Cost and positive characteristics

Any hardware store today offers many varieties of adhesives that can be used to install tiles on any substrate. However, the described composition has advantages, including: water-repellent characteristics, the possibility of adjusting products for a long time, strong adhesion to the surface, resistance to frost and water, as well as the duration of operation of the resulting coating.

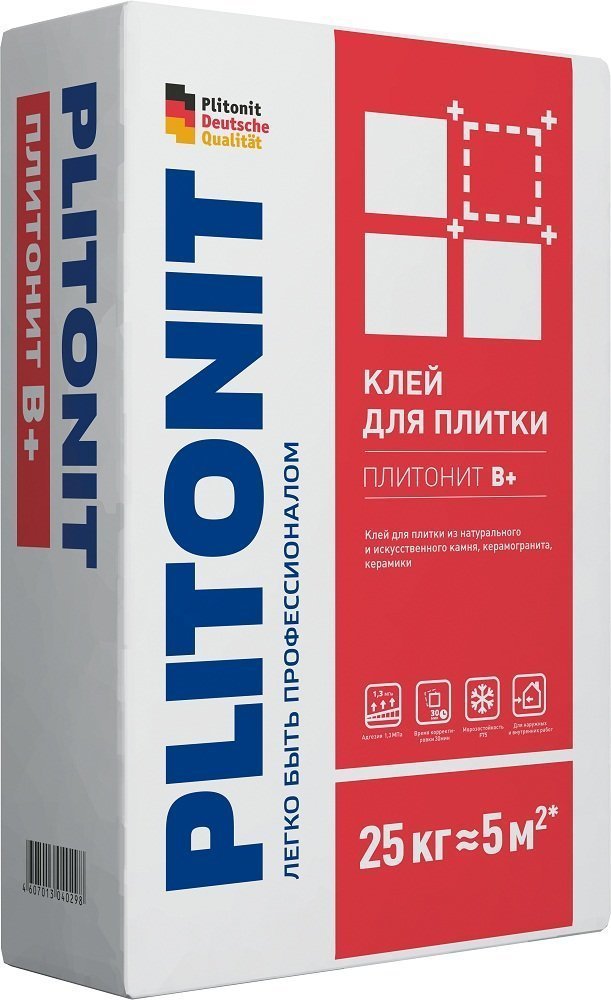

For a 25-kilogram bag, the consumer will have to pay 265 rubles, which, according to users, is an acceptable cost. Glue "Plitonit B", the price of which will allow you to calculate the consumption of the composition, is versatile, because it can be used both inside and outside the premises. The composition has become so widespread for the reason that it can be used in tandem with almost any roughing bases, which significantly expands the area of use.

Technology

Conditions

During work and during the next 3 days, it is necessary to maintain the temperature within the range from + 5 ° С to + 30 ° С.

The temperature of the mortar mixture during the work should be in the range from + 10 ° С to + 30 ° С.

Technology of work on preparation of the base

- The base for the cladding must be strong, free from dirt, dust, oils, grease, all types of paints and adhesives, as well as flaking elements.

- The base must be treated with a primer in order to increase adhesion, reduce water absorption, premature outflow of water from the mixture and dust removal of the base. We suggest using Plitonit Primer 1.

- Dilute in a ratio of 1: 4-1: 5 when working on Plitonit T1 + plaster. When working on a screed, the dilution ratio of the concentrate is selected based on the absorbency of the substrate.

- Use drinking water supply to dilute the concentrate. Stir the primer thoroughly before dilution and use. After freezing, it must be kept at room temperature until completely thawed, without forced heating.

- Surfaces are primed with a roller, brush or spray. If the soil has soaked into the base for 5-10 minutes and dried, re-priming is necessary. Re-priming and finishing work should be carried out after the first layer of soil has completely dried. Drying at an ambient temperature of 20 ± 2 ° C, a relative humidity of 60 ± 10% occurs in 1 hour.

