Solid fuel water heating equipment

The main advantage of such boilers is the ability to create a completely autonomous heating and hot water supply system. Availability and safety of fuel storage, ease of repair, long (from 15 to 50 years) service life are also important factors. Modern models allow maintaining the required coolant temperature at the outlet in automatic mode.

A certain inconvenience in the operation of this boiler creates the need for regular fuel loading, which excludes the possibility of automatic heating mode. In addition, maintenance - cleaning from ash or slag, monitoring the combustion chamber - will take time and effort.

Gas generating solid fuel water heating devices are pyrolysis boilers that work on the basis of fuel combustion (additional combustion of wood gas generated by burning wood). In such a boiler, much less soot and ash is formed due to more complete combustion of the fuel. Accordingly, and a higher efficiency (85%), compared with the usual (60%). However, such independently one or two-circuit gas boilers are dependent on electricity, gas and more expensive.

How to properly install supply and exhaust ventilation

There are several objective reasons why ventilation in the boiler room is necessary:

- supplying a sufficient amount of oxygen to the boiler to maintain the combustion process;

- removal of carbon monoxide gases outside the premises, accidentally falling into the room from the firebox;

- compensation of the amount of air used in the combustion process.

Please note that for the combustion of 1 kg of firewood, 4.6 m3 of air will be needed, and the combustion of coal requires about 8-9 m3, based on the quality of the fuel.

- Air inlet and outlet openings must be located on different sides of the boiler room. The inlet opening is made at the bottom of the wall as close as possible to the heat generator, and the exhaust outlet is made under the ceiling.

- If the boiler is equipped with a smoke exhauster or a blower fan, the hood should not be placed next to it (read: "How to choose a smoke exhauster for a solid fuel boiler - types, differences"). Otherwise, the draft will reverse, and the exhaust hole will become inlet.

- If the door from the residential building goes into the furnace, then it is advisable to build in the inlet grille in the canvas. Warm air entering the boiler will improve the fuel combustion process.

- The size of the exhaust opening should be smaller than the supply one, since most of the incoming air enters into a thermochemical reaction and comes out through the chimney in the form of CO2.

You can calculate the required size of the hood, if the boiler power is multiplied by 8 - we get the area of the hole in cm2.

Basic principles for connecting a solid fuel unit

Considering how to properly connect a solid fuel boiler, it is necessary to pay attention to the basic piping elements that ensure the safety of the heat generator. It is a safety group and a mixing unit

The safety group, which includes a pressure gauge, as well as a safety valve and an air vent, mounted on one manifold, is installed directly at the outlet of the boiler unit. A pressure gauge helps to monitor the pressure in the system, an air vent serves to remove air locks, and a safety valve releases excess steam-water mixture when the pressure exceeds the set parameters.

Important! It is forbidden to install a circulation pump, shut-off valves between the branch pipe and the safety group. A mixing unit based on a three-way valve with a thermal head is installed together with a bypass (jumper) connecting the supply and return pipes, due to which a small circulation circuit is formed

A mixing unit based on a three-way valve with a thermal head is installed together with a bypass (jumper) connecting the supply and return pipes, due to which a small circulation loop is formed.

The system is working, which protects the boiler from condensate and temperature shock, according to the following scheme :

- While the fuel is burning, the valve shuts off the flow of the cooled coolant from the large heating circuit. As a result, the circulation pump drives a limited volume of the coolant in a small circle.

- A sensor is installed on the return pipe, which is connected to the thermal head of the three-way valve. When the coolant in the return pipeline heats up to 50-55 degrees, the thermal head is triggered and pushes the valve stem.

- The valve smoothly opens and the cooled coolant begins to gradually enter the boiler jacket, mixing with the heated one from the bypass.

- When all radiators warm up and the return temperature rises to values that are safe for the boiler, the three-way valve closes the bypass, completely opening the passage to the coolant flow through the return pipeline.

The basic scheme for connecting a solid fuel boiler to a heating system is as simple and reliable as possible, the piping can be installed independently.

It is important to know how to connect a solid fuel boiler using polymer pipes in order to avoid common problems:

- It is not safe to use polymer pipes for piping the boiler - they may not withstand an emergency increase in temperature and pressure. Therefore, it is recommended that the piping be made with steel or copper, and the polymer pipes should be connected to the collector that distributes the coolant along the heating circuits. In extreme cases, the metal pipe is mounted only between the boiler supply pipe and the safety group.

- The use of a thick-walled polypropylene pipe for the return pipeline in the section between the three-way valve and the boiler branch pipe leads to the fact that the attached temperature sensor reacts to heating of the coolant with a noticeable delay. Better to install a metal pipe.

