Testing the engine

What does this code designation indicate? Error E02 signals a malfunction of the CMA motor or control board. Most Electroluxes have a collector engine installed, which can be checked by hand.

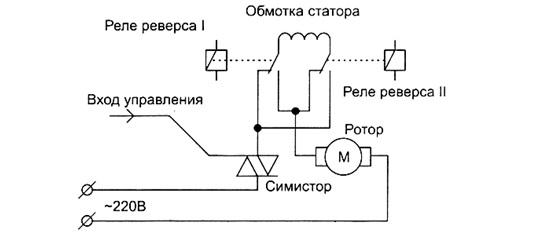

What to do before testing the motor? Initially, you need to understand the motor connection diagram. Most of the collector motors have a fairly simple circuit.

In Electrolux washing machines, a relay is used to switch the stator winding, and the contacts of the controller are used. The described accessories are located in the control unit of the washing machine.

The stator winding is divided into 2 sections. This design feature reduces the influence of intermittent interference caused by sparks on the manifold.

The drum of any washing machine rotates alternately in different directions. This movement is caused by a reversal of the polarity of the stator winding. In some models, a separate winding tap is provided; it is activated when the clothes are wrung out. In this case, the electric current is connected to either of the extreme terminals and this tap. At the stage of the main washing process, the stator winding is switched on through the extreme terminals, this ensures a leisurely, smooth rotation of the drum.

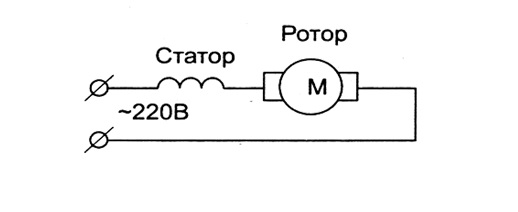

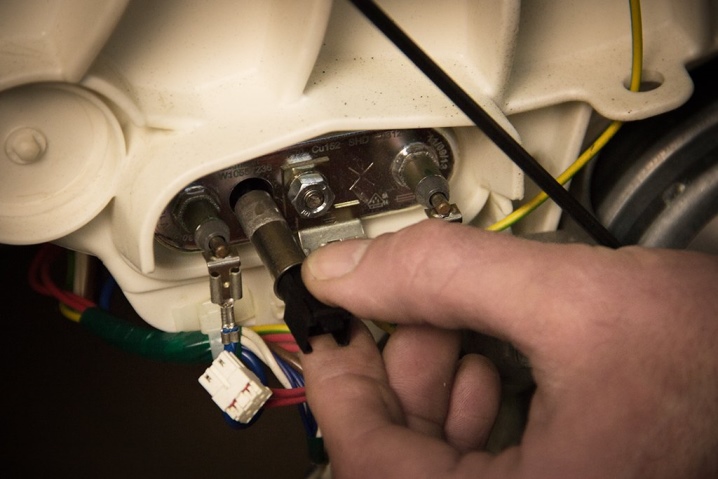

To check the motor and find a solution to the problem, it is necessary to connect the rotor and stator windings alternately and turn them on to the power grid. This connection diagram is visually represented as follows:

This diagnostic method has some disadvantages. Firstly, choosing this method of checking, you will not have the opportunity to be sure that the motor is in good working order by 100%. Regular rotation of the shaft will not be able to guarantee that the Electrolux machine will not give any malfunction at various stages of washing.

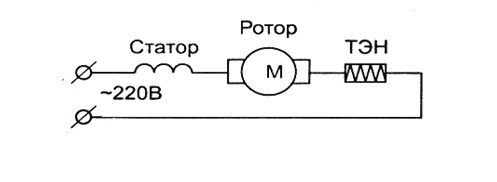

In addition, the connection of elements according to this scheme does not provide for protection. Therefore, if the engine "shorts" during the check, it will most likely simply fail. To protect the electric motor from possible damage, it is better to include an additional link in the circuit. As an additional element, you can use a heating element of a washing machine or just a high-power lamp (more than 500 W). The diagram will look like this:

The ballast included in the connection will protect the engine under test. When a short circuit occurs, the current will go to the heating element, which will begin to heat up.