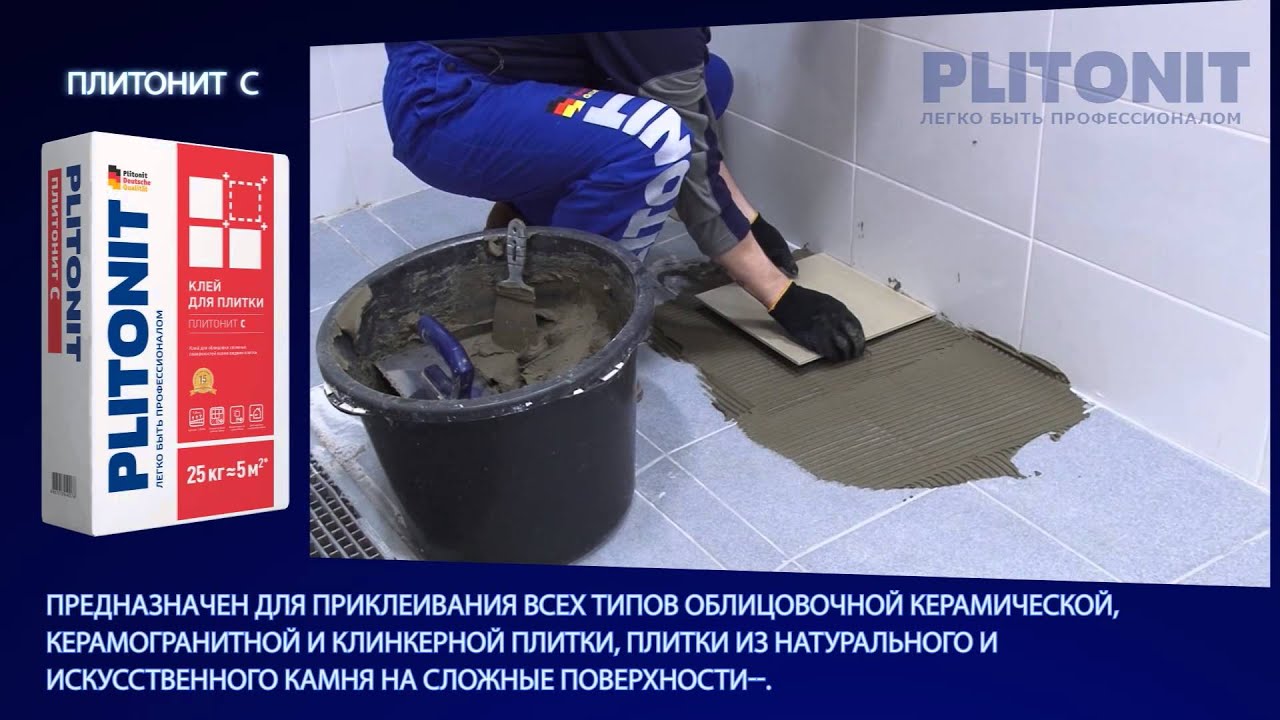

Cladding technology

- For facing work, we suggest using Plitonit B.

- Apply the prepared mortar mixture evenly to the substrate with a smooth trowel and give a comb-like structure to the serrated. The size of the tooth is selected depending on the format and type of tile. We recommend using a spatula with a tooth of at least 6 mm. for ceramic tiles and with a tooth of at least 10 mm. for porcelain stoneware tiles.

- The mortar should be applied to an area that can be tiled within 15 minutes (open time). If a dried crust forms on the surface of the applied glue (when touched, the glue does not remain on the finger), the mortar mixture must be removed from the surface and replaced with a new one.

- Place the tiles on the glue mortar and press them into it with small turning movements.

- The position of the tiles can be adjusted within the next 15 minutes. Drafts, high temperatures as well as strong surface absorbency will reduce the open time and correction times.

- The tiles are laid with open joints and leveled with appropriate tools (eg Plitonit crosses).

- Walking on the tiled floor and grouting is allowed no earlier than after 24 hours.

Grouting technology

- We suggest using Plitonit Z as a grouting compound. The product has 2 colors: gray and white for floor and wall cladding, respectively.

- Clean the base for grouting from dirt and dust, remove loose fragments. The depth of the grout should be at least half the thickness of the tile.

- Before grouting, the surface of the tiles must be cleaned with a damp sponge.

- Apply the ready-made grouting mixture to the tiles with a rubber spatula or float, distribute in diagonal movements relative to the joints and compact until the tile joints are completely filled.

- After 10-30 minutes (depending on the water absorption of the tile, ambient temperature and humidity), wipe the tiled surface diagonally to the mesh of joints with a slightly damp sponge or a foam-coated trowel. Excessive saturation of the surface of the joints with water and intensive wiping of them can lead to leaching of the grout mixture and discoloration of the grout. The wiping water needs to be changed frequently to keep it clean.

