Composition, properties and technical characteristics of various varieties

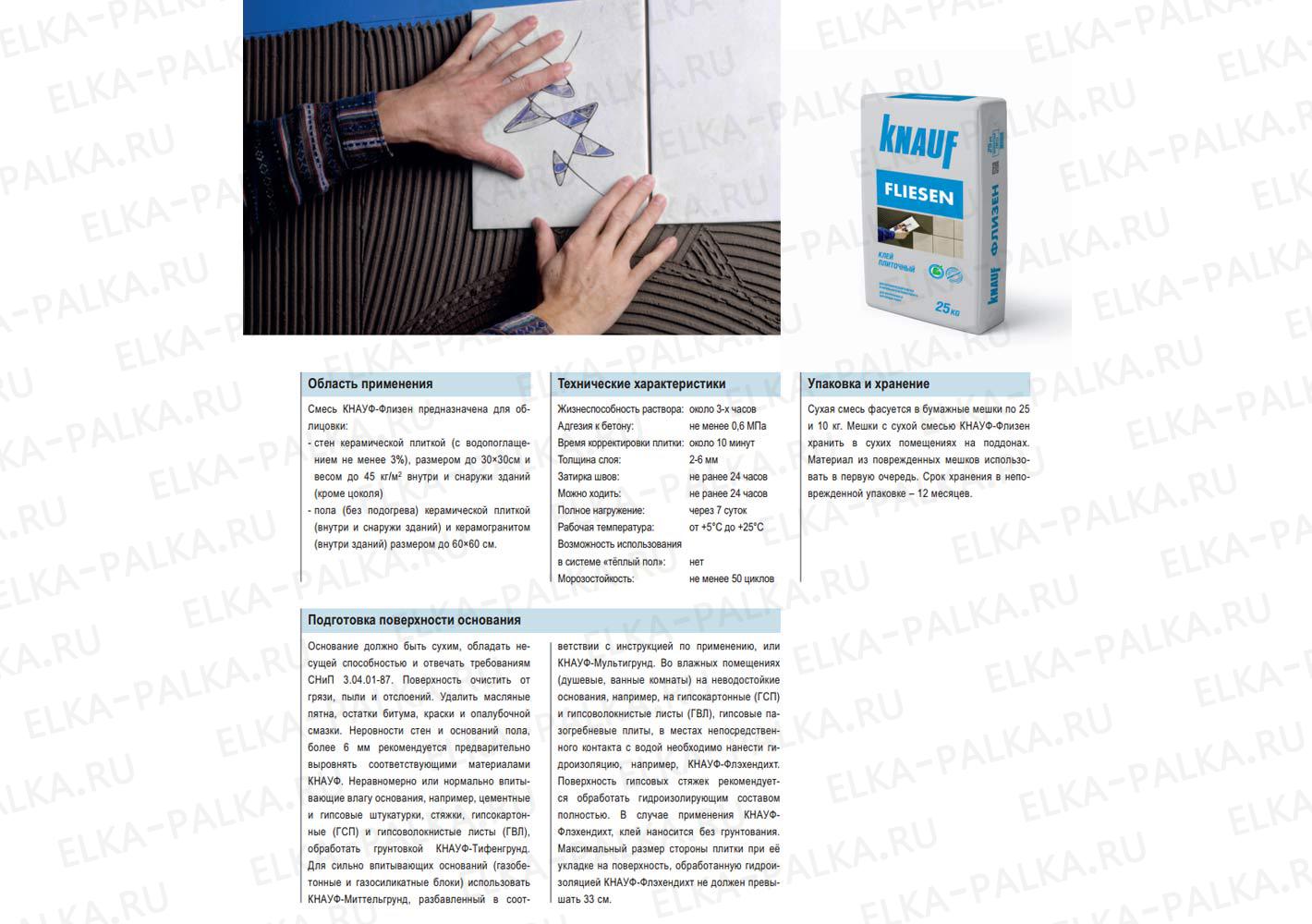

There are five manufacturers that produce high-quality glue. Before purchasing an adhesive mixture for wall cladding, it is recommended that you familiarize yourself with the characteristics of various brands of tile adhesive mixtures.

Keramik

Many people who are often engaged in wall cladding recommend using a special glue "Ceramic". It has good physical and mechanical properties, which are many times superior to the base adhesive. "Ceramic" is considered a plastic and moisture-resistant agent, which allows it to be used in rooms with high humidity levels.

This glue is considered the ideal mixture for laying porcelain stoneware and ceramic materials. It stands out for its resistance to temperature changes and has a considerable moisture absorption coefficient. Also, the advantages of "Ceramics" include the following:

- strength, thanks to which the composition can be applied to bends;

- setting speed, which is twenty hours;

- resistance to frost and high temperature indicators.

