Instruments

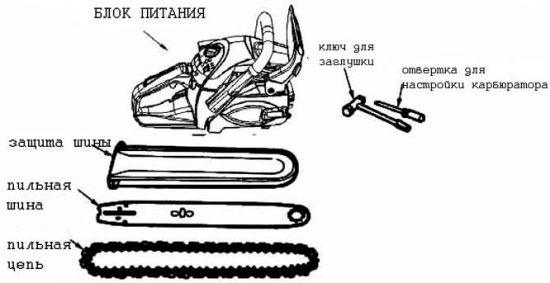

Correct adjustment of the chainsaw carburetor should be carried out using a special tool - a tachometer. It allows you to most accurately determine the maximum number of engine revolutions and adjust them according to the manufacturer's requirements. A small slotted screwdriver is required for adjustment. For some models of chainsaws, you will need a special adjusting key, without which work cannot be carried out.

The key for adjusting some models of carburetors is available only in service centers authorized for the repair of chainsaws by the manufacturer. This measure is aimed at reducing breakdowns due to incorrect settings by inexperienced users and those who are engaged in repairs without official permission to do so.

Product characteristics

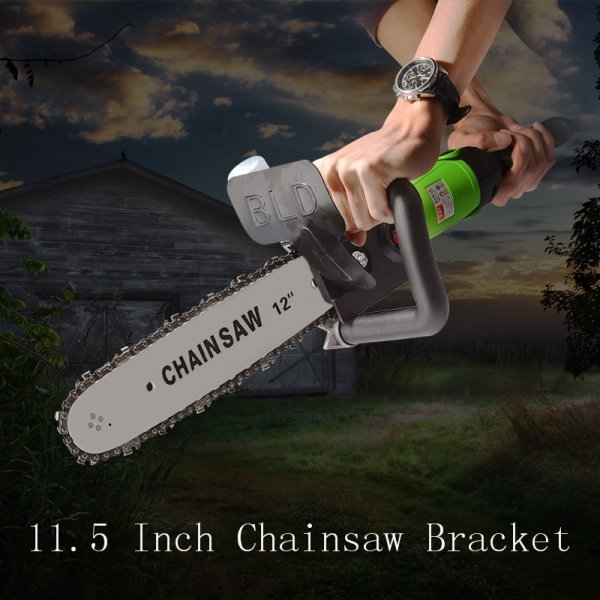

Sawing attachments for angle grinders are supplied from China or Canada. It is not recommended to purchase a Chinese product. Judging by the reviews, some of the orders come with disks scattered into small pieces. And the quality of the metal does not always reach the desired level. Therefore, the savings do not justify themselves.

Quality products successfully cope with boards of any thickness. The appearance of backlashes is also excluded. Even the high speed of the motor in the angle grinder does not cause problems. Users do not notice vibration, jerking or pushing tires out of wooden blanks. In terms of ease of use, these systems are not inferior to standard electric chain saws.

Peculiarities

It is worth considering right away: all experiments with angle grinders should be carried out only by people who are thoroughly versed in this technique. Otherwise, the consequences can be unpredictable (and hardly pleasant for the "inventors"). To use the sander for sawing, you will need a special handle, a guard and a special type of disc. A typical chain saw attachment for a grinder includes:

- a tire attached to the tool;

- handle;

- a sprocket mounted on a shaft;

- a set of fasteners and tools for working with them;

- insulating shield for the user.

disadvantages

The technical and operational characteristics of chainsaws are focused on a given level of workloads and special operating modes. Some owners of prestigious professional chainsaws oppose the use of attachments.

The refusal is motivated by the need for long-term operation of the engines at maximum speed, in some cases - a lack of torque, a forced reduction in the overhaul life.

As a result of the studies carried out, the models of cable winches, bark cleaners, wood splitters and compressors were recognized as safe for the resource and technical condition of the attachments.

The list of replaceable equipment that is not recommended, dangerous for tools, includes: grinders, brushcutters, motor-drills and outboard motors.

- In particular, when working with angle grinders, the air intake filter is intensively clogged.

- The installation of the boat equipment and the pumping nozzle assumes a long operating time of the high-speed chainsaw engine at maximum mode.

These shortcomings are partially or fully compensated for by the increased wear resistance of modern power units, an increase in the real service life of chainsaws from 1500 to 2000 or more hours. The durability of engines is also positively affected by the use of heat-resistant branded engine oils.

