Wood splitter classification

Harvesting firewood on the farm is a frequent business, it requires a lot of effort. Before making a homemade device for chopping wood with your own hands, you need to decide on the volumes, the purpose of the device. The proposed equipment is divided into main categories:

- Mechanical device - the presence of an engine, as a drive for a screw or hydraulics, electric and spring-loaded volatile wood splitters.

- Design features - rack, vertical, conical, horizontal and so on, there are a lot of structures for splitting firewood.

- The operating principles can be hydraulic or pneumatic, in the form of a screw.

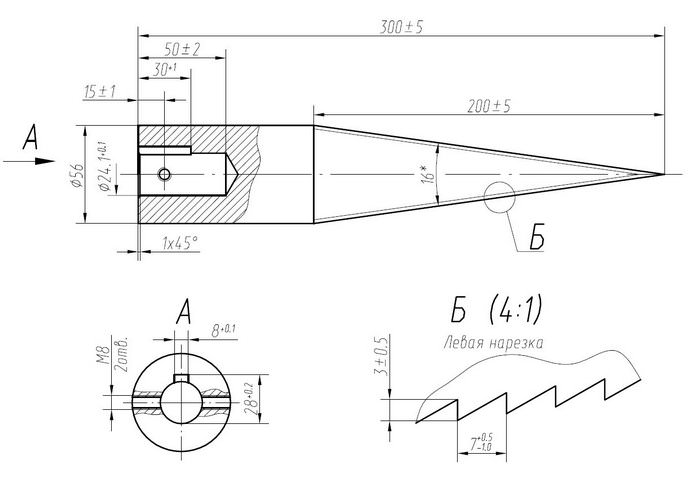

The cheapest option in terms of design is a mechanical cleaver, consisting of a stand and a support table. For more complex designs, for example, a cone wood splitter, you will need equipment for connecting the engine and the rotating element itself. This machine will significantly increase productivity compared to a mechanical device.

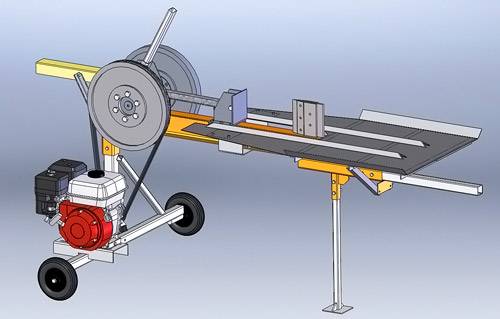

An example of a homemade mechanical wood splitter

Using the appropriate drawings, it is possible to make a more complex rack structure with your own hands. The principle of operation is based on the conversion of rotational energy into translational movements, based on this, additional materials will be needed for manufacturing.

Features of homemade models

A wood splitter is especially necessary in private households, where you have to heat the house using firewood. You can make such a tool with your own hands, it is not difficult and will save a significant amount of money. Working with a solid tree is a rather risky business, you can get injured, so you should use a good tool, observing the necessary safety regulations.

Mechanical units that help to split wood and heavy logs tend to store energy, they are economical and easy to operate. There is no need for muscle strength in working with such devices. The units can handle any kind of logs and wood ingots. They work in push mode and can be operated with logs up to 35 cm long, no physical effort is required.

Push action devices have an internal combustion engine drive, and can also be connected to an electric motor. They are not cheap, but with their use, muscular efforts that must be expended are almost completely eliminated. Using this device, you can heat a house up to 350 square meters, while frosts can be Siberian, up to -35 degrees Celsius.

The return stroke of the pusher is usually no more than 7 centimeters per second. In a few hours, more than half a ton of firewood can be prepared for one person. You cannot work with damp wood; it is recommended to put wooden blanks in a woodpile under a canopy in the warm season. In three months the tree will "fit" to the desired condition. Raw wood does not provide enough heat, the thermal conductivity is much lower (by 25%), the cleaver often gets stuck in it, and it is sometimes extremely difficult to extract it from there. A homemade wood splitter can be made no worse than a factory one, that is, it will have horizontal and vertical feed of the workpiece.

