringing to the working and transport position. It takes just a few minutes to install and remove the excavator attachment.

- Significant savings in money, reduced costs for storage and maintenance of equipment. There is no need to purchase several types of special equipment. If there is no need, the mounted excavator can be easily rented or sold.

- Reliability and durability. The attachments are manufactured with a large margin of safety. Its service life is at least 5 years.

adapted to work with almost all models of mini-tractors.The sheds can be installed on the MTZ, Belarus, Uralets and Zubr tractors. Earth-moving devices are also compatible with equipment of Japanese, Chinese and European production.

Scope of use of attachments

Today, there are mini-tractors in almost every communal and farm enterprise. Installation of additional equipment on this technique can significantly increase its efficiency and expand its capabilities. The mini-tractor excavator turns this machine into a productive, wide-profile earthmoving machine.

A trailed excavator based on a tractor can be used to solve the following tasks:

- Excavation of foundation pits for residential buildings and utility structures. The selected soil is removed to a dump or loaded into the body of a dump truck.

- Arrangement of trenches with a width of 30 cm. Buckets of various configurations and volumes can be installed on a modern excavator for a mini tractor. This allows you to carry out precise work in the cramped conditions of urban buildings or the courtyard of a private house.

- A fragment of holes for supports or for tree seedlings. With compact and economical earthmoving equipment, several hundred neat holes in the ground can be made per day.

- Terrain planning. Using a bucket and loader, the operator moves soil and bulk materials. Backfilling of holes and ditches, removal of soil from hills and mounds is carried out.

- Creation of ramparts, dams and embankments. A modern earthmoving loader can create even high quality roads.

- Destructive work. Installation on the boom of a hydraulic hammer makes it possible to break brick walls, reinforced concrete blocks and foundations.

Trailed earthmoving devices can be installed flush against walls or indoors.

General characteristics and indicators

MTZ excavators are valued primarily for their reliability and endurance. This is a powerful technique that will last for years. It rarely breaks. But even if repairs are required, it will not be difficult to find any necessary parts for it, and the price for them is several times lower than that of foreign competitors.

This tractor is used in various fields of application, namely:

- in agriculture;

- in construction;

- for road and municipal works;

- for excavation and soil cleaning.

The excavator works flawlessly in any weather, it is unpretentious in maintenance. Manufacturers have made sure that MTZ can be used in a confined space. This means it can work close to a wall while digging a trench or removing construction waste. Such a useful function appeared due to the displacement of the rear linkage, as well as the ability to adjust the turns of the wheelsets.

The control system is installed in it hydromechanical. Attached working elements are controlled by joysticks from the cab. Boom type - telescopic, almost all models of MTZ excavators. This adds even more attractiveness to it, since its coverage radius is quite extensive.

The tractor is equipped with retractable hydraulic supports. This allows him to work on uneven surfaces while maintaining a stable position. It also handles heavy ground and other loads with ease. The role of additional support can be assigned to a two-jaw bucket, and it is also possible to install removable counterweights.

Excavator MTZ with hydraulic supports

Peculiarities

Wheeled excavator tractors were produced several decades ago. Of course, those machines have long been replaced by more modern and adequate versions. However, they are all quite expensive. Moreover, a rigidly fixed excavator-type nozzle is not always needed. Sometimes it interferes with the alteration of the device for other applications.

The mounted excavator unit allows:

- dig a pit;

- prepare a trench;

- to plan the territory and change its relief;

- dig holes for poles, planting plants;

- form embankments;

- prepare dams;

- destroy buildings made of bricks, reinforced concrete and other durable materials.

When digging pits, the excavated soil can be dumped into a dump or loaded into the body of a dump truck. As for the laying of trenches, their smallest width is 30 cm. Smaller trenches are recommended to be done manually. The mini-tractor excavators produced today can be supplemented with buckets of various geometries. Their volume also differs greatly.

This technique will allow you to prepare hundreds of neat holes for planting trees without much difficulty during a working day. A bucket attached to a loader can be effective in filling depressions and ditches. He is also good at tearing soil from hills. Moreover, high-quality forklifts can help with the construction of roads under high stress.

Trailed mini excavators for skid steers

V rating of the best manufacturers trailed mini-excavators designed to work with mini-loaders are Bobcat, Avant, Ditch Witch. Lesser known manufacturers include Hysoon and CE Attachment.

The Bobcat Trailed Mini Excavator transforms a conventional skid steer loader into a versatile, powerful and economical excavator. Mounting and dismantling of this manufacturer's backhoe is carried out using a patented attachment installation system (using a special frame), which ensures a reliable and quick attachment of the trailed mini-excavator to the loader. Bobcat currently offers 6 trailed backhoe models that differ in performance and are designed for a variety of machine models and activities. These devices are controlled from the operator's cab. Bobcat mini-excavators have a maximum excavation depth of 1.5-3.5 m. A set of stabilizers is available as an option (not available for all models).