Winch - for lifting and moving loads

If the farm has a winch, but there is no drive to it, then replace it chainsaw motor... The store also has ready-made winches for connecting to chainsaws. The capabilities of an electric winch are not as high as that of a motorized device.

The attachment is attached to the machine shaft, after which it can be used for loading and unloading heavy loads, as well as for pulling stuck vehicles out of the mud cap. The winch is a versatile device with which any heavy operation is carried out with ease and high speed.

It is interesting! With the help of a winch, you can lift a load weighing up to 500 kg. This is enough for loading heavy loads into a car trailer.

In addition to those attachments that were described in detail in the material, a wood splitter can be connected to the chainsaw in order to split the sawn hemp. The wood splitter has a cylindrical shape with a sharp point, which makes it possible for the nozzle to enter the wood, and upon reaching a certain depression, the hemp splits. This nozzle eliminates the need to work with an ax.

If buying a chainsaw attachment is considered a luxury, then you can make any attachment yourself. To do this, you will need old tools, for example, to make a pump, you can take an old pump, and weld a nozzle for a chainsaw from it

It doesn't matter what brand your chainsaw is Stihl, Husqvarna, Makita or Partner. All attachments are universal, and you can be sure of this when buying. Buying a nozzle, you not only simplify your work, but also save a lot, because the purchase of electric tools will cost 3-4 times more.

Buying an attachment, you not only simplify your work, but also save well, because the purchase of electrical tools will cost 3-4 times more.

Related publications

Chainsaw carburetor cleaning and how to do it correctly

Features of replacing an asterisk on a chainsaw

Why the petrol cutter and trimmer won't start possible reasons and how to fix them

Gasoline with chainsaw oil - how to dilute and why it is done

How to choose?

Before choosing a nozzle for the device, you need to familiarize yourself with the technical documentation.

It is also important to know that not all attachments are universal - each attachment is selected for a specific model of a gasoline saw. The documents contain only an incomplete list of device models, and this greatly complicates the choice of the correct solution.

You also need to distinguish between the types of chainsaws. Professional devices have a sprocket clutch that can be changed. It is for such chainsaws that special pulleys are designed. Since the quality of professional gasoline saws will be the best, their price will be high on the market. For chainsaws such as Taiga, Partner and others, they use a grinder attachment when you need to make a smooth cut in wood and metal. Before starting work, you need to carefully inspect the installation of the nozzle itself.

There are several types of a packed pulley.

- Calm 180. Presented in the form of a cup, which is installed instead of the clutch.

- A pulley that does not have a cup. It is installed on the main sprocket of a gasoline unit and does not require clutch removal. This pulley is sold separately (as a spare part). It is also versatile and can be used in China's Partner, Taiga, and other gasoline saws.

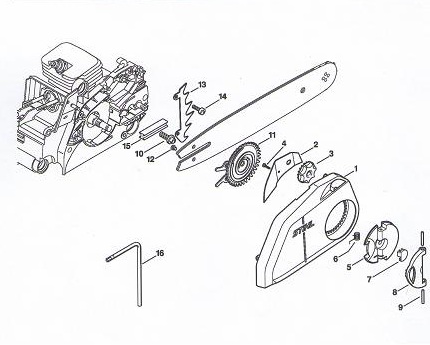

Replacing the tire of the chainsaw and its fasteners

Chainsaw tire fastening diagram

Replacing the fasteners and tires of the chainsaw is necessary when:

- Critical wear of the seat or shank elements.

- Damage to the casing.

- Loss of fixing bolts.

- Damage or deformation of the tire body.

- Abrasion or breakage of the drive and driven sprocket teeth.

- Damaged chain lubrication grooves.

- Worn chain tensioner.

- Wear of the groove and tire retainer.

That is why the guide bar and fasteners are consumable parts - only one universal wrench supplied with the tool is needed to replace them. And, of course, knowledge of the algorithm for disassembling, assembling and adjusting the mechanism.