For orientation, it is worth saying what the approximate monetary savings can be:

- a solid diesel-fueled unit designed for splitting ingots 25 cm in diameter costs from 20 thousand rubles;

- a machine that can "straighten" with blanks up to 35 cm, splitting them into 4-5 fragments, costs about 30 thousand rubles.

Tradition or technology?

Our ancestors, and not only ours, preferred to chop wood with an ax. Saws appeared in everyday life relatively recently, and were less widespread than axes. This is due both to the large losses of material - up to 5% of the wood goes into sawdust, which is not suitable for kindling - and to the fact that logs split into fibers burn better and are stored better.

The traditional ax for chopping wood is called a cleaver, from the word "chop", "stake". This is a massive product, usually weighing 2 ... 3 kg, with a weakly pronounced blade and a long handle. This design is due to the fact that all the force should go into the blow, not surrendering to the hands and shoulders of the cutter.

However, such work requires sufficient physical strength and endurance, but to a greater extent - skills. Experienced cutters claim that there are special points on any log, a blow on which can split even the hardest wood without much application of force.

A more modern option is the so-called wood splitters.

It is a mechanical device with manual, hydraulic or electric drive that allows you to split round logs into individual logs.

Since the manufacture of an ordinary cleaver, that is, a massive ax, at home is available only to practicing blacksmiths with sufficient experience and appropriate equipment, let's talk about a device for mechanized splitting of logs, which is also colloquially called a cleaver, and not just a woodbreaker.

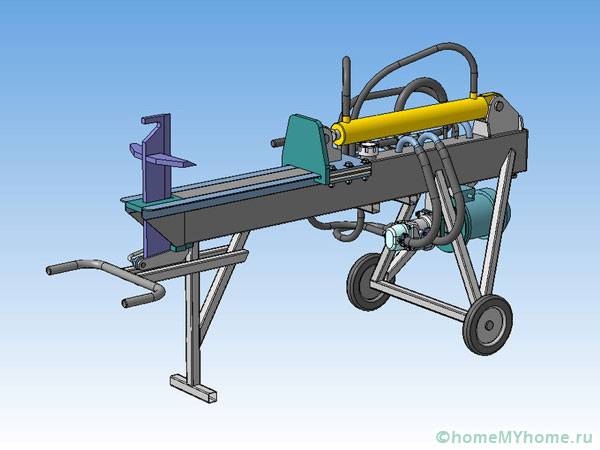

Types of hydraulic wood splitter

Let's take a closer look at the device of these mechanisms in order to understand the principle of their operation and choose the appropriate option for ourselves.

According to the number of operations performed, all wood splitters are divided into household and professional ones. The former only split firewood, while the latter are supplied with additional devices for feeding, trimming and unloading them.

Depending on the position of the log to be split, hydraulic wood splitters are divided into three types:

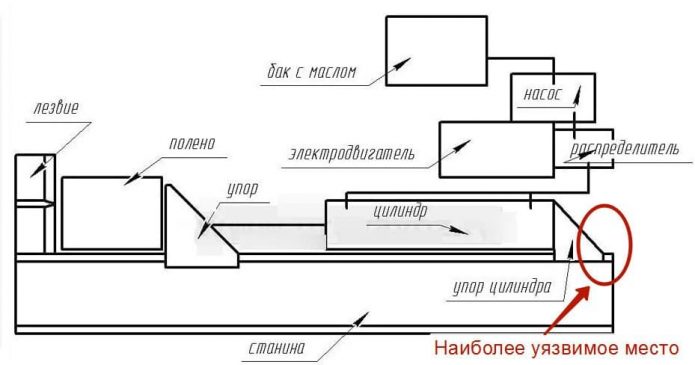

- Horizontal. The log is laid on a horizontal chute. There are two schemes for the operation of such devices. In the first case, the knife is fixed on the bed, and the pusher moves a piece of log to it. In the second version, the log stands motionless on the stop, and the hydraulic drive feeds the knife to it.