Connecting a solid fuel installation with a hydraulic boom

Connecting a solid fuel installation with a hydraulic boom

The pump for a forced heating system is installed on the return pipe between the three-way valve and the boiler. This arrangement allows it to circulate water or antifreeze in a small circle. It is impossible to put a circulation pump on the supply pipe, since the device is not designed to work with a steam-water mixture that forms when the coolant overheats. Stopping the pump will speed up or provoke an explosion in the heating boiler, since the cooled coolant will no longer flow into it.

How to reduce the cost of strapping

The basic scheme for connecting a solid fuel boiler provides for the use of a three-way mixing valve equipped with a thermal head and a patch sensor. This equipment is quite expensive and can be replaced with a cheaper option - a three-way valve with a built-in thermostatic element. Such a device has a fixed setting - the valve is triggered when the temperature of the medium reaches 55 or 60 degrees (depending on the model).

Installing a valve that maintains a fixed temperature reduces the financial costs of installing the protection of a solid fuel unit from condensate and thermal extremes. The ability to flexibly control the temperature of the coolant is lost, deviations from the set value can reach 1-2 degrees, but this is not critical.

Design features

At the moment, several types of water heating equipment are produced, each of which has its own design.Setting the differences between them will allow you to correctly evaluate the technique and choose the appropriate model.

Fire-tube

These types of heaters are equipped with a pressurized gas-tight firebox. For their work, automated burners equipped with blowing fans are used. This feature allows the equipment to work without smoke exhausters, while all the necessary parameters are easily adjustable. As a result, the device is highly efficient and has an efficiency level of 92–95%.

Almost all fire tube boilers are equipped with a cylindrical furnace and smoke tubes inside. Depending on the layout, two- and three-way models are distinguished. This equipment was used in the 19th century and has undergone many changes since then. These boilers are in demand today because they are easy to use and do not require serious maintenance.

Considering the features of the equipment, first of all, it is worth noting that fire-tube boilers can be attributed to gas appliances. On their surface, special pipes are installed along which the coolant moves.

Fire tube boilers are of two types:

- Steam. The heating medium is heated by means of steam, therefore the inside of the boiler is equipped with a special container.

- Hot water. With the help of the liquid, the entire body is heated.

The principle of operation is as follows: gas or fuel is supplied to the burner located on the front of the body, which is burned. The role of the firebox is assigned to pipes located in the water, where all combustible material is burned.

Despite their relatively compact size, such devices are highly powerful and safe to operate. In addition, they can function autonomously, but this will require additional purchase of special equipment in the form of a pressure gauge, a water pressure sensor, and so on.

Water tube

In such models, water is heated by passing through metal pipes. The working pipes located outside are heated by the products of fuel combustion. Due to the design features, an increase in the heating surface is allowed, for which a larger number of water pipes are used.

Thanks to the convection flow in such systems, the movement of water is accelerated, which means that the heat transfer coefficient also increases. The upper limit of the outlet steam temperature reaches +550 ° C.

Water-tube models are more compact than flame-tube models. It is a one-piece piece of equipment housed in a rugged case. The principle of operation of water tube technology is the natural circulation of water.

Number of contours

At the moment, the market offers a wide variety of heating equipment. First of all, you need to understand for what purpose the boiler is being bought: only for heating or even preparing hot water. To solve the first problem, a single-circuit model is sufficient - they are more affordable and less fuel intensive.

To solve the second problem, a two-circuit device should be chosen. These models, in addition to being able to heat water in a flowing way, are additionally equipped with a built-in boiler, the volume of which varies from 150 to 180 liters. Instantaneous heating is optimal if you need to wash dishes or take a shower in the country.

How the water circuit works

Before choosing and installing a heating system for a house with your own hands, you need to figure out how a wood-burning stove with a water circuit works.

- Heating of water occurs only when burning wood masonry or other type of solid fuel inside the firebox;

- Mostly coal or wood is used in a wood-burning stove;

- One load provides burning for 3-4 hours;

- To ensure a longer burning time, you should choose a gas generator type stove for a house;

- Savings in heat production are achieved by using a high quality heating stove. Also, the efficiency of heat exchange processes and accurate control of the temperature of the coolant affect the efficiency;

- The wall, where the water jacket is provided, accumulates thermal energy;

- This ensures rapid heating of water and its maintenance in a given temperature range for a long period;

- In practice, it has been proven that a solid fuel stove with a water circuit functions equally effectively with two types of circulation - forced and natural.