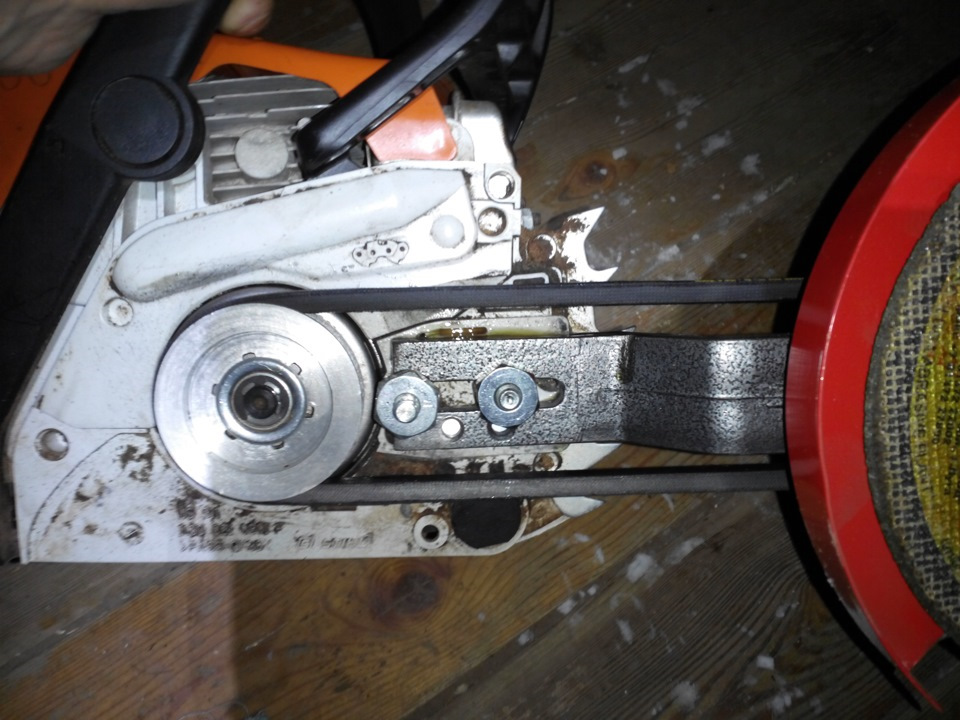

Chainsaw with tire removed

To disassemble the tire mount, you should:

- put the engine upright and, by unscrewing the corresponding nuts, remove the drive sprocket cover;

- lift the bar by the front end and turn the chain clamping screw, freeing it from the groove of the bar;

- pull the chain from below and, turning the clamping screw, release it from the groove;

- remove the chain from the drive sprocket and pull it out from under the casing, then put it aside;

- if there is damage or signs of wear, the casing and mounting gaskets should be replaced;

- remove the chain bar to be repaired or replaced from the groove mount.

The sequence of actions when removing the tire of the chainsaw in the photo

After that, the chain must be put on a new tire and the last one must be installed in the groove to be installed. Then the headset is brought into engagement with the drive sprocket and closed with a lid. Just before starting work, do not forget to check the absence of slack in the chain and the quality of its tension.

The chainsaw is back at work

If the new tire is attached and the headset is installed correctly, the chainsaw is ready for use again. By the way, just in case, you should make sure of this by sawing several thin branches.

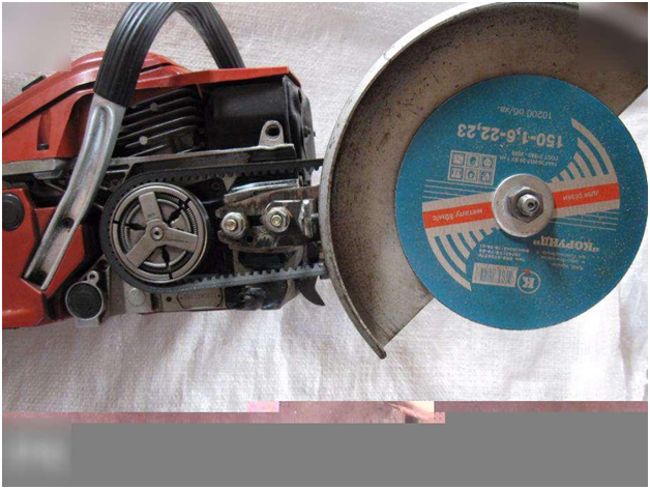

Grinder - when you have to cut thick metal

The Bulgarian chainsaw attachment is a versatile device, since such devices can be used to install not only abrasive discs for metal cutting, but also toothed wheels for wood processing or diamond wheels if you need to cut ceramic tiles or stone.

The tool is attached to the tool instead of a tire, and is driven by an even V-belt drive. The diameter of the circle must be selected depending on the power of the tool itself, therefore, the choice of such a nozzle must be approached responsibly, otherwise the motor may jam during operation. Grinders and angle grinders quickly heat up when cutting thick metal, therefore, to achieve the final result, you will need to pause so as not to burn the electric motor. A chainsaw with a UShM-1 attachment will cope with such tasks not only quickly, but also efficiently. The attachment can accommodate discs up to 20 cm in diameter, and the bore is 22 mm.

