Tools and accessories for work

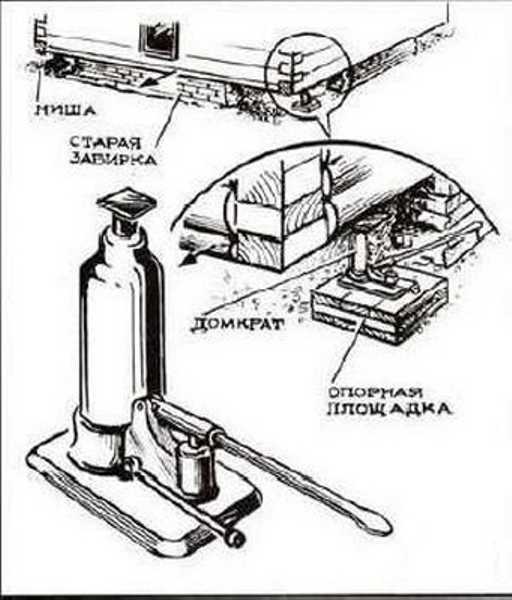

To build up the foundation of a brick house, you will need a set of certain tools. First of all jacks.

Three types of lifts are used in construction:

Diagram of a hydraulic jack.

- screw;

- rack;

- hydraulic.

They differ in the principle of the mechanism. The latter type of lifting the wall is even preferable, because the hydraulics provide a slow lifting speed and a small working stroke. These qualities are important in order to raise the brick wall evenly, without distortion.

The lifting capacity of the jack depends on the weight of the building. Brick is heavier than wood, so this figure should be in the range from 20 to 30 tons. If we are talking about raising a small country house, a carrying capacity of 8 to 10 tons is enough.

In addition to lifts, during work, you will need tools for concreting (a shovel, trowel, concrete mixer), a hammer and scrap. If the additional foundation provides for reinforcement, then a grinder will be required and scissors for metal.

To control the lifting process and avoid distortions of the structure, masters advise using levels and plumb lines. More experienced people resort to the help of levels, with the help of which it is possible to observe deviations of the house from the norm horizontally and vertically. But the use of these devices requires certain knowledge, so it is better to entrust such work to a specialist.

