Scope of application of liquid nails

Liquid nails are silicone based glue. Its main feature is the ability to solidify almost instantly, firmly connecting the parts to be glued. Either water can be used as a solvent, since organic solvents are volatile.

The glue is used to solve a variety of tasks in construction and renovation. Here are some examples:

- Pasting of heavy types of wallpaper (for example, bamboo).

- Strengthening distressed tiles when renovating floor or wall coverings.

- One-piece connection of parts made of wood, chipboard, fiberboard when assembling furniture.

Moreover, such glue is more expensive than many specialized ready-made mixtures. For example, when creating a tile backsplash in the kitchen, glueing all the tiles on liquid nails is unprofitable, but using this instant glue in problem areas (first row, corners, etc.) is quite advisable.

What glues

Thermoplastic rubber-like mass easily glues materials of different structure and origin. Paper, wood, cardboard, glass or rubber are all within the power of a glue gun.

Paper

Instant and effective adhesion of paper with a quick-setting compound is not a problem. It is much easier to fix a sticker, create an airy openwork composition or an ordinary envelope with a thermal gun in hand than in other ways.

Cardboard

Cardboard, as a denser material, is more difficult to glue with ordinary mixtures than paper. But with hot melt glue - easily. The seam is durable, water-resistant, load-bearing. A solid plus of the technology is that there is no need to wait for the solvent to disappear (the glue dries up). This significantly speeds up the assembly process.

Ceramics

Apply a layer of glue to one half of the broken cup, then to the other half, wait 15 minutes. You can forget about such a technique forever if a glue gun appears on the farm. Wait until it warms up, a drop or a strip of hot melt glue on the contact zones, press firmly - and the product is as good as new.

Wood

The high adhesion of the plastic mass allows you to easily connect wood to each other, fix the bars to other materials. Before work, you need to make sure that the surface is free of dirt and dust, dry, and degreased.

Styrofoam

Polyfoam is a difficult-to-stick material, it requires the use of special compounds. This does not apply to hot-melt equipment. We load the rod into the pistol, turn it on, pull the trigger. Then we glue at least the ceiling tiles, even the baguettes. Grabs instantly.

Glass

Another problematic substance for which it is difficult to create a strong seam. It is not only difficult, but sometimes impossible to connect glass parts to each other, to close a crack, to attach a plate to another material without a glue gun.

Rubber

To quickly glue the rubber without using special technologies and without waiting for several hours until the seam gains strength - it was impossible to think about this before. Melted glue from an electric gun solves the problem in a matter of seconds.

Metal

Ferrous and non-ferrous metals have always been difficult to glue. For this, synthetic mixtures, epoxy compounds are used, which have the greatest seam strength. But the gluing time is also considerable. Using a pistol with a set of rods saves energy, time and nerves.

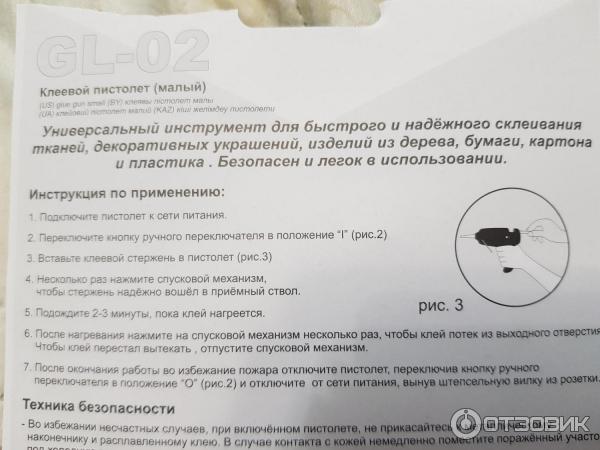

If you haven't read the instructions

Basically, the glue gun is not a space shuttle or even a supercomputer. It is difficult to spoil it with unintentional actions. It is enough to act by trial and error, observing the basic simple rules. And the process of mastering the glue craft begins with preparation.

Preparation

You bought (rented from friends) a glue gun.Don't know or forgot how to use. Take out the unit first. To do this, the pistol is removed from the blister (cheap and household models), suitcase (professional). The set "gun + glue" should be folded. This means that the accessory is installed, the rod selected and plugged into the socket. Stand-alone models are charged until the battery is fully ready. For models with manual temperature control, the regulator is set to minimum. For those equipped with a toggle switch, you need to press the key, transferring it to the power supply mode. And only after that you can start field tests.