- The final cleaning of the tile surface from dried plaque is done with a dry soft cloth.

- Walking on the floor is allowed no earlier than 24 hours. The first contact with water is possible after 48 hours.

Stages of work

In order for the repair to be carried out efficiently, it is necessary to perform sequential steps when laying the tiles.

Preparation

It is necessary to apply Plitonit B glue on a solid, even, solid base that is not subject to deformation. It is recommended to thoroughly clean the working surface of various types of contamination: debris, dust, dirt, old coating (glue, paint, wallpaper, etc.), grease. Crevices and cracks are sealed with putty, and after that the working surface is treated with a primer solution.

If the coating has a loose structure, then it must be primed in 2 layers. The floors are also treated with a special compound to prevent the appearance of mold under the tiles, especially for bathrooms.

Preparation of the mixture

Before you start preparing a tile mixture, you must take into account certain recommendations.

- All components used must be at room temperature.

- For mixing, tools and containers are used that are completely free of contamination. If they have already been used to prepare the mixture, then the remains of the solution must be eliminated. They can affect the properties and qualities of the freshly prepared formulation.

- For the convenience of pouring the mixture into the container, you can use a trowel.

- Only pure water is used for mixing, preferably drinking water. The technical liquid may contain alkalis and acids, which will negatively affect the quality of the finished solution.

For 1 kg of dry mixture, 0.24 liters of water will be needed, respectively, for 25 kg of adhesive, 6 liters should be used. Water is poured into a suitable container and the dry mixture is added. Mixing takes about 3 minutes, you can use a mixer or a drill with a special attachment, the main thing is to get a homogeneous consistency without lumps. The readiness of the mixture is determined in such a way that when applied to a vertical surface, it does not drain.

The finished mixture is set aside for 5 minutes, after which it is mixed again. In some cases, it is possible to add water, but it is not recommended to exceed the indicated values in the instructions.

Subtleties of application

- Plitonit B is applied with a smooth trowel in a thin, even layer. The adhesive mortar coating should be given a comb structure for better adhesion to the tiles.

- If a dried crust forms on the surface of the applied solution, the layer is removed and replaced with a new one. The tile is placed on the glue and pressed into the mixture with gentle turning movements. The position of the facing material can be corrected within 20 minutes. When installing tiles, it is recommended to use a laser level.

- At the end of the work, excess adhesive solution is removed from the tile joints. Peeling is done with a knife until the mixture is frozen. The front side of the tile is cleaned from dirt with a rag or sponge soaked in water or a special solvent.

- When facing floors with a heating system, as well as laying tile materials of large sizes, in order to avoid the appearance of voids under the finished coating and to increase adhesion, experts recommend applying glue using a combined method. The composition is applied both to the prepared base and to the back of the tile. It is necessary to apply the adhesive to the tiles with a notched trowel, and then level the layer with a smooth one.

You can often hear the opinion that you can walk on the tiles on the floor without waiting for the glue to dry completely. It is strictly forbidden to do this, because:

- if the adhesive solution had time to dry out, but did not gain maximum strength, then there is a great risk of shearing the masonry;

- damage to the tile material can occur, especially in areas where voids have formed due to insufficient application of mortar.

Consumption calculation

The instructions on the packaging indicate the approximate consumption of tile glue on any surface, but the amount of material required can be calculated independently. Adhesive consumption depends on many factors.

- Tile size: if it is large, then the glue consumption will be large.

- Tile material. Ordinary tiles have a porous surface that absorbs glue better. On the other hand, porcelain stoneware tiles absorb less adhesive mortar.

- Smoothness of the surface: a smooth one will need less glue than a corrugated one.

- The quality of the prepared substrate.

- Specialist skills.

For tiles measuring 30x30 cm, the average consumption of glue will be approximately 5 kg per 1 m2 with a joint thickness of 2-3 mm. Accordingly, for cladding 10 sq. m of area will need 50 kg of adhesive. For a tile of a smaller size, for example, 10x10 cm, the average consumption will be 1.7 kg / m2. A tile with a side of 25 cm will require approximately 3.4 kg / m2.

Varieties

There are six types of glue with the addition of polymers that are used most often.

For interior work

Some funds are used only for internal work. Such mixtures have the following advantages:

- environmental friendliness;

- water resistance;

- ease of use;

- reliability.

