Modifications

The Gorynych 6 wood splitter is manufactured in the following versions:

- 9T;

- Lifan 9T4;

- Honda 9T.

The wood splitter that runs on gas is represented by the Honda GX 390 unit, which has many advantages. If there is no electricity at the dacha, you simply cannot do without such equipment, since the unit can work autonomously, you just need to stock up on fuel. One pass of the cleaver is enough to completely split the log. The hydraulic system is designed to work in particularly difficult conditions. The log splitter is supplied with R13 wheels, the diameter of which is 52 cm, a hitch and a spare knife. The cost of the model is from 120 thousand rubles and may vary depending on the drive, which is in the design and type of engine.

Theoretical Foundations of Heating Engineering - Combustion of Solid Fuel

To make it easier to set fire to a tree, it must be split into relatively small fragments. After splitting the logs into separate logs, the surface of contact of the combustible material with air is increased. As a result, instantaneous heat transfer inside the furnace increases in proportion to the combustion area. Therefore, the procedure for chopping wood is a technique that allows you to increase the efficiency of fuel use.

In heat engineering, the following concepts have been introduced to characterize fuel:

- Gross calorific value, which refers to the total heat generated by the combustion of a particular type of fuel.

- Net calorific value - the actual amount of heat, which takes into account the energy consumption for heating the fuel, removing ingredients from it during combustion that are not involved in the process itself.

Therefore, drying wood is a technique that improves the performance of a fuel cell. Pre-crushing increases the efficiency of drying firewood, and later also combustion in a furnace or other device for burning solid fuel.

Varieties of wood splitters

Rack (electric) type

This type of equipment is quite easy to make. It is distinguished by the presence of a special pusher that feeds the logs to the cutting mechanism. To make such a unit on your own, you can use parts from a rack and pinion jack. During the operation of this equipment, difficulties rarely arise (due to the lack of complex mechanisms).

Diagram of a screw electric wood splitter

Diagram of a screw electric wood splitter

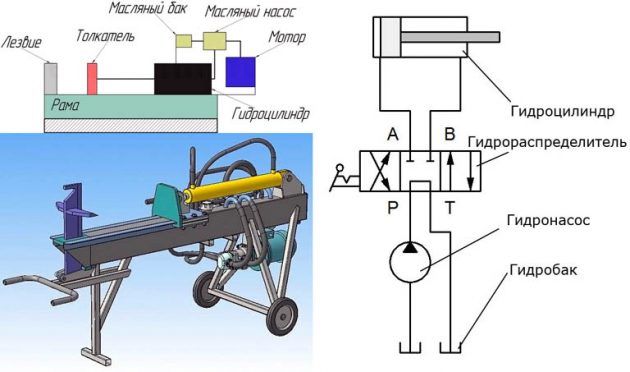

Hydraulic type

This device works on the principle of a hydraulic press. In this case, the hydraulic cylinder moves the log onto a sharp wedge, which splits it into several parts. The functioning of such wood splitters is possible due to the presence of an oil pump in their design. It is usually powered by a diesel or gasoline engine.

The main disadvantage of such equipment is its high cost. But it is offset by high performance and easy operation.

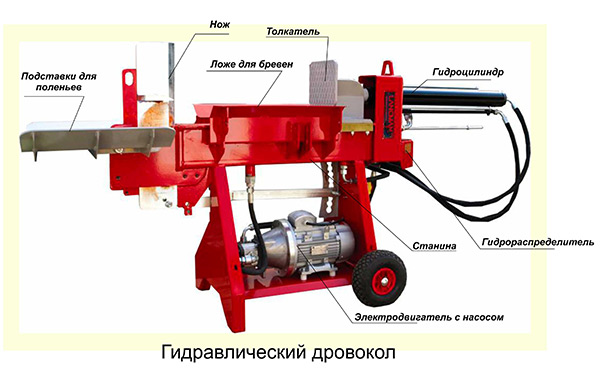

Diagram of a hydraulic wood splitter device

Diagram of a hydraulic wood splitter device

Manual type

The manual wood splitter has a simple structure. It consists of a metal pipe, which is connected to the base by means of a hinge. On a kind of "crane" there is a working blade and several reinforcing elements. To make the process of lifting the pipe easier, sometimes additional counterweights are installed on it.