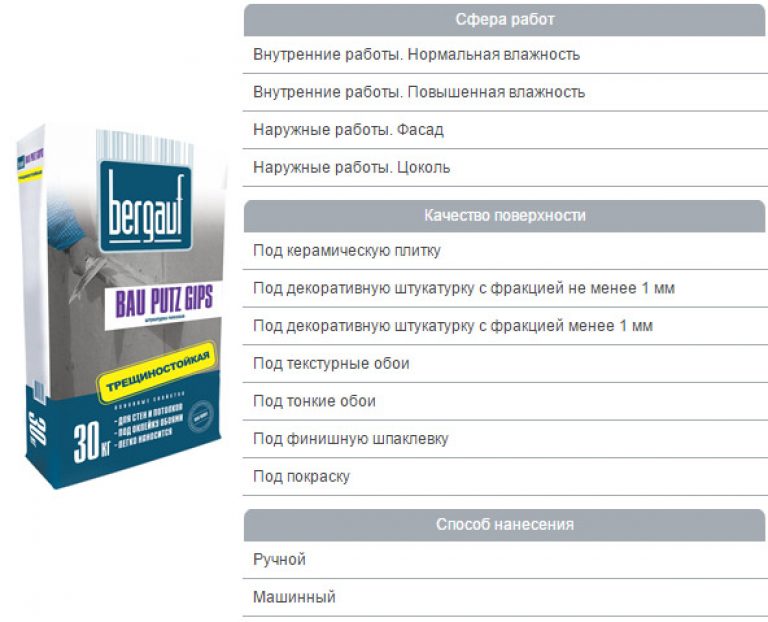

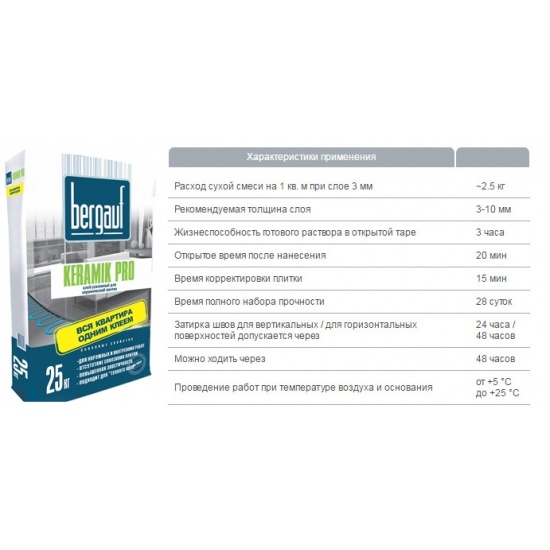

Keramik Pro

The most popular tile adhesive is considered to be the reinforced composition "Ceramic Pro", which is often used for wall cladding. Such a solution is considered highly elastic and durable. Most often it is used for laying large-sized ceramic tiles or decorative stone of medium size. "Ceramic Pro" is universal, as it can be used indoors and outdoors.

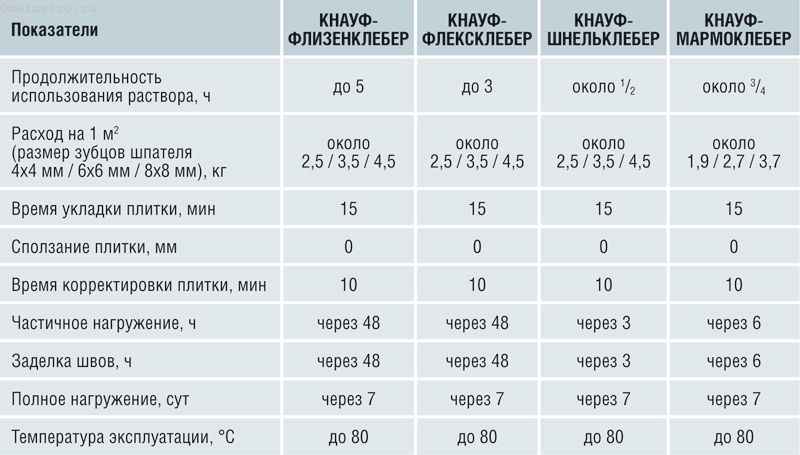

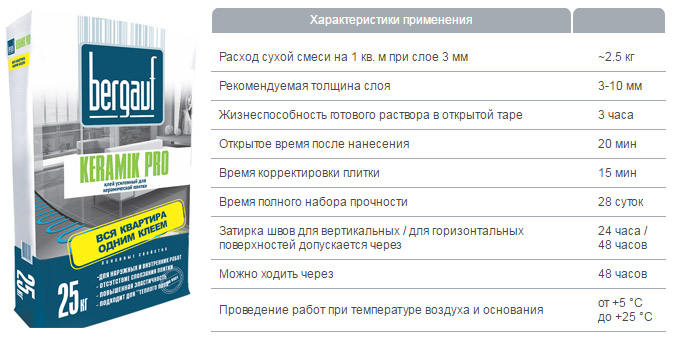

Before using "Ceramic Pro", you need to understand its main characteristics:

- Increased flexural strength, which is about 2-3 MPa.

- Resistant to sudden temperature changes. "Ceramic Pro" does not lose its properties at temperatures from -60 to +90 degrees.

- Fast solidification of the applied mixture. The glue dries up within 10-12 hours.

- Low consumption of the composition. To process a square meter of surface, you will need one and a half kilograms of solution.

Praktik

Some builders prefer to use not "Ceramics", but "Practice". This composition is recommended to be used to mount tiles made of silicate stones or concrete mixtures on the surface of the walls. "Praktik" is made from fractional sand or synthetic components. These substances make the product many times stronger and more durable than other tile adhesives. "Praktik" possesses frost resistance, which allows it to be applied on surfaces inside and outside the premises.

