Varieties of mixers depending on power

Depending on the power, which is the main technical characteristic that determines the field of application, construction mixers (both highly specialized and drill-mixers) can be divided into three main groups:

- Devices with a power of 600 ÷ 900 W are designed for mixing solutions with low viscosity and in small volumes. Suitable for the preparation of mixtures for painting, plastering and finishing works. Usually these devices are equipped with an electric motor with one speed, the rotation speed is in the range of 550 ÷ 850 rpm. The price varies between 3300 ÷ 7200 rubles. The most popular models: Zubr ZDM-820 RM, Hammer UDD600M, Felisatti MF800VE, Hitachi D13.

- Construction mixers with a power of 1.0 ÷ 1.5 kW, as a rule, have a speed regulator (2 positions). With their help, it is possible to mix both light mixtures (at the second speed, providing the spindle rotation up to 850-950 rpm), and heavy (concrete) at the first speed (with a rotation frequency in the range of 200 ÷ 400 rpm). The price for such devices is 5300 ÷ 8000 rubles. Typical models: Hammer UDD1050A, Zubr ZDM-1200 RMM2, Hitachi UM16VST, Enkor ME-2 1400E. Numerous models of double-spindle mixers belong to the same power range (1.2-1.5 kW). However, the price for such devices will be higher: within 8500 ÷ 15000 rubles. Common models from manufacturers of this type of construction mixers: Elitech MS 1600 / 2ED, Hammer MXR1400A, ZUBR ZMR-1350E-2, Felisatti MKF1200 / VE2, Stomer SMD-1400 × 2, Rubimix- 9 Duplex ".

- Construction mixers with a power of 1.8 kW and more belong to the category of professional equipment, they are used to mix large volumes of solutions of different viscosity. Such models have a rotational speed regulator for 2-3 positions. But, this equipment is quite expensive (the price is in the range of 25,000 ÷ 55,000 rubles) and its purchase is justified only in the case of daily, constant use during construction work. Models from manufacturers of professional power tools: "Bosch GRW 18-2 E Professional", "Makita UT1600", "Metabo B 32/3".

Read also: Compressor pressure switch assembly

Advice! When we choose a construction hand mixer, it is necessary to take into account not only its power, but also its weight. The more powerful the device, the heavier it is, which means that it will be more difficult to work with it.

Stirring Drill Attachment

MANUAL BUILDING MIXER or MIXER

Often, even with a small cosmetic renovation of the house, it is necessary to stir perfectly, in other words, mix a mixture of different viscosities to a suitable mixture: paint, glue, plaster, etc. Real renovation will require kneading and mixing significant volumes of different structure consistencies.

Of course, it remains for our client to do this by hand mixing operations, not sparing their own strengths and additionally the muscles of the arms and back.

Or go another method and purchase a manual construction mixer, which will allow you not only to save time and energy, but even better to mix even a very viscous solution.

Choosing the right product

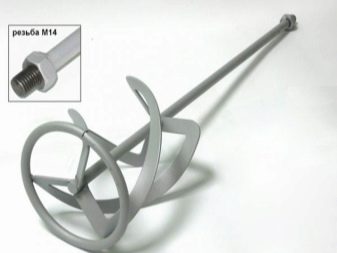

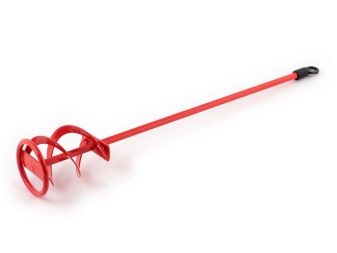

Rock drill mixers have two main parts: a shank and a working whisk. The size of the tip will vary depending on the type of media to be mixed and the scope of work to be done. Manufacturers always describe in the accompanying materials which mixtures can be mixed. As with other products, it is useful to give preference to products from well-known companies. Even the multiple difference in comparison with unknown brands is fully justified by the high quality of the products.

Much attention should be paid to the selection of whisks according to the shank format. Traditionally, they have a cylindrical or hexagonal configuration.

