Installation and running-in

In most cases, Chinese engines from Lifan are installed when the "native" motor has failed or has ceased to cope with its main task. Of course, in such a situation, the new unit will be very useful.

After purchase, such equipment will delight its owner for a long time with easy start-up and trouble-free operation. But the engine must be properly installed in order for it to work efficiently.

Installing Chinese-made engines is quite simple. Even a person who has never done this can cope with this procedure.

Consider how to properly fix the Lifan engine with your own hands.

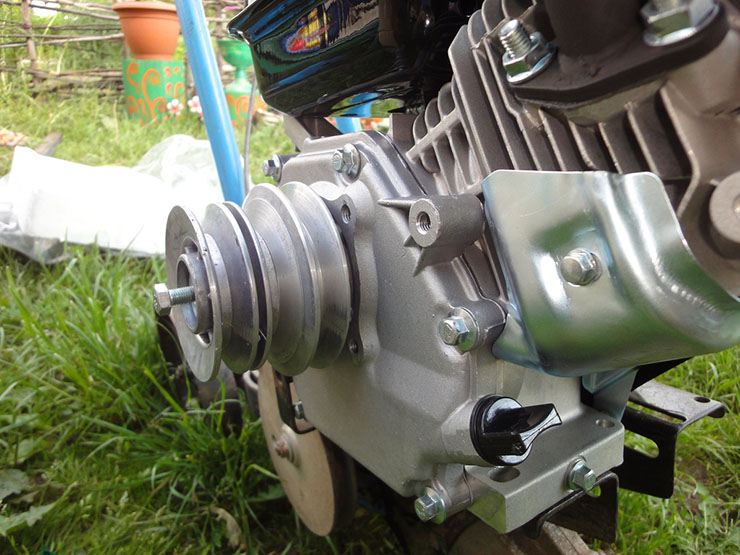

- Remove the old device first. This is done using special open-end wrenches or heads. It must be removed completely, having unfastened the gas cables before that, if they are in the structure. Before directly removing the old unit, you will need to throw off the belt that works with the gearbox (transmitting torque to it).

- Now you can install the new engine. This is done using the same fasteners, if they match. But if not, then they will need to be redone by drilling holes or attaching auxiliary metal plates by welding or placing an adapter plate.

As for running in a newly purchased engine, opinions of different people differ. Some argue that the engine needs to be started immediately, and then - to work at half of its declared power. Others advise letting the engine idle a little to warm up properly. In reality, the running-in of Lifan equipment should take place as described in the operating manual.

It is not recommended to go beyond the instructions, because they are drawn up by people with the appropriate qualifications and experience. It is better to follow their recommendations so as not to spoil the new technique.

In most cases, running in a new Lifan internal combustion engine (internal combustion engine) takes a lot of time. If you do everything based on the instructions, then there will be no shortcomings and malfunctions in the technique. If, with the right actions, some problems did arise with the new engine (for example, there was a reverse return), then do not forget that it is being sold with a guarantee.

Types of motoblock engines

For installation on garden machinery and heavy agricultural equipment, gasoline and diesel engines are used. The former are distinguished by their high productivity and the ability to work in difficult operating conditions, the latter are versatile and economical. The diesel engine of the walk-behind tractor supports a large number of attachments. The best production effect is achieved when operating at low speeds.

Such units have a good motor life and high resistance to negative weather and climatic factors. The most popular are the two-cylinder models. They are relatively inexpensive and can tolerate elevated temperatures well. When using such a motor in the summer heat, a simple air cooling system will suffice. Gasoline modifications require high operating costs for maintenance, service and operation. Their advantages are durability and reliability.

A four-stroke motor of this type has high performance and the ability to work on heavy soils. A machine equipped with a vertical shaft saves time as it can operate stably at high speeds. Power units compatible with walk-behind tractors are subdivided according to the starting method:

- for electrical;

- for manual;

- for combined.

The manual drive is found in the most budgetary and outdated models. More common are units with electric start, which provide an easy and quick start of equipment. They are economical, easy to operate and reliable. Using an electric motor for a walk-behind tractor is appropriate in the country or in your own garden. The combined modification is a convenient option. 4-stroke motors are based on this functional diagram, intended for processing large areas of arable land and agricultural land.

They greatly facilitate the operator's task, since they allow you to choose the type of launch that is convenient for you. Both petrol and diesel models are equipped with an automatic speed control. Another classification feature is the power indicator. On light motoblocks (less than 70 kg), engines up to 4 liters are installed. with. On medium (71-100 kg) motors up to 7 liters are used. with. For joint work with heavy (over 100 kg) equipment, power units from 8 liters are used. with. The power limit is set at around 16 liters. with.