What you need to know about properly lifting your home

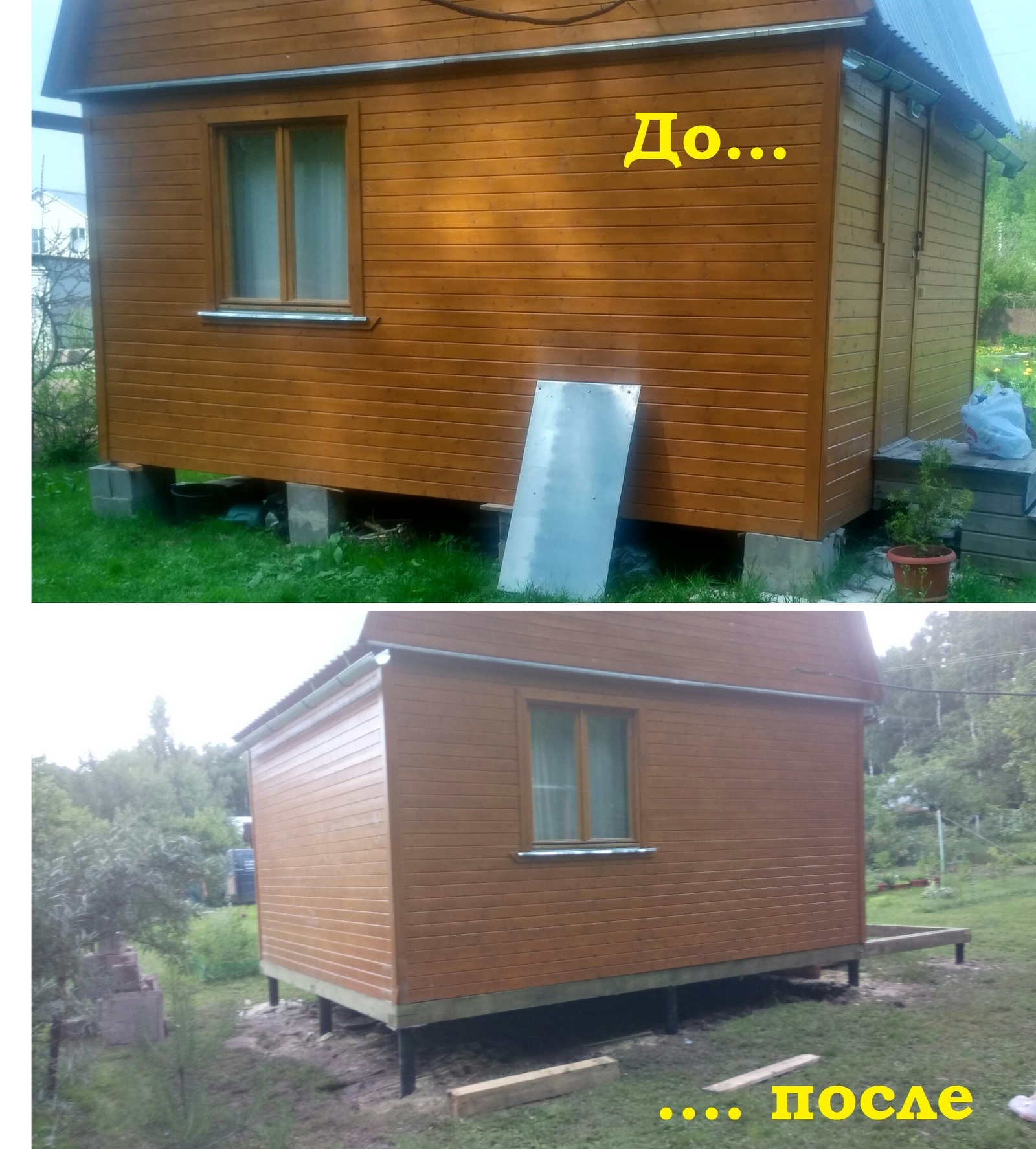

Wooden houses are raised in various ways and for different purposes. However, the general principle and algorithm of actions is the same in all cases. It looks like this:

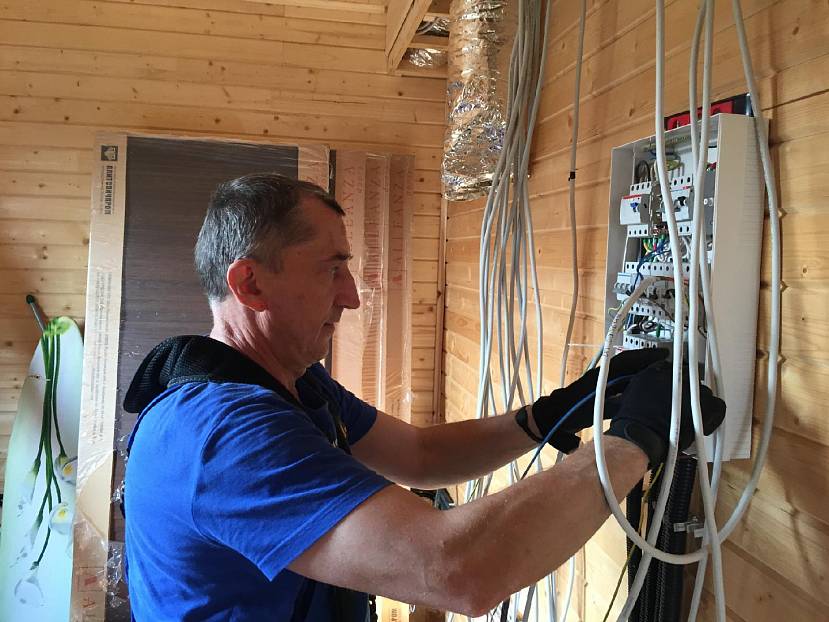

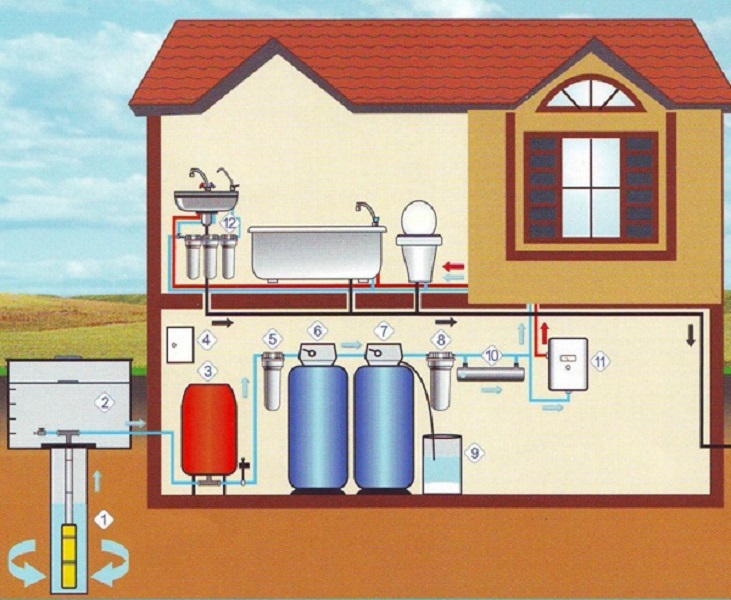

- Disconnect all communications.