Advantages and disadvantages

Choosing a solid fuel stove for your home, which is additionally equipped with a water circuit, you get efficient heating and hot water equipment with a wide range of advantages.

The main positive aspects are:

- Low cost of fuel. This is the most affordable fuel that can be used for heating boilers;

- Equipment availability. The oven itself for the home is quite low. Some people build them with their own hands. Although it is recommended to give preference to products from a trusted manufacturer;

- High reliability rates. A solid fuel furnace equipped with a water circuit demonstrates excellent reliability indicators, which has been proven by a multi-million audience of users;

- Long service life. Reliability results in excellent durability;

- Rare service intervals. Although the stove uses solid fuels, the equipment does not require complex maintenance. The most important point is to remove ash from the ash pan;

- The benefits of ash. Ash, which is formed as a result of the combustion of solid fuel, can be easily removed by hand. At the same time, you should not throw it into the trash. Since such a stove is the prerogative of private houses, you probably have a plot of land. Ash acts as a highly effective fertilizer;

- Possibility of conversion. A solid fuel boiler is wonderful in that, if necessary, the furnace can be re-equipped by adapting the equipment for operation on gas, diesel fuel, etc.

But in addition to the obvious advantages, such wood-fired home heating systems have disadvantages.

- Relatively low efficiency. With an impressive consumption of wood, the efficiency of the boiler will be no more than 70-80 percent.

- The need for regular loading of the furnace. You have to regularly add firewood to the stove with your own hands. Although there is an automatic feeding oven on sale today. You will need to make one download. Further, the automation of the wood-burning stove will independently add the required amount of firewood to maintain the specified parameters. As a result, one download is enough for several days. The disadvantage of automatic feeding is the certain requirements for the wood or coal used.

Boiler and chimney cleaning and maintenance rules

When the heat transfer of the TTC decreases, its condition should be checked. It may have been caused by soot contamination. To clean it, it is necessary to wait until the entire structure has cooled down completely, open the grates and the blower, and use a metal poker to clean the accumulations from the walls.

The soot settles on the remaining fuel, which must also be removed in order to reload the chamber. It is difficult to clean the chimney on your own, especially if there are several bends. Soot and condensate accumulate on its walls, as a result, traction worsens, and the risk of fire increases.

liquid thermal insulation

Step-by-step instructions for installing the boiler

The selection and arrangement of equipment is not yet a guarantee of the smooth operation of the system, because its elements still need to be correctly installed. And you should start with the arrangement of the boiler room, in which all this should be located

A small instruction in pictures will tell you what you need to pay special attention to

Table 2. Correct step-by-step installation.

Steps, photo

Description

Step 1. Arrangement of the boiler room

The boiler is installed after the repair is completed in the room where it will stand.

At the same time, it is important that:

non-combustible materials were used in the decoration;

the foundation was prepared for the boiler;

the air flow was necessarily organized in the room;

an outlet for the chimney must be provided in advance in the wall or ceiling.

Step 2. Choosing a place for the boiler

When choosing a place for installation, keep in mind that there must be at least 700 mm between the walls and the back and side surfaces of the boiler drum.

From the front, this distance must be at least 1250 mm (if the unit is top-loaded). If loading is done from the front, the width of the door must also be added to this distance.

Step 3. Aligning the body position

It is very important that the position of the boiler does not deviate from the vertical, so when installing it is necessary to use a level. Place it on the firebox with the lid folded back.

Step 4. Preparation of components

According to the boiler passport, check its complete set, which may vary depending on the manufacturer. All other elements necessary for installation, purchase in advance in accordance with the selected scheme.

Step 5. Preparing the toolkit

Naturally, you will need tools: adjustable, gas, ring and open-end wrenches, as well as screwdrivers of different sizes, a square and a grinder.

Step 6. Installing the combustion regulator

An FUM tape is wound onto the regulator stem, and it is installed in its regular place. Tighten the nut, set the desired temperature and fix it in this position with the screw.

Step 7. Installation of the heating element thermostat

A little further than the combustion regulator there is a hole for installing the heating element regulator. If you do not plan to install it, then a plug is simply screwed in there.

Step 8. Installation of heating elements

Next, the heating element itself is mounted - or a plug instead of it.

Step 9. Installing the crane

For ease of operation or current repair of the system, taps are installed at the inlet and outlet of the coolant from the boiler.

Step 10. Build the security group

Put together a pressure gauge, air and safety valves, which ensure the safety of the boiler and come with it in a set. The group is placed in front of the shut-off valves.

Step 11. Connecting the pipeline to the boiler

To connect the supply and return pipes to the boiler, you need to make swivel pipes. It is better if the connections are welded rather than detachable.