There is another way to diagnose the engine in the Electrolux washing machine. The stator and rotor windings are connected in the same way as in the second scheme, only they are powered by a special laboratory transformer with a power of over 500W. The advantage of the method is the ability to constantly monitor the number of revolutions and take timely action in case of any failure. For greater safety, a 5-10 Ampere fuse may be used.

Instead of an autotransformer, it is allowed to use an electronic regulator for diagnostics, which is usually used to control loads of a given power. In this case, it is better to seek help from specialists, but if you have certain knowledge in electronics, you can carry out diagnostics and repairs yourself.

Another option for checking the motor is to observe how strong and bright the sparking will be between the brushes and the commutator motor. If there is significant arcing, the washer motor is probably defective.

It is in the above ways that it is allowed to check the electric motor of the automatic machine displaying the error E02

If, after diagnosing the engine, it was not possible to find a solution to the problem, you should proceed to checking another important element of the system

Burned out triac controlling UBL

The second possible reason when an E41 error appears is a burnt triac or a faulty control board. That is, the UBL is working normally, but the system does not receive a signal that a lock has occurred. To fix a damaged module, the circuit will have to be taken out and examined. This requires:

The second possible reason when an E41 error appears is a burnt triac or a faulty control board. That is, the UBL is working normally, but the system does not receive a signal that a lock has occurred. To fix a damaged module, the circuit will have to be taken out and examined. This requires:

- take out the dispensary for detergents by shaking the tray and pulling it towards you with an effort;

- find 2 bolts in the hole next to the cell for the cuvette and unscrew them;

- get 4 more screws located at the end of the panel under the top cover of the machine;

- take the panel with your hands and gently slide it up;

- pry the latches with a flat screwdriver;

- disassemble the panel case and take out the control board.

As soon as the board is in your hands, you should carefully examine its surface for defects, traces of combustion or mechanical damage. If there is no apparent reason for concern, you will have to resort to using a multimeter again and check each triac for breakdown. The following instructions will help you understand what to do to test a module.

- We transfer the tester to the mode of sound dialing.

- We touch the A1 and A2 contacts with the probes and look at the screen. When "1" or "OL" is highlighted, the triac is operational, and when the number is close to zero, it is necessary to correct the situation by replacing the part.

- When there is no TK between the terminals, we check the control electrode. We direct the ends of the device to the power terminals and the main electrode. At 80-200 there is nothing to worry about.

- We close the main electrode, and after a couple of seconds we remove the current, observing the state of the triac. If the switch does not close, then a full repair with replacement is required.

But it is better not to experiment with the board and entrust the solution to the problem with error E41 to the service center masters. Remember that a module is a fragile and expensive thing, so without experience and practice, it is easy to aggravate the breakdown.

What to do in case of mistakes

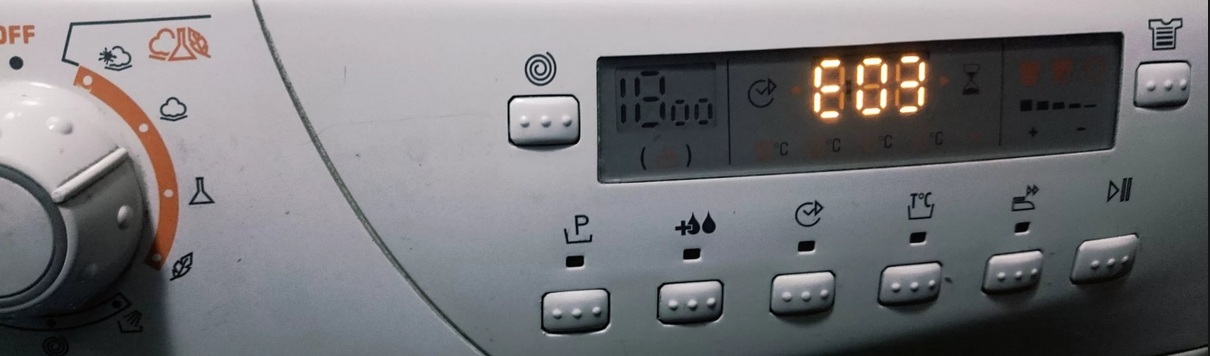

If an error code appears on the display, you need to decipher it and immediately disconnect the machine from power.