However, they are not resistant to temperature extremes and therefore cannot be used for outdoor work.

For external work

Some people have to deal with the arrangement of the facades of residential buildings. To do this, use polymer compounds that are suitable for external work. They are often used to fix insulating sheets, ceramics or mosaics.

Universal mixtures

Universal waterproof glue is used for external and internal work. It contains components that increase the frost resistance of the products and make them resistant to high humidity. Also, the advantages include the balance between product quality and its cost.

Mounting solutions

Sometimes you have to use special mounting solutions. They are used for gluing heavy products, fixing facade parts or building up chips. Such solutions are used not only in various industrial fields, but also in everyday life. The advantages of assembly tools include resistance to vibration, mechanical damage and exposure to chemicals.

Liquid Nails

Liquid nails are a polymer adhesive solution that is suitable for gluing plastic, ceramics, glass, iron surfaces, as well as drywall boards. The composition of liquid nails contains synthetic rubber, due to which the agent sets faster. The mortar is very reliable, as only a small spot application is sufficient for fixing the materials.

Cold welding

It is the least common adhesive used only for bonding wood, plastic, glass and clay surfaces. Most often, cold welding is used when it is necessary to glue a damaged or broken product.

Primers9

New

PLITONIT Ready Ground

Primer for indoor and outdoor use

-

Ready to use

-

Freezing possible during storage

New

PLITONIT AquaGrunt

Concentrated primer for damp rooms and surfaces prone to mold and mildew

-

Concentrate - dilution 1: 4

-

For wet rooms

-

Frost resistant

-

Prevents the development of mold and mildew

New

PLITONIT Soil Concrete

Adhesive primer for preparing smooth and slightly absorbent substrates

-

Ready to use

-

For interior and exterior use

-

Easy to apply by brush or roller

-

Prevents water flow from the mixture

What kind of glue can be used to glue tiles, porcelain stoneware or mosaics. Specific examples of tile adhesives of various classes

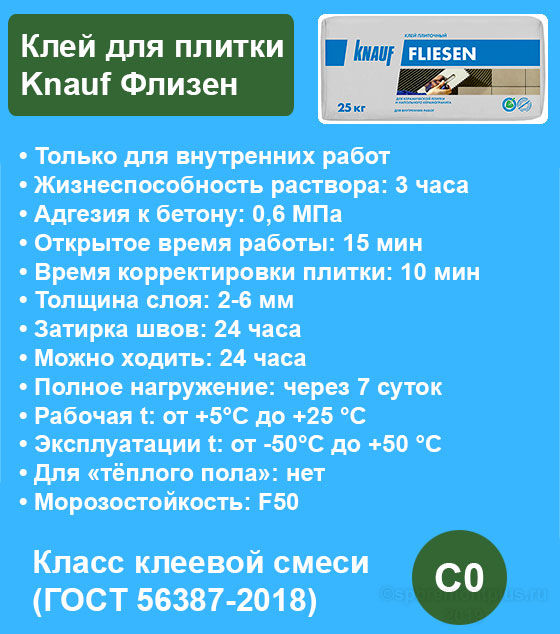

Here are two or three adhesives from different classes, which we have used more than once ourselves at our facilities when renovating apartments and offices. In addition to the C0 class, it will be presented only one, since in our practice we practically never use adhesives of this class.

Knauf Flisen mixture is intended for cladding with ceramic tiles up to 60x60 cm in size and weighing no more than 45 kg per m2 on flat, non-deformable substrates. It can be various screeds, concrete bases, gypsum plasters, cement-sand plasters, gypsum plasterboard (GKL), gypsum fiber sheets (GVL) and cement slabs of the Aquapanel type.