- Vertical. The log stands upright, and the knife is fed from above and splits it. The advantage of this scheme is higher productivity and compactness of the installation. The disadvantage is the need to hold the log with your hands, which increases the risk of injury.

- Mixed. Such mechanisms can work both vertically and horizontally. They are used in the industrial field of woodworking.

Another distinguishing feature of a hydraulically driven wood splitter is the type of engine.

The household hydraulic cleaver is equipped with an electric motor that rotates the hydraulic pump. This drive has three important advantages: reliability, ease of maintenance and environmental friendliness. The disadvantage is the rigid dependence on the power supply network.

More powerful mobile wood splitters are equipped with gasoline or diesel engines. They are used by professional loggers.

For forestry, farmers and commercial enterprises, mobile models have been created that work from the tractor's hydraulic system or from its PTO shaft.

There are universal mechanisms that can be powered by an electric motor and tractor drive or from a gasoline engine and tractor hydraulics.

The price of a household hydraulic wood splitter, depending on the brand, engine power and frame design, ranges from 9,000 to 32,000 rubles. Powerful models designed for splitting firewood in large volumes cost much more than 70,000 - 120,000 rubles and more.

Spring log splitter. Step-by-step manufacturing instructions

First, prepare all the necessary tools - in our case, these are:

- grinder (as well as stripping and cutting discs for it);

- tools for marking and measuring;

- welding machine (fortunately, today's inverter machines weigh a little, are easy to use and allow you to get neat welds).

Also prepare the following consumables:

- shock absorber from a car;

- channels;

- steel pipes (with a diameter of 4 cm to 7 cm);

- profile pipe 3x6 cm (4x6 cm);

- bushing from a car suspension (worn out is allowed);

- rail (30-40 cm);

- corner;

- I-beam (No 12-16).

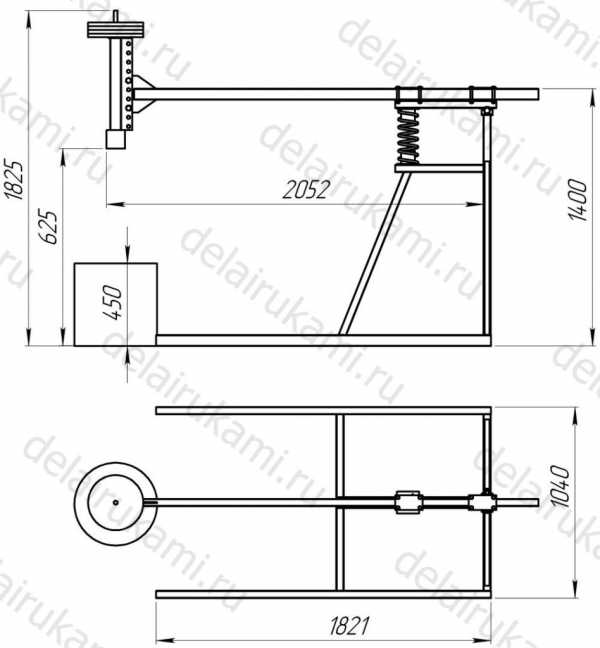

Step 1. First, prepare a sketch of the future structure. If possible, you can use a special engineering design program that allows you to work out all the details. Here is a rough diagram of the future wood splitter.

An approximate diagram of a spring wood splitter with your own hands

Step 2. Make a support from a channel, weld a post to it (it is better to make the latter from an I-beam, which is characterized by high rigidity; such a post will be difficult to bend even with prolonged loads). For greater stability, weld the jibs to the base. Also, make additional stops from the pipes to prevent the possible fall of the wood splitter.

Support of the future wood splitter

Step 3. Take the channel and cut out the spring support. Cut a square hole in the support to keep the element securely in place on the upright.

Spring support

Step 4. As for the height of the support, it depends on the length of the spring used. Also focus on the height of the entire structure and how convenient it will be to use it. So, it is most convenient to lift the load when it is at the height of the belt (it will rise slightly above the chest).

The height of the support is determined

Step 5. Make the jibs necessary to hold the support out of the corners. Due to this, the supporting surface will not move when the device is dynamically loaded.