- Prepare a place for installing jacks.

- Jacks are installed and the lower crown is detached from the foundation.

- Raise the house and put up the props.

- They carry out repair work, for the sake of which they raise the house.

- They lower the house, gradually removing the props.

Disabling communications

If you are going to raise a house, you must completely turn off all communications - electricity, water supply, gas, sewerage. If you do not do this, then there is a high probability of serious damage. In addition, it is necessary to cut all the wires and pipes that connect the house to the ground. Otherwise, they will greatly interfere with the rise and may violate the integrity of the log house.

Particular attention must be paid to the stove, because the stove is placed on a concrete foundation that is not connected to the house. It will also be necessary to ensure the free movement of the chimney through the roof. If the boiler is installed on a concrete base, disconnect it from the heating system.

If the boiler is installed on the wall, then it will in no way interfere with the rise of the house.

If the boiler is installed on a concrete base, disconnect it from the heating system. If the boiler is installed on the wall, then it will in no way interfere with the rise of the house.

Which jacks are suitable?

To raise the house, you will need jacks identical to those

which are used in car workshops. Their main feature

is the ability to lift a lot of weight. Pre-produced

calculation of the load on the lift taking into account the mass of the structure and climatic conditions:

- the total mass of the house is calculated as the sum of the masses

external and internal walls, ceilings and roofs. Total volume estimate

produced by multiplying the volume of timber structures by the density

the material used in their construction; - the weight of all is additionally added

communication lines and devices, which cannot be disconnected during

work performance; - heavy pieces of furniture and decor are not included.

They are first taken out of the house; - the final load is multiplied by 20%. it

ensures that the jacks will be able to lift the house exactly. Is being done

tolerance for moisture, which the wood actively absorbs.

In order to raise a panel board house made of wood, you will need

any of the existing types of lifting mechanisms. The main thing is to withstand

correspondence of the carrying capacity of the tool to the mass of the building. Prevent work

mechanism at maximum values.

Screw

They are distinguished by the simplicity and reliability of the mechanism. Completed in

the form of a screw, along the thread of which the contact pad is moved.

The latter is considered the fundamental bearing part of the mechanism. Product

characterized by high carrying capacity, compactness and simplicity

service. They are capable of lifting the weight of a building up to 50 tons.

Screw

Screw

Hydraulic

The mechanism of the device is based on the lifting force

liquids. It promotes the displacement of the piston when creating pressure

specialized pumping lever element.

There are several types of hydraulic devices

plan:

bottled (2-100 tons). The main disadvantage: small

initial working height. If a replacement of the location of the house in the country is being selected,

a copy up to 10 tons is suitable. The rest of the models are used preferably

professionals.

Bottle

Bottle

rolling. Carrying capacity is not more than 10 tons.

The best option for a country cottage. The cost is slightly higher than the first

the option under consideration;

Trolley

Trolley

with a low pickup. An expensive option.

Advanced functionality: the ability to work in horizontal and vertical

plane. It is allowed to raise the house on a slope. Carrying capacity does not exceed

25 t.

Both types of jacks are allowed for lifting the house. By

reliability, they are approximately equivalent. The choice depends on the price category

specific model, its capacity and build quality. Not recommended

use Chinese products. Many manufacturers of this country

insufficiently scrupulous about the issue of compliance with the specified technical and

operational characteristics.

