Recommendations for operation and repair

For long-term and fruitful use of angle grinders, it is recommended to follow all the requirements of the operating instructions for this device.

Also, do not press on the grinder when working, even if you are not satisfied with the speed - the additional pressure will lead to overload and damage to the device.

The most common malfunctions of grinders arise for several reasons:

- wear of parts (brushes are most susceptible to this);

- breakdown of the armature and stator - if you do not adhere to the operating mode prescribed by the instructions;

- breakdowns of the stator and rotor - due to malfunctions in the electricity network (voltage drops, overload);

- wear and tear of fastening parts (nuts, washers, etc.) and bearings;

- careless handling of the device (if you drop, throw the device on the floor or hit it against walls) leads to chips and destruction of the case;

- if you neglect preventive maintenance, do not regularly clean the mechanism, you run the risk of problems in the gearbox, as well as at the power button of the device.

If the angle grinder begins to work unevenly, does not respond to pressing the power button, or you smell burning, you can conduct the initial testing yourself. The reasons for such situations may be the wear of the brushes, and their hanging, and the malfunction of the power button. Turn off the device and try to spin the disc manually.

If the disc locks or turns only when a lot of force is applied, look for a breakdown in the gearbox. If the disc spins easily, test the power circuits. If there are no faults, check the brushes and the motor.

Specifications

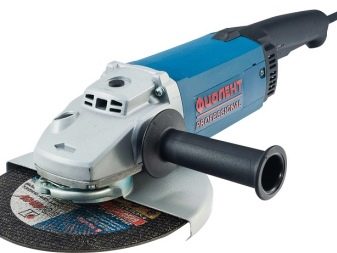

Builders usually divide angle grinders into large (grinding wheel diameter - 23 cm), medium (15-18 cm) and small (11.5-12.5 cm).

The table provides an overview of the characteristics of some models of angle grinders manufactured by the Fiolent plant.

|

Index |

MSHU 2-9-125E F0047 |

MSHU 3-11-150 F0034 |

Master MShU 2-9-125E M F0073 |

Master MShU 1-23-230 M F0072 |

|

power, kWt |

0,9 |

1,1 |

0,9 |

2,3 |

|

Disc diameter, cm |

12,5 |

15 |

12,5 |

23 |

|

Weight, kg |

1,6 |

2,5 |

1,6 |

4,6 |

|

Revolutions, rpm |

2 800-9 000 |

8 500 |

2 800-9 000 |

6 500 |

|

Smooth descent |

There is |

No |

There is |

There is |

|

Maintaining constant speed under load |

There is |

No |

There is |

No |

|

Index |

LNA 2-9-125 |

MSHU 5-11-150 F0035 |

MSHU 9-16-180 F0052 |

MSHU 9-16-180E F0053 |

|

power, kWt |

0,9 |

1,1 |

1,6 |

1,6 |

|

Disc diameter, cm |

12,5 |

15 |

18 |

18 |

|

Weight, kg |

1,6 |

2,5 |

2,8 |

2,8 |

|

Revolutions, rpm |

11 000 |

8 600 |

8 400 |

8 400 |

|

Smooth descent |

No |

No |

No |

There is |

|

Maintaining constant speed under load |

No |

No |

No |

No |

|

Index |

LNA 1-20-230 A |

MSHU 1-23-230B F0075 |

MSHU 1-20-230B F0031 |

MSHU 3-11-150 F0033 |

|

power, kWt |

2,0 |

2,3 |

2,0 |

1,1 |

|

Disc diameter, cm |

23 |

23 |

23 |

15 |

|

Weight, kg |

4,6 |

4,6 |

24,6 |

2,5 |

|

Revolutions, rpm |

6 500 |

6 500 |

6 500 |

8 500 |

|

Smooth descent |

No |

There is |

There is |

No |

|

Maintaining constant speed under load |

No |

No |

No |

No |

The smooth descent system, implemented in many models of "Fiolent" grinders, protects the gearbox and drive from overloading when the device is turned on.

Also, in the absolute majority of models, good ventilation of the mechanism is provided, which prevents clogging of the units and helps to cool the working mechanism. The gearbox is protected by a casing made of aluminum alloy, which also prolongs the life of the device and serves as an additional dissipation of excess heat. The actuator is covered with a double layer of insulating material for better protection.