Also in some cases M14 and SDL-Plus connectors are used. The choice is determined by which connector is provided by the manufacturers of the punch.Bosch Corporation, for example, equips its products with SDL-Plus connectors.

Most often, you can simply tell the sellers which device the mixer is purchased for. They will be able to offer the optimal attachment. The basket of a regular whisk is 10 to 11 cm with a diameter of 8-15 cm... If the hammer drill is very powerful or you have to mix a lot of solutions, it is better to choose a larger basket. As for the length of the mixer, the choice is simple - you need to focus on the height of the container where the solution will be mixed.

Brands and manufacturers

Small hand mixers and powerful specialized units are represented on the modern construction equipment market by a huge number of brands, both global and regional. The most amazing thing is that many brands are made in China. But the quality of many brands is decent, because everything will depend on how the brand owner controls the production technology, how the product quality is monitored.

For example, we can cite the domestic manufacturer of construction mixers for concrete, the Interskop enterprise. This company has two joint factories in China that produce tools from the Spanish brand Freud.

Interscope KM

Experts note that this device is very easy to use. He has two modes of spindle speed: the first 130-450 rpm, the second 250-850 rpm. This is a specialized device that can perform two functions: a mixer and a drill. True, the weight of almost 5 kg makes it inconvenient when drilling holes. This tool can be used to stir solutions with a volume of 120 liters or more.

SKIL

The brand's model lineup includes both mini-tools and powerful ones. For example, SKIL 1613 has a power of 1.4 kW. SKIL 1608 - 0.85 kW. The device itself is quite ergonomic.

Its comfortable handle allows for long-term mixing, while the design has a special button with which you can automatically keep the rotation of the shaft constantly.

REBIR EM

This is a mini mixer with drill functions, which is different in design from other brands. It has no ring handle. The device is equipped with a conventional handle, like a hand drill, and an additional handle from a pipe is mounted on the side. Although this model is considered a mini, its power reaches 1.3 kW. Most often, this tool is used for mixing lightweight concrete, as well as liquid mixtures.

Makita

Japanese manufacturers are jealous of the quality of their products. Therefore, the Makita brand is one of the most popular. There is also a fairly large assortment in terms of power and spindle rotation.

For example, Makita 6013 is a small mixer weighing 3 kg. But at the same time, its revolutions reach 550 rpm.

BOSCH

German quality is known to everyone, which is why the bulk of craftsmen prefer this particular brand. But as you know, quality costs money, which is why mixers of this brand are the most expensive on the market. Like all previous models, the BOSCH brand is a large number of models: from small to large. Most often these are dual-mode devices with a minimum rotation speed of 450 rpm and a maximum up to 1050 rpm.

This is a classic model that incorporates all the best features of this instrument.

Pivot table

| Brand | power, kWt | Revolutions, rpm | Weight, kg | price, rub. |

| Interscope | 1,05 | 130-850 | 4,6 | 6000—7000 |

| SKIL | 0,85-1,4 | 180-700 | 4,2-5,6 | 6500—7500 |

| REBIR | 1,3-1,45 | 500-1000 | 4,3-4.5 | 6500—7000 |

| Makita | 0,96-1,8 | 250-580 | 3-7 | 10000-24000 |

| BOSCH | 1,8 | 450-1050 | 7,2 | 29000-30000 |

Varieties of attachment attachment systems

Construction mixers from various manufacturers are equipped with different attachment fixing devices:

- Jaw chuck, in which the shank is fixed using a special crimp wrench (like a conventional electric drill).

- Cam chuck of the QuickFix system (like a household screwdriver - crimping is carried out without the use of a special tool).

- Threaded connection of the shank to the mixer M12, M14 (much less often M21), using a conventional wrench, which is included in the electric mixer kit.

- SDS-plus and SDS-max chucks (the design is similar to the mounting of drills in household rock drills).

- HEX chucks (8, 10 or 12), for quick change and fixing of attachments with a hex shank with a spring-retaining groove according to ISO 1173 E3.