To split the tree, the "crane" is sharply lowered down. Under the influence of the force of inertia, the tree is split into several parts.

The advantage of such a wood splitter is called the simplicity of its design and low cost. For the manufacture of the unit, it is enough to buy several pipes. The main disadvantage is the need to use physical force.

Types of hydraulic wood splitter

The type of wood splitter depends on the number of operations performed, it can be:

- household, whose functions include only wood splitting;

- professional, capable of splitting not only firewood, but also serving, trimming, unloading them.

The household appliance is equipped with a simple electric motor that provides the rotary action of the hydraulic pump. The drive is easy to maintain, reliable and environmentally friendly. The only drawback is that it works only from the mains, it is completely dependent on it, and the power of the device is also insufficient. More powerful wood splitters are considered more mobile, designed for use by professional loggers, and are able to chop wood faster and on a larger scale. Gasoline or diesel fuel is used to operate the engine. The hydraulic system for starting the wood splitter is supplied from the tractor, possibly from its power take-off shaft. Also, for the operation of the mechanisms, an electric motor with a tractor drive or a gasoline engine that starts to rotate when connected to the tractor hydraulics can be used.

Cleavers also differ in the way they set firewood. There are 3 types:

- Horizontal. This is the most common type. In this case, the log is placed horizontally on the rails. The movement is often carried out by the log towards the knife. But there are also models when the knife moves towards.

- Vertical. The smallest design ever. In it, the knife often moves from above to a log that is installed vertically at the bottom. But there are models when the knife is stationary, and a tree is in motion.

- Mixed. The rarest species. Basically, professional models have such a bookmark. Their main advantage is the processing of a large amount of firewood. Therefore, they are installed mainly in woodworking enterprises.

Instructions for use

Before starting to work on such a technique, the operator should first prepare the unit, and then the logs. The following tips should be followed:

- the equipment is installed on a flat surface, if there is a slope, then it is possible only to the side where the control lever is located; when the wood splitter is tilted to the side where the cleaver is located, productivity is lost, and sometimes the piston cannot work at all;

- when installing equipment on wheels for transportation, they will need to be removed or blocked;

- before switching on, the cleaver is inspected for defects, damage to parts and other malfunctions - the hydraulic system should not have oil leaks; it is impossible to use equipment with a breakdown, even if it is insignificant;

- if the wire of the wood splitter is not enough to connect to the network, you can use an extension cord, while the length of the cable cannot exceed 20 meters, since then the device loses its performance;

- the screw plug or screw of the air jet is unscrewed four turns so that the splitter is cooled during operation;

- all logs to be split must comply with the maximum permissible diameter; it is advisable that the wood dries well before work, since in this case it is less likely that the cutter can jam;

- there should be no metal objects in the tree, such as nails, staples, as they can damage the cleaver;

- the log is placed in such a way that the guides hold it correctly, only after that the start button is pressed; some time must pass for the engine to start working at the required number of revolutions; after pressing the second lever, it should be held, the log will start to rest against the wedge and split, as soon as this happens, it is released.

An overview of the work of the Gorynych wood splitter is waiting for you in the video below.

What to consider when buying?

When buying a wood splitter, there are a few basic things to consider.

- What kind of drive is installed in the structure.It can be electric or hydraulic, the power of the unit depends on its type. The most productive models are equipped with hydraulics. Most often this technique is used on a large scale. For household needs, an electric drive is enough, especially since the cost of such a wood splitter is less.

- What force does the drive make, moving the feeder and splitting the log into pieces on the cleaver blade, which is installed on a stationary base. If we talk about hydraulics, then the effort there is colossal and reaches 30 tons, on an electric drive - no more than 5 tons.

- The type of motor also plays an important role in the choice of such a technique. If this is a stationary model, then an asynchronous power unit for 220 V is more often used in its design, manufacturers for 380 V are rarely used. If a small model of a wood splitter, then both an internal combustion motor and an electric one can be used.