It is interesting! Attachments for UShM-1 chainsaws are much cheaper than buying a grinder, so you need to think carefully before buying a grinder.

Limitations of use

Where can the device described above be used? According to the experts, the grinder attachment for the Shtil chainsaw is the most suitable. As for the models, these are "Calm-180" and "Calm-250". This is due to the peculiarities and characteristics of these instruments. At the beginning of work, when the centrifugal clutch is activated, the number of revolutions is 4500 per minute. At this speed, the spindle is as stable as possible. Further, the revolutions are increased to 7000-8000 per minute.

Manufacturers advise when working with such a "grinder" to use only 75 percent of the power of the chainsaw and not to use the tool without a protective cover. This nozzle also has some limitations. So, in the process of cutting it is necessary to take care of a filter that would keep fine steel or stone dust (it will be formed during the work with the grinder). Given this circumstance, you should carefully approach the selection of abrasive wheels.

Effective air filters when working with such devices are recognized by all masters. The standard filters that modern chainsaws are equipped with are unable to cope with small particles and shavings.

There are two types of cleaning elements.For Chinese chainsaws, manufacturers install simple one-stage filters. As noted by the reviews, they should not be taken. They clog up very quickly and become unusable. For chainsaws of higher price categories (for example, "Calm" or "Husqvarna"), the manufacturer installs two- and sometimes three-stage filters. They can hold particles of different sizes.

Therefore, it is always best to work with this attachment on models with three cleaning filters. It is difficult to damage them with metal shavings. As for the selection of disks, not all of them are designed to work under high loads. This is stated by the manufacturers of chainsaws themselves. The abrasive wheel can collapse when rotating due to centrifugal force.

This chainsaw attachment is a useful tool that can be used in the household. The prices are quite affordable. For the "Husqvarna" saw, the product can be purchased at a cost of one and a half to two thousand rubles, and for the "Calm" models - about two and a half thousand rubles.

Types and features of the assembly of bark beetles for household chainsaws

Depending on the basic device, the bark beetle attachment for the chainsaw may initially be of a standard drum or disc type. When making each of these devices yourself, you will need to use various parts.

The disc bark beetle consists of a working element that is driven by a V-belt. When using a coroder, the initial speed of constant rotation of its working part can be quickly changed, based on the power indicators of the motor of the used chainsaw and the dimensions of the driven metal pulley. In this case, the main thing is that the elements correspond to the dimensions of the structure, and are securely fixed in the nozzle device.

The factory drum bark beetle design includes a standard drum and a standard cutter. Each of the parts is mounted on the assembly of the bearing being used. The production of elements can be ordered from a turner. The main thing is that the material used for grinding parts is as strong as possible and does not have any traces of corrosion. In this case, the metal should be light enough so as not to overload the chainsaw engine.

The factory drum bark beetle design includes a standard drum and a standard cutter. Each of the parts is mounted on the assembly of the bearing being used. The production of elements can be ordered from a turner. The main thing is that the material used for grinding parts is as strong as possible and does not have any traces of corrosion. In this case, the metal should be light enough so as not to overload the chainsaw engine.

The finished cutter and drum will need to be secured to the standard bearing assembly. The installation of the elements must be done in such a way that the grooves in the device are as narrow as possible.

The finished cutter and drum will need to be secured to the standard bearing assembly. The installation of the elements must be done in such a way that the grooves in the device are as narrow as possible.

Installation subtleties

Before installing the device on the chainsaw, you must read the rules.

- First you need to clean the gasoline device.

- Items such as side cover, bar and chain need to be removed.

- Since the side cover may contain accumulated small particles of wood, it is necessary to use compressed air and blow out the machine.

- You need to use a small rope with knots to unscrew the spark plug, stop the piston and crankshaft. Then you can unscrew the clutch.

- You need to unscrew the calm. It is necessary to remove the clutch cup from the crankshaft and either replace it or mount a pulley on it.

- The assembly must be carried out in the opposite direction. It is necessary to mount the grinder attachment on the standard tire. The nozzle is installed on 2 fastening screws. Cover the side cover and tighten with the screws.

- The stem of the adjusting screw must line up with the hole in the nozzle. If it does not match, the belt cannot be tightened. If everything matches, you can tighten the belt.

How to make a grinder from a chainsaw at home?