Recommended attachments

We recommend mixing attachments 120x600 mm SDS + from STARTUL and a whisk 120x600 mm M14 from GEPARD.

Mixer 120x600 mm SDS + STARTUL is a right-handed spiral and is suitable for drills and rotary hammers with SDL-Plus connector. The recommended mixing speed is 600 rpm, the nozzle is used for all types of heavy and viscous mixtures (plaster, putty, resin, concrete, etc.).

Whisk 120x600 mm M14 GEPARD has an M14 shank with a basket height and diameter of 105/120 mm. According to the configuration, it is a right-handed spiral, the optimal speed for mixing is 600 rpm.

In conclusion, we recommend that when choosing a mixer, pay special attention to the type of shank, since an error will lead to the fact that the whisk simply does not fit on a perforator or drill.

4 Useful Construction Mixer Options

Some manufacturers produce a mixer with adjustable spindle speed. The most common ones are two-speed ones. This is very convenient, since such a tool is in some way a "golden mean". With large speed control ranges, a smooth start can be made, this helps to avoid splashing of building mixtures (paints, varnishes) and does not allow a column of dust to rise when mixing cement or putty.

During long-term operation, the rotation speed lock is very convenient, it allows you to keep the speed at the same level and gives some freedom of action to your hands. An electronic speed control system is found in expensive and mid-priced models. As the saying goes, you have to pay for the pleasure.

An overwhelming number of articles tell you that it is best to buy a mixer with a T-shaped handle arrangement. However, it is not. Using a nozzle with a ring on the edge of the auger, we place the mixer on the bottom of the container, as a result of which there is no need to hold the electric tool suspended. The only force applied is to keep the mixer from rotating, and two parallel handles are suitable for this. Some manufacturers cover the handles with a special layer that reduces vibration to the hands.

The torque of a construction mixer is its main indicator, it is he who determines the suitability of the apparatus for performing various kinds of work.

In some cases, the manufacturer does not indicate this parameter in the technical documentation, limiting itself to general data on the power of the unit. You can calculate the torque yourself, having data on the power of the electric motor and the spindle speed.

M = (P * 30) / (n * pi) (Nm)

where: Р - mixer power declared by the manufacturer, Watt;

n - rotation speed, rpm;

pi - number of pi - 3.14.

Design classification

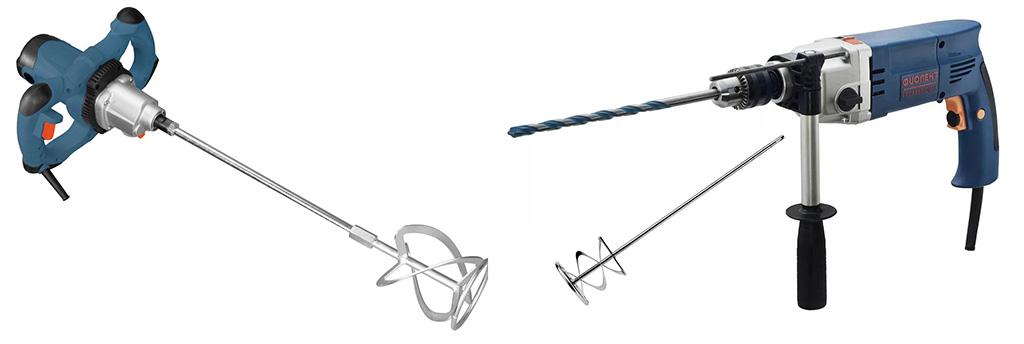

Structurally, all mixing devices consist of a drive and a nozzle. An electric motor, a gearbox, a nozzle attachment system and controls (switch, speed switch) are installed in the drive housing. The nozzles are special devices that are fixed on the drive and with the help of which the components of the mixture are mixed. According to the purpose and scope of application, modern construction mixers are divided into two classes:

