Electric circular saw overview

The design is unified, there is little difference between different manufacturers:

- Frame. It contains work items;

- Electrical engine. Responsible for power;

- Reducer. Transmits torque from the electric motor to the saw blade;

- Saw blade. Replaceable module, selected based on the material for processing;

- Protective cover. Located above the saw blade, protects the operator from splinters and blade breakage;

- Steel base. A flat platform designed to obtain a straight cut line;

- Riving knife. Located behind the saw blade. Performs protective functions.

2 Which saw to choose?

The main difference between professional and consumer models is their power: the former are equipped with a stronger motor, which allows them to use larger diameter discs and, as a result, cut the material deeper. In addition, the motor of a professional tool is able to work without interruption for a long time, and it is recommended to turn off household saws periodically to cool down.

If you plan to carry out regular construction work, you should give preference to professional models. And it is more expedient to purchase a household tool if it will be used from time to time for small operations.

The difference between handheld and tabletop (stationary) models lies not only in their design, but also in their power. Usually, this indicator for the latter is much higher than that of a hand tool. The tabletop version is optimal if you have a home workshop, in which it is possible to equip a separate workbench for working with the saw. A manual circular is also suitable for single work, especially since many manufacturers offer special devices with which the tool is fixed on the tabletop in an inverted position.

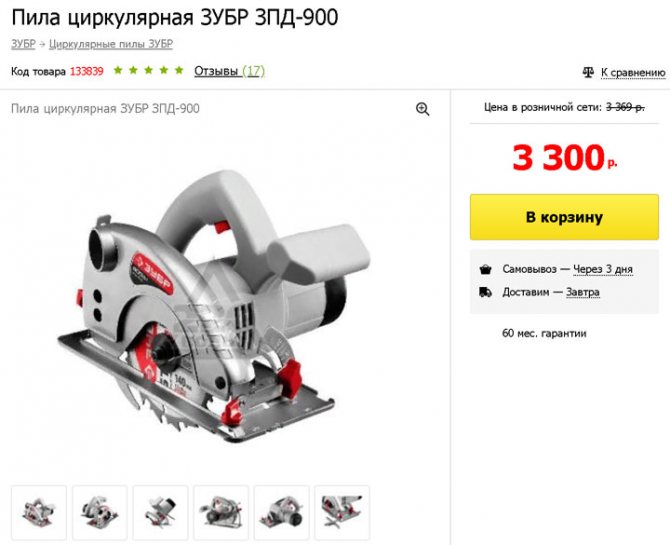

Popular models

A distinctive feature of Hitachi circular saws is that they can work not only with wood, but also with plastics, copper, aluminum and other metals. It is only necessary to choose a model that will differ in the given characteristics.

C6SS

This device has been designed for industrial design. The main advantage of the model is its excellent traction properties, which favorably distinguishes it from its competitors. Hitachi C6SS delivers high performance with a 1050 watt electric powertrain. The cutting depth when using this unit can reach 57 mm due to the fact that the blade diameter is 165 mm. Among the advantages of this model, it is possible to note its ability to rebuild in a short period of time to perform various types of cuts.

C6U2

Hitachi C6U2 is one of the most popular models, which is equipped with a powerful 1100 watt power unit. This is quite enough for the device to cope without problems with wood materials, the thickness of which is 54 mm. The presence of additional attachments allows you to make not only straight, but also corner cuts. The surface of the Hitachi C6U2 model is finished with chrome, which provides reliability and resistance to corrosion.

C7SS-NA

This model is one of the lightest in the range of Hitachi. Despite the fact that Hitachi C7SS-NA is a representative of the budget segment, it is equipped with a 1050 W power plant. Thanks to this, the blade can accelerate to 5500 rpm. With its low weight, the tool boasts the presence of an additional handle designed to simplify the operation process, as well as several protective covers.

C7MFA

Hitachi C7MFA is a semi-professional device that can be used not only in a domestic environment. Unlike previous versions, this model has been significantly improved, as a result of which its reliability and ability to cope with high loads have been increased. An upgraded 1050 W power unit is installed here.

C9U3

Hitachi C9U3 is a professional model with a large mass and a powerful power unit. The equipment received a motor with a power of 2000 W, thanks to which the disc blade boasts a diameter of 235 mm. A distinctive feature of the device is the presence of an innovative electric brake, designed to ensure high reliability and safety.

Service

Of course, this is only a small part of the quality models on the market today. Finding the perfect power tool is an eternal search for a compromise between power, workmanship, reliability, availability of additional options and the price of the device.

It is important to remember that hand-held circulars saws for wood are high-precision electrical appliances that require proper care and maintenance. Protect the device from moisture, especially network models

Cordless saws can be used in damp rooms, but not outdoors during precipitation. Over time, it may be necessary to clean the housing from accumulated sawdust, which worsen the cooling of the engine, as well as to lubricate the mechanical parts of the gearbox. Consistent substances like "Solidol" are well suited for this.

Do you use a circular saw?