There are several characteristics that are recommended to be familiar with before using the mixture:

- Strength that is maintained even in places of compression. This figure is 4-5 MPa.

- Tolerance to various temperatures. The solution is capable of transferring values from minus fifty to plus eighty.

- High speed of hardening. The applied composition hardens within thirty hours.

Isofix

"Isofix" is considered a universal adhesive, which can be used to glue not only ceramic tiles. Also, such a tool is suitable for gluing polystyrene and glass wool. Some experts recommend using Isofix as a reinforcing agent when decorating building facades.

Among the main characteristics of "Isofix" are the following:

- High adhesion to most substrates. The value of this indicator is 1-2 MPa.

- Resistance to low temperatures. "Isofix" is able to withstand temperatures below 30-40 degrees of frost.

- Solidification rate. The glue hardens in an hour and a half after application.

Mosaik

This is a high-quality moisture-resistant compound that is ideal for finishing a pool, bathroom, sauna and other rooms with high levels of humidity. The properties of "Mosaic" make it possible to use it for laying slabs not only on walls, but also on floors that are equipped with an additional heating system.

Mosaic has the following characteristics:

- High coefficient of moisture absorption. It is about five percent.

- Fast drying of the solution. The mixture has time to dry within 4-5 hours.

Economical consumption rules

To minimize the need for tile adhesive, you need to resort to some rules:

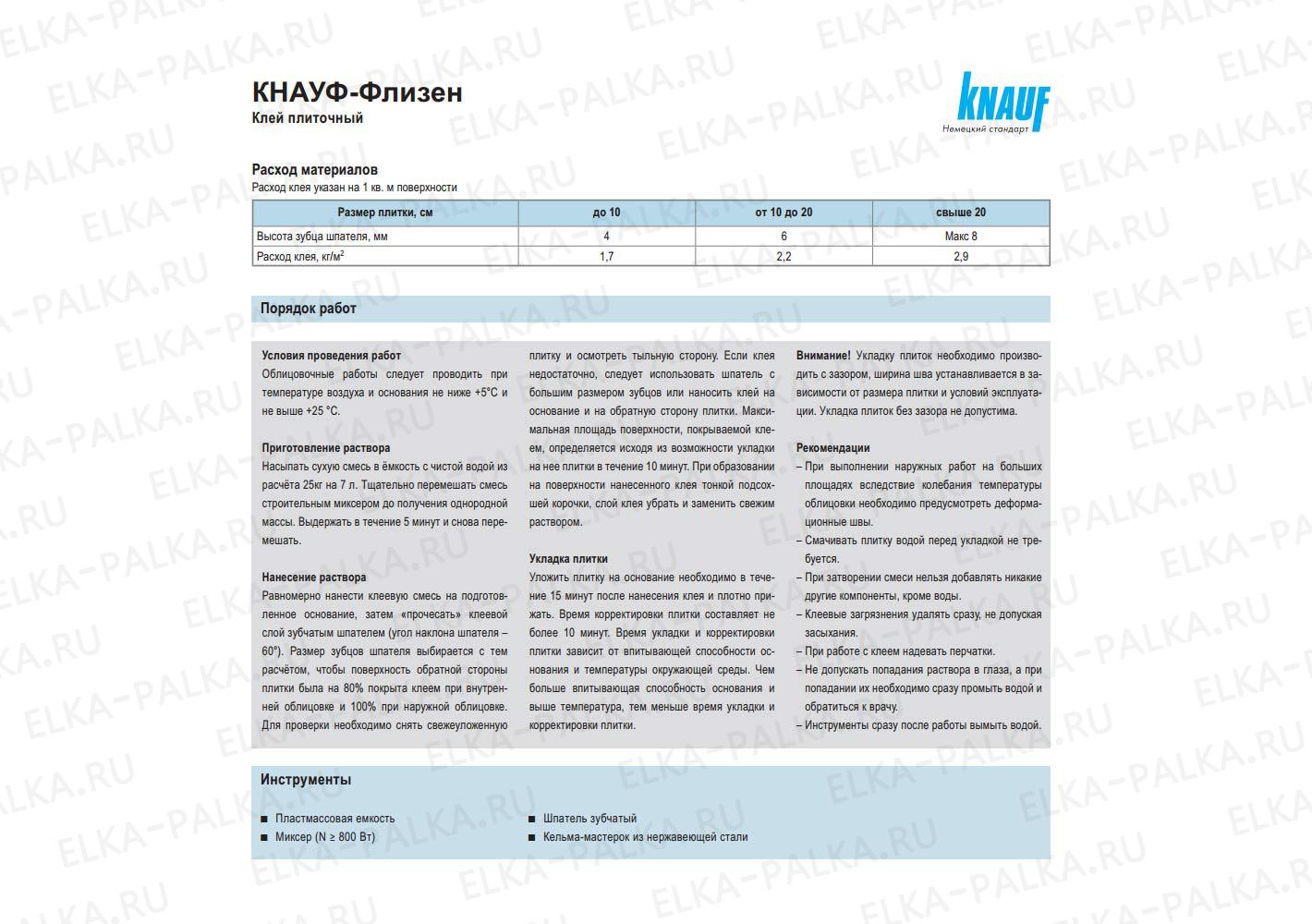

- The working base requires careful preparation. It should be smooth and clean. Deep sinkholes are not allowed. Aligning the base will facilitate the laying of tile plates, and reduce the consumption of raw materials. Additional priming will increase the adhesion, make a slight leveling, and reduce the absorbency of the adhesive part.

