Advantages

The Makita power tool, as practice shows, performs many works that are inaccessible to products of other brands. The reason for this superiority is not a simple increase in power (this is a dead-end path, as the size of the tool and its weight increase).

Makita developers prefer to achieve their goals through the use of modern technologies and original design solutions. They managed to achieve a high speed of basic manipulations. Thanks to the efforts of the engineers, it was possible to increase the torque, therefore, productivity increases significantly.

How to choose the right cartridge

Ideally, it should be the same as the old one. If you cannot find the same one, you need to look for a model with the same parameters - shape, size, principle of operation. All products are standardized, however, despite this, it is easier to combine spare parts from the same manufacturer.

When selecting, you can be guided by other principles. If the tool is used often, it is necessary to decide what is more important - the convenience and speed of changing the working part or the reliability of the connection. In the first case, a quick-clamping cylinder is suitable, in the second - a cam cylinder fixed with a key.

It is important not to make mistakes. The easiest way to look for the desired part is with a tool and a sample of an old sleeve.

How to change the chuck on a screwdriver should be written in its instructions. For connection, a thread on the body and shaft or a Morse taper is used.

For detailed instructions on disassembling a screwdriver, see the video.

Prepared by: Artem Filimonov

No comments yet. Start a discussion!

The site is a leading Internet project dedicated to the reconstruction and interior design of residential premises. The main content of the site is the archive of the Ideas for Your Home magazine - exclusive author's articles, high-quality illustrations, practical advice and lessons. A team of professionals is working on the project in close cooperation with renowned designers, architects and leading experts of the publishing house.

On our site you can find complex design solutions; view detailed market reviews building and finishing materials, furniture, machinery and equipment; compare your own ideas with the design projects of leading architects; communicate directly with other readers and editors on the forum.

How to get a drill repaired?

There can be several main reasons for a drill malfunction:

- the movable block of the electric engine breaks down (stator, armature);

- bearings fail;

- the regulating button breaks;

- the reversible regulator fails;

- collector brushes burn out;

- violation of contacts, cable break;

- failure of the chuck.

Most often, to establish the cause, the unit must be disassembled. The simplest malfunction is the chafing of the cord due to intensive use of the device.

A second common malfunction may be a contact failure in the switch block.

Chuck breakage costs on the third place by the frequency of defects. Drill repair is as follows: screws are unscrewed, the case is disassembled, contacts are checked, places of possible burnouts or breaks. It is not difficult to determine by the damaged insulation.

If the switch block is faulty, it is best to install a new one. It is not recommended to dismantle it on your own, there are too many small parts.

The brushes are usually changed without dismantling the case, most often it is enough for models to unscrew the plugs and put in new brushes.The first sign of problems with these parts is noticeable arcing and motor interruptions. This is caused by the violation of electrical contacts between the brushes themselves and the collector.

As a preventive measure, it is recommended to clean the collector from carbon deposits and test how tightly the brushes are on the drum.

And also a common breakdown can be the lack of engine operation. In the workshop or on your own, you can "ring" the contacts with a multimeter using the resistance mode.

The principle of troubleshooting an electric drill is based on the availability of many parts.

And also the breakdown of the armature itself is often found, this often happens due to the failure of the winding. A similar phenomenon is observed in budget models, world-famous manufacturers make windings with double and triple insurance, it rarely fails. If the winding begins to melt or burn, then a characteristic odor appears, the engine power is sharply reduced.

Malfunctions are also common - this is a failure of bearings, this can be determined by their characteristic grinding, deceleration of the torque.

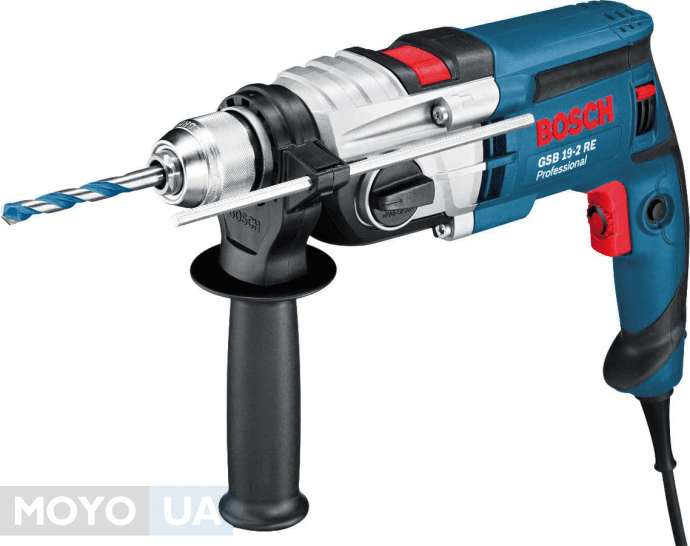

Impact drill for working with various materials

Many people these days are moving away from traditional corded drills and prefer modern, cordless ones. However, this approach does not always justify itself. First, the cordless tool has a stable electrical power and will never stop in the middle of a workflow. Also, it usually has more power than cordless drills and, accordingly, the area of its application is wider.

The hammer drill can also be used with hole saws in this mode. And when doing such tasks (reaming holes), compared to cordless or compact corded drills, the large size makes it more stable, easier to control, resulting in better performance.