Constantly! I want to try

Before each new use, sawdust, tar and other contaminants are removed from the working surface of the disc with liquid reagents, then wiped dry with a clean cloth.

Discs should be replaced immediately after the first signs of damage to the teeth are detected - if you continue to work with a faulty disk, you can not only spoil the cut, but also get serious injury.

It is permissible to sharpen dull teeth, but if you do not have experience with a sharpening tool, it is better to entrust it to a professional.

Expert opinion

Vasily Kuznetsov

We hope our advice turned out to be useful, helped you understand all the subtleties and nuances of choosing a circular saw and working with it. Use caution and caution when using any power tool. Good luck!

- Best inexpensive chainsaws

- Best cordless scythe models

- Cordless grass trimmer

Criterias of choice

With the correct selection of the saw model necessary for a home craftsman or specialist, there are usually no problems. This is due to the fact that in specialized stores this equipment is offered in a large assortment, so everyone can choose a suitable solution to solve their problems. In the selection process, it is necessary to comprehensively consider the technical and operational characteristics of this tool.

As additional, the requirements imposed by manufacturers for the safety of the work performed should be taken into account.

When choosing a saw, one of the important parameters is the ease of use of the tool. Therefore, before paying money for the saw model you like, you need to hold it in your hands. If possible, make some trial cuts. In this case, you will have an idea of how comfortable you will be using the tool. Already in the selection process, this will make it possible to conclude which models are comfortable to use.

In addition, experts advise taking into account other factors when choosing a tool:

- availability of specialized services and spare parts. If all this is easily accessible, then when a malfunction occurs, a high speed of repair work is ensured;

- laboriousness of reconfiguring parameters. Basically, when using the tool, adjustment of the cutting depth is required;

- power and number of revolutions, which is performed by the cutting part of the machine;

- cost and completeness of a specific model.

In order to eliminate the risk of overloading the electric motor when using the tool, it is necessary that an emergency shutdown mechanism is present in the saw structure. Experts advise making a choice in favor of a model that has a smooth start. In this case, jerks are completely excluded when the cut is being formed.

When performing an operation on inclined sawing, specialists may encounter such a phenomenon when the depth of processing does not at all correspond to the indications given on the adjustable scale. In such a situation, it is necessary to correct the value, for which you should use the recommendations contained in the instructions for use of the tool.

Conventional circular saws have been used to cut workpieces for many years. With all the advantages of this tool, it had one significant drawback - the low quality of the cut. To improve it, plunge saws were created by manufacturers of woodworking equipment. When used in industrial conditions and in everyday life, a good cutting quality is ensured.

Today, every home craftsman can use them to solve the tasks before him. Modern models from well-known manufacturers are of high quality and ease of use. It's pretty easy to use them. When using a plunge-cut circular saw, a high cutting speed is ensured. This is achieved by a powerful electric motor that complements the design of most modern saw models from well-known manufacturers.

Today, every home craftsman can use them to solve the tasks before him. Modern models from well-known manufacturers are of high quality and ease of use. It's pretty easy to use them. When using a plunge-cut circular saw, a high cutting speed is ensured. This is achieved by a powerful electric motor that complements the design of most modern saw models from well-known manufacturers.

Having decided to buy such a tool, you must choose the right one. Manufacturers offer a large selection of models that differ in design, price and capabilities. Based on your needs, as well as the functionality that such a saw should have, you should make a choice. They are absolutely safe to work with. To eliminate the risk of injury during work, you just need to follow all the manufacturer's recommendations specified in the instructions when using the tool. In this case, operations using this equipment will be performed quickly and safely.

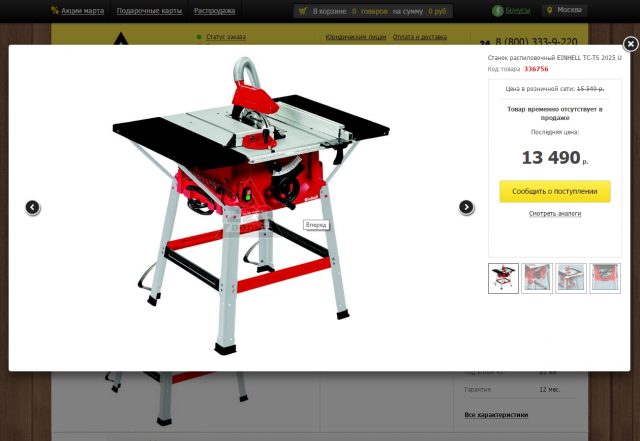

Circular Sawing Machine

To complete the picture, it is necessary to mention one more tool, which is a must in any carpentry workshop. This is a circular saw.

It can have a different design, but in all cases it is a stationary tool, completely unsuitable for transportation from place to place. As a rule, it is equipped with a fairly powerful electric motor and a large diameter saw blade. This enables it to quickly cut even thick workpieces.

The large working platform and the infinitely variable height and tilt of the saw blade enable high precision ripping of workpieces.