- The solution is prepared in small portions. The mass depends on the training, skill of the worker. The unused amount is not suitable for use after, it dries up, loses its properties. Applying such a solution to work, porcelain stoneware will quickly disappear. You will have to spend time cleaning the plane, plywood flooring, walls.

- The angle at which the mortar is applied also plays an important role. Application at an angle of 45 degrees is considered optimal. Often, craftsmen without experience raise the angle to 60 degrees, not knowing that they have increased the need for initial substances.

- Each plate requires a firm grip. The surplus is consumed in order to lay the subsequent part.

- All styling must be level.

- The trowel shape should be V-type. Other forms significantly increase the application layer, in general, the need for raw materials.

Interesting video on the topic:

Peculiarities

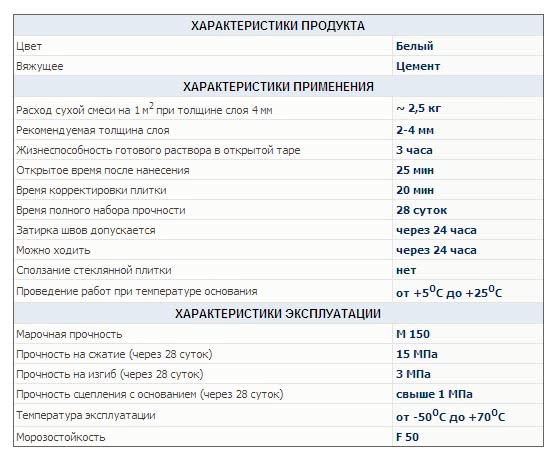

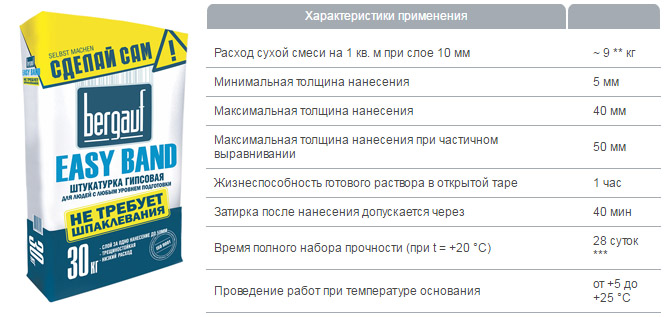

The Bergauf glue is produced using modern technologies. This results in a high quality mixture that has a long shelf life. During this period, it retains its properties and can be further applied. Only if the bag is opened will this period be slightly reduced, since the mixture is exposed to air, which degrades its quality over time.