Beads from the corners

Step 6. Make a cylindrical retainer to hold the bottom of the spring, which requires a small piece of pipe. When choosing the diameter of the pipe, be guided by the inner diameter of the spring so that it does not move during operation.

Cylindrical spring retainer

Step 7. Make a slot at the top of the rack, install the bushing there, and then weld the last

In this case, it is important to maintain perpendicularity in relation to the rack. Also make sure that the hub axle is parallel to the ground.

The hub axis must be parallel to the ground

Step 8. Install the shaft into the bushing. Weld to it a rocker from a channel, at the bottom of which install a small piece of pipe. This tube is needed to fix the top of the spring.

Channel beam rocker

Step 9. Cut through a "window" in the rocker, the dimensions of which depend on the dimensions of the rack itself. This will allow the rocker arm to move freely.

"Window" in the yoke

Step 10. Weld the profile tube to the rocker arm, place the chisel at one end. By the way, chisels are made of solid U9 or U10 carbon steel, and therefore the element will last a long time. Then, during operation, the chisel can be easily sharpened using a grinder and a sharpening wheel.

Chisel at the end of the profile pipe

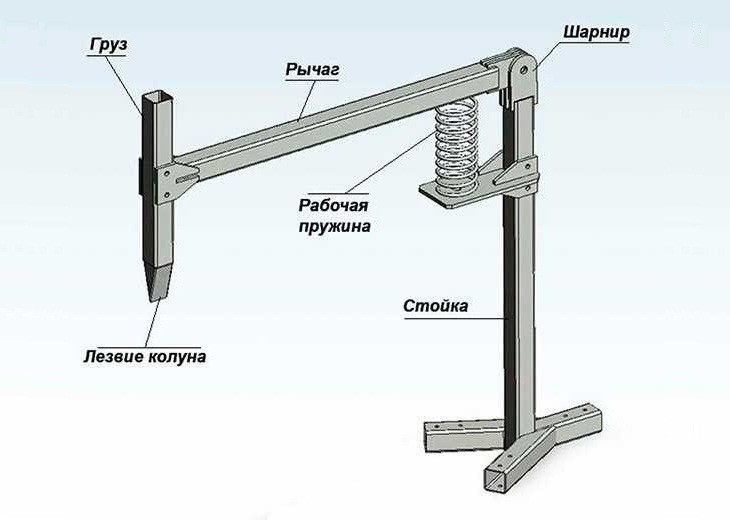

Step 11. Our log splitter is almost ready. Weld a piece of rail above the chisel, which will act as a load. Also weld on the handle to make it easier to use the wood splitter. It is advisable to put rubber elements on them - they will dampen vibrations.

For convenience, a handle is installed on the wood splitter

Step 12. Check the operability of the wood splitter. Lay the block and, holding it with one hand, lift the cleaver and strike.

Cleaver strikes

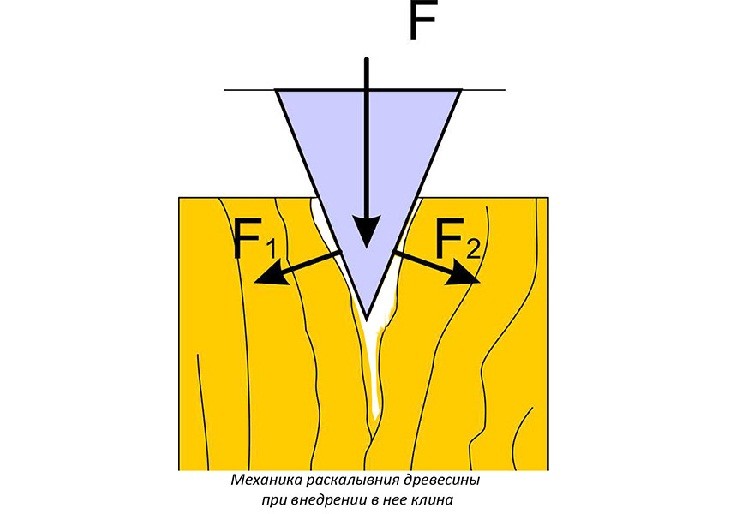

The mechanics of splitting wood when a cleaver is introduced into it

Step 13. The cleaver will go down, as a result of which the block will split.If it splits completely, then the chisel will go further, but will hit the wooden support, and therefore will not be blunt.

