Classification of motor pumps by engine type

First of all, pumps differ in the type of engine installed. The most common units are:

- gasoline;

- diesel;

- gas;

- electrical.

The portable petrol pump is versatile. With a relatively small size, it develops a fairly high power. It is easy to use and fully autonomous. Units with an electric starter are easy to start in all weather conditions and demonstrate stable performance.

Gas models are in many ways similar to gasoline ones, only a liquid propane-butane mixture is used as fuel.

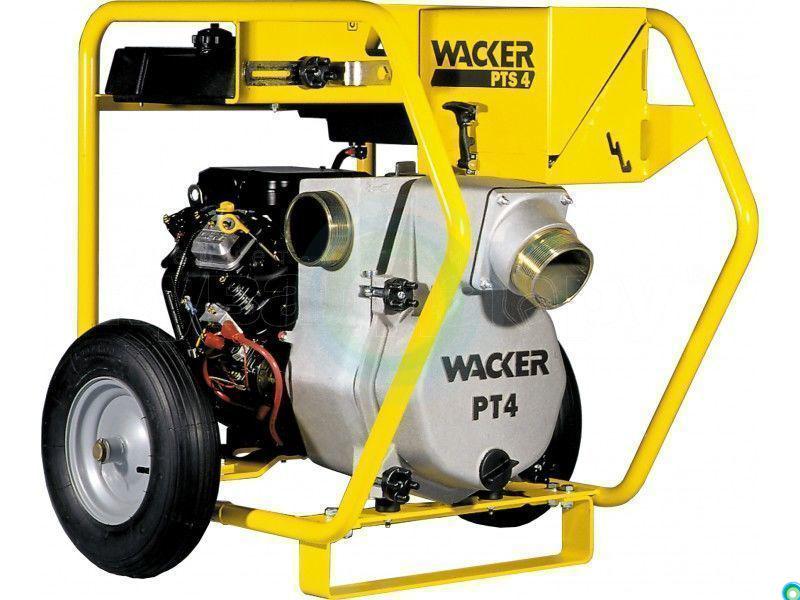

A diesel pump is needed where a high flow rate is required. These self-priming pumps are usually heavy. They are used as stationary or mounted on a trailer. They can be used as a high pressure source for pumping water over great heights and long distances.

The electric pump is extremely easy to operate, does not require special maintenance and frequent repairs. It can work in unventilated rooms, pits and wells, where equipment with an internal combustion engine cannot be installed due to the emission of exhaust gases. But a motor pump with an electric motor has one significant drawback: it cannot be used far from landscaped areas with a reliable power grid. But in urban utilities or at a summer cottage, it can be used with extreme intensity.

Top Models

There are a huge number of manufacturers on the modern market that produce gasoline motor pumps. One of the most popular is the SDMO company. Over the years of its activity, the company has been able to establish itself as a reliable manufacturer. A large assortment of motor pumps allows each person to choose the best option for him.

In the production process, SDMO uses exclusively high-end powertrains from such giants as Mitsubishi and Honda. The range of the company also includes various fire-fighting options, which are distinguished by high pressure and can provide a rise of water up to 57 meters.

The company offers its customers units for clean and polluted water. One of the main advantages of the SDMO models is the high-quality impeller, which ensures the endurance and durability of the units.

Another well-known manufacturer of gasoline motor pumps is Champion. It offers high quality devices for pumping water with particles up to 30 mm... The assortment includes a huge number of motor pumps.

For summer cottage use, the Champion GP30 model will be the ideal solution, which is characterized by a capacity of 100 liters per minute.

Thus, gasoline motor pumps will be extremely useful in the household, and sometimes even irreplaceable. They are characterized by mobility, affordable price and efficiency. Despite the minimum fuel consumption, they can show high performance without any problems, which favorably distinguishes them against the background of electric options.

In the selection process, you need to pay attention to the characteristics and materials from which the motor pump is made

For an overview of the Champion petrol motor pump, see below.

Installation, start-up and operation

To install mud pumps, in spite of the fact that they are often operated in rather harsh conditions, you should choose the most level platform in order to provide the equipment with high stability. The device should be checked for leaks both before the first and before all subsequent starts, which are carried out after each refueling of the fuel tank. In addition, before starting a gasoline or diesel motor pump, you must once again make sure that all its structural elements are securely fastened.

The motor pump should be installed at a level close to the water level. As the suction lift increases, the pump power decreases.

After the pump for pumping out dirty water is installed, an intake hose is connected to its suction pipe, and a pressure hose or a fire hose is connected to the outlet. If the pump will be used to pump liquid from a reservoir, pit or tank, at the bottom of which there is mud sediment, the immersion depth of the end of the intake hose should be adjusted so that it is at least 25-30 cm from the surface of the sediment. The intake hose of the motor pump did not get solid particles of a too coarse fraction into its working chamber; a mesh filter with cells of the appropriate size can be put on the end of the hose, which is in the thickness of the pumped liquid medium.