Algorithm of use

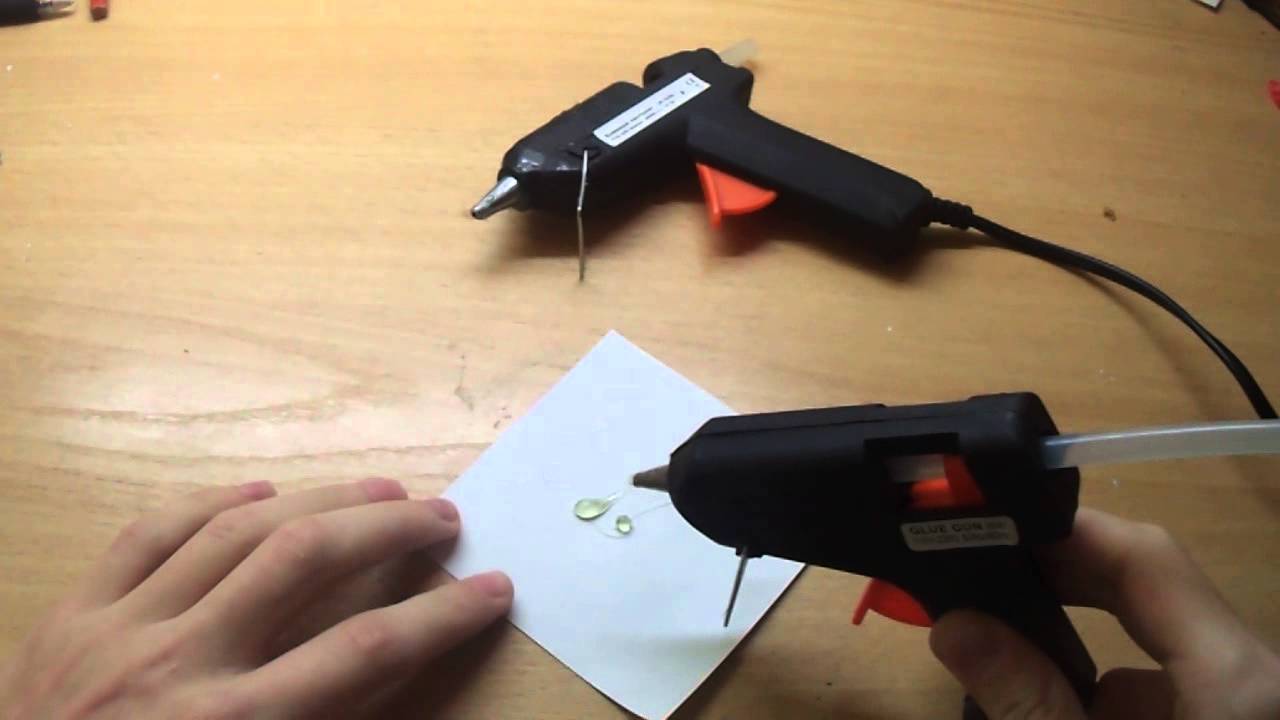

The method of using a thermal gun is simple to the point of primitiveness: wait for the prescribed time for the rod to warm up, press the button, squeezing out a stream of glue, release it, then press it again. It is not necessary to press down hard on the lever trying to speed up the flow of the incompletely melted adhesive. This impatience will cause the pistol to break.

By directing the nozzle and synchronously working with the push button of the rod, they form a layer of glue on the part (fill the seam). The length of the rod is not infinite, therefore, at the same time, they monitor the consumption of glue, adding new cartridges on time. Sometimes the glue comes out with a characteristic cotton, this is not a breakage, just air. The rod should sit tightly in the grip, resting against the chamber. As it warms up, it is moved forward. Before changing the type of rod (by color, melting point), it is advisable to clean the nozzle.

To do this, the pistol is allowed to cool, disassembled, cleaned with a wire or pin. The same procedure is recommended when you stop working with the gun. The nozzle is the hottest part of the glue gun. On some models, the case heats up noticeably. The temperature of 100-110 degrees, on average, has glue at the outlet.

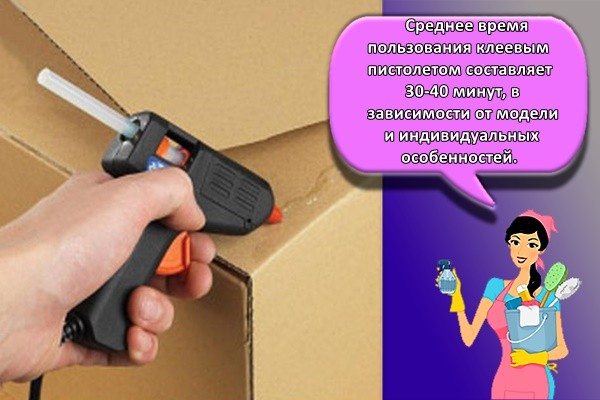

Usage time

The average time of using a glue gun is 30-40 minutes, depending on the model and individual characteristics of the unit. For different products, the body and the handle do not heat up equally, this also affects the duration of operation. Another limiting factor is the length of the glue stick. Usually, after the glue cartridge runs out, it is advised to clean the nozzle before installing a new one. This will be the operating time of the pistol. In perfect designs, the heater does not stay on all the time. When idle, it automatically switches to stand-by mode to save energy and extend the life of the pistol.

Brand glue guns

Dremel. Among the heat guns of leading companies, the products of the manufacturer of household tools, Dremel Corporation, are especially distinguished. Although manufactured in Taiwan, Dremel glue guns are prized for their high build quality. Examples include the 910 and 940 series models.