Instructions on how to raise a house with your own hands

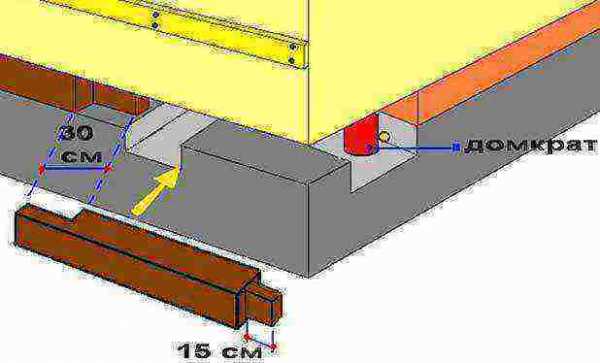

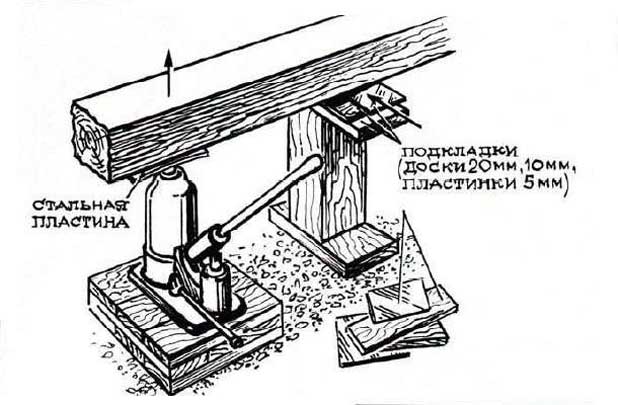

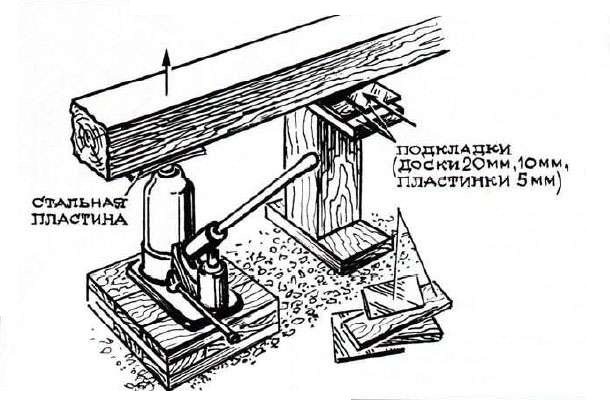

The ascent starts from one of the corners. At a distance of no more than a meter from its beginning, a solid foundation is prepared on which the lifting levers will be installed. As a sole, you can use several square or rectangular pieces of wood with a thickness of at least 15 - 20 cm. They are laid under the walls in such a way as to form a secure base for the lifting devices. If the foundation of the house is made of reinforced concrete, and at the same time has no signs of destruction, then it can be used as a basis. Next to the lifting points, prepare a chopped bar that you will use in the process. After making sure that all the elements of the house are no longer associated with the foundation and soil, you can proceed to the main task.

Having securely installed the jacks on the base, begin to slowly raise each of them - no more than 3-5 cm at a time. Having slightly raised the corner, put boards and a beam under the wall plane, then lower the lift and go to the next point. The most dangerous is the moment when the house is separated from its foundation, so carefully monitor this process. If any deterrent is found, remove it first, and only then proceed with the work.

After a safe separation of the box from the base, you can raise each corner by 7-10 cm, and, fixing it on the stands, go to the next position. Planks should be laid along all walls at a distance of no more than 2 meters.This will prevent the structure from deforming, and besides, the house will be reliably anchored to a temporary foundation. Picking it up to the desired height, the floor plane is leveled horizontally, and having securely fastened to the supports, they begin to replace or repair worn-out elements. If you need to lift the house with your own hands and move it in any direction, then logs of the same section 2-3 meters long are placed under it at a distance of 30-50 cm, and the whole cottage rolls over them in the right direction.

Tips and tricks for raising your home

At the points of installation of jacks, it is imperative to analyze the condition of the wood

At the points of installation of jacks, it is imperative to analyze the condition of the wood

You are probably thinking about how much it costs to raise a house using the services of professionals. Of course, the cost of such a service is not very cheap. For this reason, it is better to independently study the recommendations and rules, and then do all the work with your own hands. After watching a large number of videos and literature, we decided to highlight for you the most important tips that will make the procedure easier. So:

- When the gap reaches 15 cm when lifting, this means that you need to take duralumin gaskets and lay them into the gap;

- At the installation points of the jacks, it is imperative to analyze the condition of the wood. If the quality is lame, then there is a theoretical probability that the timber will not withstand the stress, and this can cause emergency situations.

- In some situations, you have to use narrow tools. With such equipment, an additional bracket must be installed at the mounting location.

- If there is a brick oven in the building, it is necessary to constantly monitor the position of the pipes and roof.

In this article, we examined in detail the process of raising a building, and found out the fact that it is very simple and easy to complete such a task on our own. But, remember, about safety rules and careful attitude to work.