Development of the layout diagram of the wood splitter

A homemade hydraulic wood splitter is performed according to a certain scheme. It must contain the main elements: 1 - a knife with a sharp blade; 2 - pusher; 3 - hydraulic cylinder rod; 4 - tank; 5 - pump; 6 - distributor; 7 - hydraulic cylinder; 8 - bed.

From the tank 4, the working fluid (oil) is supplied to the pump 5. The hydraulic distributor 6 directs the flows into different cavities of the hydraulic cylinder 7. When supplying liquid outside the cylinder rod 3 moves the pusher 2 towards the blade 1.

If at this time there is a fragment on the bed 8 that needs to be split, then it will move onto the knife blade 1 and split.

To start making an installation for mechanical splitting of firewood on your own, you need to assemble the main elements on the bed.

The frame itself must be made from a rolled profile (I-beams or channels). Since the effort will develop quite significant, then the profile elements of numbers from 14 to 20 are selected (the number is the size in height, expressed in centimeters).

The bed is installed horizontally on the chassis. This decision is justified by the fact that in the future the wood splitter can be moved over short distances in the yards. During the period of precipitation, the unit can be rolled under the roof.

For convenient placement of logs on the bed, a bed is mounted. It is made from a sheet of metal. Set the profile so that the workpiece is self-centering.

The chopped logs extend beyond the knife. Stands are mounted at the exit. It is convenient to take firewood from them and transfer them to woodpiles.

An automated wood splitter is justified when organizing the removal of chopped firewood to the storage site.

It is much easier to assemble a structure in which the operator controls each movement of the pusher. The production cycle is carried out in the following order:

- A batch of blanks is brought to the wood splitter.

- Each log of a certain size is stacked on a bed.

- The distributor is switched to supply oil to the outer cavity of the hydraulic cylinder.

- Press the pusher to be moved under pressure on the workpiece. She cracks when she hits the knife.

- The chopped logs are moved to stands outside the knife.

- The operator switches the directional valve to reverse the movement of the pusher.

- While the actuator returns to its original position, the operator takes the wood out of the installation.

- Further, the cycle of splitting logs is repeated until the delivered batch of blanks is fully processed.

Electric wood splitters

A manual wood splitter, of course, makes it easier to harvest firewood, but it still requires solid physical effort. Not so much as they are spent waving with an ordinary cleaver, but still ... The electric motor helps to make the efforts even less. On its basis, wood splitters of various designs are made. But making such a wood splitter with your own hands is more difficult.Here and the device is more complicated, and at least minimal knowledge of electricians is required - it is desirable to connect the motor through the starter, and with the buttons "start" and "start".

Screw (conical)

One of the most common models is a cone or screw log splitter. The difference between them is only in the absence / presence of threads on the piercing element, which in this model is made in the form of a cone.

The cone splitter speeds up the harvesting of firewood

Churbaks split due to the fact that the cone rotated by the motor cuts into the wood, gradually tearing it apart. In large logs, the edges are first chipped off, then the middle is torn apart.

Taper and thread options

First, the cutting part was turned into a smooth cone. If you use a smooth cone, you have to lean on the block rather strongly during work so that the cylinder "bites" into the wood. The process is much easier if a thread is cut on its surface. In this case, the block is somehow screwed onto the screw, and then cracks.

Dimensional drawing of threaded cone for screw wood splitter

The main thing is to correctly make a threaded cone. If you have a lathe and work experience, you can try to do it yourself. If not, you will have to order. The thread is made in different ways, but the following parameters are recognized as optimal: a step of 7 mm, a depth of 3 mm (minimum - 2 mm). Another important point is that the depth of the seat on the motor gearbox is at least 70 mm.

Wood splitter screw

If there is a threaded cone, it will not be difficult to make this wood splitter with your own hands.

Electric motor and gearbox

You need an electric motor powerful enough (2 kW and above or 5-9 l / s), but with a low speed: 250-600 rpm. At 250 rpm and below, it splits very slowly, and if the rpm is more than 500, it is dangerous to work, as it can pull the log out of the hands.

Wood splitter with a screw fitted directly to the crankshaft

If you managed to find an engine with such parameters, you can put the lance (screw) made directly onto the crankshaft (pictured above). If there are more revolutions, it is necessary to install a reduction gear or make a chain or belt drive to reduce the speed.