The Dremel 910 Gun is one of the smallest heat guns available. Designed for light load, the main purpose - use for work at home. The heater power of 240 W provides heating of the melting chamber in 40-50 s. The weight of the device is only 240 g, which allows you to freely glue ceiling decor, panels and borders with hot glue sticks with a diameter of 7 mm. The cost of the apparatus is $ 18-20.

The more powerful Dremel 930 is designed for continuous use in indoor and outdoor conditions. The heating temperature is 195 ° C, the rods are 12 mm. The combo power cord can be unplugged, allowing you to unplug the gun and apply in tight spaces such as basements or rooftops. The high glue consumption of 18 g / min allows you to quickly glue the surface of metal and wood.

The body of the device is designed so that it does not need a separate stand, it is enough to open the frame in front of the pistol, and it can be placed on any flat surface. The cost of a heat gun is 45-50 dollars.

BOSCH PKP18E.Among the products of European manufacturers, BOSCH PKP18E devices have a well-deserved reputation as an ultra-convenient thermal gun. Like the previous model, the PKP18E glue gun is designed for high load and productivity. The adhesive consumption for 12 mm rods is 20 g / min. The highlight of the device is that the glue heating chamber is equipped with a temperature stabilizer, which means that overheating, and even more so, ignition of the polymer will not occur even after a long idle period. Model cost - from $ 50

The model is easily recognized by its characteristic elongated spout, which is used as a spatula when the glue needs to be touched up or pressed.

Glue guns Zubr It is not necessary to purchase well-known brands if you can find almost similar glue guns from local manufacturers. For example, the Zubr Expert glue gun costs only $ 30, but in terms of performance and reliability it is not inferior to Bosch and Dremel products. In fact, this is a semi-professional model designed for long-term continuous use.

To eliminate overheating and reduce electricity consumption, a switch is installed on the pistol handle, which allows the heater to be transferred from the operating heating state to the standby semi-cold mode. This model has a very comfortable rod feed, which reduces the load on the hands during prolonged use with a glue gun.

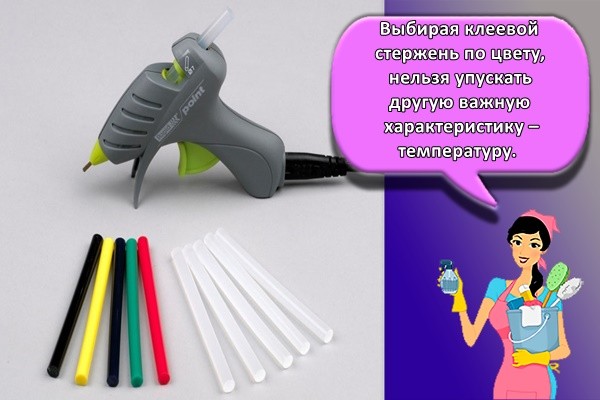

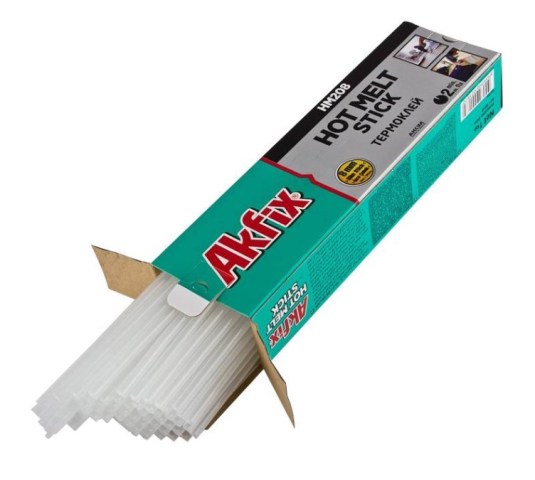

What glue to use

A good seam requires quality glue. On the other hand, it makes no sense to buy expensive Bosch or Dremel rods for a simple pistol. The choice of color depends on the nature of the work: colored glue is used for needlework, modeling. For repairs, a regular, yellow one will do. Different rods do not have the same melting point, and this indicator is related to the characteristics of the pistol. A "weak" unit will not cope with refractory glue. And, of course, the diameter of the rod must match the size of the grip in the pistol, this is an immutable axiom.

By color

The choice of color is important where it participates in the composition, you cannot do without it. In other cases, "working" yellow glue sticks are used, which give a strong and neutral in shade seam.

Yellow transparent rods

It is a "universal soldier" for most problems. The yellow rod is more often used for working with paper and cardboard, wood.

Multicolored, opaque

This group of glue sticks, oddly enough, is also considered universal. This is explained by the fact that the shade is necessary to mask the seam for the color of the parts to be joined.

Transparent adhesive

Transparent rods of white color are the most demanded. They are supplied with glue guns and will be sold at the hardware store by default. The most common consumables.

Gray or black

Darker shades of glue sticks work to create a layer of insulation, used as a sealant. In terms of quality characteristics, these glue sticks differ little from others.

Opaque white

When a gun is needed for working with metal, glass, joining white parts, you cannot do without glue sticks of the appropriate shade. Sometimes used as a marker.