Glue Bergauf with reinforcement for ceramic tiles

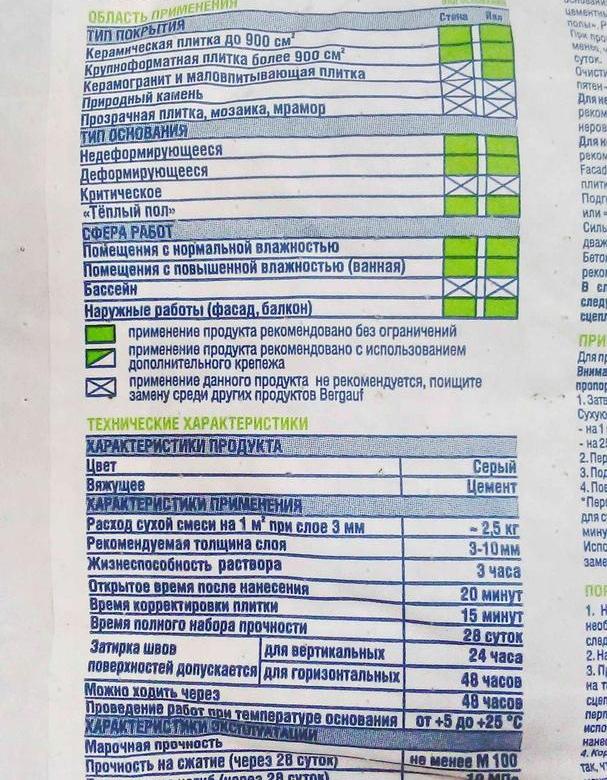

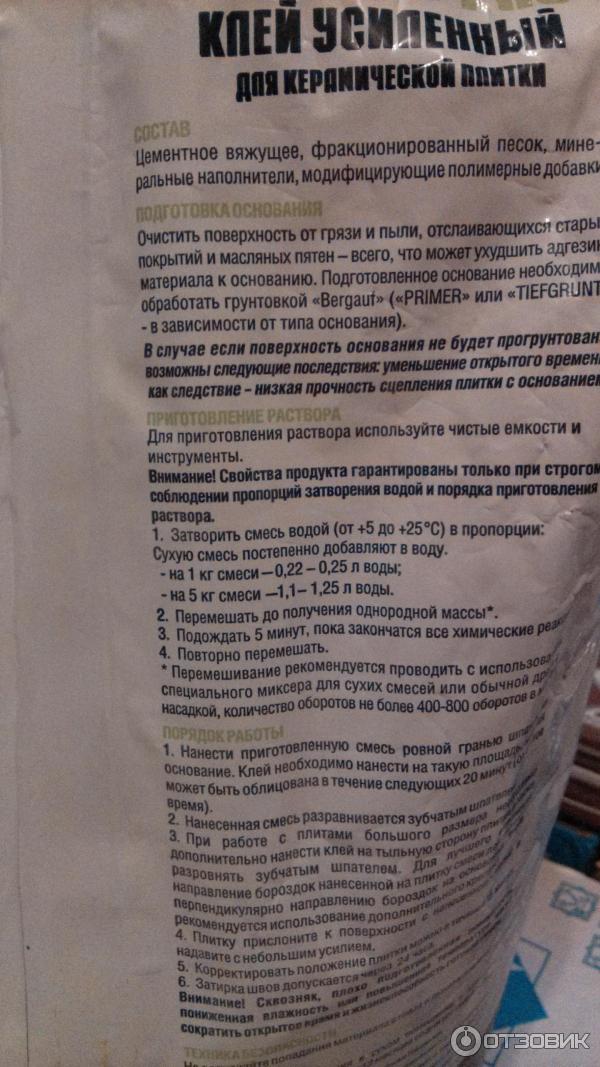

This type of glue is universal. If you compare it with analogues, then there are significant differences in many respects. First, the line-up. This type of glue consists of a cement base, graded sand and various fillers. All of them will allow you to get an excellent building mixture, which has a number of advantages. They are especially important when applying it.

What affects the consumption of tile adhesive

To correctly think over the right amount of glue, factors are taken into account:

- type of tile;

- its dimensions, thickness;

- what is the condition of the base, what technology will be used for laying;

- brand of adhesive, its type, main components;

- under what conditions the work is carried out: ambient temperature, humidity, ventilation;

- skill, experience of the stacker.

The tile is made of various components; its surface is porous and hygroscopic. Low-quality parts have plane bulges. These indicators significantly affect the consumption of tile material. So the porous plane draws in a lot of glue mass.

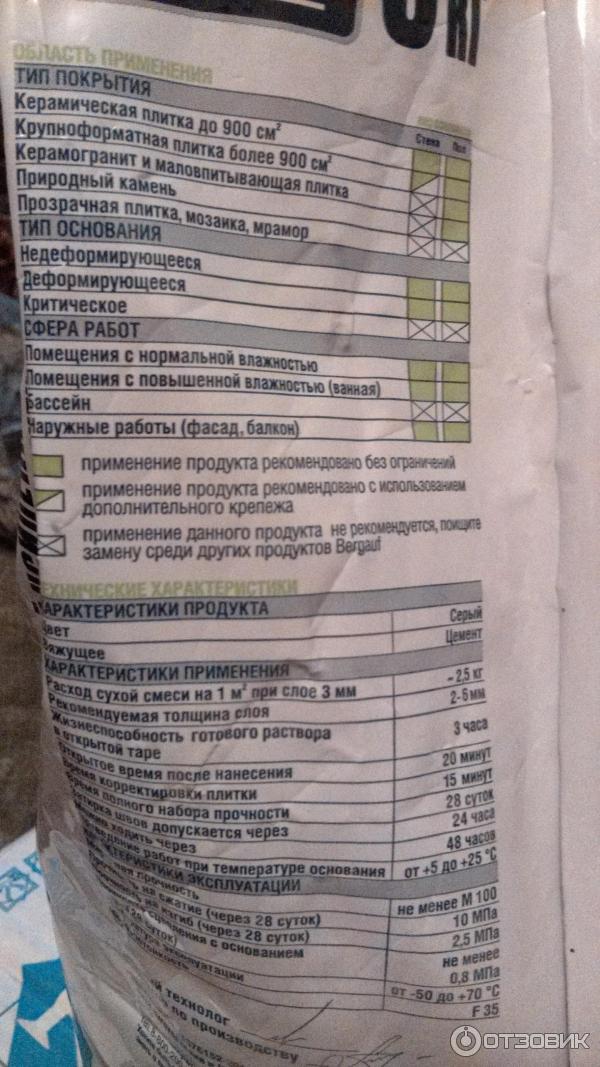

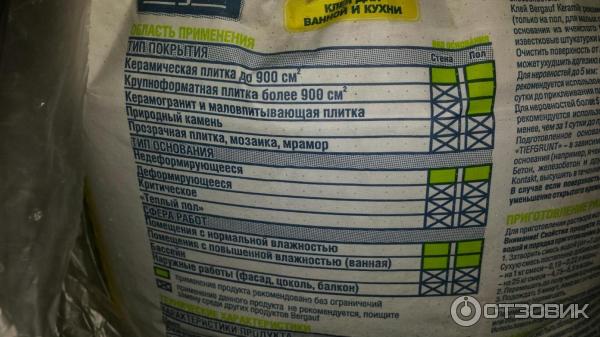

Many manufacturers show on the packaging of the glue what type of tile it is intended for. If it is difficult to determine the type of tile, what surface it has, then it is better to buy universal packaging.