Calculate the ratio depending on the engine speed. For example, there is a 900 rpm engine. Having made a 1: 2 gearbox, we get 450 rpm. Just the best option.

Reducing reducer for screw wood splitter

Transmissions can be belt or chain. Chains work many times louder, require constant strokes, and it is usually more expensive to carve sprockets with the necessary parameters. A double belt drive is desirable (as in the photo above). In this case, there will be less slippage.

Where to locate the motor

If the design provides for the presence of a transmission, it is better to put the motor below, and fix the screw itself on the working surface. Choose the height of the working surface for your height so that you do not have to work in an incline.

A safer model. Making such a wood splitter with your own hands will make your life much easier.

There is also such a parameter as the height of the screw above the working surface. The gap from the table to the cylinder should be in the region of 8-20 cm. It should not be placed higher - it can turn small-diameter blocks of wood. The optimal distance is 8-12 cm. Even small blocks of wood do not turn.

Hydraulic wood splitter

A hydraulic log splitter is the most powerful, but also the most difficult and expensive to manufacture. In addition to the bed, engine and cutting knives, a hydraulic cylinder with sufficient power is needed. They are not cheap. In addition, you also need an oil tank and a pump.

Hydraulic splitting device

Hydraulic wood cleaver develops solid efforts, therefore, in its manufacture, metal of considerable thickness is used - 6-10 mm, depending on the drive power. The developed effort is quite enough to break the chock into 6-8 logs at a time. Therefore, knives are made in the form of an "asterisk".

A hydraulically driven cleaver is equipped with a complex cutter, which breaks a block of wood into several logs at once

When making knives, they are spaced a few centimeters apart. So that there is only one in the work. For example, first - horizontal, then - vertical, then - right and at the end - left. At the same time, reinforce each of the knives by welding reinforcing plates on the back. It is advisable to use hard steel, having previously sharpened it according to the same principle as on cleavers.

What to look for when choosing a wood splitter

What to look for when choosing a wood splitter

It is necessary to pay attention to the manufacturers of equipment for splitting firewood and consider their advantages and disadvantages