In order for the centrifugal pump, which the mud pump is equipped with, to begin pumping out water, its working chamber must first be filled with liquid. This is the most significant disadvantage of this type of pumping equipment. In most modern models of mud pumps, a special vacuum automatic device is provided for performing preliminary pumping of the pump working chamber, driven by the exhaust gases generated by the drive motor. Old models and a home-made pumping unit for pumping out dirty water are not equipped with such a device, so you will have to fill the pump working chamber manually.

Running the pump dry will destroy the seals. If the pump was turned on without water, turn it off immediately, wait until it cools down and fill with water

After completing all of the above actions, the mud pump is started according to the following algorithm.

- Using a hand pump, the pumps pump gasoline from the fuel tank, after which they gently press the foot starter pedal several times.

- Press the starter button and open the damper on the carburetor of the motor pump by about two-thirds of the maximum position.

- By abruptly pressing and releasing the starter pedal, an attempt is made to start the pump motor. In the event that it was possible to start the engine, the choke on the carburetor is moved to the middle position for the period of warming up of the drive unit. After warming up the engine, the motor pump (this takes about 20-30 seconds) is closed and the equipment is used at full capacity.

That is why one should not only strictly observe all safety measures, but also constantly monitor the technical condition and correct operation of the equipment itself. In particular, it is necessary to ensure that the motor pump does not overheat, stand steadily and do not vibrate strongly, and also that there are no kinks on the hoses or hoses through which water is pumped. In addition, for the device to work efficiently and for a long time, it must be regularly serviced.

Popular manufacturers and models

On the modern market of this type of pump, there is a huge range of units from a variety of manufacturers. Today in Russia, devices made in Europe or Japan are especially popular.

- Japanese models are in great demand due to their high quality and small dimensions. The device has an approximate lifespan of 5500 hours. Motor pumps made in Japan can run on both gasoline and diesel. These devices are slightly more expensive than their counterparts. The most popular Japanese-made model is the Yanmar YDP 30 STE.

- Another solid company for the production of motor pumps is Fubag. The products of this manufacturer are also in demand in Russia. The most popular models are Fubag PG 950 T and Fubag PG 1300 T. Fubag is a German brand. And even if the components are created in China, this does not in any way affect the quality of the product.

- For the past few years, Russia has also been producing motor pumps. The Caliber trademark is very popular.These units are ideal for home use when you need to pump out water from a pool or irrigate an area. All products manufactured by this brand are also assembled in China.

- In addition to the products of the Caliber brand, Vepr units from the Light series are popular in Russia. Lombardini engines are built into the devices.

Do not forget that models made in Russia do not have the capacity of analogs made abroad.

- Models of Chinese brands are very popular on the Russian market today. One of the highest quality representatives of such products is the DDE PTR80 model.

- Also, one cannot fail to mention the company Hyundai, which produces world-class cars. It also manufactures pumps for highly contaminated water. These are very durable, powerful and efficient models.

- If we talk about the budget line, then the Green Field brand is in the lead. The company has a good demand for its products and a huge number of positive reviews.

Device and principle of operation

The main operating element of such equipment is a conventional pump, thanks to which water is pumped at high speed. As for the type of pump, it all depends on the manufacturer of the equipment. Some use centrifugal versions, while others prefer membrane varieties.

The most popular today is the centrifugal pump, the main advantage of which is the presence of a unique mechanism. The principle of operation of such a device is that the gasoline engine drives the pump wheel, which leads to the suction of water.

As for devices with a pneumatic pump, they are considered not so popular and are mainly used for pumping heavily contaminated water provided that the size of the fractions does not exceed 5 mm. The required pressure is obtained due to the movement of the membranes, alternately squeezing out the water. To some extent, the work of such membranes resembles the work of a piston in a cylinder. A gasoline pump consists of more than just a pump.

It also includes the following elements:

- check valve, the essence of which is to prevent water from leaking out;

- several filters made in mesh form; their holes differ in different dimensions and change automatically depending on the degree of water pollution;

- the body, made of durable steel, is designed to protect the motor pump from mechanical damage; almost all such devices are distinguished by a collapsible case, which makes it possible to replace or clean the filters, but it is best to choose motor pumps that have a reinforced frame, which greatly simplifies the transportation process and protects the device from damage.

Garden motor pumps

The nature of the activities of organized structures, be it a gardening partnership, a farm, a construction company or a company serving housing and communal services, involves the use of pumping equipment that can work not only autonomously, but also as long as possible, and extremely efficiently.

Particular attention is paid to profitable exploitation. It is for these requests that a wide range of high-performance units based on gasoline and diesel engines is offered.

3. Fubag PG600

Please note - when carrying out maintenance yourself, you must use a torque wrench, because ignoring the recommended tightening torque will lead to equipment damage

| Characteristic | Meaning |

|---|---|

| Fluid quality | Water with particles up to 4mm |

| Productivity, m³ / min | 0.6 |

| Depth of sampling / height of water rise, m | 8/26 |

| Diameter of branch pipes, mm | 50 |

| Engine power (modification / fuel), h.p. | 4.8 (4-stroke, gasoline) |

| Weight, kg | 27 |

Video review of Fubag PG600 from the manufacturer:

4. Robin Subaru PTG 307 ST

The low cost of the equipment is offset by the cost of the 2.5-inch fire hose required to remove fluid over long distances.