Light and medium motoblocks use two-stroke gasoline or diesel engines with an air-cooled system. They are well suited for chores in a private house. Among the farmers, the most widespread are those equipped with a 4-stroke engine with a forced liquid cooling mechanism. Depending on the modification, the engine is equipped with a gear, chain or worm-type gearbox. The latter can have a V-belt or bevel gear.

Engine oil

When you have a walk-behind tractor in your assistants, you need to constantly monitor the technical condition. Oil is a very important composition that needs to be changed on time. It is responsible for the lubrication, sealing, cooling and cleaning of the motor components in the unit.

When the device operates in a constant mode, the oil remaining in the cylinder may burn out and oxidize, as a result of which the walk-behind tractor begins to smoke. Substances with resins are also deposited in the parts, which leads to contamination. Therefore, it is recommended to use good foreign lubricants, which already contain the necessary additives.

Which engine is suitable for a walk-behind tractor?

The motor belongs to the main elements of any mechanism and the efficiency of the entire device depends on it.

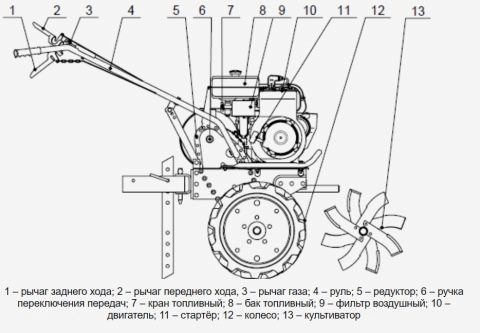

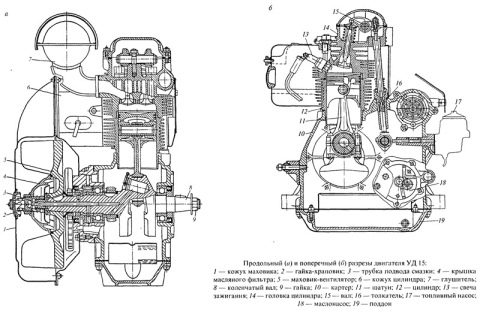

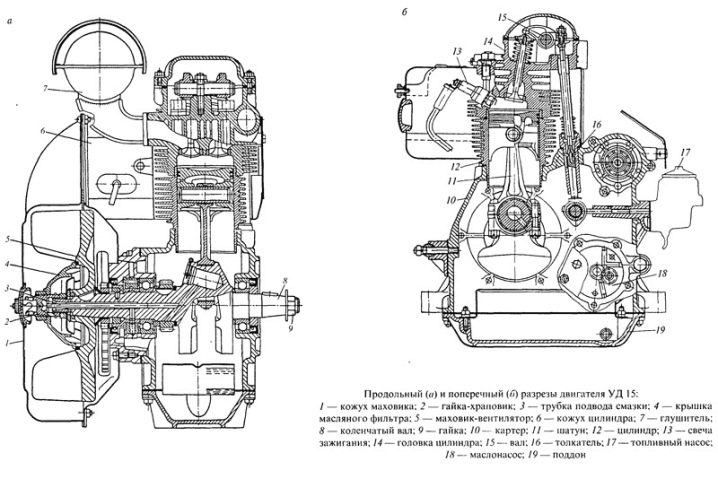

Usually the motor consists of:

- distribution mechanism;

- cylinder block;

- carburetor;

- ignition;

- starter;

- cooling systems.

Initially, the DM66 and DM68 motors were installed on the walk-behind tractors. But they often fail due to improper operation, normal wear and tear and for other reasons, and therefore it is necessary to replace such a motor if it is not possible to restore it.

Lifan 168

One of the most common replacement engines is the Lifan 168. It has an engine displacement of 196 cubic centimeters and runs on gasoline. The power is 7 horsepower, air cooling, and therefore they can only work for a short time.

Installing the motor is simple and does not require retrofitting of the frame mounts.

Fluid replacement works are performed as follows:

- on the muffled engine, unscrew the drain plug, which is located on the pallet;

- drain oil from the system;

- tighten the plug;

- fill in new oil;

- warm up the engine;

- check the level and top up if necessary.

B&S I / C

The B&S I / C engine, which belongs to modern models and is popular in domestic conditions, can also be installed.They are often used on Cascade units.

This is due to the following features of the motor:

- power 7 horsepower;

- reinforced transmission;

- enlarged combustion chamber;

- minimal noise during operation;

- high functionality even at low temperatures.

Vanguard OHV

The imported Vanguard OHV motor also belongs to powerful engines that can be installed on a walk-behind tractor of this manufacturer and cope with all the necessary tasks. This engine has a capacity of 7 horsepower.

Subaru EX17

You can also supply the Subaru EX17 engine, which is popular among the owners of the Kaskad walk-behind tractors. He has proven himself excellent. It has a special design of the distribution mechanism inside and a large diameter of the shaft, which allows to increase the engine power and its efficiency.