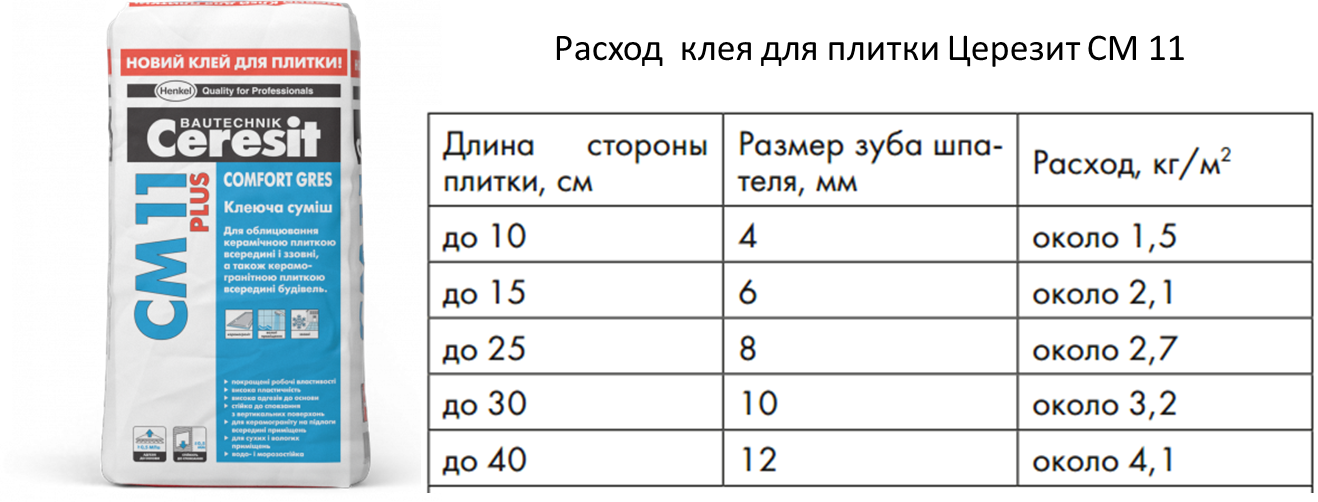

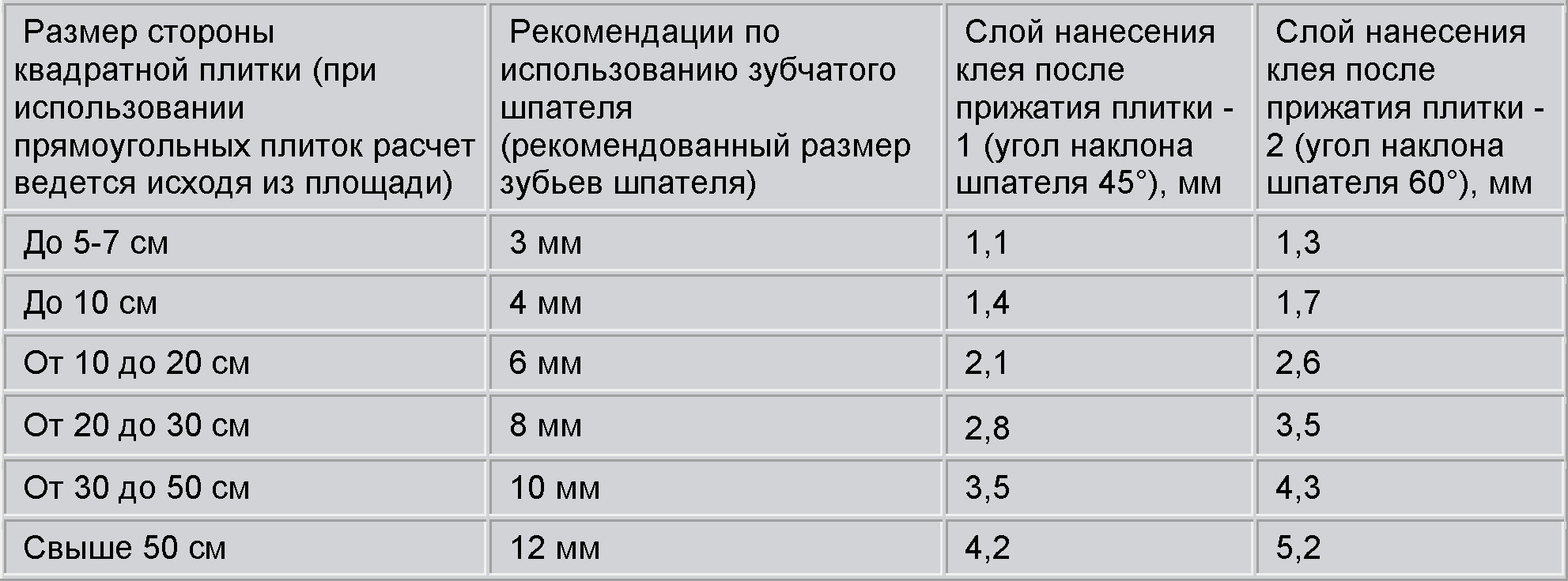

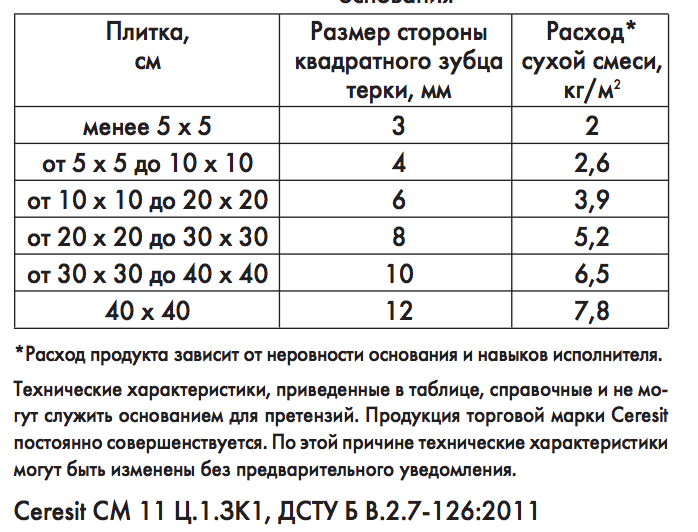

The fact is taken into account that with large sizes, mass, a larger volume of consumable raw materials is needed.

By using the correct trowel when working with large tiles, an even distribution of raw materials will be produced, which will significantly reduce its need.

Useful video on the topic:

The base must be leveled so that the adhesive only serves as a base for adhesion.If the base is uneven, then the adhesive raw material will perform a