Arrangement of a multifunctional model

For the manufacture of a multifunctional device, you must prepare:

- Steel pipes and corners;

- Sheet steel;

- Two wheels;

- Comfortable sitting;

- Welding machine and tool kit.

This adapter is a multifunctional model. It can be used for basic agricultural work and for transporting goods over uneven terrain over short distances. The structure can be equipped with such agricultural implements as a plow, a harrow, a tiller, a potato digger. In the winter months, a snow scraper can be attached to the adapter.

The main elements of the equipment are: the frame and hitch devices, as well as the wheelset and seats

The manufacturing process of the adapter at home takes place in several stages.

To ensure the balance of the structure and prevent additional overloads at the design stage, it is necessary to draw up a kinematic diagram. You can make it yourself or use a ready-made version.

This circuit is designed for the manufacture of an adapter designed to work on the "Neva" walk-behind tractor

When making and assembling the frame, it is important to provide for the arrangement of a fork with a sleeve. It is necessary to ensure free rotation of the trailer.

The frame of the structure is made of metal pipes and corners

The body of the structure is made of steel sheet. The height of its sides is made no less than 30 cm.

When making stands for the adapter wheels, you can use the diagram below

The simplest option for manufacturing a coupling assembly is a 15 cm long pin, which is stuck into the hole in the drawbar of the U-shaped motoblock "tow bar". The disadvantage of this option is quick wear: under the action of a freely rotating trailer, the hitch holes are quickly broken. To reduce wear, it is advisable to lengthen the U-shaped chain.

On the backbone frame of the adapter beam, stepping back 80 cm from the front edge, fix the seat. It is fixed with bolts. The adapter is ready. It remains only to check the functionality of the multifunctional device.

Recommendations for use

As practice shows, "Niva" goes for sale already assembled, but after purchase, before installing attachments, it is required to perform the correct adjustment of the main units. Competent preparation of equipment allows you to perform full-fledged work with the maximum use of characteristics.

For the full operation of the engine, the valve system must be adjusted. For this purpose, the carburetor is disassembled, as well as all screw connections on the upper and lower housing are unscrewed, followed by cleaning the elements. The next step is to adjust the valves using the adjusting screws.

In order for the equipment to serve as long as possible and maintain its performance, the following operating recommendations should be adhered to:

in the process of installing cultivation sheds, it is necessary to control the direction of the knives in the direction of the movement of the equipment;

if in the process of agricultural work the wheels slip, then it is recommended to install additional weights;

it is very important to control the quality and purity of the fuel used in the walk-behind tractor;

when starting up a cold device, it is necessary to close the air supply by means of a special valve;

after starting the throttle is set to position XX, and the engine warms up for about three minutes;

it is strictly forbidden to set the speed to maximum values at the stage of engine warm-up;

It is especially important to prevent oil from entering the surface of the air filter element during operation.

Before starting to work with adapters and walk-behind tractors, it is very important to familiarize yourself with the instructions supplied by the manufacturer.

Varieties of adapters for the walk-behind tractor

The adapter to the walk-behind tractor is of several types. The design is distinguished by the coupling method:

- Strong connection to the cultivator. The device has a separate steering wheel. Steering wheels are located at the front or rear (both options are possible).

- Movable connection. At the same time, the angle between the cultivator and the trolley changes all the time. Turning requires a lot of effort due to the fact that the junction is movable.

Devices are also subdivided according to the presence of driving wheels into:

- Front. The hitch assembly is at the back.

- Rear. The hitch assembly is located at the front.

Trailers are divided into:

In addition to garden work, universal ones are useful for transporting crops.

Trailers are divided according to the drawbar size:

Structures with a short drawbar are attached to low-power walk-behind tractors. Trailers with a long drawbar are attached to powerful cultivators.

There are 2 types of trailers: 1-axle or 2-axle. These couplings are factory designed by the manufacturer. The factory calculated such a design and mounted a towbar on it. A spring was installed under the seat, designed for the smooth running of the car on rocky surfaces.

The APM has special footrests, a brake that is pressed by the foot to stop the cultivator. The adapter was fitted with pneumatic tires, which provide a smooth ride at high speed.