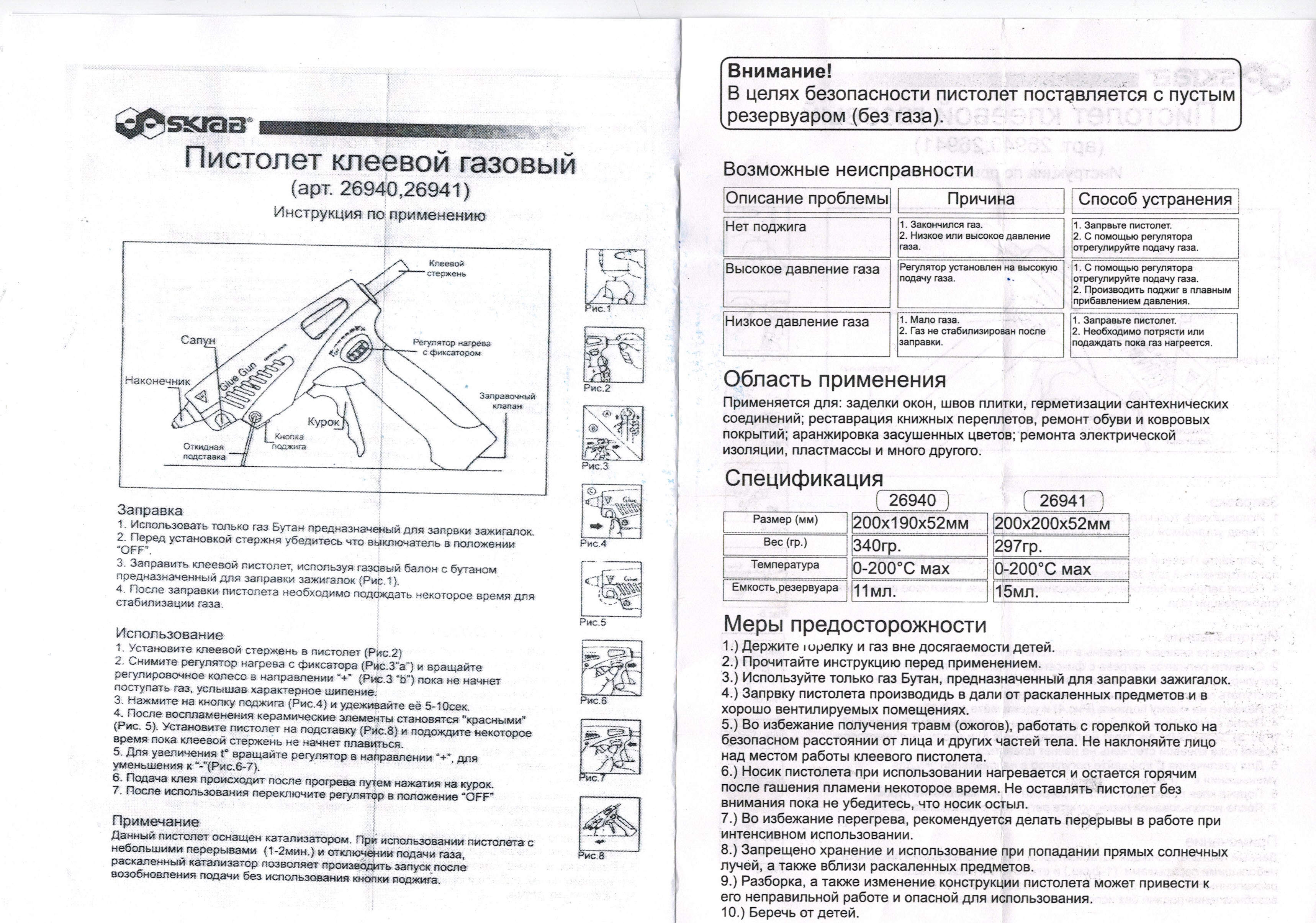

By temperature

When choosing a glue stick by color, another important characteristic should not be overlooked - temperature. It is indicated on the package with glue sticks, as well as in the specifications of the gun. It is measured in the range of 100-150 degrees, so the use of "blind" glue, which was at hand, is fraught with unexpected consequences.

It is always best to check the type of glue stick and match its melting point to the gun's capabilities.

How to choose a thermal gun?

The widest selection of various models and modifications of thermal guns is presented on the market. To determine which one is best suited for certain tasks, you need to clearly define the purpose of the acquisition.

If the device is needed for needlework, then it is better to choose a tool for small-diameter stickers. For repair or construction, productive models are suitable - they are ways to produce a significant amount of melt, which is required for gluing large areas.

Before choosing a suitable glue gun, you should understand its basic technical parameters.

Power.

For amateur pistols, the heater power rarely exceeds 150 W, professional devices are an order of magnitude more powerful and consume 300 W or more. However, this characteristic is only relevant when buying a tool for construction work, when the glue feed rate plays a decisive role.

Performance.

The parameter indicates how much of the composition is released in one minute. The average value is from 5 to 30 g.

Temperature conditions.