It is important to understand the meaning of the error and why it appears on the display.

Then you need to act based on the type of malfunction:

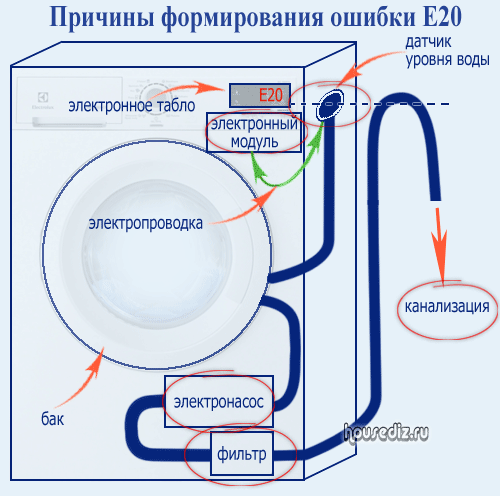

- E20: disconnect the drain hose, drain the water. If the drain is difficult, it must be cleaned. After cleaning, the error may disappear. The filter may also be dirty. It should be checked. The pump can also clog. It is better to entrust its cleaning to a professional if you are not confident in your abilities;

- E10: First you need to check the water pressure from the tap. Most often, the reason lies in the simplest. Then you need to inspect the inlet hose for integrity, for the absence of a clamp. If this is not the problem, then it is better to contact a professional. It is problematic to clean the filter or repair the control module on your own;

- E40: If the diagnostics showed that the door lock is faulty, then it can be repaired by replacing it with a new one. To do this, remove the clamp, unscrew the bolts, remove the lock, disconnect all wiring, install a new one. If the problem is a malfunction of the electrical circuit, then you need to check all the wiring by ringing them with a multimeter;

- E13: The most common cause of this breakdown is wear on one of the hoses. It is necessary to carefully check the equipment for water leaks;

- The machine does not pick up the powder. The technician is not able to detect this malfunction. Only the user can find unused gel or powder. The most common cause of this problem is a clogged dispenser. In this case, disconnect the machine from the power supply, completely remove the tray, rinse it under running water.

Causes

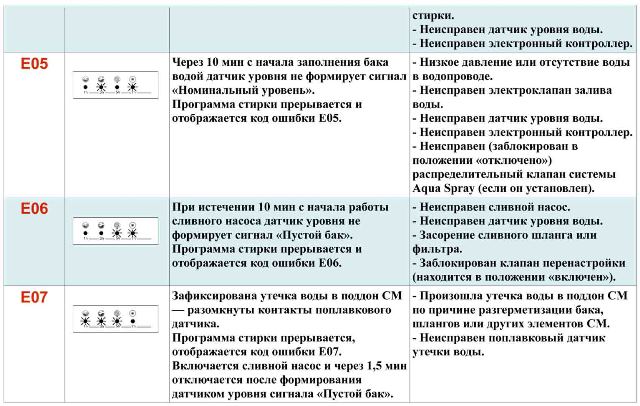

Each of the error codes has a reason (and more often than one) of occurrence. So, the E11 error code usually occurs when one of the water inlet valves or its control circuit on the electronic controller breaks down. This is the most common, but not the only reason.Among others - insufficient resistance of the valve winding (the norm is 3.75 Ohm), insufficient water pressure in the water pipes, clogging of the water inlet path.

If there are problems with the drainage of water (error code E21), it is worth checking the serviceability of the drain pump, the permeability of the filters, the pipe and the drain hose. It is the malfunctions and clogging of these elements and units of the machine that most often cause this kind of breakdown. It also makes sense to check the voltage of the drain pump winding (the norm is 170 ohms). Finally, the cause of this kind of error can be a malfunction of the electronic controller.

An EF1 error can also be associated with an exceeded drain time, and the EF2 code flashing signals an increase in foam formation, the root cause of which is also a clogged drain line. In this case, the sources of the problem are looked for in the drain hose or sewer, it makes sense to check the filter above the drain pump for blockages.