You can buy a device in a special store unassembled in a package. Collecting it is easy. There is an instruction for this. Additional knowledge and skills are not required to assemble the device. Then you need to check how the structure works.

If all parts are working well, you can start using the device. When buying a structure, you must also choose a soft pad for the seat. Then the driver's work will become more convenient. The HorsAM IS 1 adapter to the Magnum walk-behind tractor, adapters to the PNO-1, AM-3 K, BUM-3, KTZ-03 cultivators are very popular among farmers.

Steering

A high-quality adapter with a steering wheel for a walk-behind tractor makes it easier to control the cultivator. In terms of its functions, such a walk-behind tractor is comparable to a mini-tractor, only it is more economical in fuel consumption. The standard APM unit from the Krasny Oktyabr manufacturing plant does not have a rudder.

The control is carried out using the steering wheel of the cultivator. But other manufacturers produce steering units. The cart is designed for more comfortable work on the cultivator, so the presence of a steering wheel will make the operation easier.

With movable joint

With a movable hitch of a trailer with a cultivator, the angle of the vertical axis between the cart and the cultivator changes. It is easier to make such a device, but when turning, you will need to apply more strength. This type of trailer is inferior in geometric characteristics: the turning radius becomes larger.

Front and rear adapters

There are several types of trailers, depending on which wheels are driving:

- Front-wheel drive. The unit is fixed at the back of the walk-behind tractor. This is the simplest and most popular modification. It makes it easy to operate the cultivator and carry out a large amount of work.

- Rear drive. The unit is located in front of the cultivator. This design makes it possible to carry out work when using a hitch located at the rear of the cultivator.

- Four-wheel drive.The trailer can be located both in front and behind the cultivator. This design differs from the previous ones in that not 2 wheels rotate, but all 4 wheels at once. Such a device performs the functions of a mini-tractor. This increases the maneuverability of the structure, its cross-country ability, additional adhesion to the soil is carried out. The 4x4 drive is considered the most efficient.

How to make an adapter for the Neva walk-behind tractor?

Step by step guide

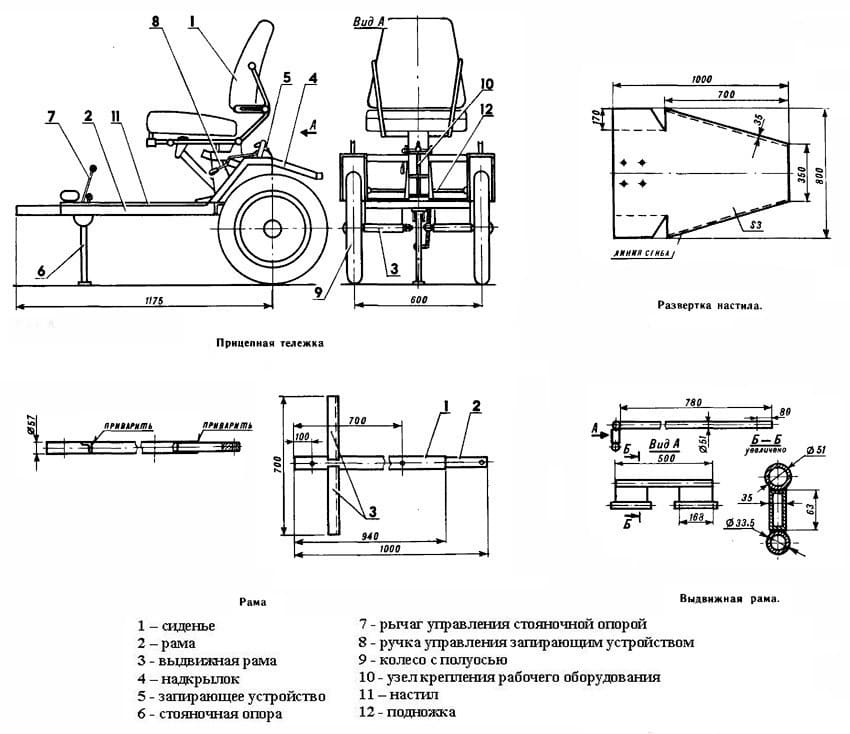

The standard equipment is presented as a steel frame. Before starting to create it, a drawing of a device for a walk-behind tractor is being prepared. The device is made from a profile pipe with a size of 1.7 meters. A pipe (50 centimeters in size) is cooked to one part of the material at a right angle. The last component is the attachment wheel strut lock. The height of the racks is 30 centimeters. For the handicraft adapter for motor vehicles, wheels from a construction and garden cart are used. They are installed on bushings with a bearing assembly.