Standard rods melt at 105 ° C, but most models heat the composition at 170-190 ° C. A technological solution is introduced to reduce the time for the initial heating of the sticker, as well as for convenience - such tools melt any rods with high quality, including high-temperature ones. There are also low-temperature pistols with a limit value of 105–110 ° C.

Functional and design features

Structurally, all thermo pistols are quite similar to each other: compact dimensions, mains power supply, trigger key

However, if you plan to frequently work with a tool and perform various operations with it, pay attention to its option

By the way, the functionality of a seemingly simple tool is impressive.

- Temperature control - it can be smooth or stepped. A wide range of temperature settings is certainly a great advantage, but such devices are more expensive.

- The presence of automation - sometimes the temperature is "monitored" by a microprocessor, which independently sets the optimum temperature at different stages of operation (heating, application, standby mode).

- Indicator - will tell you when the mass has melted and is ready for application.

- Power button - between uses, the gun does not have to be disconnected from the mains.

- Sight glass - will allow you to control the remainder of the adhesive mass, as well as monitor the integrity of the coupling (the coupling holds the melted glue, but over time the rubber parts wear out and the composition penetrates into the body, which leads to more serious damage).

Among the design features, it is worth noting the ability to disconnect the power cable, this will allow you to use the glue gun autonomously for 15-20 minutes.

Models are also distinguished by the type of power supply: network and battery. Battery operation greatly increases freedom of action, but in this case, the time of use of the tool is limited by the capacity of the battery. On average, cordless guns can be used for no longer than 45 minutes, after which they need to be recharged.

How to choose a glue gun for needlework

The thermal gun is used for different purposes, hence the prices for them from hundreds of rubles to several thousand. But for needlework there is no need for a powerful heating element, high speed and high performance. It is enough to buy an inexpensive pistol within 300-500 rubles and it will work efficiently and reliably. And if necessary, it can be used for other purposes, for example, for repairing shoes, broken ceramics, etc.

If you choose an inexpensive model of a thermal gun, then remember that you can use it for a limited time (15-20 minutes), followed by a break for cooling. This is due to the fact that the heating element for such models does not turn off automatically and the adhesive can simply overheat, which will lead to a number of negative consequences. For example, glue will begin to flow out of the body joints, "pour" not only the surface of the desktop, but also the inner parts of the electric heater.

The glue heating temperature is another parameter by which you need to choose a glue gun. The low temperature range starts from 105 degrees of heating the glue rod, and professional models can heat the glue up to 200 degrees. Accordingly, they will have a heating element of different power, from 20 to 100 watts or more. For needlework, it is better to buy a low-power pistol. True, it heats up the glue more slowly and cools down faster, but the hot glue will not damage the fabric or other material.

For those who need a universal glue gun, we can recommend buying a model with switching heating mode (105 and 165 degrees).

The nozzle of the gun can have not only a conical shape, but another. For needlework, an elongated and long nose is best suited. Firstly, you can adjust the glue flow, which makes it easier to glue small crystals, sequins, etc. And secondly, with a long nose it will be easier to reach hard-to-reach places.

Pay attention to the quality of the body material, as well as the tightness of the connection of its parts. In case you forget to turn off the heat gun, reliable connections of its parts and durable material of the body will protect your hands from the hot glue melted and flowed out of the slots of the body.

Leading brands of glue gun manufacturers - Bosch, Dremel, Makita, Hammer, etc.

Appointment

Glue guns are designed for decorative work, assembly, professional activities. There are even devices for straightening car body parts: with the help of heavy-duty glue, dents in the sheathing are pulled out. There can be no universal pistols. It is necessary to immediately decide where the hot-melt unit will be used, and after that, proceed to the choice.

Decor

The glue gun has long been used to create decorative panels, compositions in order to quickly and reliably fix parts on a base, a surface made of wood or metal.

Repair

Another area in which glue guns are used. It is not necessary to use standard methods to glue the tiles to the floor, fix the suspended ceiling, fix the wooden block on the stone wall. 5 minutes of work with a gun - and the part is in place.

Needlework

A strip of glue from a pistol glues fabric, thread products, knitting, connects the embroidered paintings to the base. Polymer mass replaces conventional synthetic adhesives, and surpasses them in strength and speed of joint hardening.

Construction

Fastening carpet, installation of electrical fittings, reliable fixation of plumbing devices - and this will help the glue gun. Polymer rods have high adhesion to any surface. You just need to clean them from dust, degrease and dry them.

Warehouses and movers

The device is suitable for temporary fastening of structures in a warehouse, creating an instant connection between plastic and metal, wood and glass. One powerful gun is enough to apply glue on the scale of a small warehouse. You can fix the details pointwise, in a strip, along the contour - there are enough options for a solution. And it is also convenient to mark the goods with colored rods, creating a strip of glue in the required place.

Everyday life

Repair broken dishes, glue the tiles, flooring, fix the countertop. To do this, you do not need to keep several different synthetic adhesives on the farm.

Plastic and PVC models

And with the help of melted glue, it will be possible to quickly and reliably fasten plastic parts. But not all. There is a limitation on PVC; hot glue cannot restore a torn shower curtain.