The reasons for the breakdown of the pressostat are mainly caused by clogging of the tube, malfunctions in the power supply, malfunctions in the program settings. The pressure switch is responsible for the overall performance of the washing machine, otherwise it is called a water sensor and a voltage sensor. That is why the failure of this element leads to the appearance of completely different "symptoms" - premature start of washing, the impossibility of activating the spin function of the laundry.

The causes of errors E40-E43 are associated with a loosely closed hatch door. It can be trash or foreign objects falling into the lock. That is, the search for the cause of the malfunction begins precisely from this zone. If everything is in order with the lock, then the cause of these error codes may be a skewed door. That is, the screws in the bolts loosened, the door "slid", so it is impossible to close it correctly. It is clear that in this case, tighten the bolts tighter with a screwdriver and return the door to the desired position.

Sometimes the reason for a loosely closed door can be hidden in power surges. You can check this in a simple way - unplug the washing machine from the mains for 10-15 seconds, and then turn it on again. Alternatively, try manually pressing the door to the hatch with your hands and wait for a characteristic click to sound and if the lock icon appears on the display.

Finally, the wear of the machine parts can become the reason for the door not closing tightly. On average, they are all designed for a 5-year service life. Malfunctions of the electric motor can be detected by the appearance of the error E50 on the display. Moreover, the cause of its occurrence may be a malfunction of the relay, bearings, the absence of a signal from the tachogenerator.

One of the weak points of washing machines is the heating element. One of the common reasons for the failure of a heating element is the formation of scale on its surface. Scale does not allow heat to pass through, that is, the heating element begins to overheat, and the heating of water during washing turns out to be insufficient.

Sometimes the heating element, on the contrary, heats the water too quickly and too much. In this case, the "fault" is the temperature sensor, which should be replaced. The relays that control the operation of the heating element may also fail.

Elimination

So, one of the most common problems is the lack of signals on the display when you turn on the machine to the network. Simply put, she does not react in any way to such actions. First of all, you should check if there is electricity in the network - plug other equipment into the outlet.

If everything is ok, check the power cord and plug. If damage is found, do not insulate but replace. The reason may be oxidation of the control panel contacts or burnout of the power filter or its elements. Elimination of this type of problem begins with removing the top cover (just unscrew the bolts). You will see the filter at the wall. When it burns out, swelling will be noticeable. In this case, the filter must be replaced. To check the keys, you must first remove the tray, after which the buttons will be visible (behind the module).

In case of problems with the intake and drainage of water, the first thing to do is to close the shut-off valve and unscrew the hose from the body. A filter will be found behind it, it is removed and washed under water, the same should be done with the hose. It makes sense to immediately dismantle the back cover and check the inlet valve located behind it with a multimeter (the norm is 2-4 ohms).

If water remains in the tank, the drain should also be cleaned. You can find it behind the door located at the bottom of the machine (on the front side). Opening this door, you will see a filter that needs to be unscrewed

Attention, at this moment water will pour out of the hole, so you should immediately prepare rags and buckets. By unscrewing the filter, it is washed, as well as the space that it closes

If the drum begins to squeeze the laundry poorly, and the machine vibrates strongly, check the tension of the drive belt. To do this, you need to unscrew the back panel of the device. If the belt has fallen off, you will immediately see it, just put it back in place (on the engine pulley). When the belt is worn out, it must be replaced. On machines with a classic motor, it may be necessary to replace the brushes. You need to check their graphite rods (remove from the case by disconnecting the contacts).

For information on how to read the error code in washing machines, see the next video.

All elements are working, but the error signal does not disappear

We figured out how to fix the problem. But sometimes a situation arises in which a known error can disrupt the operation of a washing machine for no reason. More precisely, the problem still exists, but it is not associated with the inflow or release of fluid, and the units responsible for this function normally. It turns out that the machine washes, but an alarm signal is displayed on the screen.

The reason for its appearance may be electronics. Specifically, it is the management block. It can fail for several reasons - from voltage surges, from frequent stops of the machine during the working process, from the presence of a factory defect, etc.

In this case, an experienced specialist will have to deal with this situation, since it is not recommended to dismantle and test the control unit module yourself if you do not have the appropriate skills for this.