Braces are welded to the base pipe and bushings, the length of which is directly dependent on the degree of their slope relative to the structure. The dimensions of the adapter frame are 0.4 × 0.4 meters. To adapt the equipment to the frame, a channel is cooked (size - 0.4 meters). The side pipes are bolted together. A handle with 3 knees is cooked to the frame (sizes - 20, 30 and 50 centimeters). To multiply the applied forces, the product is equipped with the same handle (75 centimeters long).

The hitch can be found in the store

If this mechanism is performed independently, in this case, close attention is paid to strength. The seat is mounted on a metal base welded to the main tube

The equipment made is ready to use.

How to make an adapter to a walk-behind tractor with your own hands?

After reviewing the drawings, you can proceed to the phased assembly of the adapter.

It is important to strictly follow the described algorithm.

If an adapter with a seat is used, the walk-behind tractor turns into a mini-tractor. The chair is selected at your discretion, but products with built-in shock absorbers are more suitable so that you do not have to install springs.

The frame is assembled in a certain sequence:

- A shank is welded to a piece of pipe with a diameter of about 6 centimeters. A swivel bracket will be mounted on it, fixed with a pin;

- The frame is welded perpendicularly with a cross-piece with dimensions of 5 * 5 centimeters;

- A sheet of steel is welded to the frame with a corner, the thickness of which is three millimeters;

- The lateral edges of the sheet with a length of about one centimeter are folded down to protect against cuts;

- The wings are bent and welded. The wing covers are welded onto the upper part, which are equipped with reflectors.

The main frame must be equipped with an additional retractable one, the thickness of which is 5 centimeters. They are fastened together with a bolt.

It is better to supplement the structure with a trunk, which is manufactured according to the following scheme:

- The frame is being assembled. The required central water pipe with a diameter of 1 "and somewhat labor with a smaller diameter (½ and ¼");

- The central tube is reinforced with additional tubes for support, the structure is welded to the trunk;

- Support pipes are connected to the block rod and gearbox.

The height of the legs depends on the location of the luggage compartment. It cannot be located above the instrument panels, fuel and oil tank.

The swivel bracket is manufactured following the following scheme:

- A workpiece from a pipe with a diameter of 5 centimeters is welded and bent. Two steel bushings are welded to the upper part, which provide swinging of the device along and across the axis;

- One side of the bracket is fixed on the shank, and the other - on the walk-behind tractor;

- For free installation and removal of the bracket, you can weld on the handle.

You need to take care of the rear-view mirror (suitable for a car or moped).The part is installed on the handle of the unit or attached to the rear of the trunk.

You need to purchase a ready-made mechanism - a brake system.

It is installed according to the following scheme:

- The rod of the blocking unit is dismantled, the thread on its surface is extended using a special die;

- A durable steel stop is created;

- A hole is drilled in the rod, the diameter of which is within 3-10 millimeters;

- The powerful return spring is installed and secured.

At the last stage, an axle with wheels is installed. Parts from old technology are suitable: a motorcycle or a moped. The axle may be too long, so it is shortened with an electric hacksaw.

In addition to detailed drawings, it is worth considering the proposed videos on the manufacture of the adapter.

A homemade adapter according to the schemes described above can be used with the following brands of motoblocks: Salute, Agro, Neva, MTZ.

The designed front adapter for the walk-behind tractor with your own hands will facilitate the work on the processing of the personal plot and garden. An additional device transforms a motor cultivator into a mini-tractor. If necessary, they install such agricultural implements as a plow, a digger, a planter, a hiller on the converter.