Operating rules

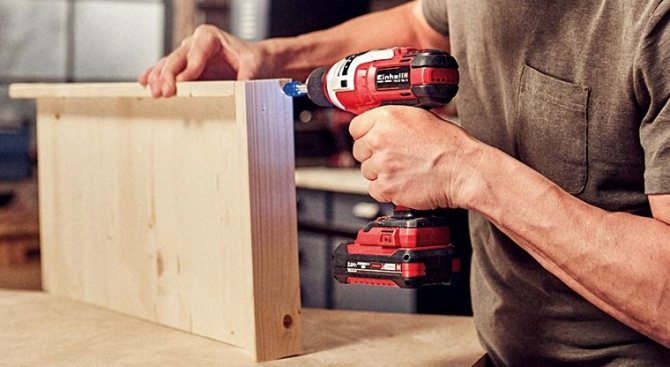

The use of an impact screwdriver will be safe and as effective as possible only if it is done correctly. Obviously, the first tip is to read the instructions before use, but there are other reasonable usage tips.

For example, if possible, do not expose equipment to maximum torque, after all, many fragile materials with a treated surface can simply be torn from this, and you will ruin the workpiece. In addition, working at maximum speed accelerates tool wear, not to mention the fact that in this mode you need to hold it tighter, otherwise there may even be the possibility of injury.

The modes of operation, by the way, are described in the instructions for a reason - each of them assumes optimal settings for performing this particular task, and for another it may not be suitable. So, drilling is needed to make holes, and the screwdriver mode is for screwing in fasteners, when used, on the contrary, efficiency decreases, but the risk of injury increases.

Always wear protective goggles and gloves, especially with fragile materials. When drilling walls, make sure there are no electrical wires in advance. Remember that the continuous operation of the device is limited - if the nozzle or any other unit gets noticeably warm, let it cool down.

By the way, if the drilling mode is not provided for in a particular model of a screwdriver, then it is better not to try to drill anything with it - such experiments often end with a burnt out engine.

Views

Drills are usually divided into home and professional. The difference between the two is due to the following characteristics:

- power level;

- duration of operation;

- twist speed of the drill;

- the largest diameter of the holes to be prepared.

Of course, you will have to pay for the increased characteristics of the tool, so you must first find out how often you have to drill, what the amount of work will be.

Such a device is needed for such purposes as:

- chisel walls for wiring and other communications;

- punching passages in concrete and masonry;

- chipping off ceramic tiles and durable finishing materials.

Drums

A conventional hammer drill is slightly inferior in performance to a hammer drill. And yet it is, undoubtedly, the tool of a professional builder. This technique can be safely used when you need to break through a brick wall.

The hammer drill uses a pair of ratchets that touch during operation. With the ability to disconnect them on command, the hammer drill can be easily switched into bumpless mode, if necessary.

Unstressed

This design eliminates the possibility of drilling materials that are harder than wood. But this does not mean that the hammerless drill is unambiguously bad. It is a great help when you need to assemble furniture, boxes, hang something on a wooden wall.

Household drilling machines are divided into cordless and electric. Having a battery means increased mobility, but a network retrofit can last much longer and is usually lighter.

As for the screwdriver, this is not a drill in the proper sense of the word, but a separate type of tool. However, the principle of operation is the same. All screwdrivers are powered by a built-in battery.

In conclusion, it is worth saying a little about the special modifications of the drills. So, magnetic drills are not so much a construction device as an industrial one. If it is used at construction sites, then it is very limited. If there is no need to repair a crane truck or build a railway bridge, such a structure is unlikely to be needed. Therefore, for domestic purposes, they are used extremely rarely.

A drill mixer is a type of device that is necessary for mixing various liquids and for giving them a special consistency. Compared to simple boring machines and even rock drills, this technique has more powerful bearings.

It is worth noting that a drill mixer is suitable only if no more than 15 liters of the working mixture need to be processed in 1 step. With a greater replacement need, you will have to buy specialized mechanisms

But this is already a topic for a separate conversation. An angle drill rarely has more than 350 watts of power. The number of revolutions she also reduced when compared with more advanced technique. But when assembling furniture in home such drilling machines very valuable.

Views

A good drill can be used not only for drilling various holes, but also for many other jobs. Drill differentiation:

- ordinary;

- drums;

- rechargeable;

- powered by the network;

- mixers;

- corner;

- diamond work.

A professional drill is more powerful, capable of working for a long time without any complaints. Such a tool costs three times more.

Rechargeable

A cordless drill can be very handy, for example, for plasterboard work. It does not require a lot of power, you need qualities such as:

- compactness;

- ease;

- autonomy.

The power of such devices does not exceed 410 W, you have to work at a height under the ceiling, and a good trouble-free drill can become an indispensable tool. In fact, the design of the battery device (including the impact version) is a combination of a drill and a screwdriver. Their advantages are that they are easy to use and reliable. Quick-release chucks have been around for a long time, when bits are installed directly into the spindle. Nonetheless, cordless drills remain in favor. Drill drivers can be "armed" with a hammer drilling mechanism.

It is important to pay attention when buying, what is the battery in the drill. Nickel-cadmium batteries do not last long, they must be constantly in operation, otherwise they quickly deteriorate

Batteries of the metal hydride group are very good, as well as lithium ion chargers.Their power is limited, does not exceed 36 W, so the work of such a drill can be effective for several hours.

Network

When choosing a corded drill, you should be guided by three important criteria.

- Engine power. The higher this indicator, the more work you can handle in a short period of time. But power drills, powered by the mains, are often cumbersome, so this factor should also be taken into account.

- The rotational ratio of the drill depends on the power of the device, the higher the ratio, the greater the performance of the drill.

- Torque is also very important, it shows how easily resistance is overcome during spindle rotation.

But it should also be borne in mind that power drills, where there is a detachable power cord, have proven themselves best in the work. It is convenient to work with it, its optimal length is four meters.