Water level information

Samsung washing machine models are equipped with a special pressure switch that controls the filling of the drum with water. When the pressure switch does not receive the signal required to start work, the display generates an error.

E7

An encrypted error is notified by a water level sensor (pressure switch). The appearance of this alphanumeric value on the display is caused by a breakdown of the sensor itself or a violation of the integrity of the tube that connects the sensor to the drum.

1C

If the 1C code is displayed, then one of the following problems has occurred:

- breakdown of the sensor that controls the level of the incoming water;

- defects in connecting contacts;

- damaged, dirty or bent section of the tube belonging to the sensor;

- breakdown of the control system.

1E

The error code often occurs as a result of an elementary failure in the operation of the control system. Then it will be enough to turn off the household appliance from the network and turn it on again after 6 minutes. In addition, the error is caused by:

- discharge of the contacts of the control panel or pressure switch;

- problems associated with the pipe connecting the sensor to the pressure take-off tank.

Meaning of error code E40

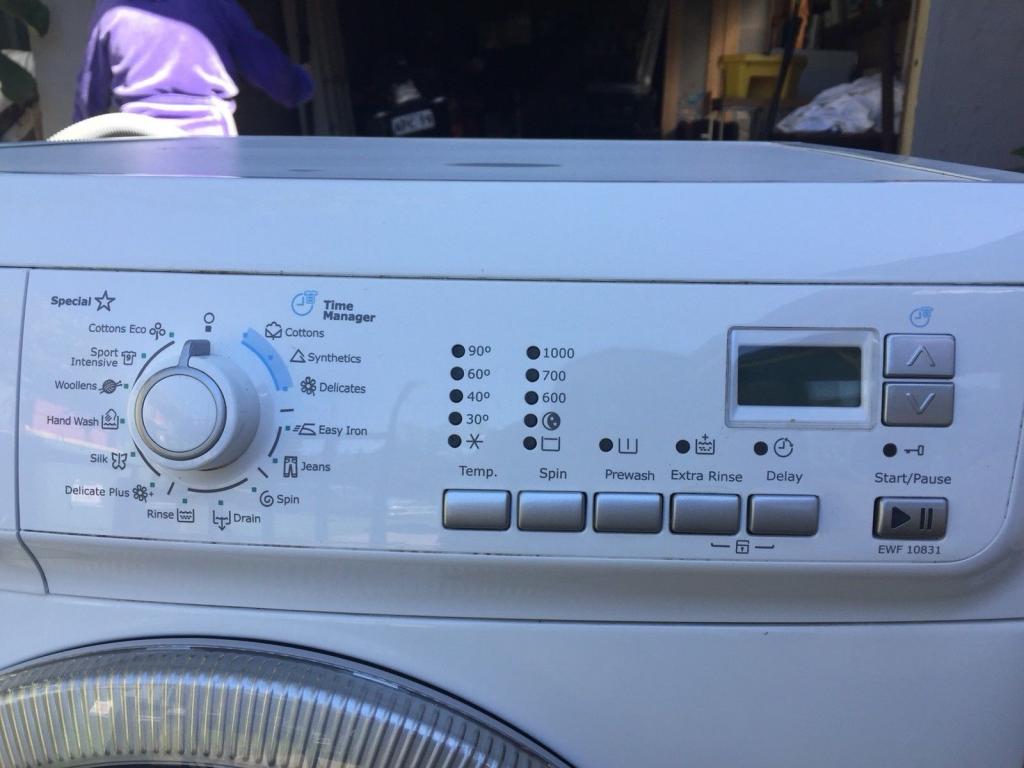

In every Electrolux washing machine, a letter and number combination like the E40 reports problems with the loading door lock. The code has a general concept. To concretize the culprit of the malfunction, you should enter the mode. The master copes well with this task, but the algorithm for general actions is as follows:

- simultaneously pressed two buttons located on the right of the control panel;

- while continuing to hold them, you must press the large orange button located on the side. We continue to press until the indicator lamps light up.

This method is recommended for use on machines that are not equipped with selector programs. If there is one, you should simultaneously activate and do not release for some time a pair of extreme buttons located on the right.