In the list of the main advantages of Avant trailed mini-excavators (this type of equipment is represented by 4 models), one can single out the presence of rear supports and a support blade as standard, a large selection of buckets for working in various conditions, and good earthmoving performance. The full swing handle allows for side trenching. Thanks to the presence of the remote control, the mini-loader can be controlled both from the operator's seat and from the ground (better visibility when cutting a deep excavation). The weight of excavators varies between 80-370 kg, the digging depth (depending on the model) is 1400-2500 mm.

The Ditch Witch trailed mini-excavator is capable of digging a trench up to 2 meters deep and is compatible with buckets up to 457 mm in size. Backhoe weight is 323 kg, height - 1.7 m, width - 1.14 m, length - 1.93 m.

| Landformer | Powerfab | LLC "Technotransdetal" | LLC "Blooming" | Bobcat | Avant | |

| Bucket volume | 0.03 m3 | 0.20 m3 | 0.036 m3 | 0.1 m3 | 0.04 m3 | 0.25 m3 |

| Loading height | 2.4 m | — | 1.6 m | 1.5 m | 2.45 m | 1.35 m |

| Digging depth | 2.1 m | 2.4 m | 1.8 m | 2.2 m | 3.5 m | 2.5 m |

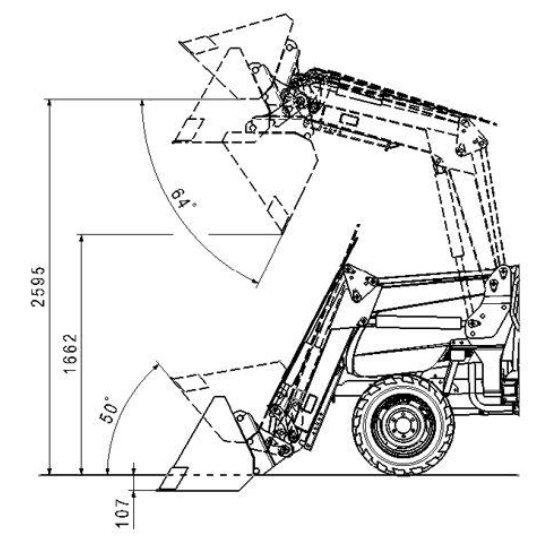

Hysoon offers two towbars designed to make your road construction and utility work easier and easier. The first is an excavator with a swivel bucket weighing 185 kg, a bucket volume of 0.014 m3 and a maximum boom swing angle of 50 °. The second is a trailed excavator weighing 123 kg, with a bucket width of 310 mm and a maximum working radius of 2531 mm.

See All ads for the sale of mini-equipment

Selection options

In order for the purchase to meet all the expectations of the owner of a mini tractor, it is necessary to take into account several important parameters when choosing a suitable mounted excavator. It is necessary to calculate the expected load that it must withstand during operation.

Another important indicator is productivity - bucket volume, hydraulic power.If it is necessary to carry out various work in confined conditions or hard-to-reach places, preference should be given to models equipped with a movable boom.

There are many varieties of similar equipment on sale in new and used condition. A new device purchased from an authorized dealer will be the best option for long-term intensive use. For one-time work or occasional use, it is better to give preference to used devices, which will significantly save money.

Trailed excavator specifications

A trailed excavator has the following technical parameters:

- two- or four-knee undercarriage;

- working supports, which are extended manually or with the help of a hydraulic drive;

- clutch, the type of which is different on a particular model.

Several types of such equipment are produced in Russia, each of which has its own users. There are such groups of mini-tractor manufacturers.

Excavators that are equipped with a boom swing mechanism. The tractor stands on a rigid frame, has 2 wheels and 2 supports. According to consumer reviews, high-quality mini-tractors are produced by the Landformer company, whose representative office is located in Zelenograd. A feature of such mini-tractors is that the buyer must independently assemble all the parts and connect them together. The excavators are equipped with a single-cylinder engine with a power of 15 hp. The engine can be changed to a stronger one that runs on gasoline and diesel fuel.

The excavator on the trailer has a different bucket volume. There are buckets on sale, the width of which is 22, 35 and 60 cm. The Landformer excavator can be used for earthmoving or water treatment, for which the tractor is submerged on floating supports, the attachments necessary for cleaning ponds are completely changed on it.

Powerfab mini-excavators are delivered to Russia unassembled. In factories, they are collected separately, which takes a little time. The hinged mini-excavator, produced by the company of the same name from Britain, is distinguished by a powerful engine. It can be either a 9 hp Honda GX-340 gasoline engine or a 10 hp Honda GD-410 gasoline engine. The package includes a set of buckets of different widths and capacities and a four-wheel undercarriage. Separately, there is the possibility to put the fenders to protect the car from dirt. The productivity of such a tractor model, which works with a trailer, is from 6 to 8 m³ per hour.