Step 12. Sealing the chimney landing site

In order for the chimney to sit tightly and not let the combustion products into the room, the place of its landing and all other connections are treated with a sealant.

Step 13. Water connection

Install a flexible pipe on the faucet mounted at the very beginning, through which the hydraulic part of the boiler will be filled with water. Open all the taps, raise the pressure to 1.3 atm, and check the tightness of the system. There should be no leak anywhere.

Step 14. We fire the boiler

Now, in accordance with the instructions, you can load the firebox with wood and light it up.

The installation process is presented only in general terms, since each boiler model has its own nuances, and the connection diagram may be different.

A few tips for the correct operation of the boiler

For your boiler to be as efficient as possible, it must be properly operated.

Here are the points you need to pay attention to so that the firewood burns longer:

- When firing up the fuel, the flap on the boiler must be completely open;

- The long burning mode is set only after heating to +600 degrees;

- The coolant at the outlet must have a temperature of 65 degrees or more;

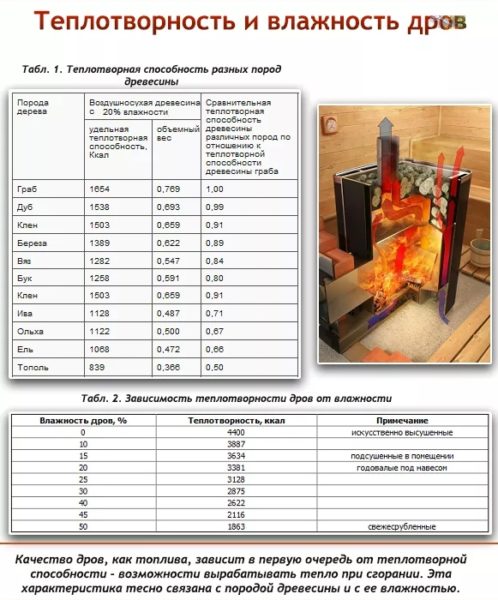

- If the boiler design does not provide for laying damp firewood, their moisture content should not exceed 20%;

Dependence of heat production on wood species

Dependence of heat production on wood species

- To avoid tar settling on the walls of the furnace and chimney, heat the boiler with deciduous wood - acacia, birch, alder, aspen. And by the way, the rock has a great influence on the amount of heat received;

- Do not grind the wood - the larger the pieces, and the more densely they are stacked to each other in the firebox, the longer they will burn;

- To prevent the logs from hanging, they should not be too long. The ideal size is the length of the combustion chamber minus 5 cm.

Two examples of wood-fired heating boilers

Two examples of wood-fired heating boilers

General installation instructions

Before buying a heating unit, you need to determine the place of its installation. The furnace is intended for this, but often there is not enough free space in it, since it is occupied by an existing gas or other heater. Then the installation of a solid fuel boiler in a private house can be done behind the wall of the furnace room, in the annex. A frame made of metal structures is installed and sheathed with sandwich panels or profiled sheet with insulation. The option is convenient for those who are going to heat with coal; there will be no dirt inside the house.

All inexpensive solid fuel boilers for a low-power home can be placed directly on the rough floor screed. They are lightweight and do not exert vibration loads on the base, since they are not equipped with a fan or a screw conveyor for feeding pellets. For units with a capacity of more than 50 kW, it is recommended to arrange a concrete foundation, which should rest on the ground and compacted crushed stone bedding. The foundation is made 80-100 mm above the level of the screed, while it should not be connected to it. Base devices also require long-burning boilers that have a mechanism for lifting and lowering a heavy load.

Projects for private houses usually provide for the installation of a chimney in the thickness of the wall with the exit of the pipe through the roof. If the shaft is absent or is occupied by an existing gas heater, it will be necessary to install a chimney for a solid fuel boiler. For this, it is better to use metal double-walled chimneys with insulation. They are lightweight, assembled from sections of the desired length and can be easily attached to the wall of the house. For turns and branches, the same double-walled tees and branches are made. Methods for installing chimneys with and without an exhaust shaft can be seen in the figure.

Chimney installation

The combustion room must have natural exhaust ventilation. When heating boilers are installed in a private house, the hood is provided through a shaft in the wall. The shaft is parallel to the chimney, only of a smaller section. If it is absent, a transfer grille is placed in the outer wall, it should be located under the ceiling of the room. The role of the hood is as follows:

- In the furnace, a vacuum is created, as a result of which supply air from other rooms is sucked in there and used for combustion. Boiler plants with a capacity of 50 kW and above require the organization of a separate supply ventilation.