Fabrics

Such a complex and impractical material in gluing, as fabric, with rare exceptions, is successfully connected using a heat gun. The choice of the base, the combination of fibers does not matter - for hot melt glue they are all equivalent, they are easily bonded.

Concrete, gypsum and similar materials

One of the few exceptions, white spots, for which a glue gun is not suitable.It will also not work to glue the plaster, to create a strong seam between the concrete surface and another structure (paper).

Range

Hot melt glue of various colors is in demand, since this makes it possible to choose the glue to match the color of your material so that the adhesive does not stand out. Of course, PVA cannot be compared with thermoplastic glue, PVA does not have such a strong adhesion.

The most common shades available on the market are transparent (universal: suitable for cardboard, ceramics, plastic, fabric, tiles), opaque (for glass and metal), yellow (suitable for wood), black (suitable for wire insulation, suitable for as a sealant), colored (suitable for decorative work, used on cardboard and paper).

Popular models:

- Bamfutura;

- 5 second fix;

- Rtv-904;

- Sealant;

- Termo.

They differ in technical properties: fire resistance, electrical conductivity, thermal conductivity, heat resistance.

Benefits and working principle

Advantages of hot melt glue:

- high strength of glue seams;

- fast polymerization;

- resistance to external influences of moisture, frost, sunlight;

- long service life of the adhesive joint.