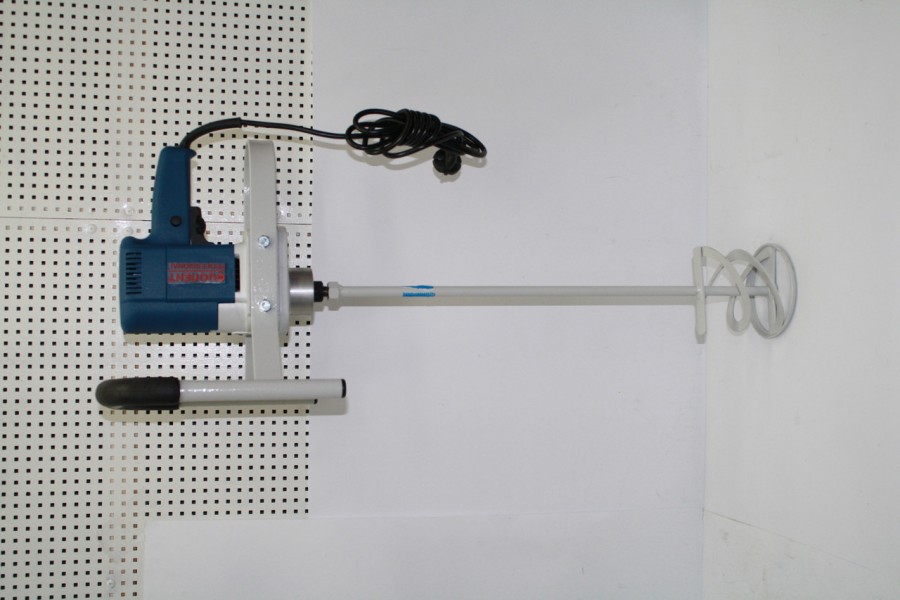

Drill mixers are dual-use devices. They are equipped with a cam chuck, which allows you to securely fix in it both nozzles for mixing mortar (with a corresponding shank diameter), and drills for arranging holes of large diameter. Such a tool belongs to low-speed drills, therefore, it cannot functionally replace a conventional electric drill. However, low rotational speed and high torque make it possible with their help not only to mix a wide variety of solutions (up to heavy cement or sand and gravel), but also to use them for drilling large holes even in very hard materials.

Electric construction mixers are highly specialized tools that are intended only for for mixing various mixtures.The range of these devices is very diverse, you can even pick up a construction mixer that will successfully replace a household concrete mixer (and not inferior to it in performance, but significantly surpassing it in ease of transportation and a variety of functional capabilities). These devices are single-spindle (they provide for the installation of only one nozzle) and two-spindle (they install two nozzles at once, which rotate in opposite directions).

Of course, when using any construction mixer, you will need an appropriate container for mixing the components.

Homemade mixer

Making an electric mixer with your own hands is quite simple. To do this, you can use an ordinary household electric drill or hammer drill as a drive. For a drill, attachments with a shank in the form of a regular hexagon or HEX are suitable. Both are conveniently fixed in the chuck of the drill. The main thing is that the size of the hexagon (standard: 8, 10 and 12 mm) corresponds to the maximum size that can be inserted into the drill chuck.

Read also: What to fill in a rolling jack

Attention! For stirring solutions, use only low-speed drills, or devices with speed control. If you use a hammer drill as a drive (naturally, in a non-impact mode), then you need to buy bits with a shank designed for mounting in an SDS-plus chuck

If you use a hammer drill as a drive (naturally, in non-impact mode), then you need to buy bits with a shank designed for mounting in an SDS-plus chuck.

However, it should be borne in mind that motors and gearboxes, both for electric drills and for rock drills (even powerful ones), are designed only for longitudinal load. Therefore, a homemade mixer based on them is quite suitable for mixing light solutions and in small volumes. When stirring solutions, the drive experiences significant radial and horizontal loads, which can lead to overheating and failure of the electric motor. Therefore, it is better not to make a do-it-yourself concrete mixer from a drill or perforator. Although their use is quite acceptable when mixing paints, thin putties and other light solutions.