leveling function, which will significantly increase the need, reduce the adhesion strength.

An important factor is the type, components, brand of raw materials. There are ready-made packages that do not require preparation, but there are raw materials that require dilution with water. Not always ready-made options are better than those requiring preparation. Glue with the same name from different manufacturers has a different composition

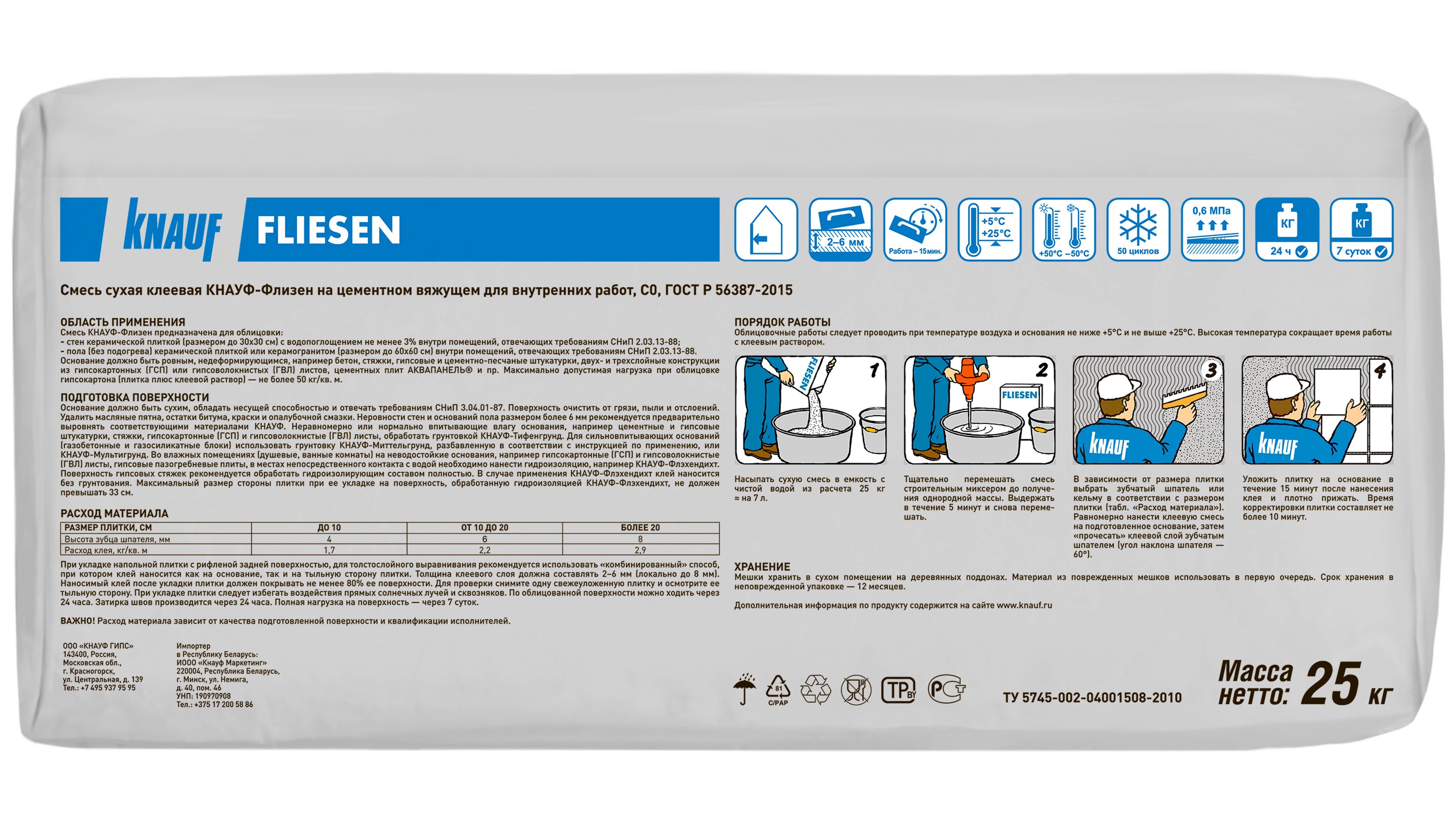

Therefore, when buying, you need to pay attention to the instructions on the back of the package.