Ultimately, the screen will display an updated error code E40:

- E41 - the loading door is not closed tightly enough;

- E42 - lock refused;

- E43 - a part responsible for blocking has broken in the control module;

- E44 - door sensor malfunction;

- E45 - there were problems in the wiring connecting the UBL and the control unit.

Electrolux error codes and their elimination

What to do if the washer won't drain? As mentioned above, the reason may be precisely in the pump, which is responsible for draining the water.

There are errors that can be easily eliminated without using any tools.

There are errors that can be easily eliminated without using any tools.

To do this, you need to prepare:

- Phillips screwdriver;

- Multimeter.

To directly clean the pump, the cover is unscrewed and the impeller is checked. It is quite possible that there is a sediment on it in the form of hair, woolen threads and the like. Garbage is cleaned off as accurately as possible, which will make the pump operational. For diagnostics, you need to attach the probe to the surface of the pump and look at the multimeter screen. If the part works, then the device will give a result of 200 ohms, and if it is absent, it will be necessary to replace the pump with a similar model suitable for this particular device for washing clothes.

As soon as the pump is replaced, the equipment is launched necessarily in the testing mode in order to track the literacy of the product. If after all the steps taken, the error continues to occur, you need to check the pressure switch and the wiring that connects the sensor that controls the water level, the pump and the electrical board for operability. No less often, the problem arises precisely because of damage to the wires, and not the pressure switch, which is much easier to fix. The problem in the pressure switch will glow with errors E11 and E32.

Reasons for the appearance of the code, decryption

The e10 error on the Electrolux washing machine, according to the table attached to the manual for most models, stands for "no water in the tank or little water comes in." Such a decoding can be considered more than lengthy, because in this case there can be quite a few reasons. In fact, it is. An Electrolux machine generates a similar error if:

- there is no water in the water supply system;

- there are problems with the inlet hose;

- there are problems with the filler valve;

- there is a self-draining of water.

The question arises, why are we listing these particular reasons, because there are other error codes in the memory of the washing machine that can clarify the malfunction by localizing the broken unit? Sometimes this happens, but in most cases, either due to the specifics of the model, or due to the specifics of the malfunction, we will be forced to follow only the code e10, keeping in mind the above reasons for the malfunction. Since the machine simply does not issue other (refined) codes.

Eliminate the causes of the error

Since our "home assistant" from Electrolux decided to give us an error e10, then we will have to check all possible elements one by one, which, in one way or another, are connected with the drain and filling of water into the tank. It would be more logical to start with the simplest, which does not require disassembling the washing machine, because in 90% of cases, the e10 error is eliminated at the household level.

We identified the first reason as: “there is no water in the water supply system”. There is no need to explain anything here, because everyone can check if there is water in the water supply system, without instructions. We pass directly to the second point - a malfunction of the inlet hose. In this case, you must proceed as follows.

- If a water filter was installed on the inlet hose, it is necessary to turn off the water supply to the machine, unscrew the filter and check it, it may just be clogged with dirt and limescale, and water cannot pass through it into the tank.

- If the hose is double, leak-proof, check the integrity of the first layer.

- Check the tightness of the connections of the inlet hose with a pipe or a machine, although in order for water not to enter the tank, it would be necessary for the hose to come off completely, and such a problem is difficult to overlook.

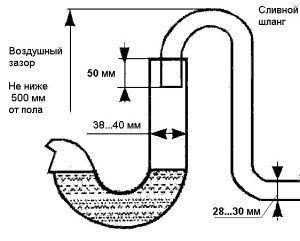

If everything is in order with the hose, experts recommend following to check if there is a self-draining of water. It is not difficult to verify this. First, lean over to the washing machine and listen, you need to hear how the water leaves the tank and gurgles in the drain. After the e10 error has surfaced, the machine stops working, which means everything will be heard well. If such a sound occurs, we proceed as follows. We check the drain hose; in no case should it lie on the floor. If so, raise the drain hose about 60 cm above the floor.

If everything is in order with the hose, experts recommend following to check if there is a self-draining of water. It is not difficult to verify this. First, lean over to the washing machine and listen, you need to hear how the water leaves the tank and gurgles in the drain. After the e10 error has surfaced, the machine stops working, which means everything will be heard well. If such a sound occurs, we proceed as follows. We check the drain hose; in no case should it lie on the floor. If so, raise the drain hose about 60 cm above the floor.