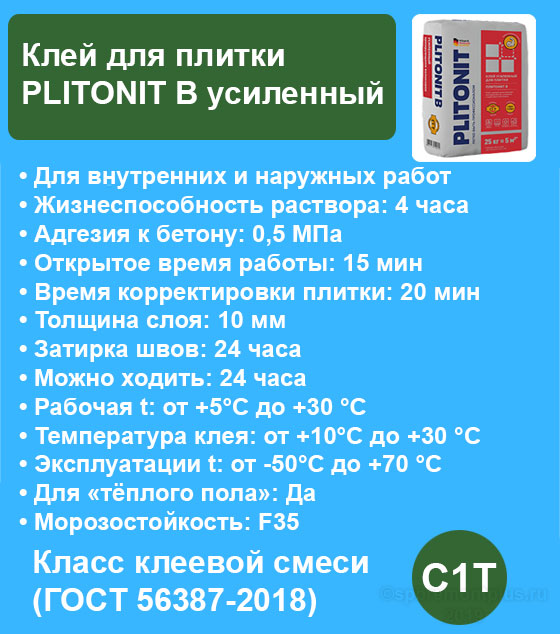

Thixotropic tile adhesive PLITONIT B, reinforced with reinforcing fibers, is used for gluing ceramic, porcelain stoneware and clinker tiles. Gluing porcelain stoneware to the wall is allowed up to 45 × 45 cm.

Surface bases on which PLITONIT B reinforced can be applied: concrete and reinforced concrete, gypsum plasters, lime-cement plasters, cement plasters, bricks, aerated concrete; gypsum plasterboard and gypsum fiber sheets, tongue-and-groove plates.

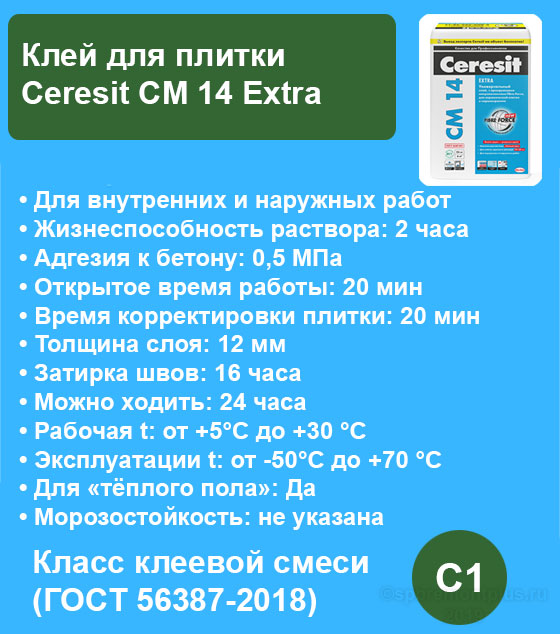

Ceresit CM 14 Extra glue is designed for laying ceramics and porcelain stoneware up to 50 × 50 cm.

Substrates on which the Ceresit CM 14 Extra adhesive can be applied: concrete and cement substrates that are not prone to deformation.

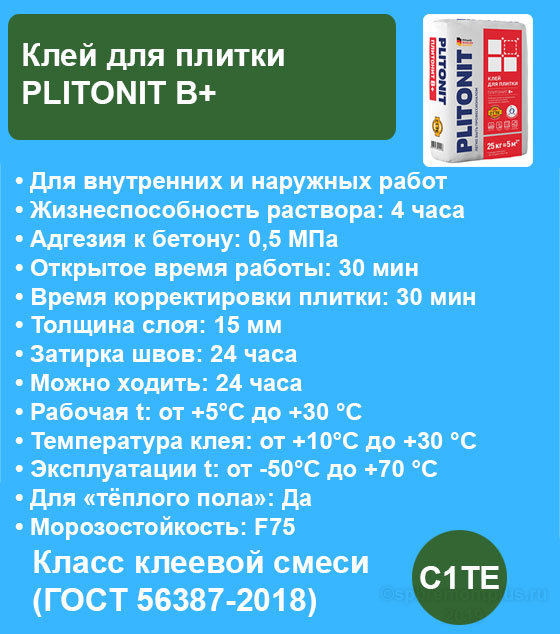

Thixotropic adhesive with extended open time PLITONIT B + is intended for laying ceramics and porcelain stoneware, natural and artificial stone. Can be used for cladding indoor pools and wet rooms (bathrooms, shared bathrooms).

Substrates of the surface on which PLITONIT B + glue can be applied: concrete and reinforced concrete, gypsum plasters, lime-cement plasters, cement plasters, bricks, aerated concrete; gypsum plasterboard and gypsum fiber sheets.