Creating a trunk for the adapter

You will need a trunk for collecting and transporting crops. Due to the fact that after mounting the trunk, the center of gravity of the walk-behind tractor is transferred, this element will also become indispensable when driving on hilly terrain. The trunk is made in the following sequence:

- First, assemble the frame - for this, take a few water pipes. One of them should be central, and have a diameter of 1 inch. All other pipes should be ½ ”or ¼” in diameter;

- Place the support pipes on the central tube and weld it to the trunk;

- Fix the support pipes to the block rod and the gearbox.

You can choose the height of the supports based on the position of the trunk. At the same time, remember that it should not lie on the walk-behind tractor, but hang over it. The trunk is mounted by means of supports over those elements of the walk-behind tractor that do not require free access to themselves. Never fasten the part above the instrument panels, as well as the fuel and oil tank.

Types of adapters

Depending on the attachment to the device, walk-behind tractors can be:

- rear - the hitch is located in the front, and therefore the adapter itself is in the rear;

- front - hitch - in the rear, respectively, it is located in front of the unit, but with a steering wheel.

For the area of use:

- shortened - small in size. Used with units designed for light work;

- elongated - overall and heavy, used with heavy-duty walk-behind tractors.

Depending on the selected walk-behind tractor, you can choose an adapter suitable for it

Depending on the selected walk-behind tractor, you can choose an adapter suitable for it

Depending on the body:

- body - there is a body for transporting goods of different dimensions;

- bodyless - used exclusively for clutching a walk-behind tractor.

In addition to the above classification, they can also be conditionally divided into simple and universal. The latter are used, in addition to their direct purpose, also for the carriage of goods.

Steering

The steering adapter provides the ability to turn an ordinary walk-behind tractor into a real mini-tractor. The engine power will remain unchanged, but the number of functions performed will increase significantly.

The attachment takes place thanks to a hitch that is placed in front of the adapter.

The design includes the following elements:

- a pair of wheels;

- clutch mechanism;

- brake and gas;

- operator's seat;

- frame.

At the back there is a mechanism to which, if necessary, additional attachments can be attached.

With movable joint

Such units are also called a break adapter. It is the lightest and most economical device to manufacture.The movable clutch is located at the front. The disadvantage is that you have to turn the entire mechanism, without using additional control. Because of this, the radius and angle of rotation will be larger.

Front and rear adapters

The front adapter is similar in design to the steering adapter. However, the clutch mechanism is located at the back. This type of construction is very convenient as it can be disassembled and easily transported.

In the rear, the layout is opposite to the front one - the hitch is in front of the unit, respectively, the adapter itself is at the back.

The front one is most often used in those works where the strength of the unit plays a key role, namely, digging, loosening.

Features of the adapter design

This attachment includes:

- frame;

- driver's seat;

- a pair of wheels;

- wheel axle;

- coupling device.

That is, the adapter gives the impression of a cart that is attached to the main equipment. As a result, it makes it look like a mini tractor.

Now let's talk about each component in detail.

To make a front adapter for a do-it-yourself walk-behind tractor, a frame is required. A body or a driver's seat is attached to it. The frame is mounted on the chassis.

The driver's seat is attached to the frame for ease of use. This was conceived in order to make it pleasant and easy to operate the equipment in the process of gardening.

Wheels and wheel axle make gardening easier for the operator with this small tractor.

There are two types of wheels for a home tractor - rubber and metal. The metal wheels can be used for reliable work in the fields. The rubber wheels are equipped with a deep tread pattern. This allows the operator to move the machine on unpaved roads and, if necessary, off-road. In any case, the wheels on the adapter are supplied upon purchase in a set for the equipment itself.

But if the user wants to change them, you need to pay attention to their type and size.

Device for coupling (fastening) with a walk-behind tractor. Mounting for the MTZ unit is made of steel or cast iron, using welding

The hitch is one of the essential building blocks. It provides a secure connection to the motorized part of the trailed implement. The most used is the U-shaped attachment point, because thanks to this device, the vehicle is more stable.