Buyers can choose the technical parameters and performance of the machine. This primarily concerns engines, the number of axles and attachments.

The advantage of the Scorpio is the use of a reinforced arrow. The motors can be either petrol from the Honda trademark (9 hp), or diesel from the ZS company. Both engines have the ability to extract soil with a capacity of 8 m³ / hour.

Buyers can choose how many wheels they want to install on the tractor. Usually these are 2 wheels and 2 supports, or 2 wheels and hydraulic cylinders for the supports. Although quite often users choose another, more stable option: 4 wheels and 4 supports, which are lowered and raised hydraulically. Engine power ranges from 9 to 15 hp. You can buy in addition: a bucket of a standard, trapezoidal shape, a special hook that helps to grip logs and stones, as well as a leveling bucket for large volumes of work. The Scorpion excavator comes with a special set of tools and replacement parts. Service departments are open throughout the country to service mini-excavators.

There are also other manufacturers, in particular, Belarusian equipment deserves attention.

Advantages

High quality backhoe loaders:

- are distinguished by increased productivity;

- more compact than combined units, but have the same power;

- relatively light (no more than 450 kg);

- easy to manage;

- quickly transferred to the transport position and back;

- allow you to save money, giving you the opportunity to refuse to purchase several mechanisms at once.

Attachments manufactured by leading manufacturers have an increased margin of safety. The operating time is at least 5 years. Such mechanisms can be installed on all mini tractors. They are also compatible with full-fledged tractors of the MTZ, Zubr, and Belarus brands.

MTZ 92 P

This is the newest and improved modification from the presented model range. It is endowed with many advantages, for example, high stability on uneven surfaces, moving ground. Because of this quality, it is more often used for earthmoving work, and not as a loader. It has become more maneuverable and precise in control, which is carried out by two joysticks in the cockpit.

Excavator MTZ 92 P

Another plus is its small size. This is the smallest backhoe loader in the series, it is convenient to use in confined spaces, small construction sites, in the yard, near walls and fences. The reduction in size was possible thanks to the vertical stacking of attachments.

It is equipped with an Italian-made hydraulic distribution system, which protects the equipment from leakage of working fluids. The rear bucket can move up to 1.3 meters from the machine. The pit is about 4 meters deep.

Video

The maneuverable and compact mini tractor with a bucket can work in limited conditions, dig holes for foundations and pools, create trenches for laying pipes. Long-term special training is not required to operate the tractor. The KIOTI is easy to dig and dig as it has a standard arrangement of levers and pedals. A test drive at the buyer's site and preliminary training will be included in the list of free services if you decide to buy a tractor-excavator from us.

The universal attachment attachment system is easy for the owner of the KIOTI tractor. The transverse and longitudinal links easily adjust the attachment, and the Category 1 and Category 2 three-point linkages are suitable for a wide range of attachments. A mini-tractor with an excavator can be used all year round for agricultural, municipal, construction, loading operations. Even in cold weather, the KIOTI engine is easy to start - cold down to -30 ° C is not a problem!

Unpretentious KIOTI equipment has a guarantee of 1,500 hours or 3 years. By purchasing a mini-tractor with a bucket, you will be able to perform a variety of work without wasting time on repairing and upgrading equipment. To further extend the life of the transmission, the KIOTI tractors have made the PTO and all-wheel drive connected via an electro-hydraulic clutch (the CK series is an exception).

How to make a bucket for a mini tractor?

Making a kuna for a mini tractor begins with the selection and study of schemes. Drawings will tell you the dimensions of all the parts used, as well as the methods of their fastening in the structure.

From the assembly tools, you will need a welding machine, a grinder and a drill with a set of drills. You will need a set of wrenches to secure the bolted connections. As a basis for the manufacture of a bucket, a steel sheet with a thickness of 6 mm is suitable, as well as pipes of different diameters.

The build order of the kun is as follows:

- First you need to make a fastener. Its base should be welded to the engine and the box of the minitractor. As a reinforcement of the fastener, a steel corner must be welded in its lower part;

- To make the bucket itself, you must use a piece of sheet steel. There is no point in bending it into a coon shape, because it is much easier to cut rectangles of suitable sizes and weld them together in the shape of a bucket.The durability of the structure directly depends on the quality of the welds. To make the device racks, you need to use pipes with a diameter of 10 cm, and for its rods - pipes with a thickness of 5 cm;

- The next step is to install a hydraulic booster. To make it more mobile, you need to use a 3 cm thick pipe;

- After that, you will need to weld the support to the front, and combine it with the racks. To strengthen the structure, you need to use "kerchiefs";

- A cylinder will be required to control and adjust the bucket angle. In most cases, a place to the right of the bucket is chosen for its installation.

The self-made construction is reliable and durable. It is lightweight, making it quick to install and remove alone.