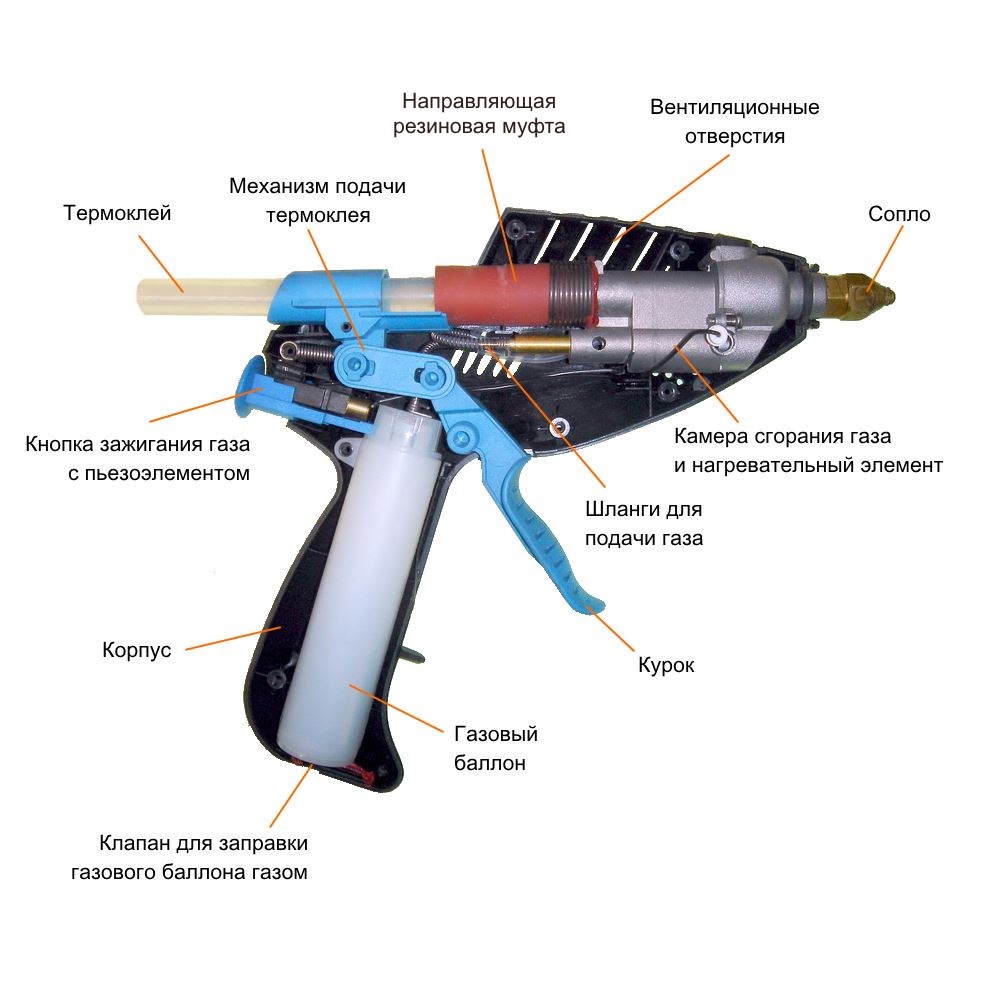

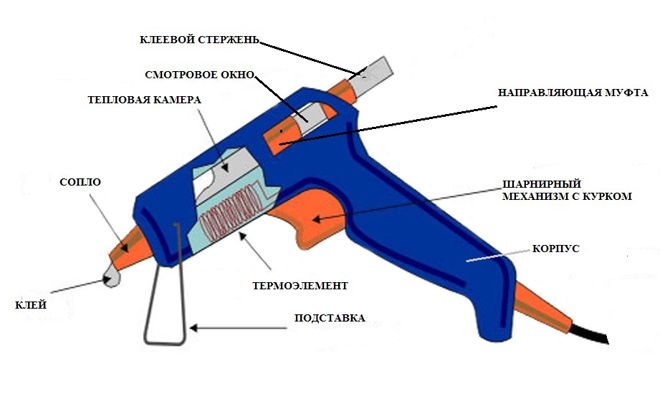

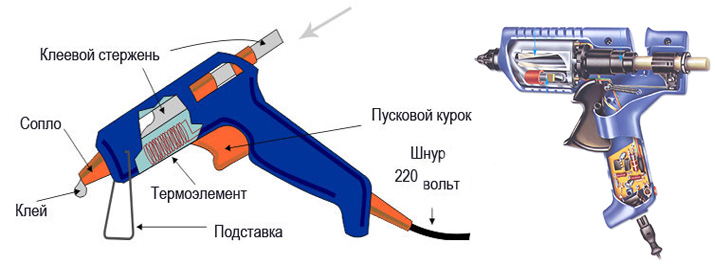

The device of the thermal gun is simple. A special glue cartridge in the form of a cylindrical rod is placed in the tool. The feeder moves the rod towards the heating chamber where the glue is melted. Pressurized liquid solution is squeezed out through the nozzle when the trigger is pulled. Heating of the glue has some inertia, so it is done in advance.

The device of the thermal gun is simple. A special glue cartridge in the form of a cylindrical rod is placed in the tool. The feeder moves the rod towards the heating chamber where the glue is melted. Pressurized liquid solution is squeezed out through the nozzle when the trigger is pulled. Heating of the glue has some inertia, so it is done in advance.

In the pistol, it is carried out by electric heating elements, which are turned on either by a button or by connecting the device to the network. The molten composition tends to flow out of the chamber on its own. In different models, this problem is eliminated by additional devices or various technical solutions for the assembly.

What can be glued with a glue gun

Glue guns are used today both in everyday life and in production. Based on the technical characteristics of the devices, as well as the wide range, they can be used for various purposes. Experts confirm that due to the effect of high temperature, even those things that cannot be processed with modern adhesives are glued together. Often, with the help of such a device, building materials of different structures are fastened: plastic, wood. The glue gun has proven itself well in the stationery industry.

Depending on the type and cost of the glue gun, its price will vary

Depending on the type and cost of the glue gun, its price will vary

Choosing a hot gun for home needs

Obviously, for occasional home use, it is better to buy a household model, and to produce a large amount of work, you need a reliable professional tool. What is the difference between them?

Obviously, for occasional home use, it is better to buy a household model, and to produce a large amount of work, you need a reliable professional tool. What is the difference between them?

DIY glue guns are so inexpensive that they fall into the “must-have” category of DIY tools. Their low cost does not mean at all that they are defective in performing everyday tasks, in comparison with an expensive tool.

First of all, devices for hobbyists are light and compact, which makes them comfortable for the inexperienced user. Home appliances do not need a high feed rate of hot glue - it is unlikely that there will be a need to glue large surfaces quickly. And an unskilled user will not be able to lay without drips and accurately with an abundantly supplied glue. Therefore, hobbyists do not have to be powerful. It is more important that they do not weigh down the hand, and that they are easy to maneuver.

Since they are supposed to work at home with easy access to the mains, the devices are equipped with only a cord and plug for power supply. Additionally, the tool can be equipped with a power cord detachment function.In this case, after turning off, due to the inertia of cooling, the gun continues to glue for 10-15 minutes, which is quite enough for most household chores.

Another difference with professional ones is the size of the cartridges for which the tool is designed. It is unlikely that large diameter rods will be needed in everyday life. Only if it is necessary to create something huge can there be a need to increase the cross-sections to the maximum. For normal work, the optimal size is 7 mm.

The ability to change the nozzle can come in handy for artistic tasks. Experienced designers know how expressive embossed patterns can be when using glossy rods.

For large volumes of work

As a rule, hobbyist devices are powered from the mains. More serious tools provide for work in conditions that do not imply the possibility of connecting to a power source using a cable. For example, it can be some repair and construction tasks. For such cases, there are models with batteries. The time of their continuous operation depends on the capacity of the battery, the possibility of their replacement and their own power. The disadvantage of such heat guns is the need to take care of charging the battery.

As a rule, hobbyist devices are powered from the mains. More serious tools provide for work in conditions that do not imply the possibility of connecting to a power source using a cable. For example, it can be some repair and construction tasks. For such cases, there are models with batteries. The time of their continuous operation depends on the capacity of the battery, the possibility of their replacement and their own power. The disadvantage of such heat guns is the need to take care of charging the battery.

In addition, professionals often deal with large bonding surfaces, large volumes of work, harsh operating conditions of the tool, as well as adhesive mixtures that require elevated heating temperatures. Therefore, heat guns for non-household needs, as a rule, are of high power, equipped with more reliable and complex mechanisms, made in a durable case and have the ability to use long and thick rods in order to ensure a high consumption of glue. All this, together with the autonomy of power supply, makes them much heavier and more expensive than an amateur instrument.