- Removal of combustion products that have accidentally entered the room.

The approximate layout of the equipment and the installation diagram of a solid fuel heating boiler are shown in the figure.

Solid fuel boiler installation diagram

Often there is no sewer outlet in the boiler rooms of country houses. This is not entirely correct, since sometimes it is necessary to empty the system or the boiler water jacket. The discharge of the safety valve is sent to the same drain.

Installation procedure

To carry out the work, the following instructions for the installation of solid fuel boilers are offered:

- Release the product from its original packaging.

- If there is not enough space in the combustion room, then it is better to assemble the product on the street. Install all doors and ash pan drawer and other items supplied separately. The fan and automation devices do not need to be installed; this is done after the installation of the boiler.

- Move the unit indoors and place it on a foundation or floor in such a way that the gas outlet is aligned with the flue pipe.At home, the installation of a solid fuel boiler with your own hands must be done with an assistant, the weight of the equipment is rarely less than 50 kg.

- Fix the boiler to a foundation or a screed so that there is no distortion.

- Connect the chimney, install a fan with a control unit and a safety group.

- Connect the boiler to the heating system according to the selected scheme.

How hot water boilers differ from other heating devices

A hot water solid fuel boiler is a device inside which, as a result of the combustion of solid fuel, the temperature of the carrier reaches 95-115 ℃. In this case, hot water circulates in the heat exchanger at a pressure of 0.6 MPa. This is the main distinguishing feature of hot water boilers from other devices, in which the movement of the coolant, first in the boiler, and then in the heating circuit, occurs freely.

Please note that when using hot water boilers, ordinary tap water with the addition of certain impurities and additives acts as a heat carrier. These additives are necessary in order to maximize the life of a complex hot water circuit, that is, a pipeline through which the circulating heat carrier is heated to a certain temperature.

When the water inside the circuit heats up to a temperature close to boiling, impurities dissolved in water begin to actively deposit on its walls. Under no circumstances should the boiler water boil. Since the heating medium is heated under pressure, it does not boil. In this case, the pressure of the coolant inside the water circuit is always higher, the water pressure at the points of maximum heating. A feature of solid fuel boilers is that they need more boiler water to heat the system than all others.

The heat carrier, which has warmed up to 115 ℃, gives off heat energy to the heating system. At the same time, the pressure in the boiler pipes is kept at a stable level. In such a system, an increase in pressure inside the heat exchanger will have a beneficial effect on its operation, since this equalizes the temperature of the coolant along the entire length of the pipeline, and scale does not fall on its walls.

As for the combustion chamber, in hot water boilers it looks almost the same as in any other solid fuel apparatus. The selected type of solid fuel, most often coal, enters the furnace, where it is burned. Heat energy is transferred through the walls of the firebox to the water circulating inside the heat exchanger. In the production of hot water boilers, manufacturers design them in such a way that the fuel burns intensively and gives off heat as efficiently as possible.

To cool the combustion products formed inside the furnace, the boilers are equipped with convective packages. In contact with their wide surface, carbon monoxide gases cool down to 200 ℃. It is noteworthy that more intensive cooling of combustion products can lead to condensation.

Classification of boilers by purpose

Not only residential buildings and apartments, but also industrial facilities need high-quality heating. Manufacturers provide for this fact and produce powerful installations, with the help of which large areas are easily heated. At the moment, there are 2 categories of boilers: domestic and industrial.

Household

This is the name of the heating equipment installed in apartments, cottages and summer cottages. For small heated areas, these devices are ideal, but for the conditions of the enterprise, their capacity will not be enough. There are no special requirements for them, the operation is simple and does not imply the presence of special skills.

Thus, domestic boilers are used for heating and hot water supply of individual houses. Also, it can be objects of public utilities.

Industrial

Nowadays, all enterprises producing heat energy have industrial equipment installed. We are talking about gas, steam and solid fuel boilers, which are fully automated, safe and functional at the same time.

An industrial boiler used for space heating and hot water supply has many advantages.

The following advantages of use are highlighted:

- ease of maintenance;

- the ability to work from several types of fuel;

- adjustment depending on weather conditions;

- upon request, the equipment can be built into a block-modular boiler room.

To regulate the operation of such systems, instrumentation and built-in automatic mechanisms are used, which makes the units safe and reliable. For the manufacture of the outer shell of the boilers, strong steel or cast iron is taken, and they are delivered to the enterprise in the most complete form, which facilitates the installation work.

The most demanded boilers in the industry are gas boilers. The fact is that this type of fuel is now the most accessible resource and, when burned, releases the most heat.