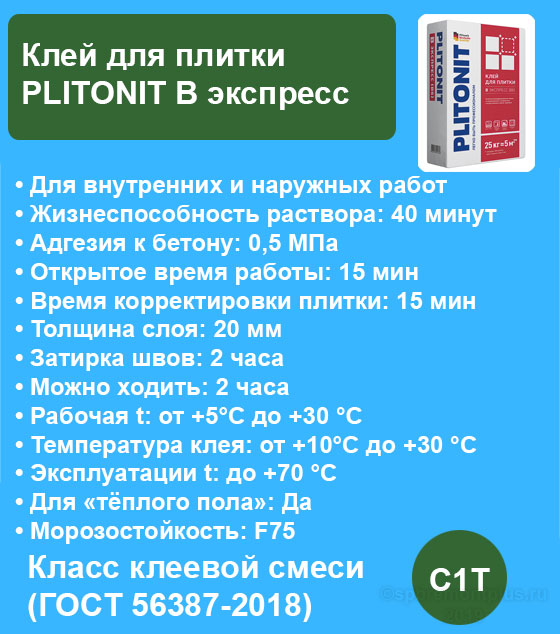

PLITONIT B express is a thixotropic, fast-hardening adhesive. Recommended for urgent commissioning of an object.

Glue PLITONIT B Express is designed for laying ceramic and porcelain tiles, natural and artificial stone. Can be used for cladding indoor pools and wet rooms.

Surface bases on which PLITONIT B express can be applied: concrete and reinforced concrete, gypsum plasters, lime-cement plasters, cement plasters, bricks, aerated concrete; gypsum plasterboard and gypsum fiber sheets.

Specifications

The Plitonit company (Russia-Germany) produces a variety of products from the category of construction chemicals, which are used by professionals and beginners for home use. The most popular tile adhesives are suitable for laying ceramics, porcelain stoneware, clinker tiles on walls and floors. Tile adhesive can be used on a variety of substrates:

- gypsum plaster and plaster;

- concrete and reinforced concrete;

- brick;

- tongue-and-groove plate;

- heated floors;

- lime-cement slabs;

- indoor pool covers.

Tile adhesives "Plitonit" A, B or C-series are produced in bags of 5 kg and 25 kg. Inside there is a homogeneous gray powder mixture, which is diluted with water in the proportion recommended by the instructions. In the composition - cement, other binders, adhesive additives, modifiers, fillers. The total grain size does not exceed 0.63 mm.

The glue is highly flexible. This property allows you to reliably hold the tiles even on vertical and difficult bases, and prevent them from slipping. The main technical characteristics of the glue:

- glue seam thickness - up to 10 mm;

- drying time before use or grouting - 24 hours;

- temperature during glue application - from +5 to +30 degrees;

- operating temperature of the glue seam - up to +60 degrees;

- maximum tile slippage - up to 0.5 mm;

- the time for adjusting the position of the tile is 15-20 minutes;

- the viability of a portion of the solution is 4 hours;

- frost resistance - F35;

- adhesion of adhesive to a concrete base - 0.6 MPa for ceramics, 0.5 MPa for porcelain stoneware;

- compressive strength - M50.

The service life of the glue in the package is 12 months. After this time, its basic properties may be reduced.

What type of tile adhesive to use for non-formatted tiles

In addition to the existing square tiles, or in the form of a rectangle with an aspect ratio of up to 1.5, for example, 20 by 30 cm, there are also non-formatted ones. For example, porcelain stoneware 10 by 40 cm, which can formally be attributed to the medium format, has an aspect ratio of four. In this case, when the ratio of length and width exceeds 1.5 - 2 times, the tiles should be classified in the next class, in this case, large-format. For such non-formatted sizes, it is necessary to use tile adhesive with higher characteristics, as well as having an additional elasticity index S1, and in the case of very large ratios and sizes, the S2 index.

Additives for solutions5

Updated

PLITONIT AntiFrost

Complex plasticizing additive with antifreeze effect for mortar and concrete mixtures

-

Increases frost resistance

-

Accelerates strength gain

-

For cement-sand mixtures and concrete

-

Concentrate

PLITONIT SuperWall

Universal additive for masonry and plaster mortars

-

increases plasticity

-

increases durability by 10%

-

increases the solution yield by 20%

-

replaces construction lime

PLITONIT WaterBarrier

Water-repellent surface treatment solution

- Gives the surface of building structures water-repellent properties

- Increases frost resistance - increases durability

- Prevents efflorescence and fungus formation

- Does not change the color of the coating

- It is used as a hydrophobizing additive

How to make your own tile adhesive?