Splitting firewood with a spring wood splitter

Product features

In the household, a wood splitter is always useful, you can either buy it ready-made or make it yourself using scrap materials. The ready-made options have been improved, there are a number of additional functions that allow you to chop a maximum of firewood in a short time.

There are many installations working in an automated format. This is good, because you can not waste time on work, but start the machine that will do everything by itself. Experts identify several features, behind which mechanisms can be categorized:

- By the way the logs are laid, the machines can be vertical and horizontal. Sheer structures are considered more powerful and durable, since they can process even a thick deck in a short period. If the log is crooked or has a lot of irregularities, then it is better to give preference to the horizontal mechanism.

- Maximum amount of stacked firewood. Depending on this criterion, the equipment can be divided into appliances for home use and for industrial scale.

- Drive types. For home use, a machine with a small power of an electric type is suitable.

In this video, we will consider a hydraulic log splitter:

Recommendations from our expert

In order for the wood splitter to be reliable and serve as long as possible, it is worth listening to the following tips:

- Do not ignore the painting of the structure, especially when it is planned to be installed outdoors.

- Make calculations with a margin. This applies to the power of the engines, the thickness of the steel and other indicators.

- Start with diagrams and drawings. Proper preparation will save installation time and help avoid material loss due to mistakes.

- First try on, and then do welding or other fixation.

The log splitter makes life much easier for users who often have to deal with logging. Once assembled, the structure will save time and effort in the future. Making it yourself allows you to avoid unnecessary expenses.

Types of wood splitter

There are many types of mechanisms that pierce wood chocks with a variety of technical characteristics and configurations. Let's consider the main ones:

There are many types of mechanisms that pierce wood chocks with a variety of technical characteristics and configurations. Let's consider the main ones:

- Mechanical. It has a small frame, welded from a steel profile, a springs of medium hardness of a knife, which directly split a wooden block. The drive in this design is manual.