It is difficult to find a gasoline tool that can be compared to a chainsaw in terms of the number of homemade products.

Winches, boat motors, motor-drills, motorbikes, go-karts, coroders can be designed on a common motor basis - a gasoline chain saw.

Among the simplest homemade chainsaw products, one cannot fail to mention the grinder, the performance and versatility of which allows you to work with various natural and artificial materials.

In order to convert a chainsaw into a grinder without a factory adapter, you will need:

- powerful chainsaw - "Calm" 180 or any other professional grade will do;

- working unit from the grinder;

- 3 factory serviceable tires of size 40-50 cm;

- 2 drums;

- belt.

Progress:

- run the belt parallel to the tire;

- equip the saw with a pulley and fix it on the drive sprocket;

- remove the gear from the head assembly of the working grinder and pre-grind it;

- assemble the pulley according to the dimensions and weld it to the structure;

- Shorten the 2 remaining guides - they should not interfere with the normal operation of the belt. It is desirable that one of the tires be sharpened for the installation of the grinder unit and connected to welding;

- weld them to the structure;

- buy grinding wheels, fix them and start working.

Optionally, you can replace the saw air filter with a more durable one, although most modern saws do not need this.

The range of these accessories is wide enough and is available for most modern chainsaws.

It consists of a drive drum (pulley), which is connected to the motor through a belt drive and rotates directly from it, a guard and fasteners.

The process of re-equipping a saw into a grinder with a ready-made auxiliary device looks like this:

- study the instructions for its correct installation;

- remove the chain saw guide, and also release the clutch;

- aggregate the pulley onto the drive shaft of the saw sprocket;

- connect a belt drive with a saw blade, which will help to change the torque of the new device (otherwise a gearbox is needed);

- take the studs that came with the grinder attachment, or use those fasteners that were removed along with the saw bar and fix the adapter with them.

Angle grinders, popularly known as the "grinder", can be recreated from numerous hand-held gasoline and power tools. But the option that we will consider using a chain saw is considered the most convenient and lightweight.

The advantages of such home-made devices are:

- autonomy - the gasoline tool does not depend on the availability of power supply, like factory-made electric grinders, which require electrical outlets and extension cords to turn on;

- high power, not comparable with the effort of factory electric grinders - the power of gas cutters based on household power saws is usually several times higher than the thrust of professional models of electric grinders;

- ease of design and assembly - everything you need for this can be found at home or bought at the nearest tool store;

- price - a grinder from a chainsaw will cost several times cheaper than its original counterpart.

The disadvantages of home-made gas cutters are:

- their sensitivity to metal dust - saw air filters quickly clog up and fail. This entails problems with starting the engine - it starts to stall, does not keep revs and wears out faster;

- danger to operator's health and life - sanding discs often burst and fly to the sides, which threatens the operator and others.

This can result in not only equipment breakdown, but also injury to the operator.

To prevent this from happening, it is recommended:

- use a protective casing - it must be new, complete, without chips and deformations;

- grinding wheels should be chosen in diameter up to 11.5 cm - large elements will disable the grinder faster;

- the set of adapters "grinder" must correspond to the modification of the saw itself - this will not only save you from the hassle of installation, but also help save the life and health of the user.

Pros and cons of a homemade saw from a grinder

When developing technology, designers, along with functionality and high performance, pay great attention to the safety of the tool. In homemade devices, folk craftsmen do not always adhere to this rule, since the usual cost savings often come to the fore.

And all the advantages are basically limited to this low cost.

However, in addition to the low cost of homemade products, on closer examination, handicraft electric saws from a grinder have many disadvantages, both technical and in terms of safety.

- The fragility of the structure due to the lack of a lubrication system.

- High probability of overheating of the electric motor due to unbalanced loads.

- Extremely low level of protection and safety when using a saw from a grinder.

Second adaptation option

The main design features of this device:

- it is fixed on the guide of the saw headset not in one place, but in two, at the tip, as well as at the beginning (constructional type - frame, which ensured maximum strength);

- the fastening area can be displaced, it all depends on your needs along the guide, which makes it possible to set the desired width relative to the size of the log;

- the component (guide) of the device can be located at any distance in relation to the tire, which also allows you to navigate in the work on the required dimensions of the boards and beams (first of all, the thickness).

How to work with such a device? Simply and easily:

- the first cut is made in a horizontal plane using a guide, a structural part of the frame installed on a log;

- the second and further cuts are made, focusing on the other main surface, which usually serves as the flat surface of the previous move.

