Helpful hints

To choose the right grinder, several important criteria must be taken into account.

To begin with, it is worth deciding on the size of the tool itself and the diameter of the disc used in it. Typically the smallest disc sizes are 115 mm and the largest 230 mm. In order to choose the right size, it is worth deciding what type of work the "grinder" will be designed for. Most often, small tools with a circle diameter of 115 mm are used for grinding and polishing all kinds of surfaces. Therefore, for processing work, it is worth choosing a compact angle grinder with a small disc diameter. But for cutting hard surfaces you need a large grinder.

No matter how professional the master working with the "grinder" is, he must always remember about the safety rules. After all, angle grinder is a dangerous tool, negligent handling of which can lead to disastrous consequences.

When cutting surfaces with a "grinder" sparks arise that can get into the eye, so it is extremely important to work exclusively with a mask to protect the organs of vision. It is also important to wear gloves and hold the grinder firmly with both hands so that it does not fall off the surface.

In the next video, you will find a brief overview of the grinder at the Bort BWS-1200U-SR metal warehouse.

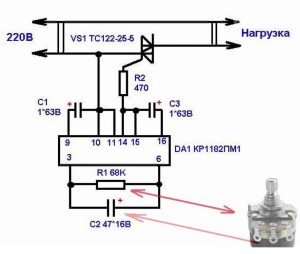

Speed governor circuit

Variable resistance alone is not enough to install this system. If you simply lower the voltage in the circuit, then the power and speed of the device will decrease. Having fallen to minimum values, such a voltage will not crank the grinder's shaft. Therefore, it is necessary to develop a complete scheme.

Variable resistance alone is not enough to install this system. If you simply lower the voltage in the circuit, then the power and speed of the device will decrease. Having fallen to minimum values, such a voltage will not crank the grinder's shaft. Therefore, it is necessary to develop a complete scheme.

The most modern regulators are manufactured using integrated circuits. The electrical circuit of the simplest tool includes an engine and a start button. These are reliable components that often outlive the device itself. Therefore, you should not be afraid of including electronic components in it in the form of a tuning module and a soft start system.