For interior work in a house or apartment, where complex mixtures for laying tiles are not required, you can use a solution prepared by yourself. Of the materials you will need:

- fresh cement grade not lower than 300 - 1 part;

- fine-grained sifted sand - 5 parts;

- water - on demand;

- plasticizer - 1/25 part.

As a plasticizer, PVA glue, slaked lime, silicate glue or liquid soap are suitable. First, cement and sand are mixed, then the mixture is brought to the desired plastic consistency with water. At the last stage, when all the lumps disappear, add any of the plasticizers.

Beginners should know that a solution prepared from a dry mixture should be used as quickly as possible, but without haste. It is impossible to leave the glue the next day - even if it does not completely harden, its useful properties will be lost.

Classification of Cement Tile Adhesives

The word "cement" comes from the Latin word "caementum" (in English it is even simpler - "cement").Therefore, the main letter that is used in the classification of tile adhesive is the capital letter "C".

С0 - cool mixtures used when laying tiles with normal water absorption, not less than 5% by weight. That is, for ordinary ceramic tiles, small sizes 10 by 10 cm, 15 by 15 cm, 20 by 30 cm, and only when doing interior work! Tile adhesive of class C0 is used for performing tasks not associated with heavy loads or the effect of temperature factors, as well as water. For example, it can be used for a ceramic tile backsplash in a kitchen or bathroom lining (but not combined with a bathroom).

C1 - cool mixes used for indoor and outdoor work and meeting the minimum standard requirements. With C1 glue, you can glue tiles of any size, clinker tiles, medium-sized porcelain stoneware (up to 40 by 40 cm). For outdoor work, this tile adhesive should be used with caution, and try not to use it for places that will be constantly under the influence of heavy loads or adverse factors, for example, a walk-through porch of a shopping center or the basement of a building.

C2 - cool mixtures used for indoor and outdoor work and meeting increased requirements. These are the so-called improved dry mixes, they can be safely used even when working on the basement of a house, in swimming pools, Turkish baths, for waterproofing. This is the best option for tiling with mosaics. By the way, white glue is better for mosaics, not gray.

Some letters are added to the main classification, which describe some additional properties that this dry mixture has for preparing tile glue:

- F - fast-setting adhesive mixtures

- T - mixtures with increased creep resistance

- E - mixtures with extended open time

- S1 - elastic adhesive mixtures (by 20 cm, a 3 mm glue plate should be bent by at least 2.5 mm)

- S2 - highly elastic adhesive mixtures (by 20 cm, a 3 mm glue plate must be bent by at least 5 mm)

For deformable substrates, for example, warm floors, in which the screed will bend, due to periodic heating and cooling; facing of unstable materials such as glass-magnesium sheets (MSL); large-format drywall; or for porcelain stoneware of extremely large formats - it is necessary to use classes of dry mixes C2 with added characteristics S1 or S2.

The E index is desirable when working on the street with large volumes of building materials. Then it is useful to increase the "open time". Since this index shows that it is possible to apply the adhesive mass over a larger space, while it does not have time to wind up, which, in general, is allowed to work faster (more area of glue was applied, more tiles were laid at a time).

A thixotropic adhesive (with the T index) is required when it is necessary to apply it in a thicker layer than 6-8 mm, for example 10-20 mm, or when facing downwards.

For cladding on old tiles, adhesives of the C2 format are guaranteed to work, and C1 selectively, because required increased strength of the adhesive bond (adhesion) close to 1 MPa.

After reading in detail the classifications of dry mixes for the manufacture of tile adhesive, you can decipher any name that the manufacturer writes on its packaging, for example:

"Dry construction adhesive mixture C2 TE S1": "C2" is a tile adhesive that can be used for indoor and outdoor work, which meets increased requirements; "T" is thixotropic, i.e. with increased resistance to slipping; "S1" - elastic; "E" - extended open time.

Table of characteristic values that tile adhesives of different classes should have

| Indicator name | Class C0, MPa | Class C1, MPa | Class C2, MPa |

| The strength of the adhesive bond after aging in an air dry environment for 28 days | > = 0,5 | > = 0,5 | > = 1,0 |

| The strength of the adhesive bond after aging in an aqueous environment | — | > = 0,5 | > = 1,0 |

| The strength of the adhesive bond after curing at high temperatures (at t more than 70 degrees) | — | > = 0,5 | > = 1,0 |

| The strength of the adhesive bond after cyclic freezing and thawing (-15 degrees, at least 25 cycles) | — | > = 0,5 | > = 1,0 |

Work rules

When carrying out facing work, the following sequence of actions should be observed:

- Preparation of the base. The surface is freed from old materials, dirt, dust and debris are removed. The base must be strong, not subject to deformation. Level the surface, seal the cracks. They are treated with a primer, for porous materials they put the soil in 2 layers. It is better to use Plitonite grade materials containing components for protection against fungus.