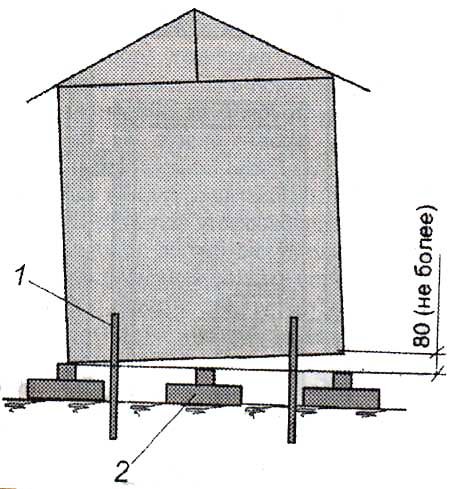

Repair of the foundation using screw piles

The piles are connected to each other by channels and form a kind of lattice. After that, the house can be lowered onto the resulting lattice.

It is this method of maintaining the foundation in good condition that has received the highest popularity. This is not strange, because it is quite simple and not expensive. Moreover, its efficiency is at its best.

When building, some forget that it is the foundation that is the most important part of the house. As a result, during operation, various cracks, chips and so on appear on it.

This is a sure sign that the base needs repair.

It is in this case that you will need to raise the foundation with jacks. In recent years, some residents of our country have begun to prefer the foundation on screw piles to the ordinary one. This is due to its many advantages over ordinary concrete.

The technology of replacing the foundation with screw piles is quite simple. Moreover, it will seem simple to those people who are reading this article, because it has already described how it is necessary to raise a house with jacks. In this case, this process is the main one. So, the installation technology is as follows:

based on the characteristics of the soil on which the installation of piles will be carried out, their exact number is calculated

This is a very important matter, because the integrity of the future structure will directly depend on it;

it is worth raising the house. This is done according to the principle that was described above.

Then you need to mark the perimeter, on the territory of which all the piles will be located. At the same time, it is very important to calculate the location of each of them. Piles should be installed at the corners of the building, as well as along the perimeter of the load-bearing walls;

then you need to start screwing all the piles in turn. This can be done manually, but you can use special equipment;

all piles are connected to each other by channels. They should form a kind of lattice.This will increase the rigidity of the structure;

only then can the house be lowered onto the resulting lattice.

Now we can state the fact that the renovation of the foundation has been completed and it will delight its owners for many years.

Foundation restoration

When installing a new foundation for a wooden house, they adhere to the following sequence:

- The existing trench is deepened and leveled for arranging a new foundation. Its depth should exceed the level of freezing of the soil, and its width should be greater than that of the previous base;

- A sand cushion with a height of about 10-20 cm is laid on the bottom;

- A reinforcing cage is formed, for which they use steel rods with a cross section of about 8-12 mm - it all depends on the dimensions of the building and its mass. The release of reinforcement for its subsequent bonding with a common reinforcement cage is impractical here;

- Formwork is mounted with careful fixing of the structure along its entire length;

- First of all, the corner supports are poured, preferably once, after which they proceed to pouring the rest of the tape. This approach will give the structure greater strength and solidity;

- During pouring, the concrete mix is carefully tamped. This can be done by means of a steel bar or a special device;

- After the end of the pouring, the concrete is allowed to harden, after which it is covered with roofing material, which plays the role of a waterproofing agent, and proceeds to the final stage of work.

The structure should be lowered very carefully and carefully, performing operations in the reverse order regarding lifting and monitoring the condition of the walls and their load. As you can see, it is not as easy to lift and replace the old foundation as it might initially seem.

Although, if you have the proper desire and the appropriate tools, you can cope with all the operations on your own. The main thing is to follow the recommendations presented above and not be too hasty.

As you can see, it is not as easy to lift and replace the old foundation as it might initially seem. Although, if you have the proper desire and the appropriate tools, you can cope with all the operations on your own. The main thing is to follow the recommendations presented above and not be too hasty.

House lifting technology with a jack

After preparing the house for lifting it with a jack, you need to make sure that the walls are secure. First, at a distance of 50-100 cm, control strips with applied markings are installed. Then the mounting holes are formed for installing the jack. If necessary, the bonding layer between the foundation and the wooden wall is destroyed.

In order to raise the jack with a jack, you need to do the following.

- Install a hydraulic jack in the mounting opening. It should be sized to fit the support boards.

- In one approach, the building rises by no more than 20 mm.

- After that, support boards are placed to fix the position.

- You need to move clockwise (or counterclockwise).

- All mounting holes are lifted at a time by a fixed amount.

- Without the involvement of special equipment, the maximum lifting height can be 50-60 cm.

After completing the work, the foundation is repaired or a new one is filled, the lower rims of the wooden house are replaced. Additionally, it is recommended to check the condition of the support beams, and, if necessary, replace some of them and treat them with antiseptics.

