Comparison by manufacturers and prices

As a result of the testing of cutting wheels of the most common brands, the efficiency coefficient of the discs was determined. The tool wear was measured after a series of cuts, and the tensile strength was also checked, for which the wheels were accelerated to a speed that was almost twice the declared one.

I would like to add that the market offers products from many companies that were not included in this testing. Traditionally, high-quality and inexpensive wheels are produced by the Kosulinsky abrasive plant, the Krasnogorsk abrasive plant, and the Ivanovo ISMA JSC. NORTON brand disks have good reviews and an average price category. The choice always remains with the consumer, and promotion and high price are not indicators of quality at all.

What is a disc for a grinder

The grinder is used to perform a variety of tasks with certain materials. In the case of concrete, the grinder is most often used for cutting, grinding, and chipping. All manipulations are carried out using circular cut-off metal discs with abrasive spraying. The spraying should be diamond, since concrete is not taken with carbide or corundum, which are relevant for cutting soft stone.

The base of the disc is made of strong hardened steel, which can withstand considerable temperature loads. The cutting part is the outer edge that contains a layer of diamond grit of a certain size. The layer is made of very small technical diamonds, which are evenly distributed throughout the entire volume.

In the process of cutting the concrete monolith, the layers are triggered, but much slower in comparison with the layers of concrete being cut. After one layer of the circle has worked, the second begins to be used, etc.

This is what makes diamond discs popular and profitable in terms of the duration of work with them - using one consumable, you can do a lot of work.

The diamond disc is used in working with such materials:

- Porcelain stoneware

- Natural and artificial stone

- Reinforced concrete

- Tile

- Concrete monolith

The circle can be of different sizes (thickness and diameter). The required inner diameter is determined by the dimensions of the equipment - tools are small, medium, large. Outside diameter discs are available with the following parameters: 125, 150, 180 or 230 millimeters.

The thickness of the disc can be 1-3.2 millimeters. Discs with a small diameter can be of any thickness, large ones - only the maximum.

Features of working with disks

The most used type of tool for a grinder is a simple cylindrical grinding wheel. It can be used with equal success for grinding flat and curved surfaces, fine adjustment of mating surfaces and even for rough cutting of long profiles "to size". If it is necessary to cut a bore hole in a concrete wall for a household electrical outlet, a diamond cutter for concrete in the form of a cup or crown will be indispensable. The grinding cup is the most common type of accessory for angle grinders and allows you to grind not only flat surfaces, but also complex-shaped parts.

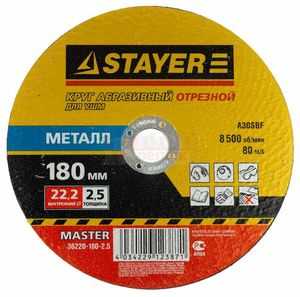

Where is the specialization of cutting discs. They are flat and thin. Such discs wear less when making long cuts, which is why the name "cutting". It is they who are used if you need to cut a piece of metal profile or sheet material, getting pieces of exactly the specified length. But such a tool tolerates end forces much worse.If the blade is skewed in the depth of the cut, the tool will jam at best. In an unfortunate combination of circumstances, the disk can burst and fly apart into wounding fragments.

Always choose a grinder cutting attachment depending on the type of work you are going to do. If it is necessary to cut a strong structure made of reinforced concrete, it is rational to use an expensive specialized disc - a multi-blade design with a thin cutting edge made of diamond or carbide materials. But almost all types of cemented floor screeds are successfully sawn with metal cutting discs.

For work on concrete in the case of "wet cutting" it is better to use multi-blade discs with wide gaps between the lamellas. If the water supply is undesirable or impossible, it is better to cut with solid discs of a thin profile. In this case, efforts to the tool should be applied with short, confident movements of the grinder. After each cut, the tool should be switched off and removed to cool. At this time, it is necessary to sweep away the accumulated dust and concrete chips from the working area with a brush.

For information on how to choose discs for a grinder on concrete, see the next video.

Classification by type of work

By the type of work performed, circles for angle grinders are:

- Cut-off. They are designed for making cuts, rough cuts, etc. The cutting disc has a cutting edge that is a solid circle or is divided into segments.

- Sawing. The cutting edge has teeth. A grinder is used to trim many types of wood products and wood substitutes. To get the job done, you need a saw blade. This type of circles is designed for smooth, clean cutting of solid boards, plywood, parquet, drywall. It is also suitable for laminate, fiberboard, chipboard (including laminated), as well as the selection of grooves in gas silicate.

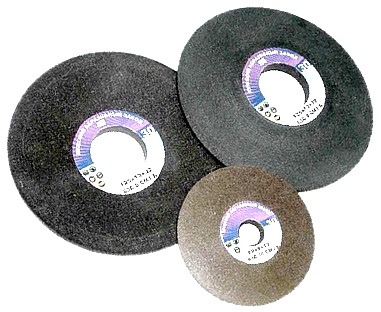

- Rough (grinding wheels). Such attachments remove the old layer of paint, varnish, primer from the treated surface, and carry out polishing.

- Stripping. This is a kind of peeling. These include disc metal brushes. They can remove rust and other stubborn dirt.

- Petal circles. They are also referred to as cleanup. The flap disc is used when processing metal, wood, plastic products, cleaning welded seams and burrs, removing rust, etc. A flap disc for a grinder consists of overlapping plates along the circumference, according to the principle of flower petals. Varieties: end, batch, with a mandrel. The flap end wheel on the grinder is designed for processing at an angle or normal flat. There are two subspecies of it - straight and conical. A straight flap disc is needed when grinding over a large area. Flap cone disc is suitable for finishing seams, joints, etc. The flap (folded) batch disc is also suitable for large areas. Grinding wheels with a mandrel for a grinder are used when working with cavities. They help to achieve the highest machining accuracy.

- For cutting seams. They are used when making joints in concrete, asphalt, etc. With such attachments, the grinder is also suitable for this work.

- Polishing. Such wheels are used for the final polishing of surfaces. These include polishing replaceable felt and felt attachments for the grinder with Velcro, as well as an emery wheel.

Features and purpose

The attachments for angle grinders help the user to work not only on wood, but also to process metal products, cut off glass, and are suitable for brushing. They can be classified by type of use, size, shape. Any nozzle that is used in the construction of angle grinders has its own color, this is a kind of marking that indicates the purpose of the product.

For example, a disc with blue paint is used for metal.The user should remember that such a product is placed on an instrument that is additionally equipped with the ability to adjust the speed, the other is not suitable for use.

The diameter outside and the thickness of the circle are the main parameters by which the discs are differentiated.

The product is produced in three versions:

- small;

- the average;

- great.

The most popular are 125 mm. The least common circles with a diameter of 150 and 80 mm.

When it comes to woodworking, it can be rough or not.

For the first option, planer discs are used, through which you can quickly cut a log or a wooden post. You can only use this attachment on an instrument that is equipped with a second handle. The guard can be removed as the bit is unlikely to break due to the integral disc design.

If it is necessary to remove the bark, it is worth using a peeling disc, which perfectly replaces the usual and more familiar hand tool - an ax. They can additionally saw not too thick boards.

For better processing of wooden blanks, abrasive discs are used, but for this the operator must have the skill and ability.

Among other things, the grinder is a tool used as a grinding unit.

If this is a primary treatment, then cord brushes are used, since they quickly level the surface. The ends are processed with the corresponding end discs.

Petal-type nozzles are always used in the amount of several products, since it will be necessary to take them separately for various operations performed.

To polish the wood, they also use appropriate discs, the working base of which is made from various, softer materials, for example, sponges, sandpaper.