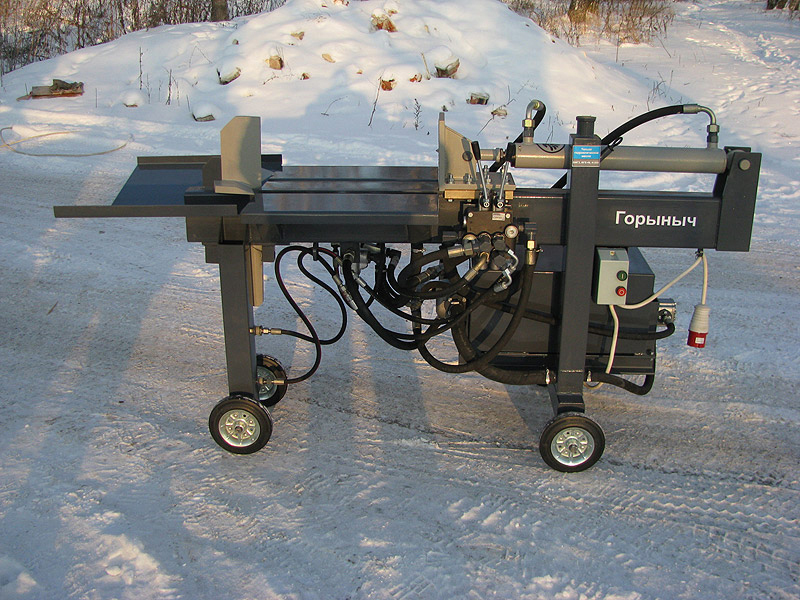

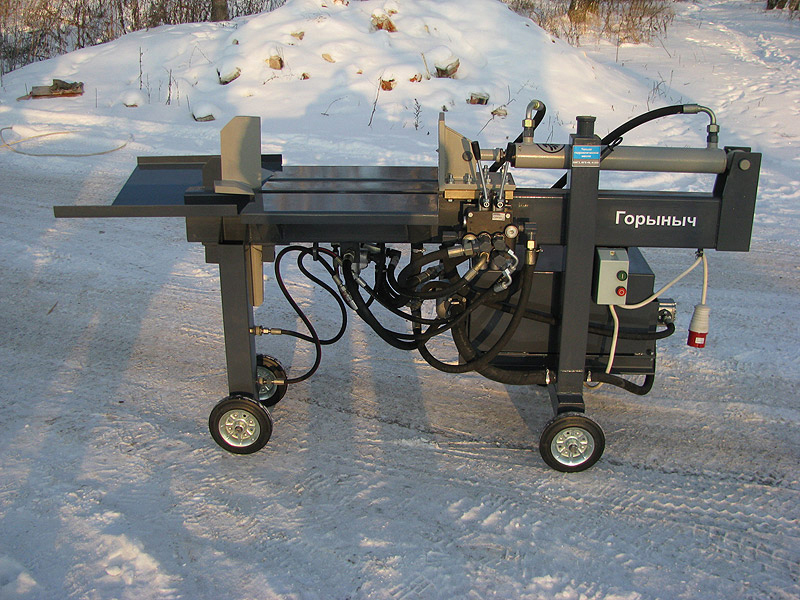

Wood splitter "Gorynych"

This is a professional instrument of domestic production. Production shops are located in the Kaluga region. The technical characteristics and diagram of the Gorynych wood splitter can tell you how best to use it.

If we consider a specific model "Gorynych 6T", then we can evaluate its performance. The wood splitter can work continuously, and the hydraulic equipment for the wood splitter is designed for 10 thousand cubic meters of firewood. The billet length is 50 centimeters, which is suitable for most boilers. Three-phase electric motor 380 Volt. The force that it transfers to the cleaver is 6 tons.

Wood splitter "Gorynych"

Useful information! An important element of the wood splitter is a hardened knife, which works as a cleaver; its service life exceeds the service life of the wood splitter itself.

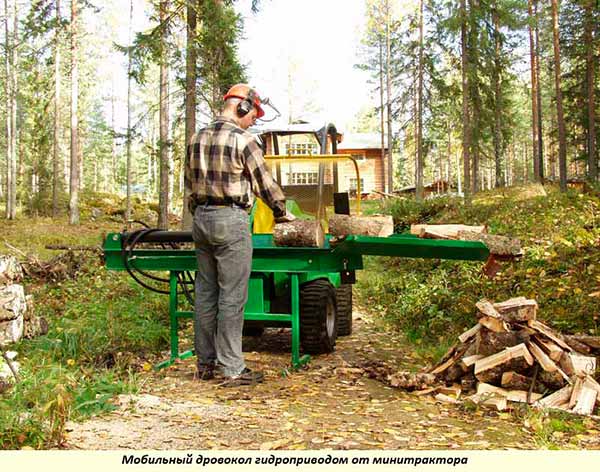

Industrial wood splitter Japa

This model also represents a cohort of professional equipment made in Finland. The wood splitter "Yapa 60" differs from its Russian counterpart.

In the model range of these woodcutters, there are tools that are powered by electricity (4 kW 380 Volt engine), there are options with an installed gasoline engine, and it is also possible to connect the Japa industrial wood splitter to the tractor's hydraulic system. It also allows you to split longer workpieces. Their maximum length can be 67 centimeters.

Note! The Japa wood splitter does not have a wood cutter

Wood splitter made in Finland "Palaks"

Wood splitter made in Finland "Palaks"

This equipment can be produced in two categories:

- With attachments for sawing firewood.

- No sawing, just a wood splitter.

The powering of the Finnish wood splitter "Palaks" is similar to its Finnish counterpart "Yapa". Also has three options. Those customers who do not have a three-phase power supply in their wood-burning warehouses can order equipment with an electric motor. And although it will cost the buyer more, its autonomy can be a big plus for such equipment.

Some models allow you to split logs up to 110 centimeters long and up to half a meter thick. The hydraulic cylinder for such a wood splitter should be much more powerful and more effort should be applied.

Note! The productivity of such equipment can be up to several cubic meters of firewood per hour of operation. Instructions for all this equipment describe how to use it correctly for efficient operation.