The optimum temperature for work is considered to be 18–20 degrees, the permissible temperature is 5–40 degrees. The fact of the influence of temperature and wind on the volume of required raw materials is taken into account. So with the wind, elevated temperature, water evaporates, which leads to an increase in the volume of raw materials.

At subzero temperatures, the mass begins to deteriorate quickly.

If the tile taker is experienced, he will choose the right tool, installation method, which will significantly reduce the need for raw materials.

Tile adhesive "Bergauf Pro"

Tile glue "Bergauf" is a strong, elastic and moisture-resistant mixture. In addition to reliably holding the surfaces together, it can withstand various loads well. Thus, it is often used for finishing swimming pools.

It is worth noting that it is not necessary to immediately cover large areas, as the mixture may harden, and you will not have time to finish it completely. An excellent option is a range that you master to complete within 15-20 minutes. The mixture is applied to the work surface in a small layer. After that, a tile is applied to it and lightly pressed. If you do everything right, then there will be no extra glue.

After the entire wall is finished, it should be left. During this time, the tile will be firmly and securely fixed. And only after 24 hours it is possible to grout in the traditional way.

Tile adhesive "Bergauf" received a lot of positive reviews. Many people were convinced by personal experience of its high quality and long service life.

Advantages

The main advantage of this glue is associated with low consumption. Thus, a large amount of work can be performed with minimal raw material costs. This will save you money. Another positive feature is that the prepared solution can be stored for quite a long time. Not all building mixtures can be said the same. It is convenient and practical.

Bonding ceramic tiles

In addition, this glue firmly bonds various surfaces. During its use, it is not required to create certain conditions. This greatly simplifies the installation process. So, it can be used over a wide temperature range. There are no specific requirements. To lay it on the wall, it is enough to prepare it in the standard way.

As for its operational properties, they are not inferior. Firstly, the glue has a high moisture resistance. Therefore, it is used in the decoration of swimming pools, saunas and other premises. The situation is the same with the temperature. It can withstand heat very well.

Characteristic

Since this glue is of different types, its composition may also differ. This mainly concerns additional components. They are added more, less, or eliminated altogether. Therefore, it is worthwhile to carefully approach the choice of this building mixture. First, evaluate what it is used for. If the glue is used at high temperatures, then it is better to give preference to its heat-resistant version.

The composition of the Bergauf Ceramic glue will also slightly differ from the standard one. It includes not only the main components, but also mineral fillers and polymer additives. This greatly improves the efficiency of its use. There are also fast-hardening types of this glue. Their solidification time is minimal.

Ceramic tile

In addition, the tiles are durable and reliable. It can withstand a variety of conditions. For example, high humidity, temperature, etc.Moreover, it is presented in a large assortment. Thus, it is suitable for the implementation of any design idea. Will make the room not only practical, but also attractive.

Using Bergauf glue

As for its styling, this process is not very difficult. It can be carried out both by a specialist and by oneself. The main thing is to know and follow the installation technology. Then the result will please you for a long time.

One of the most important aspects of tiling is the choice of glue that will help you do it efficiently and reliably. In the modern market, you can find a large selection of similar goods. It differs not only in its cost, but also in quality indicators. As practice shows, it is better to be guided by the latter when choosing. Only high-quality glue will provide reliable and strong adhesion of the tile to the surface.

How much tile adhesive do you need?

First of all, you need to pay attention to the approximate material consumption, which is indicated on the packing bag. Of course, these are only approximate figures, because the residual result will depend on many factors:

- uneven walls;

- comb selection;

- tilt of the comb;

- porosity of the tile;

- the size and type of tiles;

- the dexterity of the master and his professional skills;

- temperature indicators.

Thanks to fast online calculators, you can find out how much tile adhesive is needed and reduce the probability of error to a minimum and make a more accurate consumption of tile adhesive per square meter. To do this, you need to indicate in the proposed table the surface area, the thickness of the intended layer and the type of glue. If there is a tile measuring 20 by 30 cm, then it should be applied with a thickness of no more than 1 cm. The final figure helps the master to determine the amount of tile glue purchase, for the floor from the walls in the bathroom to the entire surface.

Also use the tile grout calculator.

Find out how many ceramic tiles you need on the floor.

Find out how many bathroom tiles you need.

Tips and tricks from specialists

Before you start applying glue to the base, you need to remember some points:

If the surface is even, and the height differences are less than 3 mm, then the glue consumption will be minimal.

It can be applied in layers up to 5 mm solely for adhesion to the tile base.

If the surface is uneven, then the glue will also serve for leveling, and therefore, when calculating the consumption of tile glue, it is important to take into account the amount of material used for rough work.

To save glue, it is advisable to carry out preliminary leveling, plastering and thorough priming of the base.

In order for the online tile glue calculator to show accurate results, you need to correctly choose the type of glue, depending on the type of composition optimized for application to various surfaces, metal, wood, concrete, old tiles, etc.

In addition to the main components, tile adhesive contains additional components that are used for better adhesion, elasticity, and resistance to temperature extremes. This indicator affects both the properties of the material and its consumption.