Scope of Hand Mixer

During the construction process, at one stage or another, it is necessary to prepare a mixture. The use of a special tool will ensure the homogeneity of the mass, which will have a positive effect on the quality of the work performed. The use of a hand mixer for concrete and other mixtures used in finishing and construction works significantly increases labor productivity.

The principle of operation and design of the tool is similar to that of a conventional drill. The main difference between the mixer is the presence of a variety of attachments, the specificity of which is different, depending on the goals. The type of tool required is determined by the amount of work performed.

The scope of the mixer is finishing and construction work. And if for mixing concrete compositions you cannot do without a concrete mixer, then a hand mixer is ideal for preparing concrete, colorful and other liquid mixtures.

Despite the fact that this tool is simple in design, it is easy to use, which allows you to quickly and efficiently prepare a variety of construction mixes.

For liquid mixtures, it is better to use a hand held concrete mixer.

For liquid mixtures, it is better to use a hand held concrete mixer.

Types of structures and their characteristics

The drill mixer is used for large-scale repair work; the user usually holds it in his hands when mixing the solution, because the device has ergonomic handles that make the operation of the tool less time consuming.If the engine of the device has a power of more than 1 kW, then a special gearbox is built into it: it is suitable for use not only at the very first speed, but also when changing from the first to the second.

The first is used to compose thick dense mixtures, for example, mastic, and the second - for gypsum and cement. Stirring paints and varnishes and other liquid substances with a minimum torque is also permissible at second speed.

These are very important options: thanks to them, when removing the device from the resulting composition, the torque remains in its original position and no splashing of the finished mixture occurs, as is the case with many other mixers.

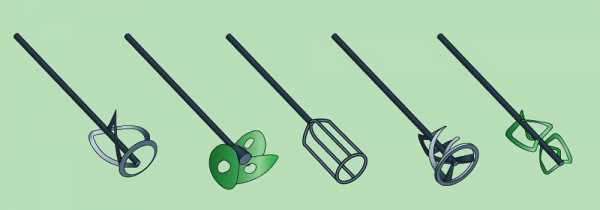

Such drills, as a rule, have different configurations. Usually they come with several types of attachments, which can have several shapes.

Right-hand spiral mixing nozzle - used for solutions that have a very viscous structure. These include cement, concrete, as well as all sorts of plasters and glue. Such a nozzle mixes the solution, as if pushing it upwards, mixes the composition at the top, and then drops back.

Left-hand spiral nozzle ideal for mixing paints and varnishes

Here the principle of operation is reversed: the mixture is pushed from top to bottom, where it is stirred and rises back.

Screw nozzles allow mixing light compounds.

The cross is a more specialized nozzle, it is used in cases where it is very important to prevent air from entering the container with the mixture.

Principle of operation and features of use

Depending on the principle of operation, there are three types of tools:

- drill mixer;

- drill mixer with one whisk;

- device with two rims.

A conventional electric drill mixer is a low-speed, impact-free type. The power of this tool ranges from 500 to 2000 W, there are 2 comfortable handles, a fairly large cartridge with a diameter of up to 16 mm.

Two-handed models are divided into options with a single whisk or with two, the difference follows from the name: mechanisms with two whisks mix even the most viscous mixture, they are equipped with a rather powerful gearbox and easily cope with solutions of a wide variety of consistencies - from light to concrete.

Conclusion

For sparsely conductive and small-scale mixing works, you can do without a mixer, using a drill or perforator for this. This will save you money.

If a mixer is necessary for everyday home, summer cottage, garage, etc. work, then usually the preference is given to household hand mixers with a power of up to 500 watts.

If you need to mix highly viscous media, dry construction, mortar, etc., then it is better to stay on models with a gearbox (multi-speed mixers), while the power can also be within 500 watts.

If a model without a gearbox is purchased, then in this case it is worth focusing on the torque and maximum revolutions of the mixer shaft. The torque should be at the maximum and the maximum speed at the minimum.

If you plan to carry out frequent, voluminous mixing work, then it is better to immediately purchase professional models with high power. In this regard, stationary mixers are well suited.