During the performance of work, it is important to observe safety rules. You cannot be under the building, all actions are performed outside the area where the base of the house is located

Before starting the repair of measures, you should make sure that the walls are securely fixed.

Upon completion of the work, you need to prepare the surface of the foundation for installing a building on it - roofing material flooring, processing with special compounds. Lowering the house is carried out in a similar way.A jack is installed in the technological opening and the wall is fixed. Then part of the support boards is removed, after which the jack is lowered. The procedure is repeated until the house is completely fixed on the foundation.

Installation of jacks and their correct position

Before replacing the base under a wooden house, you should figure out how to properly install the jacks. They are installed under the lower log, placing a board or timber under them for greater strength

And it doesn't matter if the jack rests on the ground or concrete surface, the lining must be mandatory to give the fixture better stability

A steel plate of about 10x10 cm is laid under the head. The place on the log where it will abut is also processed, making it as even as possible

It is also important to monitor the level of the hydraulic device - it must be located strictly vertically. At the slightest tilt, the work is stopped and restored to the original position of the jack

To control the height of lifting into the ground at one of the corners of the structure are installed with a rail with markings on it. Similar marks are applied to the corner itself. During the ascent, based on the difference in indicators, the real lifting height is determined.

What should you pay attention to?

Common mistakes when lifting wooden houses:

- Do not detach the cap from the foundation.

- Raise one side of the building excessively.

- Violations are allowed when installing the jack.

- Ignore the use of spacers between the lift and the crown.

- Too narrow pads are used.

The fact is that if you forget to disconnect the grillage and the crown even at one point, the probability of the lower element breaking significantly increases, as a result of which the entire structure will be shaken. This is fraught with the fact that you will have to caulk not only the crowns to be replaced, but also all other elements.

Often users make mistakes when installing the jack. If the tool pushes the soil or skews during operation, there is a possibility that the dwelling will move relative to the foundation. Returning the building to its normal position will not be easy. It is possible that you will have to completely disassemble the structure, and reassemble it on the basis. Using a jack without a fixing heel will split the bars or logs due to the small diameter of the stem, which creates tremendous pressure.

A few tips on the topic

Jack installation diagram.

In the event that the house is lifted with jacks, it is imperative to provide insurance.

If the clearance increases by 15 cm during lifting, then a special duralumin gasket is placed under it.

In the place where the installation of jacks is planned, it is imperative to check the quality of the wood. It should be on top. Otherwise, it is very likely that the building will not survive. This can lead to disastrous consequences.

Sometimes you have to use narrow jacks. In this case, an additional bracket is necessarily mounted at the installation site. It will increase the installation area

This will lead to the fact that the house will not move under its own weight, and the jack will remain in place during all the work.

If the house has a brick oven, then when raising it, be sure to pay attention to the joint between the pipe and the roof.

Sometimes a situation arises when the house needs to be lifted without fail, but the necessary jacks are simply not at hand. Here you should think about purchasing them. Although powerful enough options are currently difficult to obtain, there is always a way out of the situation.

For example, many go to the nearest depot. There must be some jacks in stock. Many employees of such enterprises will gladly go to meet the homeowner.

Types of jacks

Lifting wooden residential buildings requires the same types of jacks that are used in garages and tire shops. Only they should be designed for a significantly greater load. Therefore, before you start picking up a jack, you need to correctly calculate how much the house you plan to lift can weigh under current weather conditions:

- The total weight of the house can be calculated as the sum of the weights of the walls, ceilings, partitions and roofs. You can estimate this value by multiplying the volume of wooden structures by the density of the wood;

- To the resulting number, it is necessary to add the mass of all internal engineering devices and communications that cannot be disconnected for the period of work;

- We do not take into account the contribution of furniture that is inside the house, since it must be taken out;

- In order for the jack to be able to lift and hold the house, we increase the value calculated in the previous step by 20-25%. Thus, we take into account the influence of moisture, which is always present inside the wood material.

To raise a wooden house, two types of lifting devices are most often used: screw and hydraulic.

- Screw jacks are a simple and reliable mechanism, which is a screw, along the thread of which the contact pad moves, which is the main bearing element. Screw jacks have a high lifting capacity, compact dimensions and are quite easy to maintain and operate. An example of a screw jack

- Hydraulic lifts. Their work is based on the lifting force of the fluid, which displaces the piston when pressure is created by a special pumping lever. Hydraulic jacks are more complex than screw jacks.

How to raise a house with your own hands?