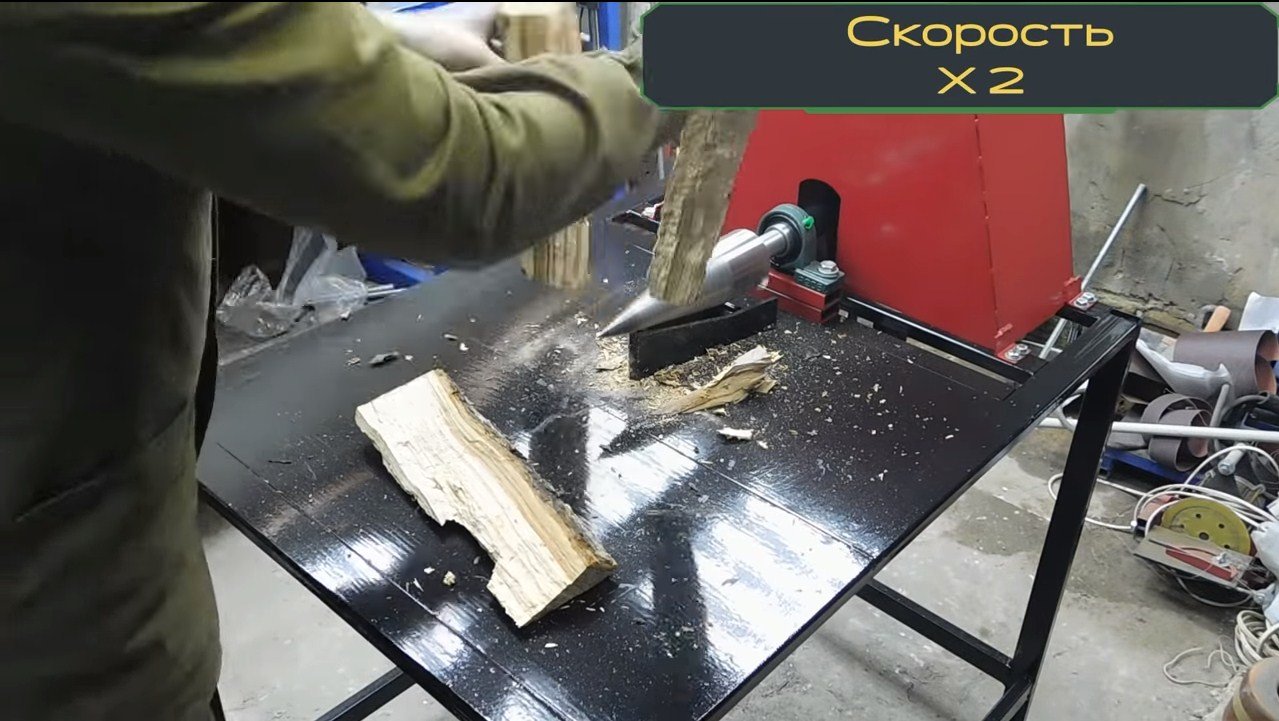

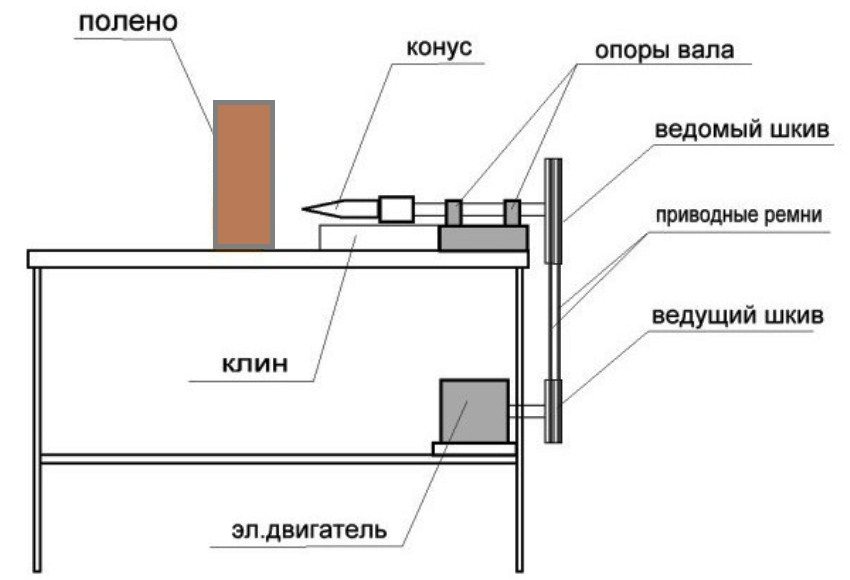

- Screw. Has a more powerful frame than mechanical. An electric, gasoline or diesel drive with a gearbox is installed on this device.

- Hydraulic wood splitter. A powerful frame made of steel profiles, an oil station that creates pressure in the hydraulic cylinder, several knives, which, when working, I split a wooden log into several parts at the same time. The hydraulic splitter-device has high productivity and is used mainly in enterprises with large volumes of firewood production.

- Rack. Steel frame, knife and drive, which pushes the log against the knife, thereby splitting it.

In the direction of splitting logs, wood splitters are divided into:

- Horizontal type. The log is positioned horizontally in relation to the cutting knife. Here the log can move to the knife or, conversely, the knife to the log.

- Vertical type. The chock is located vertically relative to the cutting knife, which is manually or mechanically driven. They have high productivity, but require special attention and safety during operation. It is mainly used in large enterprises.

- Mixed type. Combines both types of wood splitter and is used on automated lines for the production of wood.

Depending on the drive, wood splitters are divided into:

- Manual.

- Diesel.

- Petrol.

- Electric.

In addition to the above types of drive, the wood splitter can have a tractor and motoblock traction drive. When making a homemade mechanism, you can use any devices that are available on the farm. Now let's look at how to make a wood splitter with your own hands quickly and inexpensively.