Attention: modification of the fittings for smaller hoses in order to increase the outlet pressure - negatively affects the performance of the device

| Characteristic | Meaning |

|---|---|

| Fluid quality | Moderately dirty, inclusions up to 21 mm |

| Productivity, m³ / min | 1 |

| Depth of sampling / height of water rise, m | 8/23 |

| Diameter of branch pipes, mm | 76.2 |

| Engine (modification / fuel) | 4-stroke, gasoline |

| Weight, kg | 28 |

Video review Subaru-Robin PTG 307 ST:

5. Centaur KDM (LDM) 50

Of the significant drawbacks - only more expensive than gasoline, overhaul.

The centaur will appeal to those who seek to modernize equipment for comfortable operation - there is a place for an electric starter on the engine case, and within the frame there is always where to fix the battery.

| Characteristic | Meaning |

|---|---|

| Fluid quality | Pure water with inclusions up to 4 mm in diameter |

| Productivity, m³ / min | 0.36 |

| Depth of sampling / height of water rise, m | 7/27 |

| Diameter of branch pipes, mm | 50 |

| Engine power (modification / fuel), h.p. | 4.2 (4-stroke / diesel) |

| Weight, kg | 37 |

Video comparison of gasoline and diesel pumps:

6. WEIMA WMCGZ100-30

The downside is that the maximum possible savings occur only at low diesel engine speeds. The maximum permissible speed brings the flow rate to the level of the most economical gasoline unit.

Attention: the filled installation should be placed only in a horizontal position - oil starvation for a 4-stroke engine provides a tilt of 100; turning the device over will lead to leakage of fuels and lubricants

| Characteristic | Meaning |

|---|---|

| Fluid quality | Dirty water |

| Productivity, m³ / min | 2 |

| Depth of sampling / height of water rise, m | 8/30 |

| Diameter of branch pipes, mm | 100 |

| Engine power (modification / fuel), h.p. | 12 (4-stroke / diesel) |

| Weight, kg | 66.7 |

WEIMA WMCGZ100-30 video review:

7. Koshin KTH-80X

Due to the strong vacuum in the pump cavity, a decent draft is created, therefore the supply line hose, laid on the bottom without a filter, raises sludge and bottom debris.

It should be remembered that the maximum torque for this engine is reached at 2500 rpm, therefore, in heavily contaminated water, maximum gas is not the best solution. Neither in terms of performance nor in terms of fuel economy.

| Characteristic | Meaning |

|---|---|

| Fluid quality | Heavily contaminated water |

| Productivity, m³ / min | 1.3 |

| Depth of sampling / height of water rise, m | 8/27 |

| Diameter of branch pipes, mm | 75 |

| Engine power (modification / fuel), h.p. | 8 (4-stroke / petrol) |

| Weight, kg | 25 |

Video review about Koshin KTH-80X:

Is it possible and necessary to make a motor pump with your own hands

Some craftsmen report that piston pumps made from pneumatic bicycle pumps or pieces of water pipes are equipped with a motor to pump water. There is no doubt that if it is possible to start a motor pump of a similar design, it will not last long, and the efficiency of the motor will be at an extremely low level due to poor fit of the pump elements.

Being engaged in constant disassembly and assembly of units in an attempt to achieve an acceptable result is not the most rewarding task. Do I need to spend my time and energy on this? The cost of small household-class water motor pumps allows you to purchase a durable and efficient unit for your household.

Advice! Alternatively, you can try to adapt the drive from a small electric motor or a carburetor motor from an old petrol cutter to a ready-made hand pump. In this case, the layout solution will completely depend on the brand and design features of the units available.

Views

There are several main types of motor pumps, for example, with gasoline or diesel engines, for dirty or clean water. There are also a number of characteristics by which various aggregates are determined (described above). You can list the main types.

- Units for clean water. They have a small throughput for debris grains and are designed to transport liquid, which can contain grains of no more than 8 mm in diameter.

- Dirty water devices. They can pass liquids containing solids up to 30 mm in size. Liquids with a lot of sand or silt are not an obstacle for such devices.

- Pumps for medium-dirty liquids. They are used to transport water with grains up to 15 mm in diameter.

- Diesel water pumps. In such units, a diesel engine with a long service life is used. This type has the peculiarity of economical fuel consumption, but relatively low performance.

- High pressure pumps (fire motor pumps). They have a high output pressure - up to 70 meters (7 kgf / cm2). They are used for fire extinguishing and are therefore supplied with two outlet hoses of different diameters.

- Electric motor pumps. They are used most often in unventilated rooms, wells, where the exhaust gases from an internal combustion engine cannot be used for safety reasons. But in this case, there must be a good power source nearby.

- Motor pumps for salt water. They are used according to the same principle as the units for clean or moderately contaminated water. But the design must take into account the salty liquid, and this leads to rapid contamination of the pump with salt deposits and an increased metal corrosion process.

- For industrial purposes, the amount of transported water per unit of time and the diameter of the nozzles play a role.