Hydraulic cleaver "Gorynych"

Hydraulic wood splitter Gorynych

Hydraulic wood splitter Gorynych

One of the most popular cleavers on the market is Gorynych. Speed is the main distinguishing feature of this hydrosplitter. To date, he has no competitors. The reliability shown over the previous years of operation breaks all records. Over the 9 years of the existence of the "Gorynych" cleaver, more than 18 thousand m3 of forest have been processed. And at the same time, not a single node fell into disrepair. And you can work with it both at +30 and -30 - the engine, pump, distributor and hydraulic cylinder perfectly cope with any work at any time of the year. The technology is patented.

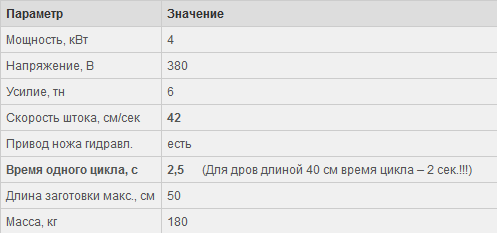

Wood splitter "Gorynych" 6T and its technical characteristics.

Major achievements:

- One cycle takes 2.5 seconds.

- It has unique parts and assembly that allows you to work at any temperature.

- Hardened iron knife. It is extremely difficult to blunt it.

- All parts are repairable.

- The structure is covered with a special compound, which makes the structure resistant to external natural influences.

Video of Gorynych's work:

Indicators of such a wood splitter:

- 25 chops were split in 3 minutes.

- For 1 hour - 500 chocks.

- If we take a workpiece with an average diameter of 20 cm and a length of 40, then it turns out 6.28 m3 / hour

An overview of mechanical log splitter designs

Several types of mechanical devices for splitting firewood are sold in the trade network. The main nodes are:

- The bed, fixed and movable elements are fixed on it. Along the way, a bed is placed on the bed, sawn workpieces are placed in it.

- A stationary ax is a sharpened plate installed perpendicular to the surface of the block.

- The movable part is an actuator. Usually, a pusher is equipped, with its help a fragment of a log is moved onto a knife blade.

- The drive mechanism and energy device that creates the force to perform the main work.

It is accepted to classify devices according to the principle of operation:

- Rotating cones - These mechanisms are screwed into the wood. The cone, when penetrating into the body of the block, pushes the fibers apart. The structure collapses and the workpiece splits into several logs.

- Dynamic action - the drive device is made on the basis of a flywheel. In this design, the moment of inertia accumulated during the rotation of a massive body is transmitted to the pusher at the right moment. He pushes the fragment onto the cutting edge.

- Rack type - the transformation of rotation into translational motion occurs in a rack and pinion mechanism. The pusher makes a reciprocating movement.

- The hydraulic drive makes it possible to obtain a significant force on the actuator from a small engine power.

- The lever action mechanism allows for high effort due to the different lengths of the levers. By pressing on the long lever, a higher force is obtained on the short one than initially applied.

According to the location of the splitting log on the wood splitting machine:

- The vertical orientation allows the compact design to be installed in confined spaces. Often, small hydro log splitters are installed next to fireplaces or stoves, where they are burned.

- The horizontal arrangement of the bed allows you to put large blocks of wood. Even workpieces with complex shapes will be split into separate elements.

Devices used at sites with power supply are based on electric motors.

Device

Wood splitter hydraulic

Although there are a lot of wood splitter varieties, almost all of them are assembled according to the same scheme. There are four main nodes in such schemes. The rest are auxiliary, increasing the usability of the tool.

- The base unit is the wood splitter frame. Much depends on its quality. It is a fastening element for all the main nodes of the wood splitter and the reliability of the tool depends on its strength. The weight of the bed also plays an important role, since the stability of the wood splitter and the ability to chop large firewood depend on it.

- The engine is the heart of the wood splitter. It can be gasoline or electric. The advantage of a tool with a gasoline engine is its autonomy, the electric one depends on the proximity of the electrical network and its parameters.

- The hydraulic unit is an additional link between the engine torque and the forward movement of the cleaver. The performance of such wood splitters depends on the maximum pressure developed by the hydraulics.

- The cleaver is usually made of high quality metal.The manufacturer guarantees that this structural element will have a resource not less than the wood splitter itself.