Worst of all, if the problem is in the filler, drain valve or pressure switch. To surely diagnose a similar problem, you need to seek help from a specialist. The professional will decide if the intake valve or other parts need to be changed.

Everything is fine, but the error still appears

In rare cases, it happens that the e10 error paralyzes the operation of the washing machine for no reason. That is, to be precise, there is still some reason, but it has nothing to do with the supply or discharge of water and the operation of the units that do it. In a word, the machine actually works "like a clock", but the system still gives an error, what's the matter?

The cause of the e10 error on the Electrolux washing machine can be electronics. Or rather, an electronic control unit. There can be many reasons for the failure of the control unit: voltage drop, frequent shutdown of the machine during operation, factory defects, etc. A specialist will have to figure it out, because you also should not disassemble and test the control module on your own, if you do not have special knowledge.

The cause of the e10 error on the Electrolux washing machine can be electronics. Or rather, an electronic control unit. There can be many reasons for the failure of the control unit: voltage drop, frequent shutdown of the machine during operation, factory defects, etc. A specialist will have to figure it out, because you also should not disassemble and test the control module on your own, if you do not have special knowledge.

In conclusion, we note that despite the fact that modern washing machines are automatic machines, they are able to carry out self-diagnostics and issue errors with a specific code, by which specialists can identify a malfunction, there are still problems. In particular, with the same error e10, which can be the result of a whole series of malfunctions, which once again confirms the idea - diagnostics and repair of automatic washing machines is the lot of professionals.