You can raise a wooden dwelling by means of different

number of lifting units:

the use of one lifting mechanism. By

queues move to various points of the structure. Strictly regulated offset

in the vertical direction - no more than 50 mm. Irreversible

damage and deformation, as a result of distortion of door and window structures,

the formation of cracks in the finishing facade material and violation of the integrity

double-glazed windows. The raised part of the house is fixed with wooden

bars, the lift moves on. Consistent work allows

raise the building to the same height;

use of two lifts. Performed

the correct layout of the units to lift and move the house vertically.

Both points do not need to be suspended simultaneously

Raise a specific area

the building is important in turn, preventing the building from shifting to the other side of

lifts and its strong deformation. Step-by-step instructions for performing work

is similar to the first method;

you can lift the house with four lifting

devices

Manipulations are characterized by synchronicity.

Disabling communications

As preliminary manipulations,

disconnection of communication lines suitable for the building. This includes

plumbing, sewerage, gas pipelines and electrical cables.

It is required to cut (if possible, disconnect) the remaining pipes supplied to

house. They will not allow the wooden building to be properly lifted, they will interfere. V

Otherwise, the risk of severe damage to the home increases.

Disconnecting communication lines

Disconnecting communication lines

The oven deserves attention. It is located on an autonomous

foundation. Before as raise the dwelling, it is recommended to make sure of

free movement of the chimney through the roof.

If the boiler is located on the floor surface,

disconnecting unnecessary hose and line. If the unit is mounted on a wall,

it does not interfere with work.

Preparations, building materials and lifting tools

Preparing to raise the house on jacks, it is necessary to complete the preparatory measures:

- make a visual inspection;

- analyze the complexity of the work performed;

- estimate the duration of repair activities;

- choose a moving method;

- prepare the building for relocation.

By external signs, it is easy to determine the need for repair measures

Pay attention to the following points:

- tilt of the house or skewing of individual parts;

- cracking of street finishes and interior coatings;

- partial or complete shrinkage of the house;

- displacement of part of the base;

- significant destruction of the support crown and foundation.

Before lifting the jack with a jack, it is necessary to calculate the approximate load that falls on each corner.

Before lifting the jack with a jack, it is necessary to calculate the approximate load that falls on each corner.

Partial or complete relocation of the building is carried out in order to perform the following restoration work:

- local restoration or overhaul of the foundation;

- preventing the shrinkage of the building;

- dismantling rotten load-bearing beams along the contour of the structure;

- elimination of distortions of walls and openings;

- performing antiseptic processing of wooden structures;

- elimination of errors made during the construction process.

To make the right decision, you need to analyze a number of points:

- the weight of the structure. The jack for moving is selected according to the carrying capacity. The volume of the building box must be multiplied by the wood density of 700 kg / m3, then the weight of the roof and cladding must be added. The resulting value, multiplied by a factor of 1.4, corresponds to the carrying capacity of the device;

- dimensions of the building. With the increased length of the building, which is more than 6.5 meters, local shrinkage of wooden beams or beams is possible at the joining areas. In order to prevent distortions during movement, it is necessary to fix additional reinforcement elements in the splicing area;

Before you start lifting the house, you need to perform a number of preparatory work

Before you start lifting the house, you need to perform a number of preparatory work

- features of interior decoration. Certain types of internal cladding significantly complicate the implementation of measures to move the building. Plasterboard and traditional plaster can crack under the influence of deformation processes. For reinforcement from the street side, boards with a thickness of 5 cm are nailed;

- the nature of the soil. The concentration of moisture in the surface layer of the soil and its structure make certain adjustments to construction activities. The jack, under the influence of loads, can easily sink into soft and damp ground. The use of metal shields and concrete elements allows you to increase the support area;

- estimated vertical offset. The design features of the lifting device limit the length of the stem extension. The required height of movement is achieved by gradually placing the beams under the support platform of the device;

- the duration of the repair work. The duration of the activities depends on the complexity of the renovation. It is risky to load the lifting device rod for an extended period. It is necessary to use strong metal structures as a temporary support for the structure.

The rise of the house to a convenient distance can be done in different ways:

- using a truck crane. Lifting equipment on a wheeled chassis is used to lift a building in order to move to another territory;

- using jacks. The use of small-sized lifting devices is popular when it is necessary to move light structures vertically.

If you doubt the correct installation of the jack, the process of lifting the housing should be stopped and the tool should be placed correctly.

If you doubt the correct installation of the jack, the process of lifting the housing should be stopped and the tool should be placed correctly.

Having decided to lift the house on screw or hydraulic supports, prepare:

- turn off the power supply;

- shut off the water supply lines;

- disconnect the sewer line;

- turn off the gas supply;

- disassemble the floor around the stove or in the boiler area;

- disconnect the gas boiler;

- ensure that the box is stationary with braces.