Sometimes bonding technologies require the use of special two-component compositions. There are machines for working with mixtures on sale. Their principle of operation is the same as for standard models. The only difference is that the materials to be joined are fed into the heat chamber separately, evenly and with respect to proportions.

All of the above must be taken into account when choosing a professional tool - unlike an amateur one, due to its greater specialization, it is less versatile.

Characteristics of hot melt sticks

As already mentioned, the form of release in the form of hot melt glue sticks is the most common due to, first of all, ease of use in conjunction with professional and household thermal guns.

There are rods on the market with different properties and characteristics, which are usually indicated on the packaging.

Appointment

Hot melt glue in the rods differs primarily in color, which usually indicates its purpose.

However, it should be noted in advance that although there is a clear unification here, still not every manufacturer adheres to it, which should be remembered when choosing these consumables.

Usually available to the buyer:

- White translucent rods are universal, used both in industry and for household needs.

- Opaque colored rods are similar to the previous version, but with the only difference that their color serves as a camouflage or decorative function. They are mainly used for gluing colored objects.

- Opaque white rods - have different purposes, depending on the manufacturer and composition. Some can only glue glass, while others are a universal option for connecting white objects (by analogy with the previous paragraph).

- Transparent yellow rods - they have a universal composition, which is mainly intended for gluing wood, cardboard and paper products. There are some opaque yellow sticks, with which they should not be confused, again, by analogy with the second paragraph.

- Gray or black rods are elastic sealants designed to insulate electrical conductors and seal seams, therefore, they are not directly related to hot-melt adhesives.

Material

Hot melt sticks are most often produced on the basis of ethylene vinyl acetate, due to which they have a low melting point, which was already noted earlier, and therefore, it is possible to use them in conjunction with.

There is also a relatively low cost.

Polyamide and modified silicone can also act as a basis.

The latter is well suited for working with fabrics.

Dimensions and weight of hot melt sticks

The diameter of the produced glue sticks can be 7 - 12 mm.

The most popular sticks are 7 and 11 mm. In length, such glue sticks reach 100 - 300 mm.

A pack of 6 - 10 rods weighs about 50 - 150 g.

Main manufacturers

On the market of manufacturers of glue guns, a kind of rating of brands that can be trusted has formed. Which one to give preference is the user's choice. Sometimes the purchase of an unnamed model is justified if you need a tool for a certain time. In the event of a breakdown, it is not a pity to throw it away later. But the marriage among such "masterpieces" of the Chinese shirportreb is great.

Dremel

A solid North American brand, famous for its high-speed grinders, which they began to call - Dremel. Thermal guns under this brand are reliable, fully justify the money spent on them. A switch is built into the handle, a special stand is created in the front part. Replaceable nozzle. It is convenient to work with such a pistol, and it will last a long time. Dremel users, all as one, note the ergonomic handle of the unit, its lightness. But the original glue sticks are not cheap.

Steinel

German scrupulousness, full compliance of the declared characteristics with the actual ones. Such a gun, purchased for home crafts or repairs, will not let you down. Designed for a household network of 220 V. There are models with temperature control, as well as rechargeable ones. By the way, autonomous Steinel pistols are considered one of the best: they contain electronic temperature controllers, an automatic shutdown unit.

Bosch

The products of the Bosch concern are known and respected far beyond the borders of Germany. Household, professional tools under this brand are reliable, trouble-free equipment. High-quality components are used in the products. We offer solutions for amateurs and pros. The pistol fits comfortably in the hand and is equipped with an electronic stabilizer.

Hobby and pro

Models of the middle class are produced for universal purposes. The gun is equipped with a switch and has good ergonomics. Of the obvious advantages of the pistol, the low price is called (700 rubles). Provides for blocking the leakage of the adhesive mass.

UHU

Another middle peasant. You should not expect super quality from products under this brand, but the hopes placed on them will justify the thermo guns. They are classified as low-temperature (110 degrees), suitable for household purposes and handicrafts.

MasterHand

Cheap and cheerful - this is how you can characterize the products of this manufacturer. Not Bosch, but suitable for home crafts. There are no additional functions, including the power supply toggle switch. There is no regulator either. One of the simplest and most inexpensive pistols, this is where its advantages end.

Stavr

Russian manufacturer. Produces pistols with good ergonomics, replaceable nozzle and comfortable rocker key. Among the undoubted advantages is fast heating (about a minute). Temperature control for melting the glue is not provided.

Defort

Glue guns with conflicting ratings. Judging by the complete case and spare attachments (2 pieces), this is a tool for professionals. The slightly curved handle leaves a pleasant impression. But the price (up to 2 thousand) and the design of the suitcase are not particularly encouraging.

Kolner

A brand with mixed Russian-Chinese roots. The manufacturer provided for the presence of a switch and illumination of the working area, equipped the gun with a long power cable. And the price of the product does not "bite". In its price range, Kolner "crushes" competitors with a set of additional functions, they have almost no backlight and a toggle switch. Not to mention the removable and spare spout nozzle.