What are they?

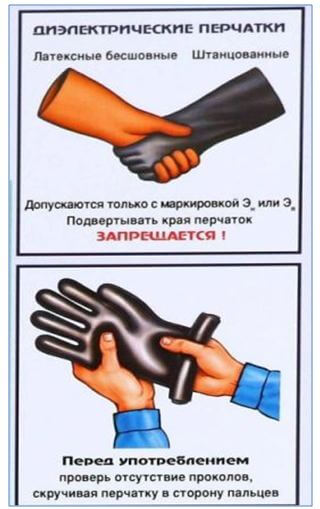

The choice of models of such gloves is not very large. When working with electrical installations, you can use two-fingered or five-fingered gloves. In addition, they come with a seam (danced) or seamless.

- Two-toed. These are products with a separate compartment for the thumb and another one of the same for the index.

- Five-fingered. They look like ordinary gloves (with compartments for each finger). Thanks to this, it is more comfortable to work in them, the fingers are free and do not hinder movement.

- Seamed or seamless. As noted above, they can be latex or made of special compacted rubber. Unsurprisingly, seamed gloves are lighter and more comfortable to use.

For any model of gloves, their length should be at least 35 cm.

What it is?

The work of an electrician is a deadly job that requires the strictest adherence to safety rules. Despite the fact that the equipment must be de-energized with mandatory grounding, the specialist is prescribed to work with tools with insulating handles and wear dielectric gloves. Electricians may use special electrician gloves that are protective against low voltage currents, but they are not dielectric. Such products are manufactured by the KBT plant.

The three types of gloves are made from several types of material, their purpose is as follows.

- KBT S-31 - lightweight gloves for precision work, the material contains polyester and elastane. It is convenient to pick up small parts in them.

- KBT S-32 is a reinforced universal series with additional protective inserts. Composition: cotton, imitation leather, PVC.

- KBT S-33 - used for working with massive machines and heavy tools. Composition: polyester, spandex, two-layer genuine leather.

Dielectric gloves are made of thick sheet rubber or latex. They have a standard socket height of 35 centimeters and a large width that allows them to be worn on warm gloves at low temperatures. The purpose of the wide flare is to keep the sleeves of the garment inside. This eliminates the possibility of a spark hitting the body. There are few categories of dielectric gloves.

- Five-fingered, two-fingered, seamless and with a seam (ditched).

- EV marking - for operation with voltages up to 1000 V, En marking - voltage over 1000 V.

Description

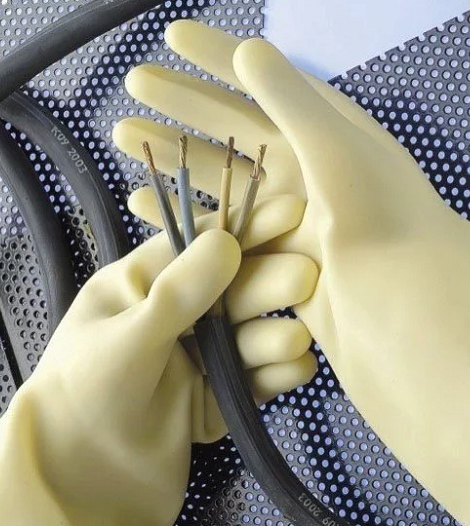

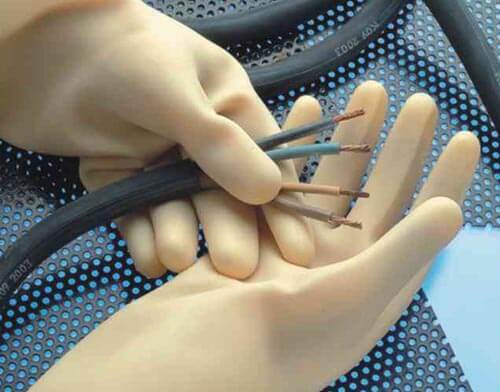

Dielectric gloves are the primary means of protection against electric shock when working with equipment with a power of up to 1000 V. Rubber is the most common material for the manufacture of such products.

Rubber is made from synthetic isoprene or styrene rubber, from which various components that affect the electrical conductivity of the finished product are removed. The material is regulated by GOST. The reliability of the gloves is their main quality for consumers. A feature of some types of gloves is a seamless production technology, which excludes tears at the seams in the event of increased mechanical stress or friction.

Other types of similar products have seams covered with solid rubber sheets. There are also dielectric gloves made of especially durable latex, manufactured according to a separate GOST, but their reliability is lower in comparison with rubber.

Tear strength is one of the most important characteristics of gloves for electricians. According to GOST instructions, it is not permissible to use latex dielectric products when servicing equipment above 1000 V, because their reliability is lower than rubber ones.

Also, for increased protection of people working with currents up to 10,000 V, it is recommended to use silicone dielectric gloves in addition to other protective tools.

Terms of use

Only gloves that are stamped with the specified test report can be used. In this case, the products should not have mechanical damage. Do not use wet or dirty PPE. Before starting work, you need to check the products for punctures or cracks. For this, gloves are placed on a flat surface and twisted towards the fingers.

Gloves should be inspected before each use. If everything is in order, they can be used for six months from the date of the inspection, after which they must be retested. If the inspection reveals cracks or punctures, the gloves should be replaced with new ones.

Tarpaulin gloves may be worn to protect the gloves. During work, care must be taken not to wrap the edges of the gloves. This compromises the user's safety. Do not inflate gloves with your mouth, this may cause them to become wet.

Disinfection cannot be ignored either, for which a solution of soda or soap is used. Gloves should be worn over clothing. When working near sharp edges, leather gloves should be worn over dielectric gloves.

Retention rules cannot be ignored. Rubber degrades when exposed to heat, gasoline, mineral oils, ultraviolet rays and alkali solutions. Store products away from heaters and radiators, not forgetting about the optimal level of humidity. Do not store gloves in direct sunlight.

Learn more about dielectric seamless gloves in the following video.