- An adhesive solution is prepared. Pure water is poured into a container (240 milliliters of water per kilogram of dry mixture), glue is added. All components must be at room temperature (10-30 °). Drinking water, mixing containers free of old materials. Use a construction mixer or drill for mixing (3 minutes). As a result, you should get a homogeneous composition without lumps. Readiness is checked on the wall - if it does not drain, the consistency is correct.

- After checking, let the glue settle for 5 minutes, mix again. Proceed with the facing, remembering to use the glue within 4 hours. In hot dry rooms, in the wind, the glue loses its properties faster, you have to hurry.

Features of tile sticker:

- the composition is distributed with a spatula with a smooth or serrated edge;

- the layer is laid with a thickness corresponding to the recommendations for a particular type of "Plitonite";

- the tiles are laid on glue and pressed in with pivoting movements;

- within 15-20 minutes, the position can be corrected using a laser level;

- the excess glue from the seams and from the surface of the tile is removed immediately, not allowing it to harden.

When working, make sure that no voids are formed, fill them with an additional amount of glue (applied directly to the back of the tile), otherwise the coating will "play" when pressed.

Trainings and seminars

Our priorities lie in the field of increasing the efficiency of construction and finishing, through the advanced training of master finishers, conducting technical seminars and master classes. We organize training seminars in various formats, incl. on the basis of the customer and the leading retail operators of the market. Qualified technical specialists introduce the students to the most modern PLITONIT technologies and materials, and also allow them to practice the acquired skills in practice.

Nearest event

November 25, 2020 Moscow

Finishing as a business: reducing financial risks, solving typical problems

Specifications

Main parameters:

- the largest grain volume - 0.63 mm;

- appearance - gray, free-flowing homogeneous mixture;

- sliding of the tile material from the vertical surface - 0.5 mm;

- open time of work - 15 minutes;

- the time for adjusting the tile material is 15-20 minutes;

- the pot life of the finished mixture is no more than 4 hours;

- maximum thickness of the adhesive layer - no more than 10 mm;

- temperature regime for installation work - from +5 to +30 degrees;

- trowelling works - after 24 hours;

- the temperature of the glue seam during operation - up to +60 degrees;

- frost resistance - F35;

- compressive strength - M50;

- adhesion strength of a tile to a concrete surface: ceramics - 0.6 MPa, porcelain stoneware - 0.5 MPa;

- shelf life - 12 months.

The choice of glue for styling

Not every construction adhesive mixture is suitable for facing a reservoir. Adhesive for tiles and other types of tiles must have certain qualities.

High adhesion (gluing) properties are required to securely hold the tiles and guarantee a complete seal

It is especially important that these properties do not change for the worse after final drying.The level of adhesion for tile adhesive should not be lower than 1 MPa, for mosaics this figure should not be lower than 2.5 MPa.

Elasticity is necessary to relieve internal stress caused by constant water pressure

In addition, after drying, high-quality waterproofing should be provided with properties such as plasticity and resilience. These properties also prevent cracking.

The glue must be waterproof as it is constantly exposed to water.

The presence of inert qualities. The elements included in the glue should not enter into a chemical reaction with salts and various chlorine disinfectants contained in water and cleaning agents.

A moisture-resistant adhesive must also have good resistance to frost and high above-zero temperatures. Temperature drops should not affect and worsen its properties.

It is important to have antifungal properties that prevent the formation and development of mold.

Sustainability is an essential quality. The glue should not release substances harmful to human health into the water.

Pool tile adhesives are produced in 2 types: powder and solution. The basis of powder mixtures is cement, and solutions are prepared on the basis of acrylic, latex, polyurethane and epoxy resin.

To select a high-quality adhesive, preference should be given to 2-component latex-based adhesives: they have the highest level of adhesion. The following brands of glue are recommended:

- Unis "Pool";

- Ivsil Aqua;

- “The Pool Wins”.