To perform recovery activities, prepare:

- jack, the carrying capacity of which corresponds to the calculated indicator;

- wooden shields, allowing to increase the area of the supporting surface;

- steel linings made of thick sheet material measuring 25x25 cm;

- tools necessary to dismantle the support beam along the contour of the building;

- grinder complete with discs for cutting metal and wood.

Having prepared the tools and materials, proceed to the ascent.

If during lifting there was a shift of the house to the side, install the jacks on the side that turned out to be lower

If during lifting there was a shift of the house to the side, install the jacks on the side that turned out to be lower

What do the experts advise?

According to reviews and expert advice, hydraulic jacks are the best jacks for lifting wooden log houses. Screw jacks can be used to raise the walls of frame and panel houses.

Photo: These small screw jacks will help lift lightweight wood structures.

Both types of jacks with a carrying capacity of two tons or more can lift the frame of a small house or bath. According to the recommendations and reviews of specialists in wooden housing construction, it is necessary to raise wooden log houses only after a detailed study of the structure of a wooden house itself. The thing is, according to what scheme the ligation of the lower crown with the floor beams of the subfloors was made. In different wooden buildings of a log structure, the fastening of floor beams and wall logs is different. The scheme of raising your log structure will depend on this variety.

How to raise a house with your own hands: step by step instructions

Date: 13 June 2017

5304

Comments: 0

The use of wood for the manufacture of cottages and country houses is popular.

Many people prefer logs, panel structures and beams that are environmentally friendly and provide, subject to special processing and proper installation, the durability of the building.

During the operation of houses made of wood, it becomes necessary to restore the base or replace the support crown. The low weight of wooden structures allows the house to be lifted using powerful jacks.

Knowing how to raise a house with your own hands, you can move a one-story building vertically and temporarily fix it with concrete blocks or metal supports

At the same time, it is important to prevent collapse, to maintain the integrity of the finish, not to violate the geometry of window and door openings.

Before you start lifting the house, you need to perform a number of preparatory work

Taking a responsible decision to raise the house with a jack without involving hired workers, you should perform a set of works, prepare the tools and materials necessary for lifting, and carefully study the technology

Particular attention should be paid to the observance of precautions. Let's consider this set of questions in detail.

conclusions

Adhering to the recommendations of professional builders, you can independently jack up the house to carry out repairs of various levels of complexity. In the absence of the necessary experience and self-confidence, it is advisable to entrust the work to professionals who will perform it with the utmost degree of accuracy. Compliance with technological recommendations will ensure smooth lifting and protect the structure from unforeseen damage.

On the site: Author and editor of articles on the site Education and work experience: Higher technical education. Experience in various industries and construction sites - 12 years, of which 8 years - abroad.

Other skills and abilities: Has the 4th group of electrical safety approval.Performing calculations using large amounts of data.

Current employment: For the last 4 years he has been working as an independent consultant in a number of construction companies.

Raising the house

Before starting to raise the building, it is necessary to completely prepare the site where the jacks are installed

Before starting to raise the building, it is necessary to completely prepare the site where the jacks are installed

Before starting to raise the building, it is necessary to completely prepare the construction area where the jacks are installed. Lay boards on all contours of the site. The fulcrum points must be maximized. We put the plate between the jack socket and the lower crown of the room. This action will make it possible to save the log from deformation that may arise from hitting a nickel. Then we make a test ascent.

Lifting a standing house must be observed height up to 4 cm... At least 2 people can perform such work, as they can cope on their own. Next, we put spacers under the building, which will further help free the jacks. Then we lift one side, about 8 cm high, and put the lining under the building.

We have already figured out how to raise the corner, now we need to do the same work on the other side of the building. After repeating the lifting process, we return to another wall. After the jacks are installed, lower the curtains. If this is not done, then there is a possibility of turning the tool out from under the building. This description of actions is repeated until the building rises to the desired height. Step-by-step instruction in actions requires compliance with the following rules and regulations:

- If you have any doubts about the correctness of the installation of the jack, it is better to stop the process of lifting the building;

- You already know how to raise a wooden house with your own efforts, but you shouldn't forget about basic safety rules. When performing work, you must not crawl under the building. It should be noted that this requirement also applies to individual parts of the body.

If the building from a bar did not succeed in raising the horizontal, then the angle of rise is chosen a little less, for example, 45 or 60 degrees. A lot of people doing the job should know not to rush, as rolling should be avoided. Violating this requirement, the building can slide and revolve around the pillar that stands on the base. The tree requires an exact sequence of work.