What if the operator needs to cut a log whose diameter is larger than the saw guide on the tool? Then you need a complex chainsaw attachment for ripping. Please note that in this case, even the rated engine speed will not allow the lubrication system to release so much oil that the entire chain is evenly lubricated.

To improve the quality of lubrication and to avoid rapid wear of the bar, sprocket and saw element, more consumables are supplied to the end of the guide from the additional system (can be made from a hose and a reservoir). In order for the oil to be supplied by gravity, the reservoir is mounted on an elevation in relation to the guide.

Uneven sharpening

According to the instructions for sharpening the chains, the teeth should be grinded at the same distance, and regardless of which side they are located on. Observing this simple requirement, you can protect yourself from the problems associated with the fact that the chainsaw is being taken away when cutting.

When sharpening the chain with a file, it is not always possible to control the length of the tooth using the technique of counting the number of movements with a file.

This is due to the fact that the wear of the teeth is uneven, some are damaged more and more movements are required with a file in order to bring them back to normal, which means that the size of such teeth will decrease significantly compared to the rest.

How to avoid improper sharpening

In order to prevent a curve cutting due to uneven sharpening, you can use a special sharpening machine from time to time or with severe damage to straighten the chain. Buy a machine and sharpen it yourself or send it to a workshop for sharpening.

The fact is that the machine during sharpening is adjusted according to the most worn tooth, which has the smallest size among all. After sharpening, all teeth will have the same size, which will be equal to the tooth on which the adjustment was made.

Device for longitudinal cutting of a log

Longitudinal sawing of a log is carried out using a special device.It consists of the following components:

- adapter that is fixed to the bus in the base area;

- guide, the main task of which is to transfer the linear motion of the main component.

The last component was attached to the board on a log that the operator was about to saw.

This kind of device, as we have already found out, having considered its design features, guarantees a rectilinear movement of the guide rail, which ensures the accuracy of the longitudinal cut.

This device makes it possible to:

- cut the log into two parts;

- cut the material into quarters;

- cut a beam from a log that will be used for construction work (it will look neat, so that the slopes of the masonry look good);

- dissolve the logs into several beams or boards.

Please note that if you set yourself the task of cutting into logs and beams, you will have to change the position of the board many times. In addition, good dexterity will come in handy for an accurate cut. Initially, the loose end of the guide bar will go sideways

This will not allow you to achieve consistency of indicators and accurate parallelism of each side of the board or beams.

Initially, the loose end of the guide bar will slide sideways. This will not allow you to achieve consistency of performance and exact parallelism of each side of the board or beams.

A device of a similar design is used and, if necessary, cut the material in a horizontal position. If we carry out a comparative characteristic, then the device for cutting along the vertical allows at the output to obtain elements of wood of the same thickness, which makes it possible to characterize this nozzle as accurate and functional.

Advantages and disadvantages

The angle grinder attachment can be made from a variety of handheld gasoline and electric tools. But the simplest and most convenient method is using a chain saw.

Advantages of the device:

- they are autonomous, that is, a gasoline device will not depend on electric power, like electric grinders, which, on the contrary, need electrical outlets and extension cords;

- the nozzle can have a very high power;

- it is easy to design and assemble, the main thing is to have the necessary drawings and tools that can be purchased inexpensively at a hardware store;

- the price of homemade equipment will be cheaper than the cost of the original.

The disadvantages of home-made baits include the following points:

- they are too sensitive to metal dust: the filters of chainsaws begin to clog up and fail, and the engine may deteriorate: at first it stalls, and then it will not be able to keep the speed and will wear out;

- sanding discs can constantly burst and fly apart, and this is very dangerous for the employee himself and the people around him.

To make the device more secure, you need to follow some rules:

- limit the number of revolutions of the gasoline saw engine;

- you need to use discs that are designed for increased rotation speed;

- it is necessary to carry out work only using a protected casing;

- the structure must have an inertial brake;

- you need to use models that have a kickback protection function.

The angle grinder has:

- a pulley that can wear out or break, so you need to monitor the device and, if necessary, change the pulleys on it;

- in order for the nozzle to serve, it must have an adaptive key, consisting of a metal plate, with a hole and 2 steel pins;

- a special V-belt can transmit torque from the engine to the cut-off wheel (belt is a consumable);

- for attachments such as LBM 1 and NK - 100, spare bearings are needed, because the bearings themselves are a consumable item.