As you can see, at present there are quite a lot of engines that can be installed on the "Cascade" walk-behind tractor. The choice of a suitable model depends not only on its functionality, but also on the financial capabilities of the owner.

It is also necessary to pay attention to the configuration, build quality and other points that are familiar to any motorist. If there are no skills, you should always turn to specialists for help.

The engine must meet all the requirements, which will allow it to operate efficiently and increase its service life.

Video: Installing a Chinese Engine On a Motoblock Cascade

Lifan 168

One of the most widely used engines. Lifan 168. It has an engine capacity of 196 cubic centimeters and runs on gasoline. Power. 7 horsepower, air cooled, so they can only run for a short time.

In order to ensure the lifespan of the Lifan engine, after installing the Chinese engine, it is necessary to constantly refill with fresh oil and carry out maintenance.

Installing the motor is simple and does not require reworking the frame mount.

Fluid change works are performed as follows:

- on the muffled engine, unscrew the drain plug located on the pallet;

- drain oil from the system;

- tighten the stopper;

- add new oil;

- warm up the engine;

- check the level and top up if necessary.

B. & S I / C

Engine B can also be installed. & S I / C, related to modern models and popular in everyday life. They are often used on cascade units.

This is due to the following engine features:

- 7 horsepower;

- enhanced transmission;

- enlarged combustion chamber;

- minimal noise during operation;

- high functionality even at low temperatures.

Vanguard s

The imported Vanguard OHV engine is also one of the powerful engines that can be installed on a walk-behind tractor from this manufacturer and can perform all the necessary tasks. This engine has a power of 7 horsepower.

One refueling is enough to work without interruption for 4-5 hours.

Subaru EX17

You can put the Subaru EX17 engine, which is popular among owners of Cascade walk-behind tractors. It turned out to be great. It has a specially designed camshaft inside and a large shaft diameter to increase the power and efficiency of the engine.

As you can see, at the moment, quite a lot of engines can be installed on the Cascade engine block. Choosing the right model depends not only on its functionality, but also on the financial capabilities of the owner.

It is recommended to purchase an engine depending on the specific use of the machine to ensure its longevity. Therefore, before buying, you need to understand the characteristics of the engine, consult with specialists and buy the best model.

It is also worth paying attention to the configuration, build quality and other points that are familiar to any car enthusiast. If you don't have the skills, you should always seek professional help.

The engine must meet all the requirements in order to allow it to operate efficiently and increase its service life.

The main problems of motors

Among the main failures of Cascade walk-behind tractors:

- The engine will not start;

- the engine runs intermittently.

The reasons for such malfunctions can be very different. from low-quality fuel to burning candles. Low battery can also be the cause. In this case, charge the battery and clean the fuel line or spark plug and replace completely if necessary.

Another malfunction could be the loss of the engine. The main reason in this case is a clogged carburetor or filter, which prevents the required amount of fuel from entering the combustion chamber. In this case, it is recommended to clean the system, as a return is possible when the engine is started.

Experts recommend that you periodically service this equipment to avoid such problems.

All of the above crashes are quite rare, and if necessary, you can fix them yourself, no special knowledge is required. If you have problems with maintenance or repairs, you can consult a specialist or get instructions on how to use the network.

Attachments

To increase the functionality of the Cascade walk-behind tractor, the manufacturer installs mounts on it, with which you can perform various operations.

Among the most common pendants:

Choice

In the widest assortment of a large and well-known Chinese manufacturer, you can simply get lost. If you went to buy a suitable unit, you should keep in mind the following important features that will prevent you from purchasing the wrong model.

The main thing that you will need to pay attention to is the power of the selected engine. As mentioned above, for a small area where you will not use the walk-behind tractor too often, it makes no sense to buy an expensive option.

A cheap, low-power instance is fine here. If we are talking about a large processing area and fairly frequent operation, then it is advisable to select more powerful and heavy units - only they can cope with serious loads.

Take a closer look at the motor mounts. They must definitely fit the mountings available on your walk-behind tractor. Of course, they may differ, but then you will have to independently "fit" them to each other, which is undesirable. If you have any difficulties in this matter, it is better to seek help from a sales consultant.

The engine, in terms of its weight and dimensions, should correspond to the walk-behind tractor that is in your arsenal.

This technique must be done with high quality. Engine assembly must be perfect

Inspect it carefully before buying, pay attention to all the details of the design.

You should buy an engine for a walk-behind tractor (or other suitable motorcycles) from Lifan in a proven specialized store where goods of a similar category are sold. You should not purchase such units in the markets or in small trading modules.

So you run the risk of stumbling upon a fake or poor quality second-hand product.