System board diagnostics

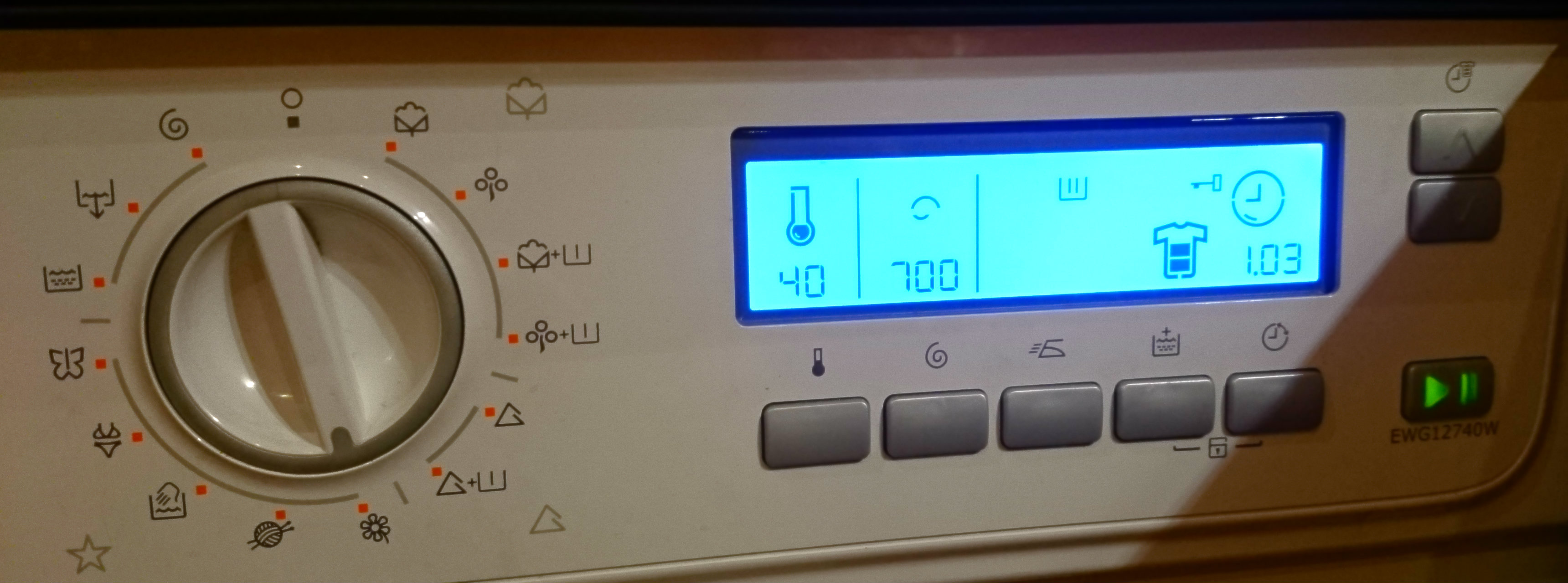

Error E20 in "Electrolux" may indicate problems with the motherboard. If the pressure switch and the wires are in good order, then it is necessary to check the electronics. But it is difficult for an unqualified user to do this, so the manufacturer recommends in this case contacting a service center or a specialist who knows the intricacies of electronics. In this case, the wizard will not only carry out diagnostics, but can also identify the real problem and eliminate it.

The control board in "Electrolux" washing machines breaks down quite rarely. Usually, when an E20 error code occurs, the problem is eliminated on its own.

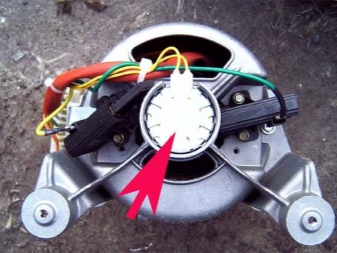

We carefully check the motor

- collector lamellas;

- rotor and stator windings;

- electric brushes.

Lamellae, which deteriorate after a short circuit in the windings, "suffer" more often. Due to current surges, the contact plates overheat and flake off, which introduces an imbalance in the operation of the motor. The "layers" are fixed with an adhesive solution directly on the collector, and the electrical connection occurs due to the formation of special hooks in the rotor section. Just the latter more often becomes impossible if, due to a breakdown, the cord breaks at the joint.

It is several times worse when the lamellas exfoliate when heated. Then the current passing through the plates and the winding becomes higher than the operating level and can lead to unpredictable consequences. You can confirm peeling by slowly turning the rotor with one hand: if you hear a clear crackling, then there is a defect. The operation of such a unit is prohibited.

Delamination does not occur by accident. This is caused by a jam in the bearings or starting the washing machine with half-open flaps when loading vertically.Also, through a similar defect, the lamellas "hint" at serious breakdowns in the motor or improper operation of the machine. With a slight flaking of up to 0.5 mm, the situation can be corrected by grooving the collector on a special machine. Do not forget about the control visual check, cleaning the case from chips and dust, manual cleaning of all irregularities.

Another problematic spot on the engine is the electric brushes. If they are worn out, then the operation of the machine becomes risky. The fact is that when the carbon tips are worn out, the "body" of the brushes begins to rub against the engine body, provoking the appearance of sparks. To minimize the risk of fire, the old pair must be replaced with a new one.

The choice of new parts should be taken very seriously. You can purchase a replacement through specialized stores, service centers, or on the Internet. In the latter case, it is enough to enter a request into any search engine, choose the organization you like, contact their support service, check the availability of a spare part, or place an order. You can navigate the assortment by the serial number of the washer, motor, or the old model. There are no universal brushes - each motor requires “its own” handpieces. Hardness also matters, as too hard coals can ruin the collector.

If there are no problems with brushes, windings and lamellas on the engine, there is only one option for a breakdown - the failure of the control board. There may be several reasons for the malfunction, but it is not recommended to diagnose it yourself. It is cheaper and more reliable to immediately contact the professionals, since the electronic module is an extremely fragile and expensive system.

Conclusion

Washing machines "Electrlux" suit users in many ways. They are quite budgetary, but they do their job perfectly. However, sometimes the technique produces errors, among which the most common is E20. The defect is usually associated with a blockage. Therefore, even at home, household appliances can be repaired.

To diagnose, you need to follow the simple steps described in the given article.

But it is important to be completely confident in your actions or to photograph every process. If there is no complete confidence in your abilities, then it is recommended to entrust household appliances to a qualified master.

Usually, repairs are not expensive because they do not require replacement of components. But if you need to purchase spare parts, you must choose them only on the advice of a specialist or be guided by the data from the instructions.